Transcell Technology NEPTUNE 4500 Manual instruction

NEPTUNE4500

Digital Indicator

Setup / Operation Manual

Revision 0.3

February 6, 2003

2003 Transcell Technology, Inc.

Contents subject to change without notice.

Transcell Technology, Inc.

975 Deerfield Parkway

Buffalo Grove, IL 60089

Tel (847) 419-9180

Fax (847) 419-1515

E-mail: [email protected]

Web: www.transcell.net

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protec-

tion against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions manual, may cause harmful interference to radio com-

munications. Operation of this equipment in a residential area is likely to cause harmful interfer-

ence in which case the user will be required to correct the interference at his/her own expense.

TABLE OF CONTENTS NEPTUNE 4500

Page

Chapter 1: Introduction To The Neptune 4500 Series Indicator..................................................... 1-1

Chapter 2: Installation ..................................................................................................................... 2-1

2.1 Stainless Steel Enclosure ............................................................................................. 2-1

2.1.1 Connecting the weigh platform......................................................................... 2-1

2.1.2 Connecting the serial printer, remote display or computer.............................. 2-1

2.1.3 Connecting the power supply........................................................................... 2-2

Chapter 3: Configuration................................................................................................................. 3-1

3.1 Configuration Overview................................................................................................. 3-1

3.2 Setup (“F”) Menu........................................................................................................... 3-1

3.2.1 Entering the Setup Menu – Stainless Steel Enclosure.................................... 3-1

3.2.2 Navigating in the Setup Menu.......................................................................... 3-2

3.2.3 Notes on the Setup Menu ................................................................................ 3-3

3.2.4 Exiting the Setup Menu – Stainless Steel Enclosure....................................... 3-3

3.3 User (“A”) Menu............................................................................................................. 3-3

3.3.1 Entering the User Menu................................................................................... 3-3

3.3.2 Navigating in the User Menu............................................................................ 3-3

3.3.3 Notes on the User Menu.................................................................................. 3-3

3.3.4 Exiting the User Menu...................................................................................... 3-3

C

hapter 4: Setup Menu Descriptions and Procedures ................................................................... 4-1

4.1 Setup Menu Descriptions.............................................................................................. 4-1

C

hapter 5: User Menu Descriptions and Procedures..................................................................... 5-1

5.1 User Menu Descriptions................................................................................................ 5-1

5.2 User Menu Procedures................................................................................................. 5-2

5.2.1 ID Number Entry (A8)....................................................................................... 5-2

5.2.2 Line Feeds Entry (A9) ...................................................................................... 5-2

i

Ne

p

tune 4500

C

hapter 6: Calibration..................................................................................................................... 6-1

6.1 Calibration Overview..................................................................................................... 6-1

6.2 Zero Calibration (F16)................................................................................................... 6-1

6.3 Span Calibration (F17).................................................................................................. 6-1

6.4 View Calibration Values (F18)....................................................................................... 6-3

6.5 Key-in Zero Calibration Value (F19) ............................................................................. 6-3

6.6 Key-in Span Calibration Value (F20) ............................................................................ 6-4

C

hapter 7: Operation....................................................................................................................... 7-1

7.1 Display........................................................................................................................... 7-1

7.1.1 Light Emitting Diode (LED) Display.................................................................. 7-1

7.2 Keyboard....................................................................................................................... 7-2

7.2.1 Function Keys................................................................................................... 7-2

7.3 General Scale Operation............................................................................................... 7-3

7.3.1 Weighing an item.............................................................................................. 7-3

7.3.2 Zeroing an item ................................................................................................ 7-3

7.3.3 Piece Counting................................................................................................. 7-3

C

hapter 8: Legal for Trade Sealing................................................................................................. 8-1

8.2 Stainless Steel Enclosure ............................................................................................. 8-1

Appendix A: Specifications................................................................................................................ A-1

Appendix B: Serial Port Information................................................................................................... B-1

B.1 Serial Port Modes.......................................................................................................... B-1

B.1.1 Full Duplex Mode ............................................................................................. B-1

B.1.1.1 Recognized Host Commands.......................................................... B-2

