1

©Transcell Technology, Inc. 2016-2020. All rights reserved.

The information contained herein is the property of Transcell Technology and is supplied without liability for errors or

omissions. No part may be reproduced or used except as authorized by contract or other written permission. The copy-

right and the foregoing restriction on reproduction and use extend to all media in which the information may be embod-

ied.

Contents subject to change without notice.

Contents

INSTALLATION & OVERVIEW..................................................................................................... 2

SCOPE OF TI-700K .................................................................................................................. 2

INSTALLATION OF TI-700K DIGITAL INDICATOR ................................................................. 3

RS-232 CONNECTIONS (COM1)............................................................................................. 5

POWER CONNECTIONS (AC VERSION)................................................................................ 5

POWER CONNECTIONS (OPTIONAL RECHARGEABLE BATTERY VERSION).................. 5

USB PORT................................................................................................................................. 6

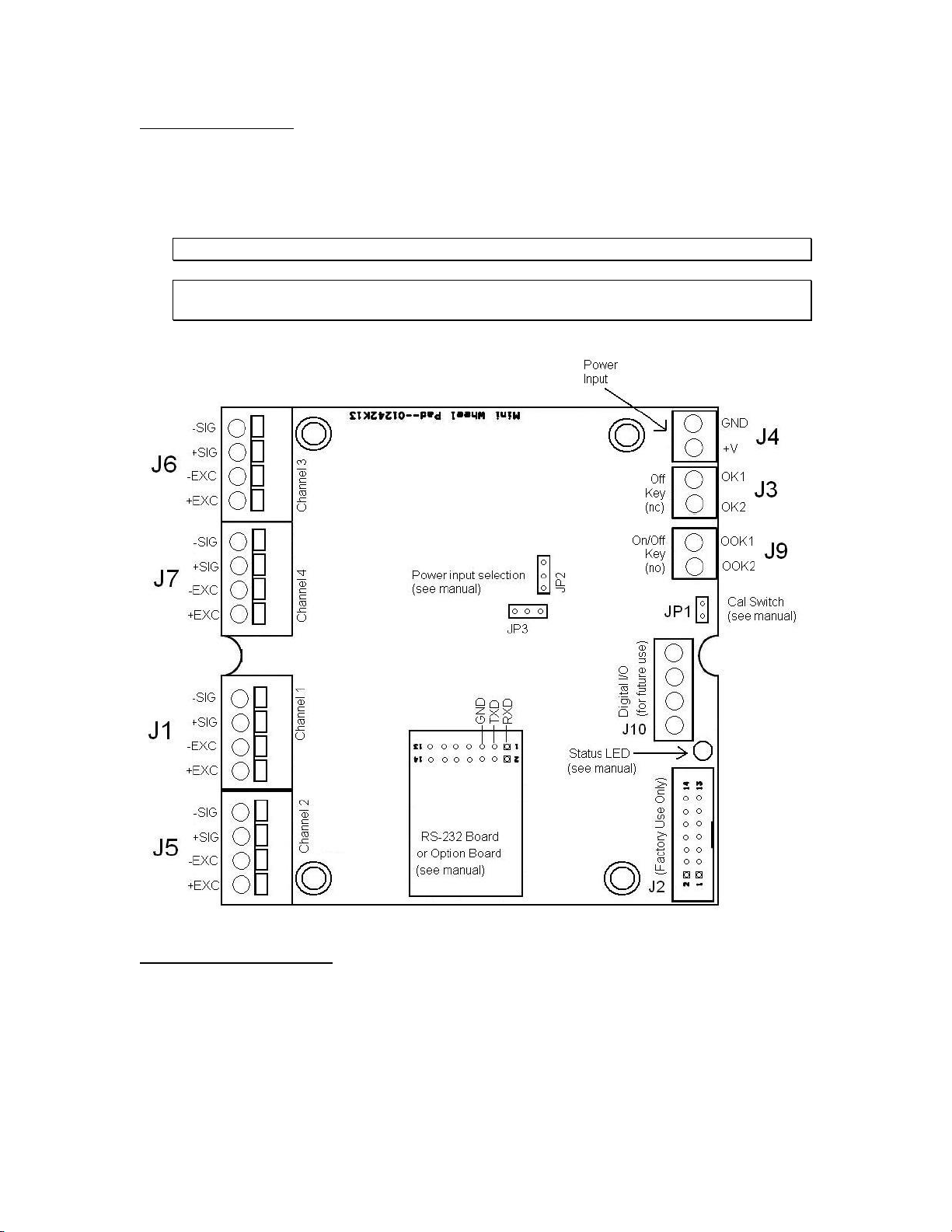

INSTALLATION OF TI-500 RFTM REMOTE WIRELESS A/D MODULE................................. 6

INSTALLATION OF LCT-1 REMOTE WIRELESS DIGITAL JUNCTION BOX......................... 8

GETTING STARTED –CABLED SYSTEMS ..........................................................................10

GETTING STARTED –WIRELESS SYSTEMS......................................................................10

SYSTEM CONFIGURATION.......................................................................................................11

