Transonic 400 Series User manual

Transonic®400-Series Consoles &

Modules For Research Use

Models:

Consoles: T402, T403

Modules: TS410, TS420 & SP430

AU-OPR-400Ser-EN, Rev D Last Updated 12/22/17

OPERATOR’S MANUAL

P

M

C

AMERICAS

Transonic Systems Inc.

34 Dutch Mill Rd

Ithaca, NY 14850

U.S.A.

Tel: +1 607-257-5300

Fax: +1 607-257-7256

support@transonic.com

EUROPE

Transonic Europe B.V.

Business Park Stein 205

6181 MB Elsloo

The Netherlands

Tel: +31 43-407-7200

Fax: +31 43-407-7201

europe@transonic.com

ASIA/PACIFIC

Transonic Asia Inc.

6F-3 No 5 Hangsiang Rd

Dayuan, Taoyuan County

33747 Taiwan, R.O.C.

Tel: +886 3399-5806

Fax: +886 3399-5805

support@transonicasia.com

JAPAN

Nipro-Transonic Japan Inc.

7th Floor, Maruha Building

11-1Matsuba-cho

Tokorozawa City, Saitama

359-0044 Japan

Tel: +81 04-2946-8541

Fax: +81 04-2946-8542

japan@transonic.com

ii AU-OPR-400Ser-EN,

Rev D

Table of Contents

Table of Contents.....................................................................................................................................................................ii

Warnings & Precautions .........................................................................................................................................................iv

I. Introduction.......................................................................................................................................................................1

II. T402 & T403 Multi-channel Consoles................................................................................................................................2

A. T402 Multi-Channel Bench-top Console ..................................................................................................................................... 2

B. T403 Multi-Channel Bench-top Console..................................................................................................................................... 2

C. Console Care............................................................................................................................................................................. 2

i. CONSOLES: FUNCTIONS & CONTROLS .......................................................................................................................................... 3

ii. CONSOLES: SPECIFICATIONS ......................................................................................................................................................... 4

iii. CONSOLES: DIRECTIONS FOR USE................................................................................................................................................. 5

A. Installing Modules ..................................................................................................................................................................... 5

B. Removing Modules.................................................................................................................................................................... 5

C. Synchronization ......................................................................................................................................................................... 5

1. Self-Triggering....................................................................................................................................................................... 5

2. Sequential Triggering ............................................................................................................................................................ 6

III. TS410 Tubing Flow Module ...............................................................................................................................................7

A. Compatible Flowsensors ............................................................................................................................................................ 7

i. TS410 MODULE: FUNCTIONS & CONTROLS................................................................................................................................... 8

A. Modes of Operation................................................................................................................................................................... 9

B. Filter Settings ............................................................................................................................................................................ 9

C. Analog Outputs......................................................................................................................................................................... 9

ii. TS410 MODULE: SPECIFICATIONS ............................................................................................................................................... 10

iii. TS410 MODULE: FUNCTIONAL TESTS.......................................................................................................................................... 11

A. Flow Module Set-up ................................................................................................................................................................ 11

B. Flowsensor Zero Offset............................................................................................................................................................ 11

C. User Adjusted Gain.................................................................................................................................................................. 12

D. Calibrating a Data Acquisition System ...................................................................................................................................... 12

iv. TS410 MODULE: DIRECTIONS FOR USE ....................................................................................................................................... 13

A. Program Menu ........................................................................................................................................................................ 13

B. Alarms Menu........................................................................................................................................................................... 14

C. Use of Clamp-on Flowsensors.................................................................................................................................................. 14

D. Use of Inline Flowsensors......................................................................................................................................................... 16

IV. TS420 Perivascular Flow Module.................................................................................................................................... 17

A. Compatible Flowprobes ........................................................................................................................................................... 17

i. TS420 MODULE: FUNCTIONS & CONTROLS ................................................................................................................................ 18

A. Modes of Operation................................................................................................................................................................. 19

B. Filter Settings .......................................................................................................................................................................... 19

C. Analog Outputs....................................................................................................................................................................... 19

D. Calibration (Cal) Keys............................................................................................................................................................... 19

ii. TS420 MODULE: SPECIFICATIONS ............................................................................................................................................... 20

AU-OPR-400Ser-EN,

Rev D

iii

All contents of this document Copyright © 2017 Transonic Systems Inc.®All Rights Reserved.

