Transonic AureFlo HT300 Series User manual

AureFlo®

Vascular Flow Measurement System for use with Transonic®HT300 (-FT) Series

FlowTrace®Compatible Flowmeters or Optima Flow-QC®Meters

FlowTrace Version 4

AU-OPR-AureFloFT-EN, Rev H Last Updated 8/25/21

OPERATOR’S MANUALOPERATOR’S MANUAL

Transonic Europe B.V.

Business Park Stein 205

6181 MB Elsloo

The Netherlands

Tel: +31 43-407-7200

Fax: +31 43-407-7201

europe@transonic.com

USA/Canada

Transonic Systems Inc.

34 Dutch Mill Road

Ithaca, NY 14850

U.S.A.

Tel: +1 607-257-5300

Fax: +1 607-257-7256

suppor[email protected]

Asia/Pacic

Transonic Asia Inc.

6F-3 No 5 Hangsiang Rd.

Dayuan, Taoyuan County

33747 Taiwan, R.O.C.

Tel: +886 3399-5806

Fax: +886 3399-5805

suppor[email protected]

Japan

Nipro-Transonic Japan Inc.

7th Floor, Maruha Building

11-1 Matsuba-cho

Tokorozawa City, Saitama

359-0044 Japan

Tel: +81 04-2946-8541

Fax: +81 04-2946-8542

japan@transonic.com

2797

P

M

C

ii AU-OPR-AureFloFT-EN,

Rev H

All contents of this document Copyright © 2012 Transonic Systems Inc.®

All Rights Reserved.

The following are Registered, U.S. Patent and Trademark Ofce:

AureFlo®

Charbel Probe®

Charbel Micro-Flow Probe®

Circle of Care®

Clear Advantage®

COndence Flowprobe®

COstatus®

ELSA®

EndoGear®

Endosomatic®

F.A.S.T®

FlowEdge®

FlowSound®

FlowTrace®

Flow-QC®

Optima Flow-QC®

OptiMax®

PhysioGear®

PhysioView®

ReoCath®

Transonic®

Transonic Systems Inc.®

For Sales and Product Assistance in Australia Please Contact:

Transonic Systems Inc.

34 Dutch Mill Road

Ithaca, NY 14850, USA

Market Access Pty Ltd.

P.O. Box 1019

Wahroonga NSW 2076

Australia

AU-OPR-AureFloFT-EN,

Rev H

iii

Table of Contents

Table of Contents....................................................................................................................................................................iii

Warnings & Precautions ..........................................................................................................................................................v

I. INTRODUCTION................................................................................................................................................................1

A. INTENDED USE .......................................................................................................................................................................... 1

B. INDICATIONS FOR USE.............................................................................................................................................................. 1

C. AUREFLO®MONITOR & FLOWTRACE®SOFTWARE ................................................................................................................... 1

D. AUREFLO®CART....................................................................................................................................................................... 2

E. HT300 SERIES (-FT) COMPATIBLE FLOWMETERS........................................................................................................................ 2

F. PERIVASCULAR FLOWPROBES & CLAMP-ON TUBING FLOWSENSORS ....................................................................................... 3

1. Perivascular Flowprobes........................................................................................................................................................ 3

2. Clamp-on Flowsensors.......................................................................................................................................................... 3

II. FUNCTIONS & CONTROLS................................................................................................................................................4

A. FRONT PANEL ........................................................................................................................................................................... 4

1. Disposable Flow-QC®Key (Flowmeter Models: HT314-FT, HT354 & HT364) .......................................................................... 5

2. Invert Function ..................................................................................................................................................................... 5

3. Chart Recorder (Not provided on Models HT310-FT, HT320-FT, HT350 & HT360) .................................................................. 6

B. BACK PANEL ............................................................................................................................................................................. 7

1. FlowSound®......................................................................................................................................................................... 8

2. Flowmeter Outputs: Connect to Patient Monitor.................................................................................................................... 8

III. SPECIFICATIONS ..............................................................................................................................................................9

A. FLOWTRACE®SOFTWARE......................................................................................................................................................... 9

B. HT300(-FT) SERIES COMPATIBLE FLOWMETERS......................................................................................................................... 9

C. AUREFLO®CART..................................................................................................................................................................... 11

IV. FUNCTIONAL TESTS .......................................................................................................................................................12

A. SETTING UP THE AUREFLO®SYSTEM ...................................................................................................................................... 12

B. CONNECTING A PRINTER ........................................................................................................................................................ 13

C. TESTING THE AUREFLO®SYSTEM............................................................................................................................................ 13

D. TESTING THE FLOWPROBES..................................................................................................................................................... 14

E. TESTING THE CLAMP-ON FLOWSENSOR.................................................................................................................................. 15

V. USER INTERFACE MENUS...............................................................................................................................................16

A. SYSTEM SETTINGS MENU........................................................................................................................................................ 16

1. FlowTrace®Settings............................................................................................................................................................ 16

2. Help Menu ....................................................................................................................................................................... 17

B. PATIENT SETTINGS MENU ....................................................................................................................................................... 17

1. Surgery Selection................................................................................................................................................................ 17

2. PATIENT operations ............................................................................................................................................................ 19

C. VESSEL SELECTION.................................................................................................................................................................. 20

VI. AUREFLO®OPERATION..................................................................................................................................................21

A. REALTIME MODE: REALTIME DISPLAY OF FLOW WAVEFORM & DATA ..................................................................................... 22

B. RECORDING MODE: CAPTURING CONTINUOUS FLOW DATA................................................................................................... 23

C. SNAPSHOT MODE: TAKING A PICTURE OF THE FLOW WAVEFORM & DATA............................................................................. 23

1. Printing snapshots .............................................................................................................................................................. 23

D. PORTFOLIO MODE: REVIEW AND PRINT WAVEFORMS & DATA ............................................................................................... 24

iv AU-OPR-AureFloFT-EN,

Rev H

VII. DIRECTIONS FOR FLOWPROBE USE ...............................................................................................................................28

A. INTRAOPERATIVE MEASUREMENTS WITH PERIVASCULAR FLOWPROBES................................................................................ 28

B. TUBING FLOW MEASUREMENTS WITH CLAMP-ON FLOWSENSORS......................................................................................... 29

C. AFTER MEASUREMENTS ARE COMPLETED.............................................................................................................................. 30

D. CLEANING & STERILIZATION................................................................................................................................................... 30

1. AureFlo®Monitor ............................................................................................................................................................... 30

2. HT300 Series Compatible Flowmeter................................................................................................................................... 30

3. AureFlo®Cart..................................................................................................................................................................... 30

4. Perivascular Flowprobes...................................................................................................................................................... 31

5. Tubing Flowsensors............................................................................................................................................................. 31

VIII. GUARANTEE, SERVICE & WARRANTY ...........................................................................................................................32

A. CALIBRATION GUARANTEE..................................................................................................................................................... 32

B. LIMITED PRODUCT WARRANTY AND CLAIM........................................................................................................................... 32

C. OUT OF WARRANTY REPAIRS ................................................................................................................................................. 33

D. EXTENDED WARRANTY .......................................................................................................................................................... 33

E. MAINTENANCE AGREEMENT .................................................................................................................................................. 33

IX. EQUIPMENT RETURN INSTRUCTIONS ............................................................................................................................34

A. AUREFLO®MONITOR OR FLOWMETER.................................................................................................................................... 34

B. REUSABLE FLOWPROBES/FLOWSENSORS ................................................................................................................................ 34

C. REPLACEMENT PARTS ............................................................................................................................................................. 34

Appendix A: Initial AureFlo®Setup.......................................................................................................................................35

D. AUREFLO®ASSEMBLY ............................................................................................................................................................. 35

E. INSTALLING FLOWTRACE®SOFTWARE INITIALLY.................................................................................................................... 35

F. UPGRADING FLOWTRACE®SOFTWARE .................................................................................................................................. 36

Appendix B: Replacing the Printer ........................................................................................................................................38

