ZL3-

Serie

The intended use of this product is

1

These safety instructions are intended to prevent hazardous situ

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)

*1)

ISO 4414: Pneumatic fluid power

ISO 4413: Hydraulic fluid power

IEC

(Part 1: General requirements)

•

Refer to product catalogue

Precautions for SMC Products for additional information.

•

Keep this manual in a safe place for future reference.

•

Always ensure compliance with relevant safety laws and

•

compliance with applicable national regulations.

X189EN

3/ZL6

The intended use of this product is

These safety instructions are intended to prevent hazardous situ

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)

ISO 4414: Pneumatic fluid power

ISO 4413: Hydraulic fluid power

-

(Part 1: General requirements)

-

1: Manipulating industrial robots

Refer to product catalogue

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

Caution

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Always ensure compliance with relevant safety laws and

carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

The intended use of this product is

These safety instructions are intended to prevent hazardous situ

These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)

ISO 4414: Pneumatic fluid power

-

General rules relating to systems.

ISO 4413: Hydraulic fluid power

-

General rules relating to systems.

-

(Part 1: General requirements)

1: Manipulating industrial robots

Refer to product catalogue

, Operation Manual and Handling

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Always ensure compliance with relevant safety laws and

carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

These safety instructions are intended to prevent hazardous situ

These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

, and other safety regulations.

General rules relating to systems.

General rules relating to systems.

Electrical equipment of machines.

1: Manipulating industrial robots

-

, Operation Manual and Handling

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Always ensure compliance with relevant safety laws and

carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

These safety instructions are intended to prevent hazardous situ

These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

, and other safety regulations.

General rules relating to systems.

General rules relating to systems.

Electrical equipment of machines.

etc.

, Operation Manual and Handling

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Always ensure compliance with relevant safety laws and

carried out in a safe manner by a qualified person in

These instructions indicate the level of

They are all important notes for safety and must be followed in addition

, and other safety regulations.

General rules relating to systems.

General rules relating to systems.

Electrical equipment of machines.

, Operation Manual and Handling

Caution indicates a hazard with a low level of risk which, if

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

Always ensure compliance with relevant safety laws and

carried out in a safe manner by a qualified person in

Refer to catalogue for more details.

Operating temperature range

Operating temperature range

measurement standards. They depend on atmospheric pressure (weather, altitude,

etc.) and measurement method.

Refer to catalogue for more details.

,

*

Operating temperature range

*

,

*

Operating temperature range

*

)

Values are at the same standard supply pressure and based on SMC’s

measurement standards. They depend on atmospheric pressure (weather, altitude,

etc.) and measurement method.

)

10 to 500Hz for 2 hours in each direction of X, Y and Z (de

)

3 times in each direction of X, Y and Z (de

*4)

Refer to operation manual of solenoid valve (

Do not install the product unless the saf

read

When m

ounting the product, tighten with the recommended

tightening torque of the following screws.

-

Top surface and side surface mounting: 0.56 to 0.76

-

Bottom mounting: 0.29 to 0.30

When

installing the product, secure the space required for

maintenance and inspection of the product

Do not drop

, hit, or apply excessive impact to the product.

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not

install in a location subject to vibration or i

the product’s specifications

Do not mount in a location exposed to radiant heat

in temperatures in excess of the product’s specifications

the u

sage environment of the product, consider using a vacuum filter

(AFJ series)

Do not use in place where static electricity build up can occur.

Do not use in an environment where surges occur

Refer to catalogue for more details.

*

*

Operating temperature range

*

*

*

Operating temperature range

*

Values are at the same standard supply pressure and based on SMC’s

measurement standards. They depend on atmospheric pressure (weather, altitude,

etc.) and measurement method.

10 to 500Hz for 2 hours in each direction of X, Y and Z (de

3 times in each direction of X, Y and Z (de

Refer to operation manual of solenoid valve (

10

series) for the characteristics.

Do not install the product unless the saf

.

ounting the product, tighten with the recommended

tightening torque of the following screws.

Top surface and side surface mounting: 0.56 to 0.76

Bottom mounting: 0.29 to 0.30

installing the product, secure the space required for

maintenance and inspection of the product

, hit, or apply excessive impact to the product.

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

install in a location subject to vibration or i

the product’s specifications

.