B.1.2 Print Ticket Mode ............................................................................................. B-2

B.1.3 Simplex Mode................................................................................................... B-3

Appendix C: Determining Proper Span Gain (F2) ............................................................................. C-1

C.1 Span Gain Overview ..................................................................................................... C-1

C.2 Setting the initial value for span gain ............................................................................ C-1

C.3 Viewing the internal counts........................................................................................... C-1

Appendix D: Displayed Error Codes.................................................................................................. D-1

ii

Ne

p

tune 4500

iii

Ne

p

tune 4500

LIST OF FIGURES

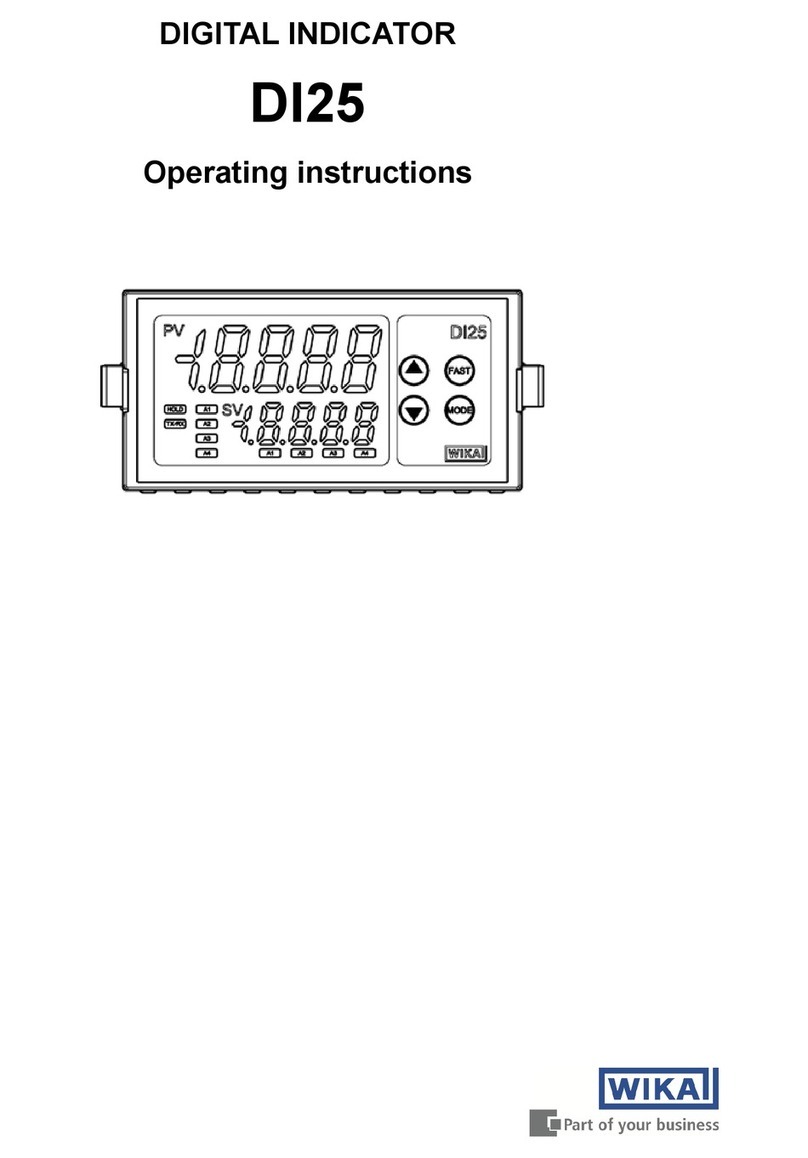

1-1 Neptune 4500 Front Panel...................................................................................................... 1-2

2-1 Neptune 4500 Main Circuit Board Overview .......................................................................... 2-1

2-2 Connection assignments for load cell..................................................................................... 2-1

2-3 Connection assignments for the serial communication terminal............................................ 2-2

3-1 Setup Menu Key Assignments................................................................................................ 3-2

3-2 Setup Menu Chart................................................................................................................... 3-3

3-3 User Menu Key Assignments.................................................................................................. 3-4