Appendix C: ECG Signal, D/S Ratio & DF ...............................................................................................................................39

Appendix D: ReTrace Software..............................................................................................................................................42

Appendix E: Theory of Operation..........................................................................................................................................43

Appendix F: EMC Tables AureFlo System ..............................................................................................................................44

Appendix G: Service & Maintenance.....................................................................................................................................49

Appendix H: Symbols & Signs................................................................................................................................................50

Appendix I: Software Icons ...................................................................................................................................................52

Table of Contents

AU-OPR-AureFloFT-EN,

Rev H

v

Warnings & Precautions

√The AureFlo® System is intended for the measurement of blood or liquid volume ow with Transonic®

Perivascular Flowprobes in adult and pediatric patients:

●on non-aerated synthetic vessel grafts

●where surgery is medically indicated

●on major and peripheral arteries, veins and ducts

●at intraoperative sites which admit and retain ultrasonic couplant

●with minimal vessel manipulation or constriction (to avoid vessel spasm)

●where application does not unnecessarily lengthen surgical procedure

●for the measurement of blood volume ow with Clamp-on Flowsensors

●on exible tubing specic to the Flowsensor (never on arteries, veins)

●for non-aerated media which are transparent to ultrasound

Transonic Systems Inc.®disclaims responsibility for all other uses, and the user agrees to assume liability for

damages resulting from non-intended use or operator-error by the User or User’s associates.

√The HT300 (-FT) Series Compatible Surgical Flowmeter and AureFlo®Monitor are intended for use only with

Transonic®Perivascular Flowprobes and Flowsensors designated for HT300 (-FT) Series Compatible Flowmeters.

AureFlo®system is intended to be used with a printer that is powered off the supplied DC patient isolation

transformer.

√The AureFlo®System is not intended for use as the sole basis for diagnosis.

√Rx Prescription Device: Federal law (USA) restricts this device to sale or use by or on the order of a physician.

√To prevent unintended burns when using high frequency (HF) surgical equipment such as a electo-cautery device

or Bovie, keep the Flowprobe away from the grounding pad(s).

√The HT300 (-FT) Series Compatible Surgical Flowmeter and AureFlo®Cart are IEC 60601 Class 1 instruments. Only

power cords supplied by Transonic®should be used.

√The AureFlo®System should be positioned in such a manner as to provide unobstructed access to the power cord

connection.

√To avoid the risk of electric shock, this equipment must only be connected to a supply mains with protective

earth.

√Use only Transonic®approved accessories, cables or sensors. The use of non-Transonic approved accessories could

result in increased electromagnetic emissions or decreased electromagnetic immunity of this equipment and

result in improper operation.

√This equipment can be used anywhere in any hospital or clinic except near active HF surgical equipment or the

RF shielded room of an MRI magnetic imaging system where the intensity of EM disturbances is high.

√If this equipment does come into range of high levels of EM disturbances the meter may:

●display incorrect ow values

●momentarily stop working and restart at the same volume reading on the meter

●stop working and need to be turned off and on again (very rare occurrence)

√Safe and effective use of the Transonic®HT300 (-FT) Series Compatible Surgical Flowmeter depends on correct

application technique, adequate precaution and readiness for emergencies.

√The AureFlo®Monitor, HT300 (-FT) Series Compatible Surgical Flowmeter and Transonic®Flowsensors are fragile.

They must be transported and stored at temperatures ranging from -10ºC to 50ºC.

√Transonic®Perivascular Flowprobes may be used in pericardiac applications such as ascending aorta and

coronary graft ow measurement, but are neither designed nor approved for intracardiac ow measurement.

√If the Flowprobes are used in patients suspected of having Creutzfeldt-Jakob or other prion diseases they should

be handled according to procedures given in the World Health Organization’s Guidelines.

vi AU-OPR-AureFloFT-EN,

Rev H

√Always follow the correct shut off procedure see "After Measurements Are Completed" on page 30.

Appropriately exit FlowTrace®software before turning off power to the AureFlo®Monitor.

√In the event of the loss of power during operation, a loss of data may occur when using continuous recording

mode.

√Patient data downloaded from the AureFlo®must be handled in accordance with institutional and HIPPA

guidelines and in accordance with the patient condentiality requirements.

√Do not connect the AureFlo®system to the internet during use with a patient.

√The operator should not touch the cart or its components except for the applied parts (probes) and the patient

at the same time.

√The AureFlo monitor has been congured to work with the AureFlo system, changes to the PC settings such

as adjusting screen resolution, enabling WiFi or installing additional programs can impact the functionality of

the AureFlo or cause a loss of patient data. Please consult with Transonic before making changes to the PC not

specied in the manual or Transonic support materials.

√For a comprehensive list of possible warning symbols please refer to Appendix H: Symbols & Signs.

TRANSONIC®FLOWPROBES/FLOWSENSORS DO NOT CONTAIN LATEX MATERIALS.

Warnings & Precautions

AU-OPR-AureFloFT-EN,

Rev H

1

I. Introduction

NOTE: In this manual, “Flowmeters” will refer to HT300 Series

(-FT) FlowTrace®Compatible Flowmeters. “Flowprobes” refer to

Perivascular Flowprobes. “Flowsensors” refer to Clamp-on Tubing

Flowsensors.

Transonic®AureFlo®System is a stand-alone, integrated system

used during surgery with Transonic®Perivascular Flowprobes

or with Transonic®Sterile Tubing Flowsensors to continuously

measure, display, capture and document absolute volume ow and

other derived parameters in vessels or tubing circuits (Fig. 1.1).

A. Intended Use

Transonic’s Optima Flowmeters, AureFlo System, and FlowXL®Flowmeters and Flowprobes and Flowsensors

use transit-time ultrasound technology to measure volume ow of blood and other liquids, and derived

parameters thereof, during surgical interventions and extracorporeal applications.

B. Indications for Use

Flow measurements are indicated to support surgeons and other clinical staff in identifying and evaluating

ow rates to support their clinical impressions. The Optima Flowmeters, AureFlo System, and FlowXL®

Flowmeters and compatible perivascular Flowprobes are indicated for use in adult and pediatric patients

during surgeries on major and peripheral arteries, veins, and ducts; on non-aerated synthetic vessel grafts;

intraoperatively where surgery is medically indicated; at intraoperative sites which admit and retain

ultrasonic couplant; with minimal vessel manipulation or constriction, and where application does not

unnecessarily lengthen surgical procedure. The Optima Flowmeters, AureFlo

System, and FlowXL®Flowmeters and compatible tubing Flowsensors are

indicated for use in extracorporeal applications; on exible tubing specically

calibrated to the Flowsensor and in non-aerated media which are transparent to

ultrasound. No contraindications are identied for this product.

C. AureFlo®Monitor & FlowTrace®Software

The AureFlo®Monitor’s touch-panel display is loaded with Microsoft Windows®.

FlowTrace®Software works exclusively with HT300 (-FT) Series Compatible

Flowmeters to provide a real-time waveform display of volume ow, mean

ow, pulsatility index (PI), pressure and ECG. It is designed for use only with a

Transonic®safety-tested and approved touchscreen panel PC used in conjunction

with the AureFlo®System. During surgery FlowTrace®calculates the Diastolic/

Systolic (D/S) ratio of the bypass graft or diastolic fraction (DF) (see "FlowTrace®

Settings" on page 16 for enabling DF).

FlowTrace® Software has four modes of operation. They are:

1) Realtime: Continuous display of ow (and ECG, if present) in real time, plus

calculated parameters

2) Recording: Captures the displayed ow data (and ECG, if present) for later

review and analysis

3) Snapshot: Captures the 8 seconds of ow data shown on the display for

printing or later review

4) Portfolio: Enables review of recordings and Snapshots with printing capability

to document ow information for the patient record Fig. 1.1: AureFlo®System with Cart.

ECG SIGNAL

During surgery, an ECG signal can

be displayed on FlowTrace®at the

bottom of the touch-panel display.

The diastolic and systolic segments

of the waveform and the ECG will be

colorized. If an ECG is not connected

during surgery, the area under the

waveform will not be colorized.

