Transcell Technology TI-1680 Manual instruction

i

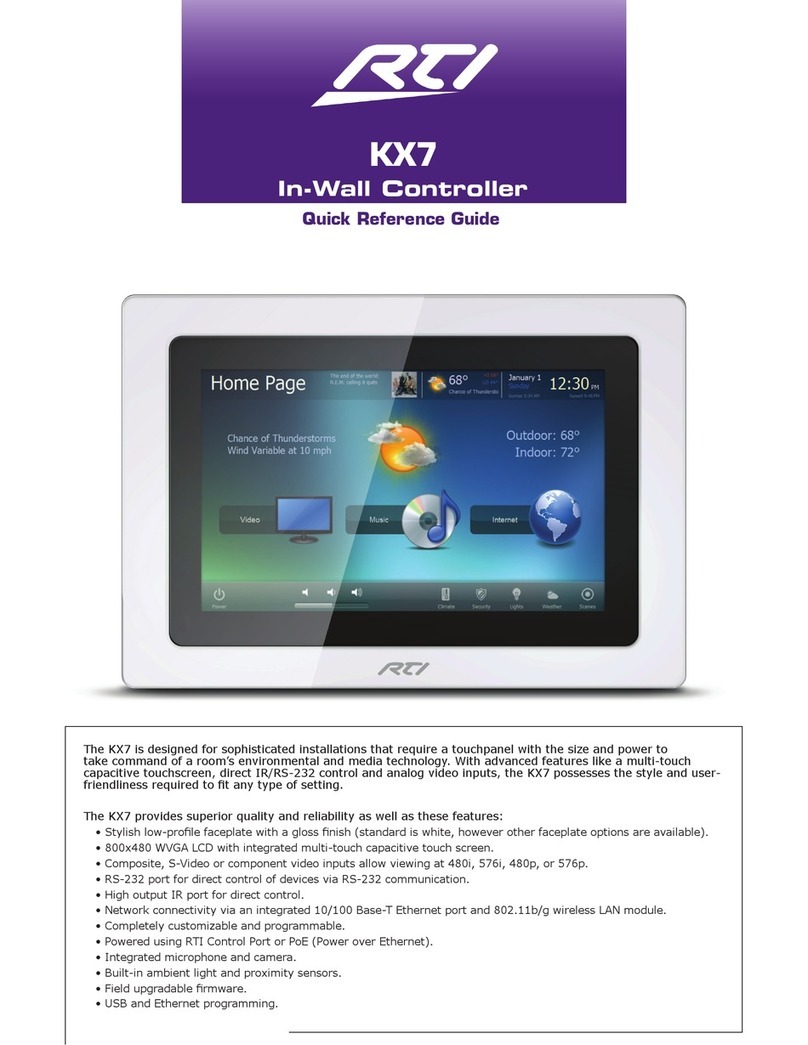

TI-1680

DIGITAL WEIGHT INDICATOR

Setup / Operation Manual

Revision 1.31 975 Deerfield Parkway Buffalo Grove, IL 60089

March 22, 2013 Tel (847) 419-9180 Fax (847) 419-1515

http://

www.transcell.

com

ii

TABLE OF CONTENTS

Page

INTRODUCTION.................................................................................................................................................1

FCC NOTE...........................................................................................................................................................1

INSTALLATION...................................................................................................................................................1

PREPARATION ................................................................................................................................................1

CONNECTIONS................................................................................................................................................2

CONNECTING THE WEIGH PLATFORM.......................................................................................................2

CONNECTING THE SERIAL I/O DEVICE (COM1)......................................................................................2

CONNECTING THE CONTROL I/O ..............................................................................................................3

CONNECTING THE RS-232 PORT (COM2)................................................................................................3

CONNECTING THE OPTIONAL WLAN (COM2).........................................................................................3

CONNECTING THE OPTIONAL RS-485 (COM2).......................................................................................4

CONNECTING THE OPTIONAL BLUETOOTH (COM2).............................................................................4

CONNECTING THE OPTIONAL ANALOG OUTPUT..................................................................................4

CONNECTING THE POWER SUPPLY.........................................................................................................4

CONFIGURATION..............................................................................................................................................5

OVERVIEW......................................................................................................................................................5

ACCESSING THE MENUS.............................................................................................................................5

MENU STRUCTURE.......................................................................................................................................6

SETUP MENU DESCRIPTIONS....................................................................................................................7

SETUP MENU PROCEDURES....................................................................................................................10

USER MENU DESCRIPTIONS....................................................................................................................11

USER MENU PROCEDURES......................................................................................................................13

BATCH MENU DESCRIPTIONS..................................................................................................................15

BATCH MENU PROCEDURES...................................................................................................................15

EXITING THE MENUS..................................................................................................................................16

CALIBRATION...................................................................................................................................................17

CALIBRATION OVERVIEW.........................................................................................................................17

ZERO CALIBRATION (F16).........................................................................................................................17

SPAN CALIBRATION (F17).........................................................................................................................17

VIEW CALIBRATION VALUES (F18).........................................................................................................18

KEY-IN ZERO CALIBRATION VALUE (F19).............................................................................................19

KEY-IN SPAN CALIBRATION VALUE (F20).............................................................................................19

DISPLAY........................................................................................................................................................20

KEYBOARD...................................................................................................................................................21

FUNCTION KEYS......................................................................................................................................21

NUMERIC KEYS........................................................................................................................................22

GENERAL SCALE OPERATION ................................................................................................................22

WEIGHING AN ITEM.................................................................................................................................22

ENTERING A KNOWN TARE WEIGHT..................................................................................................23