3-4 User Menu Chart..................................................................................................................... 3-5

5-1 User Menu Key Assignments.................................................................................................. 5-3

6-1 Setup Menu Key Assignments................................................................................................ 6-2

7-1 Neptune 4500 Series LED Display Detail............................................................................... 7-1

7-2 Function Keys Layout ............................................................................................................. 7-2

B-1 Cable Diagram for Indicator to IBM PC .................................................................................. B-1

B-2 Consolidated Controls Demand Mode.................................................................................... B-1

B-3 Print Ticket.............................................................................................................................. B-2

B-4 Cable Diagram for Indicator to Printer .................................................................................... B-2

B-5 Consolidated Controls Continuous Mode............................................................................... B-3

LIST OF TABLES

1-1 Neptune 4500 Series Product Matrix...................................................................................... 1-1

4-1 Invalid Setup Selections for commercial applications............................................................. 4-3

6-1 Calibration Value Table........................................................................................................... 6-3

7-1 Neptune 4500 Series Annunciator Definitions........................................................................ 7-2

C-1 Minimum Recommended Span Gain Table............................................................................ C-2

CHAPTER 1: INTRODUCTION TO THE Neptune 4500 SERIES DIGITAL INDICATORS

The Neptune 4500 Series Digital Indicator is a general purpose, industrial grade weight indicator.

All models operate identically, can readout up to 50,000 display divisions and can supply enough

current for up to 4-350Ωload cells. All setup parameters may be entered via the front panel keys,

including calibration.

If your Neptune Model 4500 Series Digital Indicator is part of a complete floor scale or has been

installed for you, you may skip to Chapter 7 for operating instructions. Prior to using the indicator,

please read this chapter carefully and completely. Store the manual in a safe and convenient

place so it will be available if you have questions concerning the operation of the scale.

If you are an installer, the indicator's installation and wiring instructions are found in Chapter 2.

The indicator contains two main setup menus: The Setup (“F”) menu, which configures the

indicator to your weigh platform and the User (“A”) menu, which configures the serial

communication port and enables some user options. Chapter 3 gives an overview and explains

how to use the two front panel keys to maneuver and save settings in both menus. Chapters 4

and 5 explain the Setup and User Menu options, respectively. Chapter 6 covers system

calibration. Prior to installing the indicator, please read this manual carefully and completely.

Store the manual in a safe and convenient place so it will be available if you have questions

concerning the setup and operation of the scale.

MODEL DISPLAY

TYPE ENCLOSURE

TYPE POWER SOURCE

Neptune 4500 LED Stainless Steel 110/220 VAC, 50/60 Hz

TABLE 1-1: Neptune Series Product Matrix

FIGURE 1-1: Neptune 4500 Front Panel

Neptune 4500 Page 1-1

CHAPTER 2: INSTALLATION

2.1 STAINLESS STEEL ENCLOSURE

For indicators contained in a stainless steel enclosure, the rear cover must first be removed to

make the appropriate connections to the weigh platform, printer, remote display and power supply.

o remove the rear cover, simply remove the screws that secure it to the enclosure and set aside.T

NOTE: On earlier units, the rear cover must remain off to access the Setup Menu and calibration

procedures.

J8

S- SHE+ S+ E-

CPU

EPROM

J3

TXD RXD GND

J1

P+ P-

JP2

J4

J6

+5

Figure 2-1: Neptune 4500 Main Circuit Board Overview

2.1.1 CONNECTING THE WEIGH PLATFORM

1. Connect your shielded load cell cable (not included) to the appropriate terminal on the

main board. Connection assignments for the Load Cell Terminals are shown in Figure

2-6.

Figure 2-2: Connection assignments for the Load Cell Terminal

Neptune 4500 Page 2-1

2.1.2 CONNECTING THE SERIAL PRINTER, REMOTE DISPLAY OR COMPUTER

The Neptune 4500 Series indicator comes standard with one full duplex RS-232 serial port,

designed for connection to either a PC or a serial printer. The same port may be also used

as a simplex, RS-232 port designed for connection to a remote display.

Connection assignments for all serial communication terminals are shown in Figure 2-7.