2AU-OPR-AureFloFT-EN,

Rev H

D. AureFlo®Cart

The AureFlo®Cart holds the AureFlo®Monitor, one HT300 Series

Compatible Flowmeter and a standard PC printer. It provides AC power

to the Flowmeter and touch-panel display, and an isolated 18VDC power

supply for a Transonic® recommended printer. The cart has two xed

shelves, 1 sliding drawer, 1 VESA mount for the Panel PC and 1 mounting

bracket for an HT300 (-FT) Series Compatible Flowmeter (Fig. 1.1).

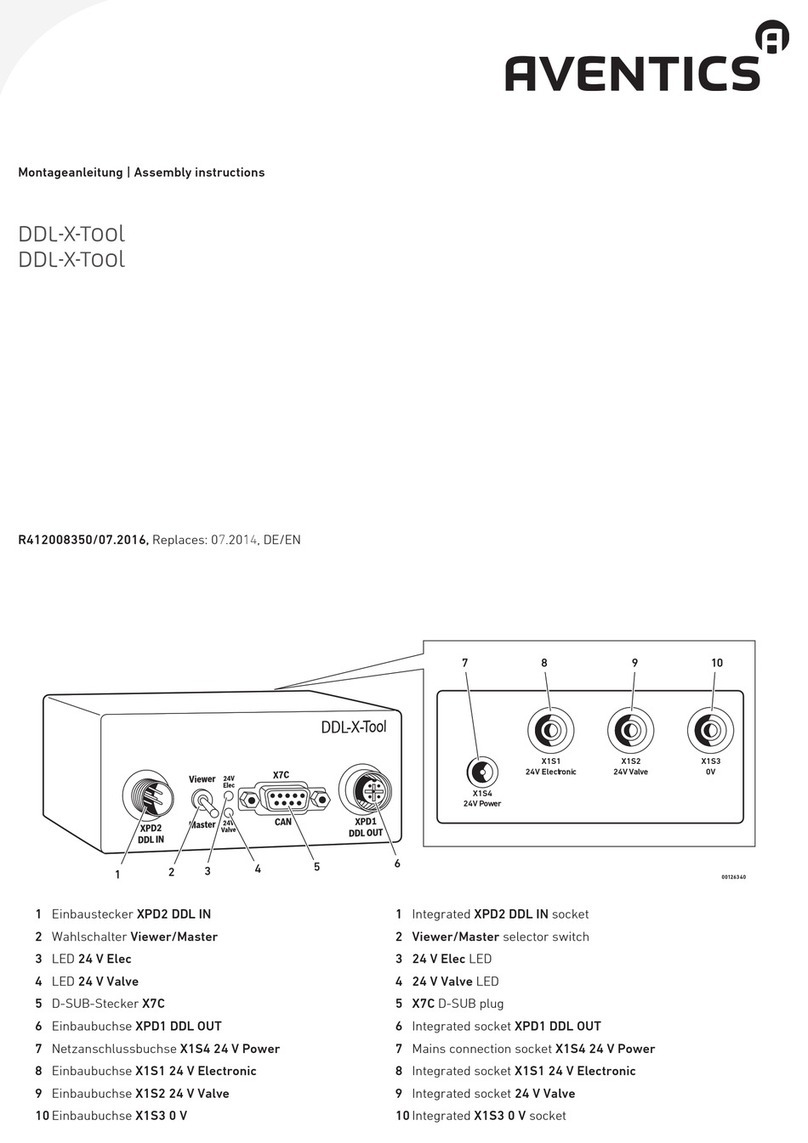

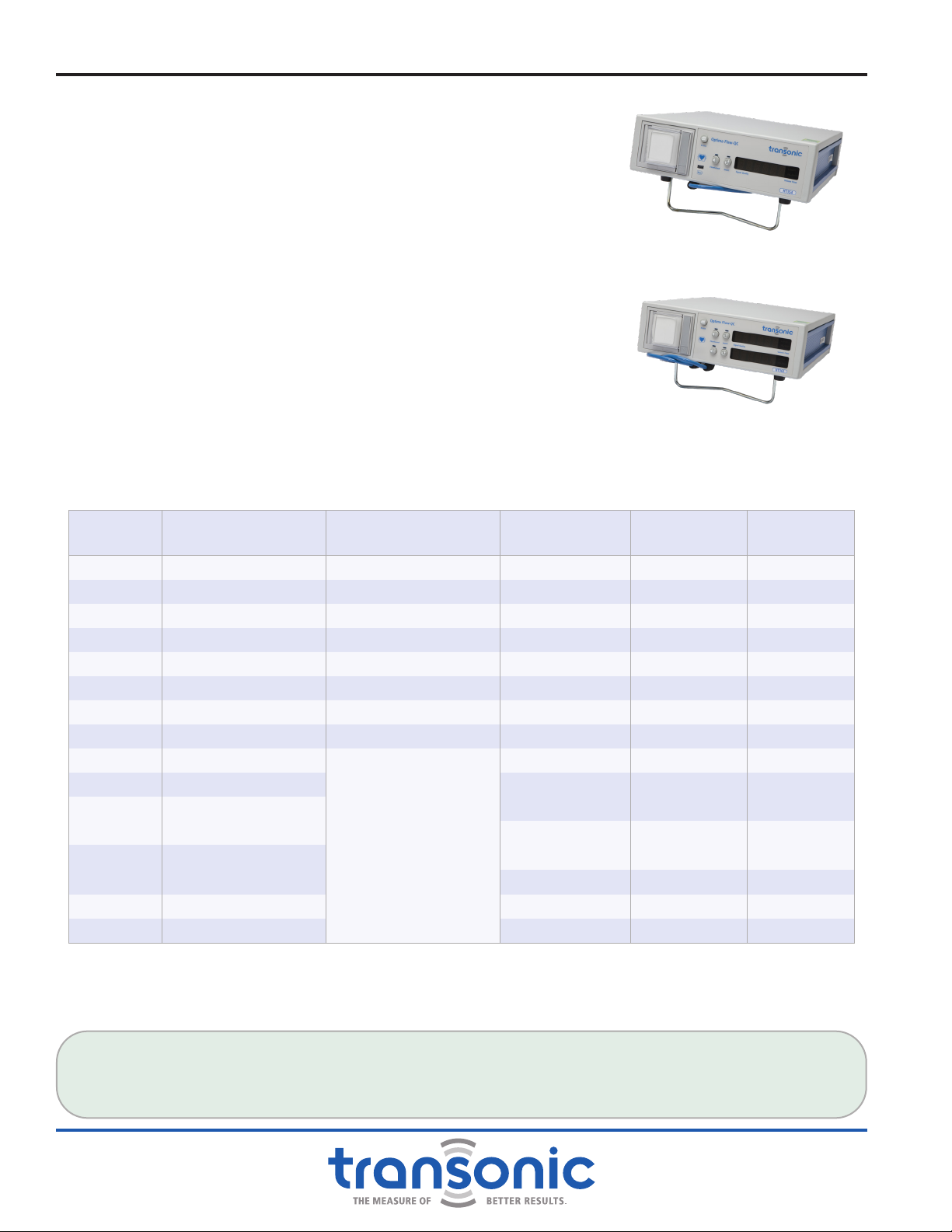

E. HT300 Series (-FT) Compatible Flowmeters

HT300 Series Flowmeters house electronics for processing ultrasonic

transit-time ow signals. AureFlo®works with HT300(-FT) Series

FlowTrace®Compatible Flowmeters ONLY. For AureFlo®to work with

HT300 Series Flowmeters not listed below, the Flowmeter must be

returned to Transonic®for an -FT upgrade (IX. Equipment Return

Instructions, page 34). All HT35x/HT36x Series Flowmeters are

FlowTrace®compatible without requiring an upgrade.