CLEARING A TARE WEIGHT..................................................................................................................23

ENTERING AN ID NUMBER....................................................................................................................23

PROGRAMMING SET POINTS ...............................................................................................................23

PROGRAMMING OVER/UNDER VALUES............................................................................................24

ADVANCED SCALE OPERATION..............................................................................................................25

APPLICATION (F30) SUMMARY ............................................................................................................25

STANDARD OUTPUTS ............................................................................................................................26

ACCUMULATION APPLICATION (F30 = 1)...........................................................................................26

REMOTE DISPLAY APPLICATION (F30 = 2)........................................................................................26

PIECE COUNT APPLICATION (F30 = 3)................................................................................................26

PERCENTAGE APPLICATION (F30 = 4)...............................................................................................27

HOLD APPLICATION (F30 = 5)...............................................................................................................28

CHECKWEIGHING APPLICATION (F30 = 6) ........................................................................................28

BATCHING APPLICATION (F30 = 7) .....................................................................................................29

TRUCK WEIGH IN/WEIGH OUT APPLICATION (F30 = 8)...................................................................30

LEGAL FOR TRADE SEALING ......................................................................................................................31

iii

APPENDIX A: SPECIFICATIONS...................................................................................................................32

APPENDIX B: SERIAL PORT INFORMATION..............................................................................................33

SERIAL PORT MODES................................................................................................................................33

DEMAND DUPLEX MODE.......................................................................................................................33

CONTINUOUS DUPLEX MODE ..............................................................................................................33

AUTO PRINT MODE.................................................................................................................................33

OUTPUT STRING..........................................................................................................................................34

TEXT PRINT TICKET................................................................................................................................35

STRING FORMAT 1 (Condec Demand String).....................................................................................36

STRING FORMAT 2 (Condec Continuous String) ..............................................................................37

APPENDIX C: DISPLAYED ERROR CODES....................................................................................................39

APPENDIX D: WIRING EXTERNAL OUTPUT RELAYS .................................................................................40

OUTPUTS......................................................................................................................................................40

INPUTS...........................................................................................................................................................41

APPENDIX E: INFO ON ANALOG OUTPUT OPTION .....................................................................................42

©Transcell Technology, Inc. 2010-2013. All rights reserved.

The information contained herein is the property of Transcell Technology and is supplied without liability for errors or omissions. No

part may be reproduced or used except as authorized by contract or other written permission. The copyright and the foregoing

restriction on reproduction and use extend to all media in which the information may be embodied.

Contents subject to change without notice.

1

INTRODUCTION

The TI-1680 Digital Indicator is a multi-purpose, industrial grade weight indicator. The Table below

summarizes the main physical parameters.

MODEL

DISPLAY

TYPE

ENCLOSURE

TYPE

POWER SOURCE

TI-1680 LED Stainless Steel 100-240 VAC, 50/60 Hz 30W

The unit can readout up to 50,000 display divisions and can supply enough current for up to 8-350Ωload

cells. All setup parameters may be entered via the front panel keys, including calibration.

If your Model TI-1680 Series Digital Indicator is part of a complete scale or has already been installed for

you, then you may skip to the operating instructions. Prior to using the indicator, please read this manual

carefully and completely. Store the manual in a safe and convenient place so it will be available if you

have questions concerning the operation of the scale.

FCC NOTE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Subpart J of Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own expense.

INSTALLATION

PREPARATION

Any precision instrument requires a suitable environment in which to operate as intended. Please review

each of the following prior to installation:

Electrical Power

The TI-1680 indicator has been designed to operate from 100 to 240 VAC at 50/60 Hz. All units ship with

the appropriate power plug for its area of intended use.

To avoid electrical noise interference and/or stray AC electrical transients, try to operate the indicator from

a circuit separate from any equipment containing inductive devices such as a contactor coil, solenoid,

relay coil, or motor. Be sure to use shielded cables for the load cell connections (ground shield wire at

indicator) and run these cables away from your AC/DC power cables if possible.

In extreme cases, it may be necessary to install surge suppressors, line conditioners or even UPS

(Uninterruptible Power Supplies) systems (not included).

2

Environment

-Avoid installing the indicator in areas of direct sunlight or high humidity

-Avoid sudden temperature change – if this is unavoidable allow equipment to ‘soak’ at a constant

temperature for at least three hours before use

-Ensure that steady, clean AC power is available to the unit

Remember that the installer is ultimately responsible to assure that a particular

installation will be and remain safe and operable under the specific conditions

encountered.

CONNECTIONS

For the TI-1680 model, the rear cover must first be removed to make the appropriate connections to the

weigh platform, serial I/O device and other peripheral equipment. To remove the rear cover, simply

remove the six acorn nuts that secure it to the main enclosure and set aside.

Caution! Disconnect power source from indicator prior to removing rear cover.

CONNECTING THE WEIGH PLATFORM

The TI-1680 indicator contains a connection terminal on the main board for connection to the load cell

cable or junction box. Connect your shielded load cell cable (not included) to the appropriate terminal on

the main board. NOTE: 6-wire connection is a factory option

Load Cell Connector J1

Pin No.

Wire Name

Pin No.

Wire Name

1 + Excitation (E+) 5 + Signal (S+)

2 + Sense (SEN+) 6 - Signal (S-)

3 - Excitation (E-) 7 Shield (SH)

4 - Sense (SEN-)

CONNECTING THE SERIAL I/O DEVICE (COM1)

The TI-1680 indicator contains a connection terminal on the main board for connection to a serial I/O

device, e.g. ticket printer. You can choose either RS-232 or USB 2.0 - but not both at the same time.