NOTE: Do not connect any RS-232 equipment to the “+5V” terminal (not shown).

1. Connect your serial printer, remote display or computer communication cable (not

included) to the appropriate terminal on the main board.

Figure 2-3: Connection assignments for the serial communication terminal

2.1.3 CONNECTING THE POWER SUPPLY

The Neptune 4500 indicator ships with an AC line cord attached to the indicator. Simply plug

the unit into a standard wall outlet.

1. Simply plug the AC adapter into the indicator’s DC Power Jack first, and then plug into a

standard wall outlet. Make sure that the AC voltage appearing at the wall outlet

matches the input voltage marked on the AC adapter.

Neptune 4500 Page 2-2

CHAPTER 3: CONFIGURATION

3.1 CONFIGURATION OVERVIEW

The indicator contains two main setup menus: The Setup (“F”) menu, which configures the indicator

to your weigh platform and the User (“A”) menu, which configures the serial communication port

and enables some user options. TheSetupand User menus consist of several menu selections, each with

its own sub-menu of choices.

To set up the indicator, you must first enter the appropriate menu mode. Once there, the front panel keys

become directional navigators to move around in the menus, and one key is used to save or SET the

selections.

3.2 SETUP (“F”) MENU

3.2.1 ENTERING THE SETUP MENU – STAINLESS STEEL ENCLOSURE

1. Power off the indicator.

2. Locate the slide switch on the rear cover and move it to the right.

NOTE: A metal plate held on by two drilled-head screws may conceal the slide switch.

3. Power on the indicator. The indicator shows ” F 1” to indicate that you are in Setup

Menu mode.

Note 1: Access to the back cover is inhibited if the indicator has been sealed for commercial

use. For more information, please refer to Chapter 8.

3.2.2 NAVIGATING IN THE SETUP MENU

Use the directional keys shown in Figure 3-1 to move around in the Setup Menu Chart

shown in Figure 3-2 on the following page.

1. To move to a new “F” heading, use the ZERO (left) key to move in the Setup Menu

Chart.

2. To move to the selection level, press the UNIT/SET (down) key once. The current

saved selection is shown.

3. To view the available selections for the current “F” heading, use the ZERO (left) key to

move through the selection field.

4. To save/exit a new selection, press the UNIT/SET key .To exit without saving, press

the UNITS (up) key to return to the current “F” heading.

5. Repeat Steps 1 through 4 until the Setup Menu is programmed.

Neptune 4500 Page 3-1

Figure 3-1: Setup Menu Key Assignments

Neptune 4500 Page 3-2

Figure 3-2: Setup Menu Chart

3.2.3 NOTES ON THE SETUP MENU

1. There is an F21 sub-menu present that is for FACTORY USE ONLY!

2. Detailed descriptions of the setup menu parameters can be found in Chapter 4 of this

manual.

3. The User (“A”) menu sub-menus appear when scrolling left or right from the “F” menu.

4. Some selections shown are not available on all models in the series. Likewise,

additional selections may be available on other models in the series. See Chapter 4

for more information.

3.2.4 EXITING THE SETUP MENU – STAINLESS STEEL ENCLOSURE

1. Power off the indicator.

2. Move the slide switch on the rear cover back to the left.

3. Power on the indicator. The display will go through a digit check, then settle into Normal

Operating mode. All front panel keys will now return to their normal mode of operation.

3.3 USER (“A”) MENU

3.3.1 ENTERING THE USER MENU

1. Enter the Setup (“F”) menu by following the directions in Section 3.2.1 or 3.2.2.

2. Use the ZERO directional keys shown in Figure 3-3 to move right or left in the Setup

(“F”) menu until the indicator shows ” A 1”.

3.3.2 NAVIGATING IN THE USER MENU

Use the directional keys shown in Figure 3-3 to move around in the User Menu Chart shown

in Figure 3-4 on the following page.

1. To move to a new “A” heading, use the ZERO (left) or PRINT (right) key to move right

or left in the User Menu Chart.

2. To move to the selection level, press the ZERO (down) key once. The current saved

selection is shown.