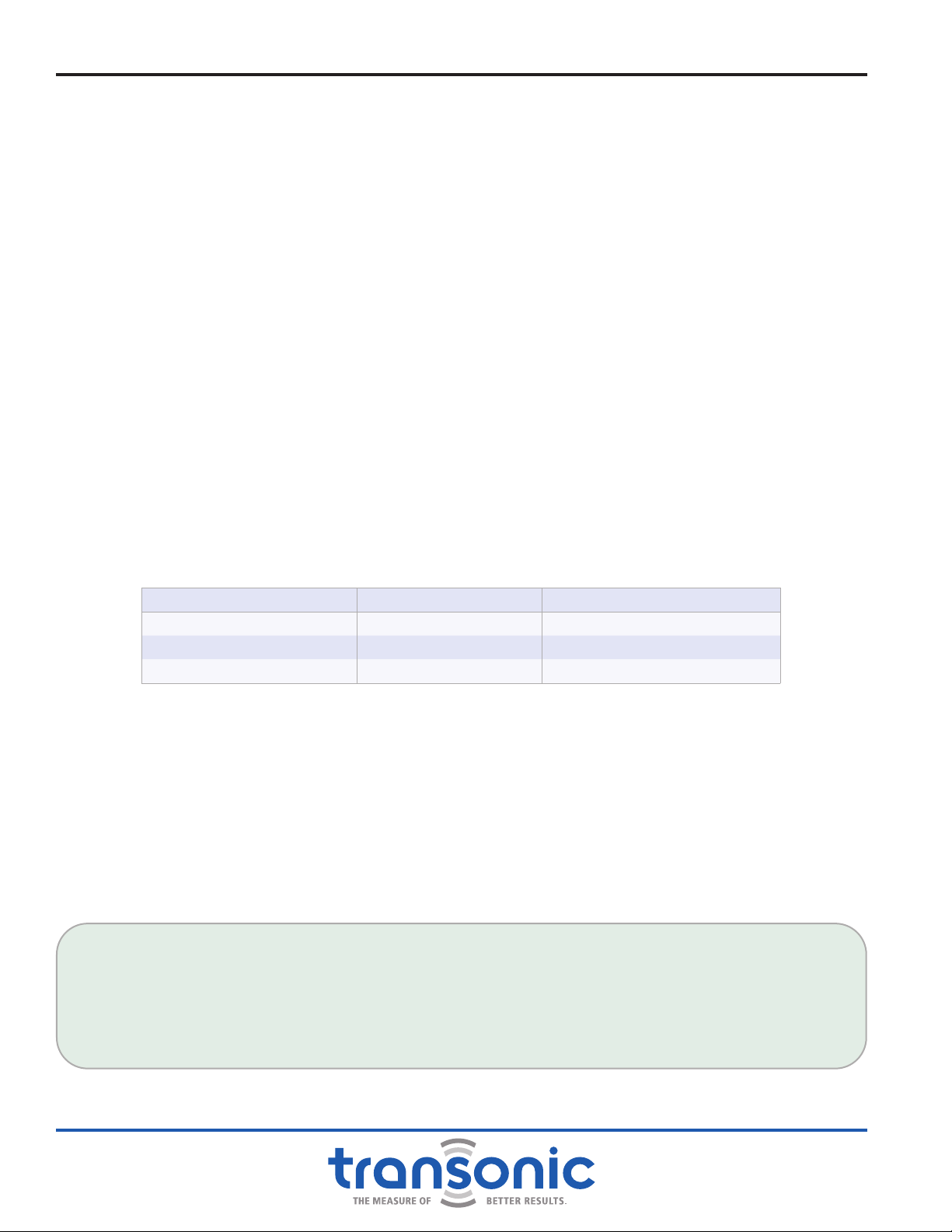

The table below lists all HT300(-FT) Series FlowTrace®Compatible Flowmeters with their distinguishing

features (channels, RoHS compliance, key operated) and compatible Flowprobe/ Flowsensor Series.

MODEL # # OF CHANNELS COMPATIBLE

FLOWPROBE SERIES

FLOWPROBES #

OF USES

RoHS

COMPLIANT

KEY

ACTIVATED

HT310-FT 1HQD- 50 No No

HT312-FT 1H Q C- 8, 16 No No

HT313-FT 1HQD- 50 No No

HT314-FT 1HQD- 50 No Yes

HT320-FT 2HQD- 50 No No

HT322-FT 2H Q C- 8, 16 No No

HT323-FT 2HQD- 50 No No

HT331-FT 1HQN- 1, 16 No No

HT350 1

All HQ-Series

Perivascular Flowprobes

(HQC-, HQD-, HQE-,

HQF-, HQG- & HQN-)

1, 8, 16, 50* Yes No

HT353 1 1, 8, 16, 50* Yes No

HT353C 1 1, 8, 16, 50* Yes No

HT354 1 1, 8, 16, 50* Yes Yes

HT354C 1 1, 8, 16, 50* Yes Yes

HT360 2 1, 8, 16, 50* Yes No

HT363 2 1, 8, 16, 50* Yes No

HT364 2 1, 8, 16, 50* Yes Yes

* Number of Flowprobe uses depends on Flowprobe Series (some Probes are available in multiple versions with different number of

uses). Length of measurement period is also Probe type dependant.

Fig. 1.2: HT354 Single Channel Flowmeter

Fig. 1.3: HT363 Dual-Channel Flowmeter

Introduction

FLOWTRACE®(-FT) COMPATIBILITY

Isolated USB ports on the back panel of HT300 Series FlowTrace®Compatible Flowmeters provide a

digital output to FlowTrace®. Older Flowmeters must be upgraded by factory authorized service staff to

communicate with FlowTrace®.

AU-OPR-AureFloFT-EN,

Rev H

3

F. Perivascular Flowprobes & Clamp-on Tubing Flowsensors

Transonic®offers a wide range of intraoperative Perivascular Flowprobes and Extracorporeal Clamp-on

Tubing Flowsensors. Transonic®Flowsensors connect to a two-meter (~ 6.5 ft.) extension cable attached to

the front of the HT300 Series Compatible Flowmeter. Two or four ultrasonic transducers within the Sensor

body transmit a minimal level of ultrasound through a rectangular sensing window (Appendix E: Theory

of Operation, page 43). Volume ow of all non-aerated liquid passing through the sensing window is

measured.

1. PERIVASCULAR FLOWPROBES

Transonic®HQ-Series Intraoperative,

Perivascular Flowprobes work with HT300

Series Compatible Flowmeters to measure

instantaneous and average volume ow in

blood vessels or grafts, 0.5 mm to 36 mm in

diameter (Fig. 1.4). Perivascular Flowprobes

measure blood ow in exposed vessels:

a) at the beginning of a procedure, for accurate

assessment of volume ow.

b) at the conclusion of surgery prior to patient

closing, on newly implanted natural or

articial bypass grafts, on vessels supplying

restored, reconstructed or transplanted

organs and tissues.

2. CLAMP-ON FLOWSENSORS

Transonic®HQ-XL-Series Clamp-on Tubing Flowsensors apply ultrasound

energy through exible tubing to monitor instantaneous and average

volume ow of blood, cardioplegia or other solutions in (Fig. 1.5):

a) Extracorporeal procedures such as cardio-pulmonary bypass (CPB);

extracorporeal membrane oxygenation (ECMO); hemodialysis;

plasmapheresis; arteriovenous hemoltration (CAVH)

b) Extracorporeal perfusion, infusion or transfusion procedures (such

as allograft perfusion for pre-transplantation preservation; coronary

reperfusion or retroperfusion; continuous total nutrient infusion,

saline or dextrose infusion; blood transfusion)

c) Extracorporeal shunts (portal vein bypass shunts, or lower body/upper

body bypass shunts during liver transplants).

Fig. 1.4: An Array of Perivascular Flowprobes

Fig. 1.5: Clamp-on Flowsensor

Introduction

4AU-OPR-AureFloFT-EN,

Rev H

II. Functions & Controls

A. Front Panel

CABLE FOR FLOWPROBE /FLOWSENSOR CONNECTION

Two meter cable attached to accept HQ-style connector of Flowprobe/Flowsensor.