For USB, the TI-1680 is considered a peripheral device, i.e. the host device supplies the power (VBUS).

Try not to exceed cables lengths of 5 m (16 ft).

Selection between RS-232 and USB is made via JP4, JP5, JP7 and JP8:

Function

J

P

4

JP5

JP7

JP8

RS-232 SHUNT OPEN SHUNT OPEN

USB OPEN SHUNT OPEN SHUNT

NOTE: For remote display emulation application (F30=2), use COM2 only

3

Connection assignments for COM1 RS-232 communication terminal on the TI-1680 are shown below.

RS-232 Connector J9

Pin No.

Wire Name

Pin No.

Wire Name

1 RXD 4 RTS

2 TXD 5 Ground

3 CTS

Connection assignments for COM1 USB communication terminals on the TI-1680 are shown below.

USB Connector J6

Pin No.

Wire Name

Wire Color

Pin No.

Wire Name

Wire Color

1 VBUS Red 3 D+ Green

2 D- White 4 GND Black

CONNECTING THE CONTROL I/O

The TI-1680 indicator features one remote input and four output terminals for connection to process

control equipment. A +5VDC terminal is also included for connection to the outputs if an external supply is

not available.

The outputs are labeled OUT1-OUT4. The single remote input is triggered by simple contact closure. For

suggested wiring diagrams, see Appendix D.

Connection assignments for all control I/O terminals on the TI-1680 are shown below.

Control I/O Connector J4

Pin No.

Wire Name

Pin No.

Wire Name

1 +5V 6 OUTPUT1

2 GND 7 OUTPUT2

3 INPUT 8 OUTPUT3

4 GND 9 OUTPUT4

5 CATCHDIODE

CONNECTING THE RS-232 PORT (COM2)

The J11 terminal allows for a 2nd RS-232 port. This is realized by an optional board soldered to J11 pads.

RS-232 Connector J9A

Pin No.

Wire Name

Pin No.

Wire Name

1 RXD 4 RTS

2 TXD 5 Ground

3 CTS

CONNECTING THE OPTIONAL WLAN (COM2)

The J11 terminal allows for an optional WLAN (Wireless Ethernet) communications port. This is realized

by an optional board soldered to J11 pads.

4

CONNECTING THE OPTIONAL RS-485 (COM2)

The J11 terminal allows for an optional half duplex, Multipoint EIA-RS-485 communications port. It is also

compatible with it is compatible with TIA/EIA-422-B.This is realized by an optional board soldered to J11

pads.

RS-485 Connector J2

Pin No.

Wire Name

1 Tx+/Rx+ (AA)

2 Tx-/Rx- (BB)

CONNECTING THE OPTIONAL BLUETOOTH (COM2)

The J11 terminal allows for an optional Bluetooth port. This is realized by an optional board soldered to

J11 pads.

CONNECTING THE OPTIONAL ANALOG OUTPUT

The J3 terminal allows for an optional analog out. This is realized by an optional board soldered to J3

pads.

Please see Appendix E for more information on this option.

CONNECTING THE POWER SUPPLY

The TI-1680 indicator ships with an AC line cord attached to the indicator. It has been pre-wired on J7 at

the factory. Simply plug the unit into a standard wall outlet.

5

CONFIGURATION

OVERVIEW

The indicator contains two main configuration menus:

•The Setup (“F”) menu, which configures and calibrates the indicator to your weigh platform

•The User (“A”) menu, which configures the serial communication ports and enables some

user options

•The Batching (“B”) menu, which configures the I/O for process control and checkweighing

functions

All menus consist of several menu selections, each with their own sub-menu of selections or

programming procedures. To configure the indicator you must first enter the appropriate menu mode.

Once there, four of the front panel keys become directional navigators to move around in the menus, and

one key is used to save or SET the selections.

ACCESSING THE MENUS

To access the Setup (“F”) menu:

1. Power off the indicator.

2. Locate the slide switch on the rear cover and move it to the opposite position.

NOTE: A metal plate conceals the slide switch; remove the two drilled-head screws and cover

plate to access the slide switch.

3. Power on the indicator.

The display shows “ PASS_” to indicate that you need to enter a password to access Setup Menu

mode.

4. Key-in the password (1397) and then press Enter key

The display shows ” F 1” to indicate that you are in Setup Menu mode.

To access the User (“A”) menu:

1. Power off the indicator.

2. Locate the slide switch on the rear cover and move it to the opposite position.

NOTE: A metal plate conceals the slide switch; remove the two drilled-head screws and cover

plate to access the slide switch.

5. Power on the indicator.

The display shows “ PASS_” to indicate that you need to enter a password to access User Menu

mode.

3. Key-in the password (1793) and then press SET (MODE) key

The display shows ” A 1” to indicate that you are in User Menu mode.

To access the Batch (“B”) menu:

1. Power off the indicator.

2. Locate the slide switch on the rear cover and move it to the opposite position.

NOTE: A metal plate conceals the slide switch; remove the two drilled-head screws and cover

plate to access the slide switch.

6. Power on the indicator.

The display shows “ PASS_” to indicate that you need to enter a password to access User Menu

mode.

3. Key-in the password (1234) and then press SET (MODE) key

The display shows ” B 1” to indicate that you are in Batch Menu mode.

6

MENU STRUCTURE

All menus consist of a top level (heading) and a secondary level. The top level contains the code (e.g. F1)

for the parameter to be configured. The secondary level contains the selection list or allows access to a

programming sequence.

Use the directional keys to move around in the Menu Structure shown below.