3. To view the available selections for the current “A” heading, use the ZERO (left) or

PRINT (right) key to move through the selection field.

4

. To save/exit a new selection, press the UNIT/SET key .

5. Repeat Steps 2 through 5 until the User Menu is programmed.

Neptune 4500 Page 3-3

Figure 3-3: User Menu Key Assignments

Figure 3-4: User Menu Chart

3.3.3 NOTES ON THE USER MENU

1

. Detailed descriptions of the user menu parameters can be found in Chapter 5 of this manual.

2. Some selections shown are not available on all models in the series. Likewise, additional

selections may be available on other models in the series. See Chapter 5 for more information.

3.3.4 EXITING THE USER MENU

1. Exit the User (“A”) menu by sliding the setup switch to its original position. Replace the metal

cover. The display will go through a digit check, then settle into Normal Operating mode. All front

panel keys will now return to their normal mode of operation.

Neptune 4500 Page 3-4

CHAPTER 4: SETUP MENU DESCRIPTIONS AND PROCEDURES

4.1 SETUP MENU DESCRIPTIONS

This section provides more detailed descriptions of the selections found in the Setup Menu Chart.

Factory-set defaults are shown in bold with a checkmark (√).

Table 4-1 shows the selections that are not allowed for “Legal-for-Trade” applications:

NAME/CODE DESCRIPTION CODE/VALUE

F1

Graduations Specifies number of full-scale graduations. Value should be consis-

tent with legal requirements and environmental limits on the useful

system resolution.

500 1,000

1,500 2,000

2,500 3,000

4,000 5,000√

6,000 8,000

10,000 12,000

20,000 30,000

40,000 50,000

F2

Span Gain Span Gain is related to A/D integration time. The larger the span

gain, the higher the internal resolution, but the slower the update

speed. Note that the scale must be re-calibrated whenever this pa-

rameter is altered. See Appendix C for more information.

25 50

75√100

150 200

F3

Zero Track

Band

Selects the range within which the scale will automatically zero. Note

that the scale must be in standstill to automatically zero. Selections

are in Display Divisions.

0d

0.5d√

1d

3d

5d

F4

Zero Range Selects the range within which the scale may be zeroed. Note that the

indicator must be in standstill to zero the scale. 100%√

1.9%

F5

Motion Band Sets the level at which motion is detected by comparing the present

display update with the previous one. If motion is not detected for two

seconds or more, scale is in standstill and can process a Print or Zero

command. Maximum value varies depending on local regulations.

0.25d (TI-500-SL)

1d√

3d

5d

10d

F6

Digital Filter Averages weight readings to produce higher stability. The higher the

filter setting, the greater the stability but the slower the indicator’s

response time. Choose 8 unless a very fast response is needed.

1 2

4 8√

Page 4-1

Ne

p

tune 4500

F7

Overload Limit Selects the desired formula which determines the point at which the

indicator shows overload. All selections are based on the primary unit

selected in F8.

"FS" = Full scale in primary units.

FS

FS + 2%√

FS + 1d

FS + 9d

F8

Calib. Unit Selects the primary base unit to be used in the calibration process.

Also the default unit for normal operation.

"1" = primary unit is lb. "2" = primary unit is in kg.

1√

2

F9

Display

Divisions

Determines the desired weight increments. Value should be consis-

tent with legal requirements. 1√

2

5

F10

Decimal Pt. Determines location of the decimal point. 0√0.0

0.00 0.000

0.0000 00

F16

Zero Calibra-

tion

Places indicator into the zero calibration routine. Scrolling down with

the UNIT/SET key one level begins the procedure. Press UNIT/SET

key to begin se-

quence

F17

Span Calibra-

tion

Places indicator into the span calibration routine. Scrolling down with

the UNIT/SET key one level begins the procedure. NOTE – press and

hold the UNIT/SET for three seconds for effect.

Press UNIT/SET

key to begin se-

quence

F18

View Calibra-

tion

Actuates the function that allows you to view both the zero and span

calibration value. The values displayed in this function are valid only

after Calibration (F16 & F17) has been successfully completed.

Scrolling down with the UNIT/SET key one level begins the proce-

dure.

