Trane SSC-APG002-EN User guide

Other Trane Heat Pump manuals

Trane

Trane 4TTB6018A Assembly instructions

Trane

Trane 4TWR4 Assembly instructions

Trane

Trane 2TWB0-UM-2 Installation instructions

Trane

Trane Variable Speed ComfortLink II 4TWV8024A1000B Assembly instructions

Trane

Trane 2TWR1 Assembly instructions

Trane

Trane 13.4 SEER2 J4PH4 Series User manual

Trane

Trane ProSpace PTEG0701GAA Installation and operating instructions

Trane

Trane A4AC4018B1000B Assembly instructions

Trane

Trane TWA Series User manual

Trane

Trane 4YCY4024 Assembly instructions

Trane

Trane CAUC-C80 Owner's manual

Trane

Trane IC-IH 039 Owner's manual

Trane

Trane 4WHC3036 Assembly instructions

Trane

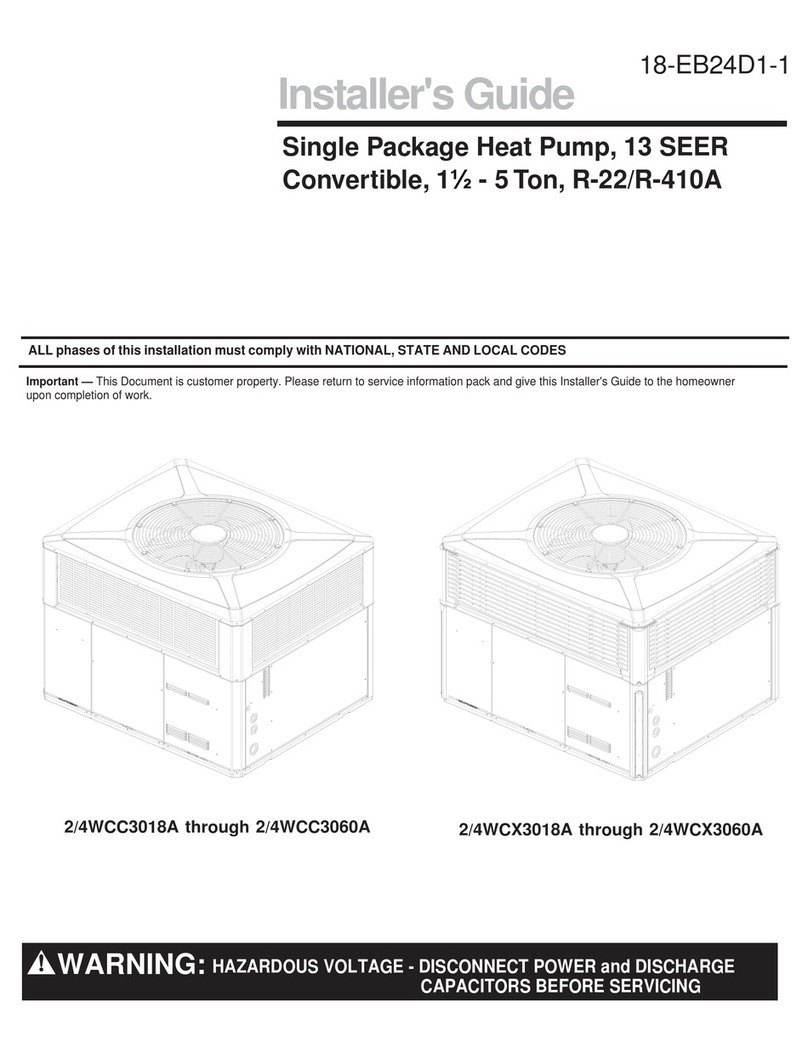

Trane 2/4WCC30 Series Assembly instructions

Trane

Trane 4TWA3030A3 Assembly instructions

Trane

Trane Precedent DSJ150 Installation and operating instructions

Trane

Trane A4AC4018A1000A Assembly instructions

Trane

Trane LIFT 162-P-1204-P Owner's manual

Trane

Trane 4TTR3 Assembly instructions

Trane

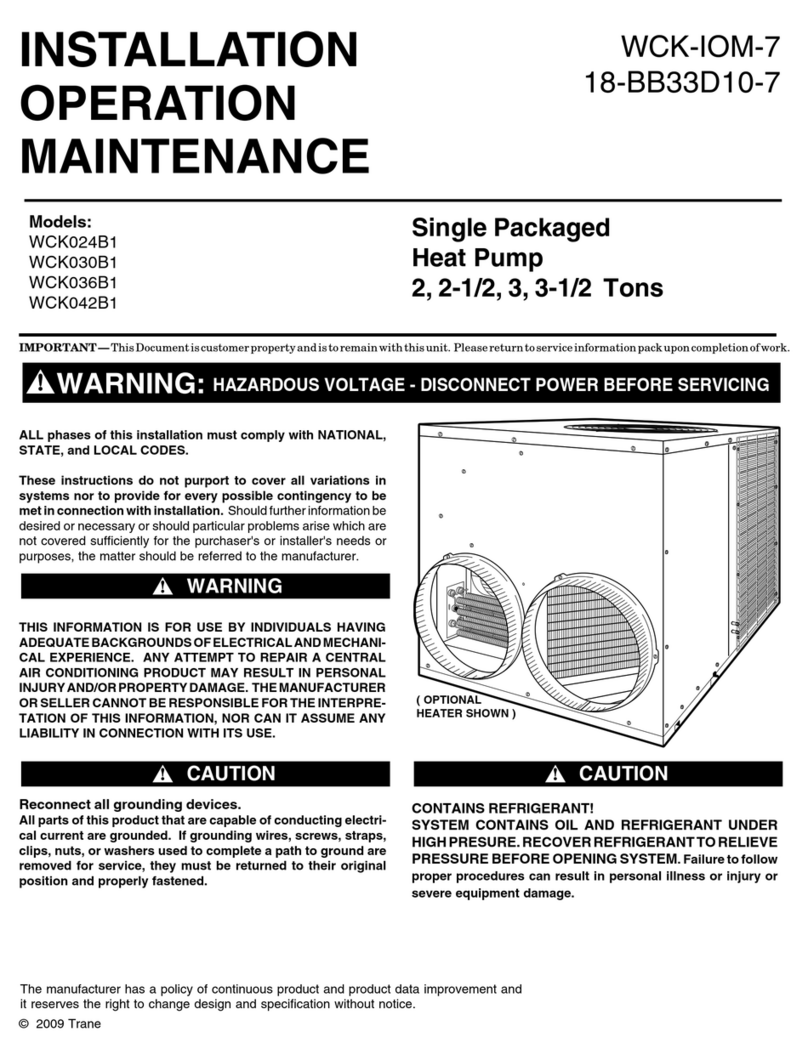

Trane WCK024B1 Owner's manual

Popular Heat Pump manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PUZ-SWM60VAA Service manual

Dimplex

Dimplex LI 16I-TUR Installation and operating instruction

Carrier

Carrier WSHP Open v3 Integration guide

TGM

TGM CTV14CN018A Technical manual

Carrier

Carrier 38MGQ Series installation instructions

Kokido

Kokido K2O K880BX/EU Owner's manual & installation guide

Viessmann

Viessmann VITOCAL 300-G PRO Type BW 2150 Installation and service instructions

Carrier

Carrier 48EZN installation instructions

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions for contractors

Ariston

Ariston NIMBUS user manual

Weishaupt

Weishaupt WWP L 7 Installation and operating instruction

GE

GE Zoneline AZ85H09EAC datasheet