F1

Grads

10 80

F2

Sampling Rate

Selection List

Etc.

1. To move to a new heading, use the TARE (left) or PRINT (right) key to move right or

left in the Menu.

2. To move to the selection or programming level, press the ZERO (down) key once. The

currently saved selection is shown.

3. To view the available selections for the current heading, use the TARE (left) or PRINT

(right) key to move through the selection field.

4. To save a new selection, press the MODE (Set) key .To exit without saving, press the

UNITS (up) key to return to the current heading.

5. Repeat Steps 2 through 5 until the Menu is programmed.

To exit any setup Menu, press the C/CE key. To exit all the way out return the slide switch to its original

position.

7

SETUP MENU DESCRIPTIONS

This section provides more detailed descriptions of the selections found in the Setup Menu Chart. Factory-

set defaultsare shown in bold; (NA) for North America and (€)for Europe.

NOTE: Some selections are subject to local legal metrology regulations

CODE/NAME DESCRIPTION SELECTION LIST

F1

Graduations Specifies number of full-scale graduations, i.e. capacity ÷ division.

For example, if scale is to be 5000 lb x 1 lb, then F1 should be set to

5000 (5000 ÷ 1). Value should be consistent with legal regulations

and environmental limits on the useful system resolution. Pressing

the ZERO key to scroll down one level begins the sequence.

Key-in

100 - 50000

10000 (NA)

6000 (€)

F2

Sampling Rate Sets the sampling rate in Hertz (measurements per second). Use

10 Hz for most applications or 80 Hz for extra fast response time 10√

√√

√(NA/€) 80

F3

Zero Track

Band

Selects the range within which the scale will automatically zero. Note

that the scale must be in standstill to automatically zero. Selections

are in display divisions per second (d/s).

0d

0.5d √

√√

√(NA/€)

1d

3d

5d

F4

Zero Range Selects the range (expressed as a percentage of full scale capacity)

within which the scale may be zeroed. Note that the indicator must be

in standstill to zero the scale.

100% (NA)

1.9%

2% (€)

20%

F5

Motion Band Sets the level at which motion is detected. If motion is not detected,

the scale can process a Print or Zero command. Maximum value

varies depending on local regulations. Expressed as scale divisions

per second (d/s). Pressing the ZERO key to scroll down one level

begins the sequence.

Key-in

0.0d/s – 32.0d/s

1.0d/s (NA/€)

F6

Digital Filter Averages weight readings to produce higher stability. Choose the

speed that works best for your application.

“FAST” = Fast “nnEd” = Medium “SLo” = Slow

FAST

nnEd√

√√

√(NA/€)

SLo

F7

Overload Limit Selects the formula which determines the point at which the indicator

shows overload. All selections are based on the primary unit selected

in F8.

"FS" = Full scale capacity.

FS

FS + 2% (NA)

FS + 5%

FS + 1d

FS + 9d (€)

F8

Calib. Unit Selects the primary base unit to be used in the calibration process.

Also the default unit for normal operation.

"1" = primary unit is lb. "2" = primary unit is in kg.

1 (NA)

2 (€)

F9

Display

Divisions

Determines the desired weight increments. Value should be

consistent with legal requirements. 1 (NA)

2

5 (€)

F10

Decimal Pt. Determines location of the decimal point. 0 (NA) 0.0 (€)

0.00 0.000

0.0000 00

8

CODE/NAME DESCRIPTION SELECTION LIST

F11

Custom Unit

Multiplier

Actuates the function that allows you to enter a multiplier for the

custom unit., i.e. the conversion factor that you would divide the

calibration unit by in order to obtain the custom unit of weight.

Pressing the ZERO key to scroll down one level begins the

sequence.

Key-in

0.0001 - 1000

1.0 (NA/€)

F14

Units

Conversion

Allows the UNITS key to be disabled so that an operator cannot

accidentally press the key and change the displayed units.

"0" = Disable the Units key "1" = Enable the Units key

0 (€)

1 (NA)

F15

Third Unit

Selection

Selects the third unit to appear after lb and kg when toggling the

UNITS key. "0" = No Third Unit, "1" = Grams, "

2" = oz, “3” = custom unit

0√

√√

√(NA/€)

0-3

F16

Zero

Calibration

Places indicator into the zero calibration routine. Scrolling down with

the ZERO key one level begins the procedure. Press ZERO key

to begin sequence

F17

Span

Calibration

Places indicator into the span calibration routine. Scrolling down with

the ZERO key one level begins the procedure. Press ZERO key

to begin sequence

F18

View

Calibration

Actuates the function that allows you to view both the zero and span

calibration value. The values displayed in this function are valid only

after Calibration (F16 & F17) has been successfully completed.

Scrolling down with the ZERO key one level begins the procedure.

Multi-point cal

Press ZERO key

to begin sequence

F19

Key-in Zero Allows you to key-in known zero calibration value in case of memory

loss in the field. Scrolling down with the ZERO key one level begins

the procedure.

Press ZERO key

to begin sequence

F20

Key-in Span Allows you to key-in a known span calibration value in case of

memory loss in the field. Scrolling down with the ZERO key one level

begins the procedure.

Press ZERO key

to begin sequence

F21

Factory Reset

North America

This sub-menu will reset all parameters in the “F” and “A” menu to the

default settings for North America. USE WITH CAUTION!

“tF” message means ‘busy – please wait’

Press the ZERO

key twice to

execute.

F22

Factory Reset

Europe

This sub-menu will reset all parameters in the “F” and “A” menu to the

default settings for Europe. USE WITH CAUTION! “tF” message

means ‘busy – please wait’

Press the ZERO

key twice to

execute.