DEFIBRILLATOR - PROOF TYPE CF

Cardiac-oating equipment.

FLOWSOUND®ON/OFF

Turns FlowSound®on and off. Volume control knob is located on the

rear panel.

INVERT ON/OFF

Reverses the polarity of the ow signal on the AureFlo®Monitor

screen, chart recorder, front panel LED display, rear panel analog

outputs and USB connector.

PRINT ON/OFF

Starts and stops the chart recorder.

CHART RECORDER

(Not provided on Models HT310-FT, HT320-HT, HT350 & HT360)

The chart recorder automatically scales the paper to the ow being

measured.

LED ALPHANUMERIC DISPLAY

●ULTRASOUND SIGNAL QUALITY

●MEAN VOLUME FLOW in mL or L/min and

●STATUS/ERROR MESSAGES

Fig. 2.1: HT353 Flowmeter Front Panel

Chart Recorder

Print On/Off

Signal Quality Indicator

Chart Recorder Door

LED

Alphanumeric

Display

FlowSound®On/Off Invert On/Off

Disposable Flow-QC®

Key Port

Cable for Flowprobe/

Flowsensor Connection

Fig. 2.2: HT364 Flowmeter Front Panel

BENEFITS OF

FLOWSOUND®

Provides audio feedback on

signal quality. The surgeon

can hear when there is good

contact while still focusing on

the surgical eld.

The surgeon has

instantaneous feedback on

changing ow conditions.

FOR EXAMPLE: A surgeon can

manipulate a kinked vessel or

graft and immediately detect

an improvement in ow.

FlowSound®warns that a key

activation period is ending

by emitting three beeps

each minute for the last ve

minutes of key activation.

AU-OPR-AureFloFT-EN,

Rev H

5

1. DISPOSABLE FLOW-QC®KEY (FLOWMETER MODELS: HT314-FT, HT354 & HT364)

HT314-FT, HT354 & HT364 Flowmeters are activated by inserting a disposable Flow-QC®Key or single

use disposable Probe. When the Meter is turned on and no Flow-QC®Key or single use Probe is

inserted, the Meter Display reads “INSERT KEY OR 1X USE PROBE”

Two Flowprobe Tests can be performed without the Flow-QC®Key inserted in the Flowmeter.

a) Flowprobe/Flowmeter Compatibility Test. When a Flowprobe is connected to the Flowmeter, the

Flowmeter displays one of two messages:

i) The Flowprobe’s ID such as “HQD3FMC”

ii) “NO PRB” or “NO PROBE” (Meter dependant)

b) Flowprobe Ultrasonic Signal Quality Test. If the Flowprobe

is coupled by immersion in saline or ultrasonic couplant and

the Flowprobe is connected to the Flowmeter, the Flowmeter

tests the transmitted ultrasound signal and displays either:

i) “GOOD SIGNAL”

ii) “LOW SIGNAL”

iii) “X NO SIGNAL” (where X equals the Probe ID).

FUNCTIONALITY OF A FLOW-QC®KEY

When a Flow-QC®Key is inserted into the Flowmeter without a Flowprobe attached, the Flowmeter

displays either (messages are Meter dependant):

i) “DISCARD KEY” or “DISCRD KEY” indicating that the key has already been used.

ii) “NO PRB” or “NO PROBE” indicating that the key is good but no Probe is connected.

FLOW-QC®KEY MEASUREMENT PERIOD

The Flow-QC®Key’s 4 hour measurement period begins when a Flowprobe is connected to the

Flowmeter and the Flowprobe’s ultrasonic window is lled with ultrasonic couplant enabling signal

transmission (Fig. 2.3). Once the Flowprobe is coupled (with saline or gel), the Flow-QC® Key’s specied

time period begins. At the end of the time, the Flow-QC®Key expires. Please note, if the Flowmeter is

unplugged during the measurement period for 20 minutes or more, the Flow-QC®Key will expire.

FLOW-QC®KEY MEASUREMENT PERIOD EXPIRATION

To warn the user that a Flow-QC®Key’s measurement period is ending, the Flowmeter generates two

types of alarms beginning ve minutes before the Flow-QC® Key’s ow measurement period is up.

i) Display Alarm as the minutes count down: “TIME LEFT 5 MIN”, “TIME LEFT 4 MIN”, “TIME LEFT 3

MIN”, “TIME LEFT 2 MIN”, “TIME LEFT 1 MIN” then “TIME IS UP”

ii) Audio Alarm during the last ve minute count down: three beeps, once each minute.

FLOW-QC®DISPOSAL

When a Flow-QC® Key’s ow measurement period is up, the Flowmeter will display “TIME IS UP.” Flow

measurement will continue to be taken until the acoustic transmission is disrupted for more than 15

seconds or the Key is removed. Once the signal is interrupted or the Key removed, ow measurement

stops and the message “DISCARD KEY” or “DISCRD KEY” is displayed. Discard the key immediately, it

can no longer be used to activate the Meter.

2. INVERT FUNCTION

Transonic® Flowprobes are bi-directional: they measure forward and reverse ow. If the ow

waveform is upsidedown, the [Invert] button can be used to ip the waveform without having to

adjust the Flowprobe. The indicator light above the button illuminates when the button is pushed and

the invert function is active. The invert function remains active until the button is pushed again or the

meter is powered off.

Fig. 2.3: Perivascular Flowprobe with

Ultrasonic Window Filled with

Ultrasonic Couplant

Functions & Controls

6AU-OPR-AureFloFT-EN,

Rev H

3. CHART RECORDER (Not provided on Models HT310-FT, HT320-FT, HT350 & HT360)

The chart recorder is used to document ow measurements, including phasic ow patterns (Fig. 2.4).

It automatically scales for the full range of ow measurements.

The chart recorder has 3 settings, selected by the rear panel Chart Recorder slide switch:

a) RUN/STOP prints continuously at 20 mm/sec; push the [Print] button to start/stop printing.

b) SLOW prints 8 seconds of ow data at 20 mm/sec: SELECT THIS MODE FOR ROUTINE OPERATION

c) FAST prints 4 seconds of ow data at 40 mm/sec.

TESTING THE CHART RECORDER: Push [Print] button. When engaged, the chart recorder prints a

header and then pauses momentarily while the paper is automatically scaled to actual ow conditions.

The chart recorder will then print a strip of ow data in real time. There is another brief pause toward

the end of the print run while ow statistics are calculated.

The print cycle can be interrupted at any time by pushing

the [Print] button a second time. Once the chart recorder

has stopped, pushing the [Print] button a third time will

initiate a new print cycle. In “RUN/STOP” Mode the chart

recorder will print continuously until the user pushes the

[Print] button a second time.

The printout is scaled to the ow conditions 8 seconds prior

to printing. Scaling cannot be modied during a print run.

Therefore, if ow increases dramatically while printing, the

measurements will go off scale. Wait until the mean values

have stabilized before attempting to print again.

CHART RECORDER END OF PROBE LIFE MESSAGE:

As the Flowprobe approaches its use limit, the following

message will be printed on the strip chart recorder:

Attention: Probe serial # xxxxxxxxxx has reached the end

of its calibration period. Please contact Transonic Systems

Customer Service @ 1-800-353-3569 to order a replacement

Flow-QC®Probe.

NOTE: Date and time on the chart recorder printout

come preset from the factory. Call Customer Service for

instructions.

LOADING THE THERMAL PAPER

1) To open door, press the bottom of

the gray bar on the recorder.

2) Remove empty paper spool.

3) Place a new spool of paper on the

paper holder so that the paper exits

the spool from the left-hand side.

4) Thread the paper through the

front panel paper deector of the

recorder.

NOTE: Installing paper with incorrect

side out will prevent proper printing.