Press UNIT/SET

key to begin se-

quence

F19

Key-in Zero Allows you to key-in known zero calibration value in case of memory

loss in the field. Scrolling down with the UNIT/SET key one level be-

gins the procedure.

Press UNIT/SET

key to begin se-

quence

F20

Key-in Span Allows you to key-in a known span calibration value in case of mem-

ory loss in the field. Scrolling down with the UNIT/SET key one level

begins the procedure.

Press UNIT/SET

key to begin se-

quence

F21

Factory Reset This sub-menu will reset all parameters in the “F” and “A” menu to the

default settings. USE WITH CAUTION! Press the

UNIT/SET key

twice to execute.

F24

Piece Count

Enable

Used to enable or disable the piece count feature. This feature must

be disabled for commercial applications.

"0" = Disable piece count "1" = Enable piece count

0√

1

Page 4-2

Ne

p

tune 4500

Page 4-3

Ne

p

tune 4500

SUB-MENU TITLE SELECTIONS

F1 Graduations 6,000 8,000

10,000 12,000

20,000 30,000

40,000 50,000

F3 Zero Tracking

Band (SAZSM) 0d

5d

F5 Motion Band 3d 5d

10d 15 d

20d 30d

40d 50d

F6 Digital Filter 1

2

4

Table 4-1: Invalid Setup Menu selections for commercial applications

CHAPTER 5: USER MENU DESCRIPTIONS AND PROCEDURES

5.1 USER MENU DESCRIPTIONS

This section provides more detailed descriptions of the selections found in the User Menu Chart.

Factory-set defaults are shown in bold with a checkmark (√).

NAME/CODE DESCRIPTION CODE/VALUE

A1

Baud Rate Selects the baud rate for data transmission through the serial port. 1200 2400

4800 9600√

A2

Data Bits and

Parity

Selects the number of data bits and parity of serial transmission.

"8n" = 8 data bits with no parity bit and one stop bit

"7O" = 7 data bits with odd parity bit and one stop bit

"7E" = 7 data bits with even parity bit and one stop bit

"7n" = 7 data bits with no parity bit and two stop bits

8n√

7O

7E

7n

A3

Mode of Serial

Transmission

Selects when data will be sent out of the serial port to a printer or

computer: "C" = Continuous mode; send data continuously

"d" = Demand mode; send data when a PRINT command is issued

from the printer, computer, or indicator.

C

d√

A4

Display Check Actuates the function that illuminates all digit segments, decimal

points, and LCD annunciators in a test sequence. Pressing the

UNIT/SET key to scroll down one level begins the test sequence.

Press UNIT/SET

key to begin

sequence

A5

Disable the

lb/kg Key

Allows the lb/kg key to be disabled so that an operator cannot

accidentally press the key and change the displayed units.

"0" = Disable the lb/kg key "1" = Enable the lb/kg key

0

1√

A6

Serial Port

Mode

Selects the mode of the RS-232 serial port: Refer to Appendix B for

more information. "0" = Full Duplex Mode

"1" = Print Ticket Mode

0√

1

A7

ID No. Enable Allows the ID number to be disabled in the Print Ticket mode. Valid

only when A6 is set to “1”.

"0" = Disable the ID No. "1" = Enable the ID No.

0√

1

A8

ID No. Entry Actuates the function that allows entry of a new ID No. Valid only

when A6 is set to “1”. Pressing the UNIT/SET key to scroll down one

level begins the sequence.

123456√

A9

No. of Line

Feeds

Actuates the function that allows entry of the desired number of line

feeds to be printed in Print Ticket Mode. Valid only when A6 is set to

“1”. Pressing the UNIT/SET key to scroll down one level begins the

sequence.

0 - 99

5√

Neptune 4500 Page 5-1

5.2 USER MENU PROCEDURES

This section provides instructions for all of the User Menu procedures.

5.2.1 ID Number Entry (A8)

1. While in the User Menu mode, scroll to "A 8", then scroll down once using the

UNIT/SET key to enter the ID Number menu.

2. The display will momentarily show "ID NO", followed by a value with one flashing

digit. This value will be the current ID number value.