Do not mount in a location exposed to radiant heat

in temperatures in excess of the product’s specifications

sage environment of the product, consider using a vacuum filter

Do not use in place where static electricity build up can occur.

Do not use in an environment where surges occur

Refer to catalogue for more details.

ZL3M□□

1.9

0.35 MPa

-91 kPa

L/min (ANR)

5 to 50

o

C (No

ZL6M□□

1.9 x 2

0.35 MPa

0.37 MPa

-91 kPa

L/min (ANR)

5 to 50

o

C (No

Values are at the same standard supply pressure and based on SMC’s

measurement standards. They depend on atmospheric pressure (weather, altitude,

10 to 500Hz for 2 hours in each direction of X, Y and Z (de

3 times in each direction of X, Y and Z (de

Refer to operation manual of solenoid valve (

series) for the characteristics.

Warning

Do not install the product unless the saf

ety instructions have been

ounting the product, tighten with the recommended

tightening torque of the following screws.

Top surface and side surface mounting: 0.56 to 0.76

Bottom mounting: 0.29 to 0.30

N•m

installing the product, secure the space required for

maintenance and inspection of the product

, hit, or apply excessive impact to the product.

Warning

Do not use in an environment where corrosive gases, chemicals, salt

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

install in a location subject to vibration or i

Do not mount in a location exposed to radiant heat

in temperatures in excess of the product’s specifications

-

in suction filter. If there is dust in

sage environment of the product, consider using a vacuum filter

Do not use in place where static electricity build up can occur.

Do not use in an environment where surges occur

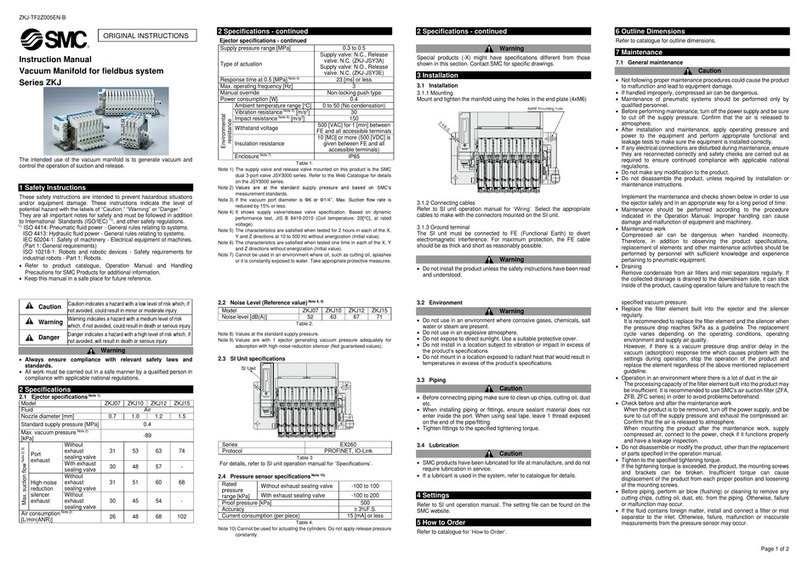

ZL3H

0.50

-

135

6 MPa

Air

2

2

ZL6H

1.5 x

0.50

0.52

-

270

6 MPa

Air

2

2

Values are at the same standard supply pressure and based on SMC’s

measurement standards. They depend on atmospheric pressure (weather, altitude,

10 to 500Hz for 2 hours in each direction of X, Y and Z (de

energised, initial value)

Refer to operation manual of solenoid valve (

JSY3000

series) for the characteristics.

ety instructions have been

ounting the product, tighten with the recommended

Top surface and side surface mounting: 0.56 to 0.76

installing the product, secure the space required for

, hit, or apply excessive impact to the product.

Do not use in an environment where corrosive gases, chemicals, salt

Do not expose to direct sunlight. Use a suitable protective cover.

install in a location subject to vibration or i

mpact

Do not mount in a location exposed to radiant heat

in temperatures in excess of the product’s specifications

in suction filter. If there is dust in

sage environment of the product, consider using a vacuum filter

Do not use in place where static electricity build up can occur.

Do not use in an environment where surges occur

.