The following are Registered, U.S. Patent and Trademark Ofce: COndence Flowprobe®, EndoGear®,

Endosomatic®, PhysioGear®, PhysioView®, Transonic®, Transonic Systems Inc.®

Table of Contents

iii. TS420 MODULE: FUNCTIONAL TESTS.......................................................................................................................................... 21

A. Flow Module Set-up ................................................................................................................................................................ 21

B. Perivascular Flowprobe Signal Quality Test............................................................................................................................... 21

C. Flowprobe Zero Offset............................................................................................................................................................. 22

D. Determining Scale Setting........................................................................................................................................................ 22

E. Calibrating a Data Acquisition System ...................................................................................................................................... 22

iv. TS420 MODULE: DIRECTIONS FOR USE....................................................................................................................................... 23

V. SP430 Pressure Amp Module ..........................................................................................................................................25

A. Compatible Pressure Catheters and Transducers....................................................................................................................... 25

1. Transonic Scisense Pressure catheters.................................................................................................................................. 25

2. Transpac®IV Pressure Transducer (Transonic®part # YS100)............................................................................................... 25

i. SP430 MODULE: FUNCTIONS & CONTROLS ................................................................................................................................ 26

A. Front Panel.............................................................................................................................................................................. 26

B. Modes of Operation................................................................................................................................................................. 27

C. Analog Outputs....................................................................................................................................................................... 27

ii. SP430 MODULE: SPECIFICATIONS ............................................................................................................................................... 28

iii. SP430 MODULE: FUNCTIONAL TESTS.......................................................................................................................................... 29

A. Transducer Calibration Check................................................................................................................................................... 29

B. Calibrating a Data Acquisition System ...................................................................................................................................... 29

iv. SP430 MODULE: DIRECTIONS FOR USE....................................................................................................................................... 30

A. Transonic Scisense Pressure Catheters...................................................................................................................................... 30

B. Dual Pressure Catheters........................................................................................................................................................... 30

C. Catheter Cleaning & Care ........................................................................................................................................................ 30

D. Transpac®IV Pressure Transducers........................................................................................................................................... 31

VI. Guarantee, Service and Warranty...................................................................................................................................32

A. Limited Warranty..................................................................................................................................................................... 32

VII. Equipment Return Instructions .......................................................................................................................................33

A. Consoles & Modules................................................................................................................................................................ 33

B. Flowprobes, Flowsensors & Transonic Scisense Pressure Catheters ........................................................................................... 33

Appendix A: Theory of Operation .........................................................................................................................................34

Appendix B: EMC Tables ........................................................................................................................................................35

Appendix C: Symbols & Signs ................................................................................................................................................36

iv AU-OPR-400Ser-EN,

Rev D

Warnings & Precautions

√Read this manual before use. Failure to follow the instructions and the Warnings and Precautions below

may result in risk of re or electric shock.

√Research Consoles & Modules

●Transonic® Research Consoles and Modules, and compatible Probes, Sensors, Transducers and Catheters

are designed only for investigative use with animals and are not for use in humans. Contact Transonic

Systems Inc.®for alternative products for human use applications.

●Safe and effective use of the Transonic® Console with Flow Module(s) and/or Pressure Amplier

Module(s) depends on correct application technique, adequate precaution and readiness for

emergencies. Prevent liquids and vapors from entering the device.

●The instrument Console and/or Modules are fragile electric equipment. They must be transported and

stored at temperatures between -20ºC to +60ºC with humidity between 0 - 90% RH non-condensing.