CONFIGURATION MENUS..................................................................................................... 11

ENTERING THE SETUP (“F”) CONFIGURATION MENU......................................................12

SETUP (“F”) MENU DESCRIPTIONS ..................................................................................... 12

ENTERING THE USER/COM1 (“A1”) MENU.......................................................................... 17

USER/COM1 (“A1”) MENU DESCRIPTIONS ......................................................................... 18

SETTING SYSTEM TIME AND DATE (A1-20) .......................................................................20

DIAGNOSTICS (A1-24)........................................................................................................... 21

ENTERING THE COM2 (“A2”) MENU.....................................................................................22

COM2 (“A2”) MENU DESCRIPTIONS .................................................................................... 22

SCALE SYSTEM CALIBRATION................................................................................................24

CALIBRATION OVERVIEW .................................................................................................... 24

DIGITAL ZERO/SPAN CALIBRATION (F16 AND F17) ..........................................................24

KEY-IN ZERO CALIBRATION VALUE (F19) .......................................................................... 25

KEY-IN SPAN CALIBRATION VALUE (F20) ..........................................................................25

MV/V SPAN CALIBRATION (F52)...........................................................................................26

SERIAL PORT INFO ................................................................................................................... 28

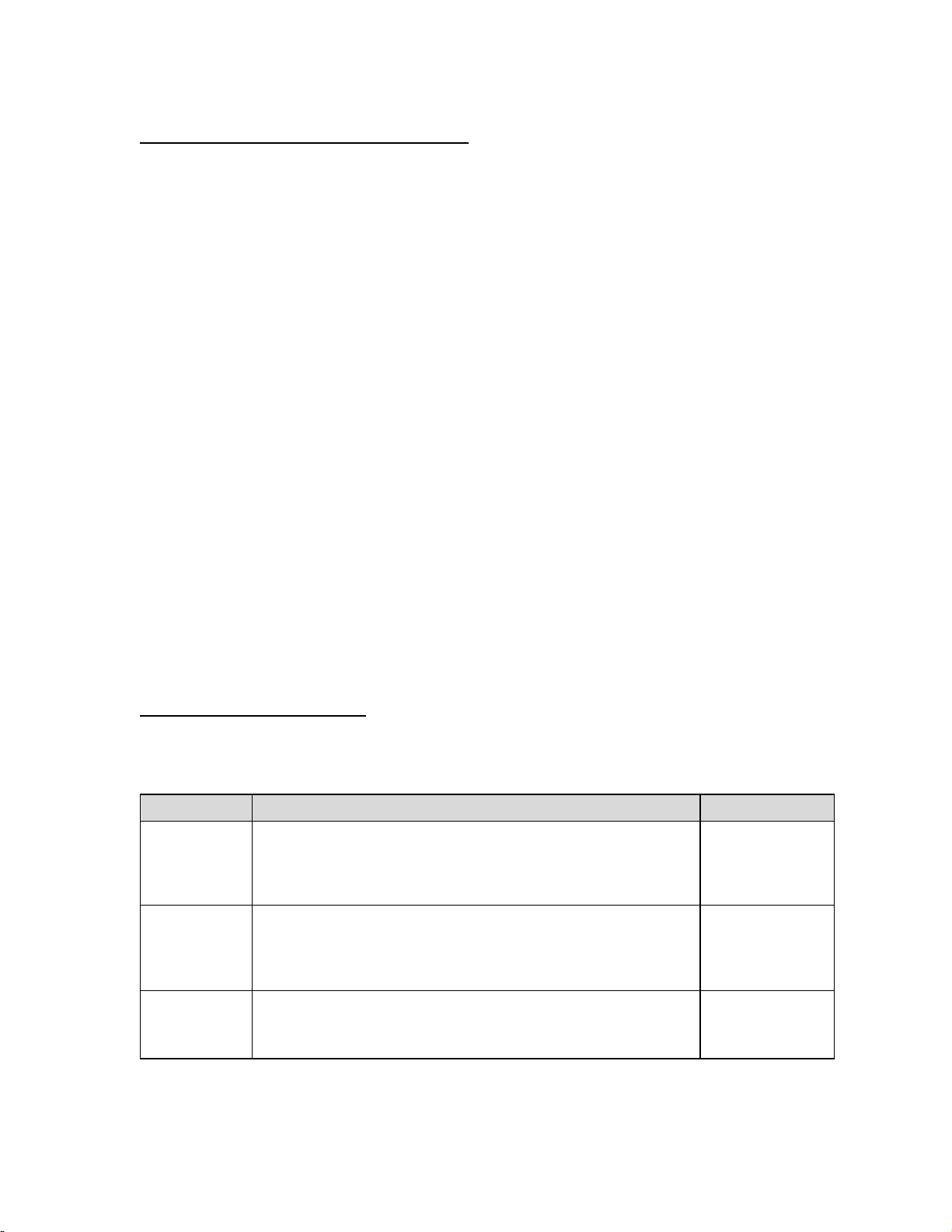

SERIAL PORT MODES........................................................................................................... 28

OUTPUT STRINGS................................................................................................................. 29

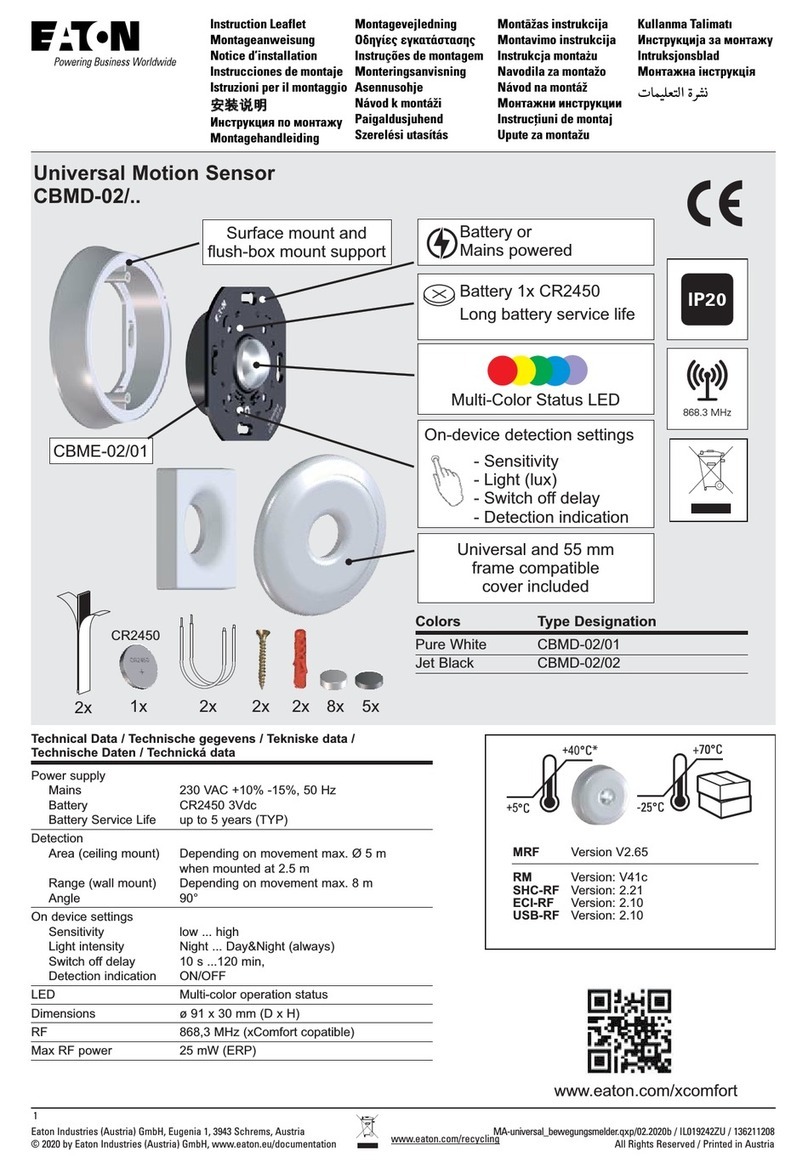

“CE” logo here somewhere…