2

Values are at the same standard supply pressure and based on SMC’s

measurement standards. They depend on atmospheric pressure (weather, altitude,

10 to 500Hz for 2 hours in each direction of X, Y and Z (de

-energised,

energised, initial value)

series) and

ety instructions have been

ounting the product, tighten with the recommended

Top surface and side surface mounting: 0.56 to 0.76

N•m

installing the product, secure the space required for

Do not use in an environment where corrosive gases, chemicals, salt

Do not expose to direct sunlight. Use a suitable protective cover.

in suction filter. If there is dust in

sage environment of the product, consider using a vacuum filter

Do not use in place where static electricity build up can occur.

3

3.3

●

Do not use air containing chemicals, synthetic oils containing organic

solvents, salts, or corrosive gases.

●R

ecommended quality of the

compressed air cleanliness grade "2:

2010.

•

Do not supply the pressure

3.4

•

•

gets inside the port. When using sealing tape, wind it with one thread

left.

•

Tighten fittings to the specified tightening torque

•Fix

the side of the body when piping to the vacuum (2 / V) port and

piping to the exhaust (3 / E) port.

3.5

Refer to the operation manual of solenoid valve (

4

4.1

Manual Override (With supply valve and release valve)

Refer to the operation manual of the solenoid valve JSY

for the manual operation method.

4.2

When the release valve is turned on, vacuum break air is let out.

The release flow adjusting needle allows to control the vacuum break

To adjust the break air flow, pull the push

break flow, and turn the handle anti

5

Refer to

6

Refer to the catalogue for

-

Do not use air containing chemicals, synthetic oils containing organic

solvents, salts, or corrosive gases.

ecommended quality of the

compressed air cleanliness grade "2:

Do not supply the pressure

connecting

piping make sure to clean up chips, cutting

installing piping and fittings, make sure that no sealing material

gets inside the port. When using sealing tape, wind it with one thread

Tighten fittings to the specified tightening torque

(2/V) port

(3/E) port

the side of the body when piping to the vacuum (2 / V) port and

piping to the exhaust (3 / E) port.

to the solenoid valve and pressure switches

Refer to the operation manual of solenoid valve (

Manual Override (With supply valve and release valve)

Refer to the operation manual of the solenoid valve JSY

for the manual operation method.

When the release valve is turned on, vacuum break air is let out.

The release flow adjusting needle allows to control the vacuum break

To adjust the break air flow, pull the push

push-

locking handle clockwise to reduce the vacuum

break flow, and turn the handle anti

catalogue

Refer to the catalogue for

release

Body surface

(

Do not use air containing chemicals, synthetic oils containing organic

solvents, salts, or corrosive gases.

ecommended quality of the

supplied air be equivalent to the

compressed air cleanliness grade "2:

Do not supply the pressure

in excess of the product’s specifications

piping make sure to clean up chips, cutting

installing piping and fittings, make sure that no sealing material

gets inside the port. When using sealing tape, wind it with one thread

Tighten fittings to the specified tightening torque

Port size

1/2 or 3/4

1

1/8

the side of the body when piping to the vacuum (2 / V) port and

port and

fix the side of the port block when

piping to the exhaust (3 / E) port.

to the solenoid valve and pressure switches

Refer to the operation manual of solenoid valve (

series).

Manual Override (With supply valve and release valve)

Refer to the operation manual of the solenoid valve JSY

for the manual operation method.

needle

When the release valve is turned on, vacuum break air is let out.

The release flow adjusting needle allows to control the vacuum break

To adjust the break air flow, pull the push

locking handle clockwise to reduce the vacuum

break flow, and turn the handle anti

-

clockwise to increase the flow.

Refer to the catalogue for

)

Vacuum pressure detection(G) port

Do not use air containing chemicals, synthetic oils containing organic

supplied air be equivalent to the

in excess of the product’s specifications

piping make sure to clean up chips, cutting

installing piping and fittings, make sure that no sealing material

gets inside the port. When using sealing tape, wind it with one thread

Tighten fittings to the specified tightening torque

torque

the side of the body when piping to the vacuum (2 / V) port and

fix the side of the port block when

to the solenoid valve and pressure switches

Refer to the operation manual of solenoid valve (

J

Manual Override (With supply valve and release valve)

Refer to the operation manual of the solenoid valve JSY

When the release valve is turned on, vacuum break air is let out.