Functions & Controls

Fig. 2.4: Chart Recorder print out

Waveform Flow Data

Flow Scale

AU-OPR-AureFloFT-EN,

Rev H

7

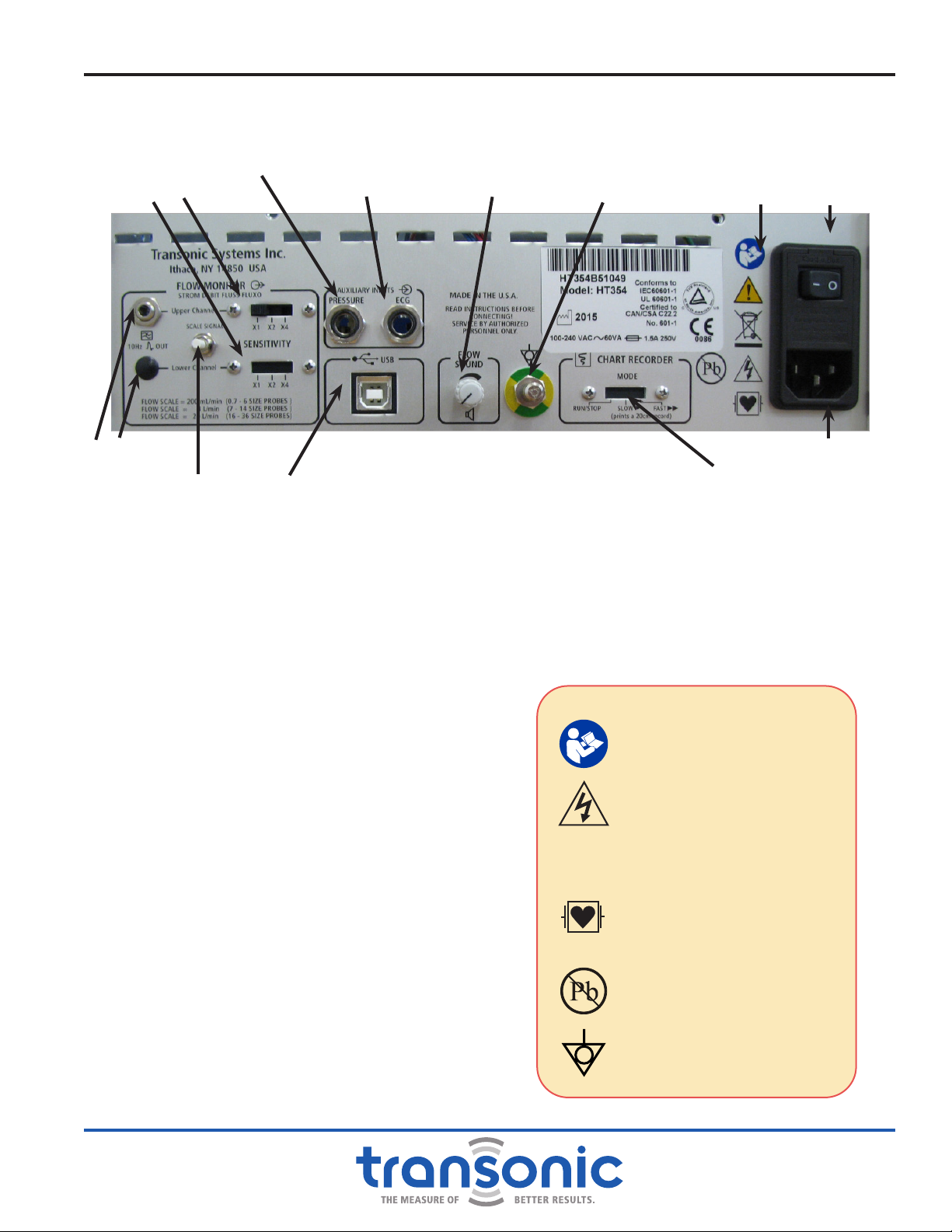

B. Back Panel

POWER ON/OFF SWITCH

To turn on power press (—) to turn off power press

(0)

ANALOG OUTPUTS

UNISCALE Output: 10 Hz low pass ltered;

Automatic gain adjustment for xed scaling of

multiple Probe sizes. Accepts 1/8"miniphono

connector.

HT31x-FT & HT35x: 1 Uniscale output

HT32x-FT & HT36x: 2 Uniscale outputs

SENSITIVITY SWITCHES

To select the Uniscale scaling for analog outputs

SCALE SIGNAL BUTTON

To set scaling of external devices connected to

Uniscale and USB outputs.

PRESSURE INPUT

1/4” Phono Jack input for pressure signal from

patient monitor.

ECG INPUT

1/4” Phono Jack input for ECG signal from patient

monitor.

USB PORT

For USB (Type B) connection to a PC-style

computer

FLOWSOUND®VOLUME CONTROL

Adjusts the volume level of the audio output.

CHART RECORDER MODE

RUN/STOP: for continuous printing at 20 mm/sec

SLOW: Prints strip at 20 mm/sec

FAST: Prints strip at 40 mm/sec

Fig. 2.5: HT35x/HT36x Flowmeter Back PanelAnalog Outputs

Sensitivity Switches

Auxiliary Analog

Input (ECG) FlowSound®Volume

Control Safety Legends Power On/Off

Switch

Power Supply Plug

Scale Signal Button Chart Recorder Mode

Switch

Ground Pin

USB Port

WARNINGS

Attention: Consult

accompanying documents

Dangerous Voltage: service

by trained technicians only

C

2797 CE Conformity Mark

Debrillator proof type CF

equipment when used with

the proper cables.

This device was manufactured

in accordance with RoHS

standards for lead content.

Equipotentiality pin:

Instrument ground

Functions & Controls

Pressure Input

8AU-OPR-AureFloFT-EN,

Rev H

1. FLOWSOUND®

FlowSound® provides an audio feedback of volume ow. It is analogous to audio Doppler, but the

sound corresponds to true volume ow, rather than to velocity. The higher the pitch, the higher the

volume ow. An octave increase in pitch corresponds to a 4-fold increase in ow. At zero ow, there is

a low hum sound. The indicator light above the button illuminates when the button is pushed and the

FlowSound®function is active. The FlowSound®function remains active until the button is pushed

again or the meter is powered off.

TO TEST FLOWSOUND® : Connect a Perivascular Flowprobe to the Flowmeter and immerse the Probe’s

head in a container of water. Turn on [FlowSound®]. The FlowSound®knob on the rear panel can

be used to adjust the sound level. Swish the Probe back and forth in the water and note the changes

in pitch as the volume of ow passing through the Probe’s ultrasonic sensing window changes.

FlowSound® is heard only when the ultrasonic signal quality is adequate for ow measurement, i.e. if

the Probe is immersed in water or applied to a vessel without air obstructions.

a) Low Pitch = ZERO or Low ow

b) Higher Pitch = Higher ow

c) No Sound = “NO Signal”: apply gel or saline inside the ultrasonic window

2. FLOWMETER OUTPUTS: CONNECT TO PATIENT MONITOR

There is one analog output on the rear panel of the Single Channel Meters and two on the Dual

Channel Meters. The voltage levels of these ow signals follow Transonic®Uniscale convention

to simplify connection to commercial intraoperative Monitors. The Uniscale is scaled according to

Flowprobe size:

PROBE DESCRIPTION PROBE SIZE SENSITIVITY AT 1X

Small Probes 0.7 - 6 size 1 Volt = 200 mL/min

Medium Probes 7 - 14 size 1 Volt = 4 L/min

Large Probes 16 - 36 size 1 Volt = 20 L/min

Therefore, when the [Flow Scale] rear panel button is momentarily depressed during normal ow

measurement:

a) Voltage on the rear panel output and USB port is switched to + 1 Volt for 10 seconds, then to 0 Volt

for 10 seconds.

b) The front panel Meter Display will simultaneously indicate the corresponding ow levels: First, the

Flowprobe’s Uniscale level of 1 Volt (200 mL/min, 4L/min or 20L/min) and then “0 mL/min” (0 Volt).

(With [Sensitivity] switch set at 1x.)