F23

Fine Tune

4-20 mA

Actuates the function that allows you to fine-tune the optional

4-20 mA analog output. Pressing the ZERO key to scroll down one

level begins the sequence.

Press the ZERO

key to begin

sequence

9

CODE/NAME DESCRIPTION SELECTION LIST

F30

Special

Application

Used to select one special application feature, subject to local legal

requirements.

“0” = None (Gross/Net), “1” = Accumulation, “2” = Remote Display,

“3” = Piece Count, “4” = Percentage1, “5” = Hold,

“6” = Checkweighing, “7” = Batching, “

8” Truck Weigh In/Weigh Out2

0√

√√

√(NA/€)

0 - 8

F31

Gross Zero

Band

Selects the range within which the scale will automatically clear the

tare and switch to Gross mode. Note that the scale must be in

standstill. Selections are in display divisions (d). Scrolling down with

the ZERO key one level begins the procedure.

“0” = Disabled

Key-in

0 - 10

0 (NA)

10 (€)

F32

Center of Zero

Band

Selects the range around gross zero within which the scale will

display the Center of Zero annunciator. Selections are in display

divisions (d).

0.25d (US)

0.5d (€)

F34

Auto Print Min.

Weight

Selects the minimum weight at which the auto print function will work

if enabled. Selections are in display divisions (d). Scrolling down with

the ZERO key one level begins the procedure.

“0” = Disabled

Key-in

0 - 100

1 (NA/€)

F35

Hold Mode

Selects the “Hold” mode operation. See Operation section for more

details.

“1” = Automatic Hold, “2” = Manual, “3” = Peak Hold

1

2

3√

√√

√(NA/€)

F36

Percentage

Hold Wt

Allows you to select the percentage (of the displayed held value) of

weight change before the scale automatically unlocks the held weight

and relocks onto the new weight. If F35 is set to “0”, this function

does nothing.

Key-in

0 – 100 %

10 (NA/€)

F37

Min. Hold Wt Sets the minimum weight that can be captured and held; expressed

in display divisions (d). If F35 is set to “0”, this function does nothing. 1, 2, 5 √

√√

√(NA/€),

10, 20, 50, 100,

200, 500, 1000

F38

Permanent

Tare2

Allows a TARE to be stored with an ID number. Used for the Truck

Weigh In/Weigh Out application.

"0" = Disable "1" = Enable

0√

√√

√(NA/€)

1

F39

Set Point

Password3

Allows the Password prompt to be disabled so that an operator need

not enter one in order to program in a new Set Point value.

"0" = Disable the prompt "1" = Enable the prompt

0

1√

√√

√(NA/€)

1Appears on Version 2.34 and below only

2Appears on Version 2.4 and above only

3Appears on Version 2.5 and above only

10

SETUP MENU PROCEDURES

This section provides instructions for all of the Setup Menu procedures except F16 through F20. Those

procedures can be found in the Calibration section.

Key-in Operation (F1, F5, F11, F31, F34 and F36)

Follow these general instructions for those parameters requiring keyed-in data:

1. While in the Setup mode, scroll to "F xx", and then scroll down once using the ZERO key.

The display will momentarily show a brief description, followed the currently stored value.

2. If the displayed value is correct, simply press the ENTER or C/CE key to escape.

3. If the displayed value needs to be changed, use the front panel numeric keys to key-in the

new value and then press ENTER. If you make a mistake, press the C/CE key as a

backspace key. The display will show "Set" momentarily, and then revert back up to "F xx".

Fine-tune 4-20 mA output (F23)

1. While in the Setup Menu mode, scroll to "F 23", then scroll down once using the ZERO key to

enter Fine-tune menu. The indicator outputs 4 mA and displays a number.

2. While monitoring the voltage across RL (see Appendix E), use the right (PRINT) or left

(TARE) keys to change the displayed value until the measured voltage is exactly 1 VDC.

3. Press the SET (Mode) key to save. The indicator outputs 20 mA and displays another

number.

4. While monitoring the voltage across RL, use the right (PRINT) or left (TARE) keys to change

the displayed value until the measured voltage is exactly 5 VDC.

5. Press the SET (Mode) key to save and revert back to F23.

11

USER MENU DESCRIPTIONS

This section provides more detailed descriptions of the selections found in the User Menu Chart.

Factory-set defaults are shown in bold; (NA) for North America and (€)for Europe.

CODE/NAME DESCRIPTION SELECTION LIST

A1

Baud Rate Selects the baud rate for data transmission through the serial port.

This menu selection has two sub-menus; “A1U1” (COM1) and “A1U2”

(COM2), both with identical selections.

600, 1200, 2400,

4800,

9600√

√√

√(NA/€),

19200, 38400

A2

Data Bits and

Parity

Selects the number of data bits and parity of serial transmission. This

menu selection has two sub-menus; “A2U1” (COM1) and “A2U2”

(COM2), both with identical selections.

"8n" = 8 data bits with no parity bit and one stop bit

"7o" = 7 data bits with odd parity bit and one stop bit

"7E" = 7 data bits with even parity bit and one stop bit

"7n" = 7 data bits with no parity bit and two stop bits

8n√

√√

√(NA/€)

7o

7E

7n

A3

Serial Port

Mode

Selects the mode of the I/O serial port: Refer to Appendix B for more

information. This menu selection has two sub-menus; “A3U1”

(COM1) and “A3U2” (COM2), both with identical selections.