The release flow adjusting needle allows to control the vacuum break

To adjust the break air flow, pull the push

-

locking handle to unlock it.

locking handle clockwise to reduce the vacuum

clockwise to increase the flow.

.

.

Exhaust block surface to be held

Vacuum pressure detection(G) port

Do not use air containing chemicals, synthetic oils containing organic

supplied air be equivalent to the

-1:

in excess of the product’s specifications

piping make sure to clean up chips, cutting

installing piping and fittings, make sure that no sealing material

gets inside the port. When using sealing tape, wind it with one thread

to 30 N・m

to 38 N・m

to 5 N・m

the side of the body when piping to the vacuum (2 / V) port and

fix the side of the port block when

to the solenoid valve and pressure switches

3000

Manual Override (With supply valve and release valve)

Refer to the operation manual of the solenoid valve JSY

3000

When the release valve is turned on, vacuum break air is let out.

The release flow adjusting needle allows to control the vacuum break

locking handle to unlock it.

locking handle clockwise to reduce the vacuum

clockwise to increase the flow.

Exhaust block surface to be held

Vacuum pressure detection(G) port

Do not use air containing chemicals, synthetic oils containing organic

in excess of the product’s specifications

.

installing piping and fittings, make sure that no sealing material

gets inside the port. When using sealing tape, wind it with one thread

the side of the body when piping to the vacuum (2 / V) port and

fix the side of the port block when

The release flow adjusting needle allows to control the vacuum break

locking handle clockwise to reduce the vacuum

7

•

•

•

•

•

•

•

•

•

•

•

•

•

1) Loosen the two mounting screws of the silencer assembly and

2) Replace the sound absorbing material inside the silencer case (Fig.2)

3) Attach the silencer assembly using the mounting screws.

1) Align the hook of the silencer assembly with the groove of the body,

2) When removing, slide the silencer

Not following proper maintenance procedures could cause the

product to malfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be per

Before performing maintenance,

sure to cut off the supply pressure. Confirm that the air is released to

atmosphere.

After installation and maintenance, apply operating pressure and

power

to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance,

ensure they are reconnected

ou

t as required to ensure continued compliance with applicable

Do not make any modification to the product.

Do not disassemble the product, unless required by installation or

Implement the maintenance and check shown below to use the

multistage ejector safely and in an appropriate way for a long period

of time.

Drain

the air filter and mist separator regularly

Replace the sound absorbing material (silencer) built into the ejec

regularly

Refer to the online operation manual for replacement parts.

Do not use

benzene or thinner for cleaning.

Replacement method of sound absorbing material (ZL3)

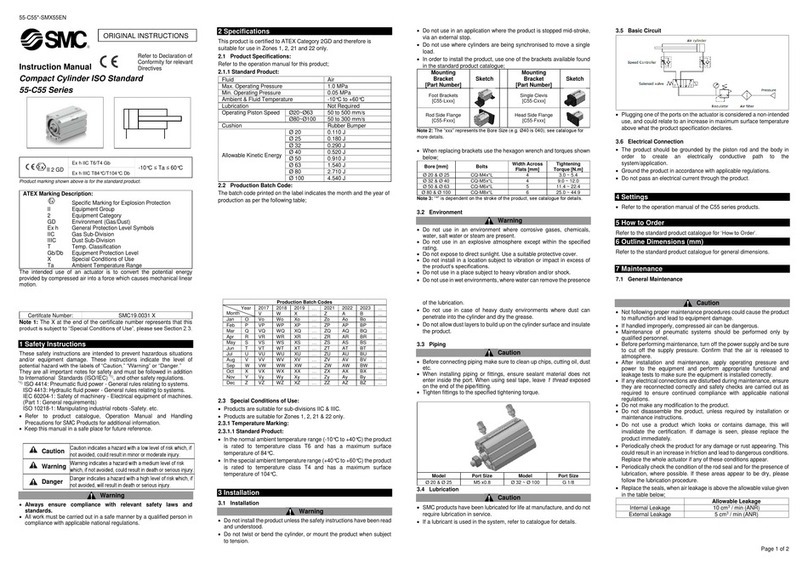

1) Loosen the two mounting screws of the silencer assembly and

remove the sil

2) Replace the sound absorbing material inside the silencer case (Fig.2)

3) Attach the silencer assembly using the mounting screws.