The Uniscale voltage output for a given real ow displayed on the front panel can be multiplied by a

factor of 2 or 4 by switching the [Sensitivity] switch from 1x to 2x or 4x which corresponds to 1V, 2V

and 4V respectively.

EXAMPLE OF UNISCALE SENSITIVITY

A cardiac surgeon routinely uses a 2, 3 or 4 mm Flowprobe in CABG surgery and wants to see the real-

time ow curves displayed on the central patient Monitor. Although each of these Flowprobe sizes has

a different scale factor, the Uniscale output has automatic gain adjustment, so 1 Volt = 200 mL/min, no

matter which Flowprobe size is used. If the scaling of the waveform is not appropriate, (e.g. for increased

resolution of low ows) it can be adjusted using the [Sensitivity] switch.

Functions & Controls

AU-OPR-AureFloFT-EN,

Rev H

9

III. Specications

A. FlowTrace®Software

FlowTrace®Software is designed to work with a Transonic®safety-tested and approved Transonic®model

Monitor with the following minimum specications:

●Windows XP,

Windows 7, or

Windows 8.1

●1.6 GHz processor or higher

●CD Rom drive ●1 GB of RAM

●Serial Port ●20 GB Hard Drive

●2 USB Ports ●Touch-panel display

Monitor display: 17” touch screen

B. HT300(-FT) Series Compatible Flowmeters

●Single-channel (HT31x-FT & HT35x Series), dual-channel (HT32x-FT & HT36x Series) Flowmeters

●Weight: Single Channel: 10 lb (4.5 kg); Dual Channel 11 lb (5 kg)

●Dimensions all Models: 11 3/8” (28.9 cm) wide x 4” (10.2 cm) high x 13 1/2” (34.3 cm) deep

●Attached two meter Flowprobe-to-Flowmeter extension cable per channel

●Separate grounded medical grade power line-cord is supplied with the Flowmeter.

INPUT POWER

Universal Power Supply; 50-60 Hz; 100 -240 V ± 10% (automatic voltage adjustment)

FUSES

1.5A fast blo, mfg bussman: #GMA1.5, 250 VAC (HT31x-FT & HT32x-FT Series)

1A Slow Blo, mfg. Bel: # 5HT1-R 250VAC (HT35x & HT36x Series)

Both power entry conductors are protected by size 5 x 20 mm fuses.

ELECTRICAL ISOLATION

●Cabinet is grounded; line to ground leakage current: less than 50 μA @100-120 V line; less than 100 μA @

220-240 V line.

●All electronic components and cabling of the Flowprobe/Flowsensor extension cable, Flowprobe/

Flowsensor cable and Flowprobe/Flowsensor are fully isolated from the Flowmeter’s electrical circuitry to

meet IEC60601 “cardiac oating” specications.

●Debrillator Protection: Class I “CF” IXPI device: Probes can be left attached to the patient during cardiac

debrillation for instantaneous report on the restoration of ow.

ENVIRONMENTAL

●Operating temperature range: 15ºC to 40ºC

●Operating, shipping and storage humidity: 0 to 90% RH non-condensing

●Shipping and storage temperate range: -10ºC to 50ºC

●RoHS compliant (HT35x & HT36x Series)

AUTOMATIC METER ADJUSTMENTS

●Ultrasound frequency and insonication parameters

●Flowprobe size and corresponding ow output ranges

●Volume ow calibration of connected Flowprobe

●Sampling rate optimized for local acoustic conditions

10 AU-OPR-AureFloFT-EN,

Rev H

DIGITAL FLOWPROBE/FLOWSENSOR IDENTIFICATION

Probe identication and calibration parameters are programmed on an EPROM housed inside the

Flowprobe/Flowsensor connector.

COMPATIBLE FLOWSENSORS

These Flowmeters accept a range of HQ- Series Flowprobes/Flowsensors for intraoperative surgical use. See

Probe specication sheets or your local Transonic®representative for models, sizes and recommended uses.

FLOWMETER INPUTS

Two 1/4” Phono Jack connectors are provided on the rear panel as auxiliary input for the Pressure and ECG

signal. They accept a signal range of ± 5 Volts.

USB OUTPUT PORT

Electically isolated output connector meeting IEC60601 patient isolation. For connection to the AureFlo®

Monitor. The ± 5V analog Flow signals and ECG signal are digitized at 100 Hz sampling rate with 12-bit

resolution. Data is supplied at 19200 Baud with 8 data bits, 1 stop bit, and no parity for use with FlowTrace®

software.

ULTRASONIC FREQUENCY/PARAMETERS

The ultrasound output level of the Flowprobes/Flowsensors is factory-set and does not incorporate any

interactive system features. These settings are made using “ALARA” principles (As Low As Reasonably

Achievable), and are orders of magnitude below the FDA “preamendment levels,” the USA insonication

safety limits. These settings satisfy the requirements of IEC 60601-2-37 for exemption from Mechanical

Index (MI) and Thermal Index (TI) reporting during use.

●Transducer excitation: Burst of 10 to 24 waves (probe size dependent).

●Transducer excitation frequency: 900 kHz to 9.6 MHz (probe size dependent).

●Transducer excitation rate: 900 Hz to 14 kHz (probe size dependent).

PARAMETER MEANING TRANSONIC®FLOW SENSOR

THEORETICAL MAX

IEC 60601-2-37

EXEMPTION

FROM DISPLAY

PRE-AMENDMENT

MAX (FOR CARDIAC

APPLICATIONS)

MI Mechanical Index 0.021 1 1.9

TI Thermal Index 0.91 1N/A

IMAX Maximum Peak

Intensity 2.5 W/cm2N/A 310 W/cm2

ISPTA

Spatial Peak,

Temporal Average

Intensity

45 mW/cm2N/A 430 mW/cm2

ISPPA

Spatial Peak,

Pulse Average

Intensity

2.53 W/cm2N/A 190 W/cm2

Device testing has shown that measurements are well below theoretical maximum values. Measurement uncertainties did not

exceed 30%.

REGULATORY COMPLIANCE

Transonic®Flowmeters and Flowprobes/Flowsensors comply with acceptable standards for medical and

electrical equipment (IEC60601-1). These Transonic®products are CE marked per 93/42EEC Annex II as

amended by Directive 2007/47/EEC. Transonic® is an ISO13485 certied facility.

Specications

AU-OPR-AureFloFT-EN,

Rev H

11

C. AureFlo®Cart

MECHANICAL SPECIFICATIONS

Height: 63” (160.02 cm); Width: 20” (50.8 cm); Depth: 20” (50.8 cm)

Footprint: 22” x 22”

Weight: 107 lbs. (48.6 kg)

VESA Mount: Industry standard mount for attaching a VESA Mount 2.95” x 2.95” for 12” - 22” diagonal

screen with weight range up to

30 lbs (14 kg)

LOADING CONDITIONS

●Shelf with HT300 Series mounting bracket: Flowmeter: 22 lbs maximum; Shelf load: 6 lbs maximum

●Shelf with sliding drawer: Drawer capacity 5 lbs maximum; Shelf load 15 lb maximum; 2-4 inch locking

casters

●Maximum system weight: 110 lbs.

ELECTRICAL SPECIFICATIONS

The cart provides connections to the AC power source for the HT300 Series Compatible Flowmeter, printer

and the AureFlo®Monitor. Do not plug any ancillary equipment other than that recommended in this

manual into the AureFlo’s®power outlet on its cart. Before installing any devices on the AureFlo®cart,

make sure that the system is powered off and the line cord is disconnected from the cart.

INPUT POWER

100-240VAC; 50/60Hz; 500VA Maximum

FUSES

BEL T4L: Transonic® Part #: TFSB4AM5 x 20; Mfg. part #: BEL5ST4-R

PRINTER

18VDC auxiliary power connection: The auxiliary power connection is provided to power printers that

support an 18VDC input voltage.