"d" = Demand Duplex

"C" = Continuous Duplex

"AUto" = Auto Print

d√

√√

√(NA/€)

C

AUto

A4

Output String Selects fixed output string for serial port. Refer to Appendix B for

details. This menu selection has two sub-menus; “A4U1” (COM1) and

“A4U2” (COM2), both with identical selections. “tF” message means

‘busy – please wait’ "0" = Text Print Ticket Basic

"1" = Text Print Ticket Accumulator

"2" = Text Print Ticket Piece Counting

"3" = Text Print Ticket Percentage4

"4" = String Format 1 (Condec Demand)

"5" = String Format 2 (Condec Continuous)

“6” Truck Weigh In/Weigh Out5

0√

√√

√(NA/€)

1, 2, 3, 4, 5, 6

A5

Handshaking Selects handshaking for serial port. This menu selection has two sub-

menus; “A5U1” (COM1) and “A5U2” (COM2), both with identical

selections. "0" = Off (no handshaking)

"1" = RTS/CTS

"2" = XON/XOFF (Ctrl-Q/Ctrl-S)

0√

√√

√(NA/€)

1

2

A6

Set Time Actuates the function that allows setting the time. Pressing the ZERO

key to scroll down one level begins the programming sequence. Press ZERO key

to begin sequence

A7

Set Date Actuates the function that allows setting of the date. Pressing the

ZERO key to scroll down one level begins the programming

sequence.

Press ZERO key

to begin sequence

4Appears on Version 2.34 and below only

5Appears on Version 2.4 and above only

12

CODE/NAME DESCRIPTION SELECTION LIST

A8

Time Format Selects the printed format for time. This menu selection has two sub-

menus; “A8U1” (COM1) and “A8U2” (COM2), both with identical

selections. "0" = AM/PM "1" = 24 Hr

0 (NA)

1 (€)

A9

Date Format Selects the printed format for date. This menu selection has two sub-

menus; “A9U1” (COM1) and “A9U2” (COM2), both with identical

selections.

"1" = mm/dd/yy "2" = mm/dd/20yy “3” = dd/mm/yy

"4" = dd/mm/20yy "5" = yy/mm/dd “6” = 20yy/mm/dd

1 (NA) 2

3 (€) 4

5 6

A10

Decimal Point Selects printed (not displayed) decimal point character. This menu

selection has two sub-menus; “A10U1” (COM1) and “A10U2”

(COM2), both with identical selections.

"0" = Period (‘.’)

"1" = Comma (‘,’)

0 (NA)

1 (€)

A116

Report Actuates the function that sends all configuration and calibration data

to COM1. Pressing the ZERO key to scroll down one level begins the

sequence.

Press ZERO key

to begin sequence

A12

Diagnostics Used to access the listed test functions (one at a time). Pressing the

ZERO key begins the sequence.

"A12U1" = Display segment test, "A12U2" = A/D converter test,

“A12U3” = Input test, “A12U4” = Output test (all)

“A12U5” = Serial Port test (both), “A12U6” = Keyboard test

Press ZERO key

to begin sequence

A136

Expanded

(x10) Mode

Actuates the function that displays weight in expanded (x10) mode.

Pressing the ZERO key to scroll down one level begins the

sequence.

Press ZERO key

to begin sequence

A14

Edit Output

String

Actuates the function that allows editing of output string. This menu

selection has two sub-menus; “A14U1” (COM1) and “A14U2”

(COM2), both with identical selections. Pressing the ZERO key to

scroll down one level begins the sequence.

Press ZERO key

to begin sequence

A157

MP-20 Print

Header

Tells MP-20 printer to print the header information. This menu

selection has two sub-menus; “A15U1” (COM1) and “A15U2”

(COM2), both with identical selections.

"0" = Do NOT Print Header "1" = Print Header

0 √

√√

√(NA/€)

1

A167

MP-20 Auto

Label Feed

Tells MP-20 printer to automatically advance to next label after

printing. This menu selection has two sub-menus; “A16U1” (COM1)

and “A16U2” (COM2), both with identical selections.

"0" = Disable "1" = Enable

0 √

√√

√(NA/€)

1

6Appears on Version 2.34 and below only

7Appears on Version 2.4 and above only

13

USER MENU PROCEDURES

This section provides instructions for all of the User Menu procedures.

Set Time (A6)

Your indicator will keep track of the current time for you, which can then be printed on the print ticket.

Use this procedure to set the time, which must be entered in military (24-hr) format. For example, for

9:00 AM, you would enter 09.00.00. For 5:00 PM, you would enter 17.00.00.

1. While in the User Menu mode, scroll to "A 6", and then scroll down once using the ZERO key to

enter the set time menu. The display will momentarily show "ENT TI", followed by the time

(hh.mm.ss) currently set on the machine.

2. If the displayed value is correct, simply press the ENTER or C/CE key to exit this mode without

saving any changes.

3. If the displayed value needs to be changed, first press MODE (Set). The display changes to all

zeroes (00.00.00).

4. Use the front panel numeric keys to key-in the new time and then press ENTER. If you make a

mistake, use the C/CE key as a backspace key. The display will show "Set" momentarily, and

then revert back up to "A 6".

NEW for version 2.5 and higher: it is no longer necessary to enter the User Menu to set the time. Simply press

and hold the ENTER key while powering up the unit and then follow directions are written above.

Set Date (A7)

Your indicator will keep track of the current date for you, which can then be printed on the print ticket.

Use this procedure to set the date, which must be set in mm/dd/yy format. For example, for January

7, 2010, you would enter 01.07.10. For November 30, 2010 you would enter 11.30.10.