S

1) Align the hook of the silencer assembly with the groove of the body,

break it, and push it in the direction of the arrow until it clicks.

2) When removing, slide the silencer

to the mounting direction to remove it.

Not following proper maintenance procedures could cause the

product to malfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be per

Before performing maintenance,

sure to cut off the supply pressure. Confirm that the air is released to

After installation and maintenance, apply operating pressure and

to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance,

ensure they are reconnected

t as required to ensure continued compliance with applicable

Do not make any modification to the product.

Do not disassemble the product, unless required by installation or

Implement the maintenance and check shown below to use the

multistage ejector safely and in an appropriate way for a long period

the air filter and mist separator regularly

Replace the sound absorbing material (silencer) built into the ejec

Refer to the online operation manual for replacement parts.

benzene or thinner for cleaning.

Replacement method of sound absorbing material (ZL3)

1) Loosen the two mounting screws of the silencer assembly and

2) Replace the sound absorbing material inside the silencer case (Fig.2)

3) Attach the silencer assembly using the mounting screws.

tightening torque: 0.76 to 0.84 Nm)

1) Align the hook of the silencer assembly with the groove of the body,

break it, and push it in the direction of the arrow until it clicks.

2) When removing, slide the silencer

to the mounting direction to remove it.

Caution

Not following proper maintenance procedures could cause the

product to malfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be per

Before performing maintenance,

turn off the power supply and be

sure to cut off the supply pressure. Confirm that the air is released to

After installation and maintenance, apply operating pressure and

to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance,

and safety checks are carried

t as required to ensure continued compliance with applicable

Do not make any modification to the product.

Do not disassemble the product, unless required by installation or

Implement the maintenance and check shown below to use the

multistage ejector safely and in an appropriate way for a long period

the air filter and mist separator regularly

Replace the sound absorbing material (silencer) built into the ejec

Refer to the online operation manual for replacement parts.

benzene or thinner for cleaning.

Replacement method of sound absorbing material (ZL3)

1) Loosen the two mounting screws of the silencer assembly and

2) Replace the sound absorbing material inside the silencer case (Fig.2)

3) Attach the silencer assembly using the mounting screws.

tightening torque: 0.76 to 0.84 Nm)

1) Align the hook of the silencer assembly with the groove of the body,

break it, and push it in the direction of the arrow until it clicks.

2) When removing, slide the silencer

assembly in the direction opposite

to the mounting direction to remove it.

Assembly

screws

Not following proper maintenance procedures could cause the

product to malfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be per

turn off the power supply and be

sure to cut off the supply pressure. Confirm that the air is released to

After installation and maintenance, apply operating pressure and

to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance,

and safety checks are carried

t as required to ensure continued compliance with applicable

Do not disassemble the product, unless required by installation or

Implement the maintenance and check shown below to use the

multistage ejector safely and in an appropriate way for a long period

the air filter and mist separator regularly

Replace the sound absorbing material (silencer) built into the ejec

Refer to the online operation manual for replacement parts.

Replacement method of sound absorbing material (ZL3)

1) Loosen the two mounting screws of the silencer assembly and

2) Replace the sound absorbing material inside the silencer case (Fig.2)

3) Attach the silencer assembly using the mounting screws.

tightening torque: 0.76 to 0.84 Nm)

1) Align the hook of the silencer assembly with the groove of the body,

break it, and push it in the direction of the arrow until it clicks.

assembly in the direction opposite

Fig.2

1 of 2

Not following proper maintenance procedures could cause the

turn off the power supply and be

sure to cut off the supply pressure. Confirm that the air is released to

After installation and maintenance, apply operating pressure and

to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance,

and safety checks are carried

t as required to ensure continued compliance with applicable

Do not disassemble the product, unless required by installation or

Implement the maintenance and check shown below to use the

multistage ejector safely and in an appropriate way for a long period

Replace the sound absorbing material (silencer) built into the ejec

tor

Replacement method of sound absorbing material (ZL3)

1) Loosen the two mounting screws of the silencer assembly and

2) Replace the sound absorbing material inside the silencer case (Fig.2)

1) Align the hook of the silencer assembly with the groove of the body,

break it, and push it in the direction of the arrow until it clicks.

assembly in the direction opposite