3. Use the directional keys to adjust the displayed value to the actual ID Number

value. Increase the flashing digit by pressing the UNITS key. Pressing the ZERO to

change the position of the flashing digit.

Figure 5-1: User Menu Key Assignments

4. After setting the exact value, hold the UNIT/SET key to save the ID Number value.

The display will show "END" momentarily, then revert back up to A8.

Neptune 4500 Page 5-2

Neptune 4500 Page 5-3

5.2.2 LF (Line Feeds) Number Entry (A9)

1. While in the User Menu mode, scroll to "A 9", then scroll down once using the

UNIT/SET key to enter the Line Feeds menu.

2. The display will momentarily show "LF", followed by the current line feeds value.

3. Use the directional keys (shown in Figure 5-1 above) to adjust the displayed value

to the actual line feeds value. Increase the flashing digit by pressing the UNITS key.

Pressing the ZERO key will change the position of the flashing digit.

4. After setting the exact value, hold the UNIT/SET key to save the line feeds value.

The display will show "END" momentarily, then revert back up to A9.

CHAPTER 6: CALIBRATION

6.1 CALIBRATION OVERVIEW

The indicator is calibrated by following the procedures embedded in F16 (Zero) and F17 (Span) of

the Setup Menu. Each procedure enters a value into the indicator's non-volatile memory - F16 the

zero value (deadweight) and F17 the span value (test weight). The minimum test weight that can be

used is 1% of full-scale capacity. After the two calibration procedures are executed successfully,

you should record both calibration values in Table 6-1 using the F18 View procedure.

In the unlikely event that either value is lost while in the field, the setup menu makes provisions for

re-entering these values via F19 and F20, thus eliminating the need for re-calibration with test

weights.

NOTE: This chapter assumes that the indicator is in Setup (“F”) Menu mode. If the indicator is not

in Setup Menu mode, refer to Chapter 3 for instructions.

6.2 ZERO CALIBRATION (F16)

1. While in the Setup mode, scroll to "F 16", then scroll down once using the UNIT/SET key to

enter zero calibration menu. The display will momentarily show "C 0" followed by a value. This

value is the internal A/D count and can prove useful when trying to troubleshoot setup

problems.

2. After making sure that there are no test weights on the platform, press the ZERO key again to

zero out the displayed value.

3. Press the UNIT/SET key to save the zero point value. The display will show "EndC0"

momentarily, then revert back up to F16. At this time, proceed to the F17 span calibration to

complete indicator calibration.

6.3 SPAN CALIBRATION (F17)

1. While in the Setup mode, scroll to "F 17", then scroll down once using the UNIT/SET key to

enter span calibration menu.

2. The display will momentarily show "C 1" for the span calibration, followed by a value with one

flashing digit. This value will be zero with the Decimal Point parameter selected in F10. Place

the test weight on the weighing mechanism.

3. Use the directional keys (shown in Figure 6-1 below) to adjust the displayed value to the actual

test weight value. Change the flashing digit by pressing the UNIT/SET key. Pressing the ZERO

key will change the position of the flashing digit.

Neptune 4500 Page 6-1

Figure 6-1: Setup Menu Key Assignments

4. After setting the exact value, press and hold the UNIT/SET key for three seconds to save the

value.

5. If the calibration was successful, the display will show "EndC1" momentarily, then revert back

up to F17. At this time it is suggested that the calibration values be recorded for future use (see

Section 6.4).

6. If the calibration was not successful, one of the error messages below will appear. Take the

indicated action to correct the problem, then perform a new calibration.

"Err0" - The calibration test weight or the adjusted keyed-in weight is larger than the full

capacity of the scale. Change the calibration test weight or check the input data.

"Err1" - The calibration test weight or the adjusted keyed-in weight is smaller than 1% of the full

capacity of the scale. Change the calibration test weight or check the input data.

"Err2" - The internal resolution of the scale is not high enough to accept the calibration value.

Select a larger parameter for the Span Gain (F2). SEE APPENDIX C FOR MORE

INFORMATION.

Neptune 4500 Page 6-2

Table of contents

Other Transcell Technology Touch Panel manuals