●Output voltage: 18VDC ± 5%

●Output current: <2.5A

Specications

12 AU-OPR-AureFloFT-EN,

Rev H

IV. Functional Tests

A. Setting Up The AureFlo®System

When you receive your AureFlo®System, all power cords will be attached to

the AureFlo®Cart’s medically isolated power source. Before turning on the

AureFlo®System these power cords must be connected to the touch-panel

PC, an HT300 Series Compatible Flowmeter and the optional printer. Use the

following steps to set up your AureFlo®System for more detailed instructions

see (Appendix A: Initial AureFlo®Setup, page 35).

1) Prior to making any connections on your AureFlo®System, make sure that

the line cord is disconnected from the AureFlo®Cart and the system is powered

“OFF”.

a) Position and attach the AureFlo®touch-panel PC to the AureFlo®Cart.

Connect one end of the USB cable to a Flowmeter (Fig. 4.1). Then

connect the opposite end to any open USB port on the bottom of the

AureFlo®touch-panel PC.

b) AureFlo®Cart’s Power Cords:

i) Connect one power cord from the AureFlo®Cart to the Universal

Power Supply port of the Flowmeter. With the AureFlo®Cart’s line

cord still disconnected, turn the Flowmeter’s power switch to “ON”

and leave it in the “ON” position.

ii) Connect the other power cord from the AureFlo®Cart to the

Universal Power Supply port of the AureFlo®touch panel PC which is

wired to turn on automatically.

c) Line Cord: connect one end of the line cord to the Universal Power

Supply port on the AureFlo®Cart. Connect the line cord to an electrically

grounded power receptacle.

2) Now turn on the AureFlo®System via the [Power On/Off] switch on the back

of the AureFlo®cart (Fig. 4.2).

3) FlowTrace®will start automatically and display on the AureFlo®Panel PC.

A FlowTrace®dialog displaying “PLUG IN A FLOWPROBE” will appear.

FlowTrace®is now ready to use.

IMPORTANT! EXIT FLOWTRACE®SOFTWARE AND POWER DOWN THE MONITOR BEFORE TURNING OFF POWER ON THE

CART. FAILURE TO PROPERLY POWER DOWN THE SYSTEM MAY CAUSE SYSTEM ERROR. FOLLOW THE DIRECTIONS IN "AFTER

MEASUREMENTS ARE COMPLETED" ON PAGE 30 FOR PROPER SHUTDOWN METHOD.

ECG / PRESSURE SIGNAL: IF PERFORMING SURGERY IN WHICH AN ECG AND/OR PRESSURE SIGNAL IS

DESIRED, CONNECT THE ECG /PRESSURE SIGNAL FOR USE WITH THE AUREFLO®SYSTEM AS FOLLOWS:

●Identify an appropriate ECG / Pressure source on the anesthesia patient monitor (with assistance from

perfusion or Biomedical Engineering, if necessary). This will be the same port as that used for the Intra-

Aortic Balloon Pump. The maximum voltage input is -5V to +5 V.

●Connect the anesthesia monitor to the AureFlo meter with the supplied cable, using the ECG or Pressure

port. Make sure both ends are connected to the same output, either 'ECG' or 'Pressure'.

●If the connection is not a 1/4" phono plug, a different cable will have to be specied and ordered

through Transonic.

●Turn on the ECG / Pressure source.

Connect to Flowmeter

Connect to Monitor

Fig. 4.1: USB Cable

Fig. 4.2: AureFlo®Cart rear pole

view with [On/Off]

switch

Flowmeter

On/Off

Cart On/Off

AU-OPR-AureFloFT-EN,

Rev H

13

Functional Tests

B. Connecting a Printer

If you have purchased a printer from Transonic Systems

Inc.®, your printer’s cord is already connected to the

AureFlo®Cart’s integrated medically isolated power

supply and the printer driver has been installed on the

AureFlo®Panel PC. The printer will always need to be

turned “ON” via the [On/Off] button on the printer if

the power to the AureFlo®Cart has been turned “OFF”.

IMPORTANT: ONLY USE A PRINTER THAT IS POWERED FROM THE

SUPPLIED, MEDICALLY ISOLATED 18 VDC CONNECTOR.

For a printer not purchased from Transonic®:

1) Verify the connection of the supplied USB cable

to the appropriate port on the rear of the printer.

Verify the connection of the opposite end of the USB

cable to an available port on the Panel PC.

2) Connect the loose end of the printer’s power cord

& adaptor cable to the power port on the rear of

the printer. Power “ON” the printer via the printer’s

[On/Off] button. Note: Depending on the printer a

different adaptor cable may be required.

Printing options are controlled from the dialog box that opens after selecting [Print] (Fig. 4.3).

C. Testing The AureFlo®System

The following tests acquaint the user with operation of the AureFlo® System:

1) Turn on AureFlo®System per instructions above. If the system is on but FlowTrace®is not open, double

click the FlowTrace®icon on the desktop of the Monitor. During FlowTrace®startup the AureFlo®

Monitor will display a start-up message. The Realtime screen will be displayed with the message “Plug in

Flowprobe.” This indicates that there is still no Flowprobe/Flowsensor connected to the Flowmeter.

2) From the [System Settings] menu, use the [FlowTrace®Settings] dialog on the AureFlo®Monitor

to enter the institutions’s name for display on printouts only. Enter all Surgeon's names for inclusion in

patient information. The default surgery is the last surgery selected and all FlowTrace®Settings default

to last selected (Fig. 7.1, page 28). If nothing has previously been selected the default surgery is CABG

and all FlowTrace®settings are selected as active.

3) Use the [Patient Settings] menu to update patient name and information. Update surgery type if

necessary.

4) Use the self-aligning push-lock connector to connect a Flowprobe or Flowsensor to the Probe extension

cable at the front of the Flowmeter. Make sure that the connector is fully pushed in. The AureFlo®

Monitor’s display will show “NO SIGNAL” at the top center of the new screen (Fig. 4.4, page 14).

The ve black bars on the right-hand side of Fig. 4.4 indicates that there is no ultrasonic transmission

reaching the Flowprobe because there is no acoustic coupling. See Fig. 4.5 on page 15 for signal

indicator bar strength explanation.

Fig. 4.3: Print options dialog box. Printer drop-down menu is

only available if multiple printers are installed on the

AureFlo®system.

14 AU-OPR-AureFloFT-EN,

Rev H

D. Testing The Flowprobes

NOTE: Flow-QC®keys are not required to test signal quality. Single use Probes should only be tested shortly

before use as the signal test will begin the measurement period.

1) Immerse the Flowprobe in a container lled with sterile saline to establish ultrasonic coupling.

2) Dislodge any air bubbles from the Flowprobe’s surfaces. Gently move the Flowprobe back and forth in

the saline to remove all air bubbles.

3) Observe the Signal Indicator Display on Realtime mode (Fig. 4.4). The bars will change from black to red

to yellow to green as the strength of the signal increases and acoustic transmission is established (Fig.

4.5, page 15).

4) When a Flowprobe is connected and there is adequate ultrasonic transmission, ow can be measured.

This is indicated by a waveform on the scrolling bar of the touch-panel display.

Functional Tests

FLOWPROBE/FLOWSENSOR QUALITY TEST

Three yellow bars indicate an adequate signal strength for ow measurements with Flowprobes/

Flowsensors. However, ultrasound signal attenuation will be higher on blood vessels during surgery.

Therefore, the Flowprobe/Flowsensor quality acceptance level during saline testing should be at least four

green bars.

Fig. 4.4: FlowTrace®screen in Realtime mode. The “NO SIGNAL” message at top of the screen and signal

indicator lights on the touch-panel display’s right side indicate that the Flowprobe is not receiving

ultrasonic transmission.

NO SIGNAL!

ECG Signal

This manual suits for next models

16

Table of contents

Other Transonic Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT564258 Operation manual

SEW-Eurodrive

SEW-Eurodrive MOVIGEAR MGF-DBC Series operating instructions

Matsing

Matsing MS-MBA-4.4-SH2-SH2 instruction manual

ABB

ABB THF Series Installation and operation instruction

Graco

Graco Power-Lock Instructions - parts

NOZAG

NOZAG NSE S Series Assembly and operating manual