1. While in the User Menu mode, scroll to "A 7", and then scroll down once using the ZERO key to

enter the date entry menu. The display will momentarily show "ENT DT", followed by the date

(mm.dd.yy) current set on the machine.

2. If the displayed value is correct, simply press the ENTER or C/CE key to exit this mode without

saving any changes.

3. If the displayed value needs to be changed, first press MODE (Set). The display changes to all

zeroes (00.00.00).

4. Use the front panel numeric keys to key-in the new date and then press ENTER. If you make a

mistake, use the C/CE key as a backspace key. The display will show "End DT" momentarily,

and then revert back up to A7.

NEW for version 2.5 and higher: it is no longer necessary to enter the User Menu to set the date. Simply press

and hold the ENTER key while powering up the unit and then follow directions are written above.

14

Diagnostics (A12)

Here is a brief description of each test mode:

A12U1 Display Test – Lights up all display segments, counting down from 666666 to 11111. Test

ends automatically when complete.

A12U2 ADC Test – Shows internal A/D converter counts – useful for troubleshooting weighing

issues. End test manually by pressing the MODE (Set) key.

A12U3 Input Test – Displays input logic (0 or 1) of input terminal (J4:3). “0” mean input pin is

grounded; “1” means input pin is open. End test manually by pressing the MODE (Set) key.

A12U4 Output Test – Sets all output pins (J4:6 thru J4:9) ‘ON’. End test manually by pressing the

MODE (Set) key.

A12U5 Serial Test – Transmits a data string continuously out both serial ports (“TEST1” on COM1

and “TEST2” on COM2). End test manually by pressing the MODE (Set) key.

A12U6 Keyboard Test – Displays a keycode for each key pressed on the keypad. See Table below.

End test manually by pressing the MODE (Set) key.

Key

Keycode

Key

Keycode

Units

UnIts

0

0

Zero

2Ero

1

1

Tare

tArE

2

2

Print

PrInt

3

3

C/CE

CE

4

4

F1

F1

5

5

Set Point

SP

6

6

Under

UndEr

7

7

Over

ovEr

8

8

ID

Id

9

9

*

StAr

Enter

EntEr

Dec. Pt.

dP

Mode

SEt

Expanded Mode (A13)

This mode displays weight in the calibration unit (programmed in F8) at ten times the number of

graduations (programmed in F1) setting. For example if the scale is configured to 5000 lb x 1 lb, then

the expanded mode will display weight to 5000 lb x 0.1 lb. Exit this mode manually by pressing the

MODE (Set) key.

Edit Output String (A31)

Please see Appendix B for more information.

15

BATCH MENU DESCRIPTIONS

This section provides more detailed descriptions of the selections found in the Batch Menu Chart.

Factory-set defaults are shown in bold; (NA) for North America and (€)for Europe.

CODE/NAME DESCRIPTION SELECTION LIST

B1

Input Function Use this menu to assign a keyboard function to the input terminal

(J4:3). "0" = Print, "1" = Zero, “2” = Tare, “3” = Units, “4” = F1

0(NA/€)

1, 2, 3, 4

B2

Input Logic Use this menu to assign the active logic level to the input terminal

(J4:3). "0" = Low logic, "1" =High logic

0(NA/€)

1

B3

Batch Mode Use this menu to assign the batch mode. F30 must be set to “7”.

“0” = Manual, “1” = Automatic, “2” = Filling, “3” = Continuous

0(NA/€)

1, 2, 3

B4

Output Logic Use this menu to assign the active logic level to each of the output

terminals (OUT1 thru OUT4). This menu selection has four sub-

menus: “B4U1” (OUT1), B4U2” (OUT2), B4U3” (OUT3), and

B4U4” (OUT4), all with identical selections.

"0" = Low logic, "1" =High logic

0

1(NA/€)

B5

Front Panel

Access

Password

There are three keys on the front panel which allow set point or

over/under values to be entered into the system. Front panel access

is password protected. Use this menu to assign or change the

password.

Key-in

0 - 999999

336699 (NA/€)

B6

Output Trip

Delay

Use this menu to assign a cutoff delay (in seconds) to each of the

output terminals (OUT1 thru OUT4). This is for in-flight

compensation method. This menu selection has four sub-menus;

“B6U1” (OUT1), B6U2” (OUT2), B6U3” (OUT3), and B64U4” (OUT4),

all with identical selections.

Key-in

0.0 – 10.0

0(NA/€)

BATCH MENU PROCEDURES

This section provides instructions for all of the Batch Menu procedures.

Key-in Operation (B5 and B6)

Follow these general instructions for those parameters requiring keyed-in data:

1. While in the Setup mode, scroll to "B x", and then scroll down once using the ZERO key. The

display will momentarily show a brief description, followed the currently stored value.

2. If the displayed value is correct, simply press the ENTER or C/CE key to escape.

3. If the displayed value needs to be changed, use the front panel numeric keys to key-in the

new value and then press ENTER. If you make a mistake, press the C/CE key as a backspace

key. The display will show "Set" momentarily, and then revert back up to "B x".

16

EXITING THE MENUS

Exit any configuration menu by pressing the C/CE key. To exit the PASS screen, move the slide switch

back to its original position. The display will gothrough a digit check, and then settle into Normal Operating

mode.

All front panel keys will now returnto their normal mode of operation.

17

CALIBRATION

CALIBRATION OVERVIEW

If your indicator was shipped as a complete scale, then calibration is not necessary. Please check

with your installer or supplier if you are unsure. Transcell recommends having your weighing

equipment checked by a qualified scale technician at least once a year depending on its intended

use and working environment.

The indicator requires two types of calibration: zero and span. Zero calibration (F16) requires the scale to

be empty (nothing on scale) and the span calibration (F17) requires known test weights. After a

successful calibration, you should record all calibration values in Table 1 using the F18 View Calibration

procedure.

In the unlikely event that any calibration value is lost, the setup menu makes provisions for re-entering

these values via F19 and F20; thus eliminating the need for re-calibration with test weights.

NOTE: This section assumes that the indicator is in Setup (“F”) Menu mode. If the indicator is not in

Setup Menu mode, refer to previous section for instructions.

ZERO CALIBRATION (F16)

1. While in the Setup mode, scroll to "F 16", and then scroll down once using the ZERO key to

enter zero calibration menu. The display will momentarily show "C 0" followed by a value. This

value is the internal A/D count and can prove useful when trying to troubleshoot calibration

problems.

2. Remove all test weights from the platform and then press the ZERO key to zero out the

displayed value.

3. Press the MODE key to save the zero point value. The display will show "EndC0" momentarily,

and then revert back up to F16. At this time, proceed to the F17 span calibration to complete

indicator calibration.

SPAN CALIBRATION (F17)

1. While in the Setup mode, scroll to "F 17", then scroll down once using the ZERO key to enter

span calibration menu. The display will momentarily show "C 1" for the first span calibration

point, followed by a value with one flashing digit. This value will be zero with the Decimal Point

parameter selected in F10.

2. Place the first test weight on the weighing mechanism.

3. Use the front panel keys to key-in the actual test weight value. There is no need to enter a

decimal point, since it is fixed on the display. If you make a mistake, use the C/CE key as a

backspace key.

4. After entering the exact value, press the MODE key to save the value. If the C1 calibration was

successful, the display will show "EndC1" momentarily, followed by

"C 2" for the second calibration point.

5. Repeat steps 2 thru 4 for C2 and C3. At the conclusion of C3, the indicator reverts back up to

F17. NOTE: If you wish to use only one calibration point (C1), simply press the MODE key

when prompted for C2 and C3 (do not enter in a calibration value).

Other manuals for TI-1680

1

Table of contents

Other Transcell Technology Touch Panel manuals

Popular Touch Panel manuals by other brands

iWalldock

iWalldock In-Wall Tablet Mounting System installation guide

Pentair

Pentair HYDROMATIC H-03-400 Installation and service manual

Winmate

Winmate W22IK3S-SPA3 quick start guide

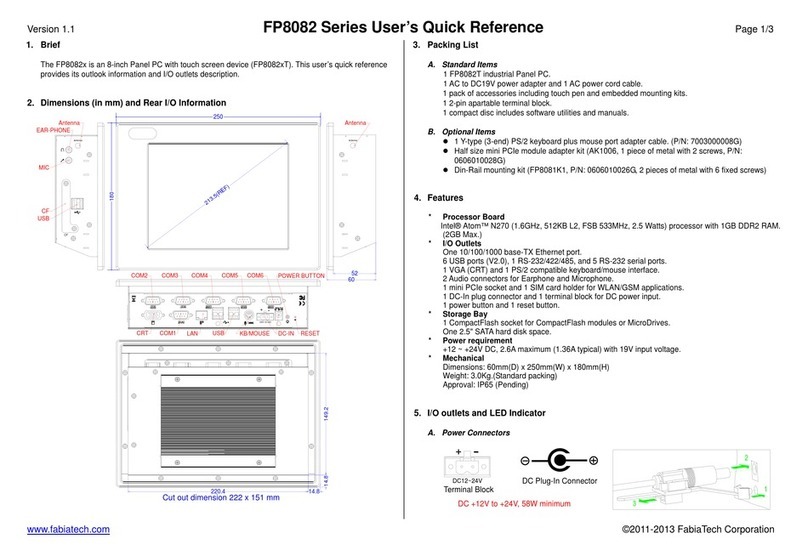

FabiaTech

FabiaTech FP8082 Series Users Quick Reference

ELMARK

ELMARK MS-9Z08 user manual

AMX

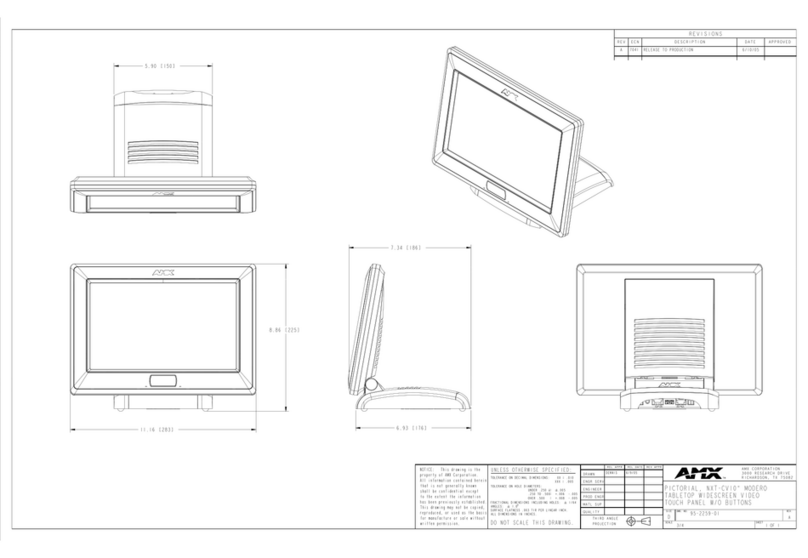

AMX Modero NXT-CV10 Dimension Guide