Rated altitude: 2000 meters. Operational temperatures must be between 0°C to +40°C with humidity

between 20 - 90% RH non-condensing.

√Perivascular Flowprobes

●Transonic® Perivascular Flowprobes are designed for acute use and/or chronic implantation in animals.

Excessive vessel manipulation or constrictive Flowprobe t may cause vessel spasm or damage and thus

should be avoided.

●Recalibration of the Flowprobe is necessary if the Flowprobe is to be used at a different temperature or

on a liquid other than the one for which it was calibrated.

√Tubing Flowsensors

●Transonic® Flowsensors are designed for laboratory use only.

●Transonic® Tubing Flowsensors are designed for measuring non-aerated liquid ow in tubing and should

not be applied to blood vessels or other internal ducts. They should be used only on tubings and for

liquids for which they were calibrated.

●Tubing Flowsensors are not designed to measure non-liquid (gaseous) uid ow.

●Clamp-on Flowsensors are not designed to measure liquid ow in metal or hard plastic pipes. Clamp-on

Flowsensors should not be immersed in liquids for extended periods of time.

●Factory or on-site recalibration of Tubing Flowsensors is necessary if the Flowsensor is to be used on a

different tubing, liquid or temperature other than for which it was calibrated.

√Pressure Transducers

●Pressure Transducers compatible for use with the SP430 Transonic Scisense Pressure Amplier Module

must be used according to manufacturers’ instructions and are only intended for use with animals or

in laboratory models when connected to a SP430 Pressure Amplier Module in a 400-Series Console,

regardless of individual Pressure Transducer classication.

●Transonic Scisense Pressure Catheters contain metal and are not compatible with MRI.

√Safe Electrical Use

●Use only with grounded power receptacle to reduce risk of shock.

●Position instrument so that rear panel switch and plug are accessible for quick disconnect.

●Install only Transonic®manufactured Modules in 400-Series Consoles. Do not use with alternative power

supplies.

●Do not turn on Console unless Modules are installed and panel covers are in place for empty bays.

●Do not remove or replace Modules in the Console with power turned on.

●Keep ammable liquids and vapors away from the Console and Modules. They may cause a re in the

instrument.

●All repair on Consoles or Modules must be performed by qualied electrical technicians authorized by

Transonic Systems Inc.®

√For a list of possible warning symbols please refer to “Appendix C: Symbols & Signs”

AU-OPR-400Ser-EN,

Rev D

1

I. Introduction

NOTE: In this manual, “Consoles” refer to T402 & T403 Multi-channel Consoles.

NOTE: “Modules” refer to the TS420 Perivascular Flow Modules, TS410 Tubing Flow Modules & SP430

Transonic Scisense Pressure Amplier Modules.

NOTE: In this manual, “Probe” and “Flowprobe” refer to Transonic® Precision Perivascular Flowprobes.

NOTE: “Sensor” and “Flowsensor” refer to Transonic® Clamp-on and Inline Tubing Flowsensors.

NOTE: “Transducers” refer to Pressure Transducers including Transonic Scisense Pressure Catheters and/or

Transpac® IV Pressure Transducers. “Catheters” refer to Transonic Scisense Pressure Catheters.

Mix and match the measurement capabilities you need in a single instrumentation Console. T402 and T403

line cord powered Consoles are multi-channel capacity cases with a shared universal power supply and

back-panel analog outputs compatible with most data acquisition systems. The T402 and T403 Consoles

accept any 400-Series Modules:

●TS420 Perivascular Flow Module: for in vivo arterial/ venous blood ow

●TS410 Tubing Flow Module: for volume ow of uid in tubing

●SP430 Transonic Scisense Pressure Amplier Module: for arterial/venous blood pressure

BOTH A CONSOLE AND A MODULE ARE REQUIRED TO TAKE MEASUREMENTS.

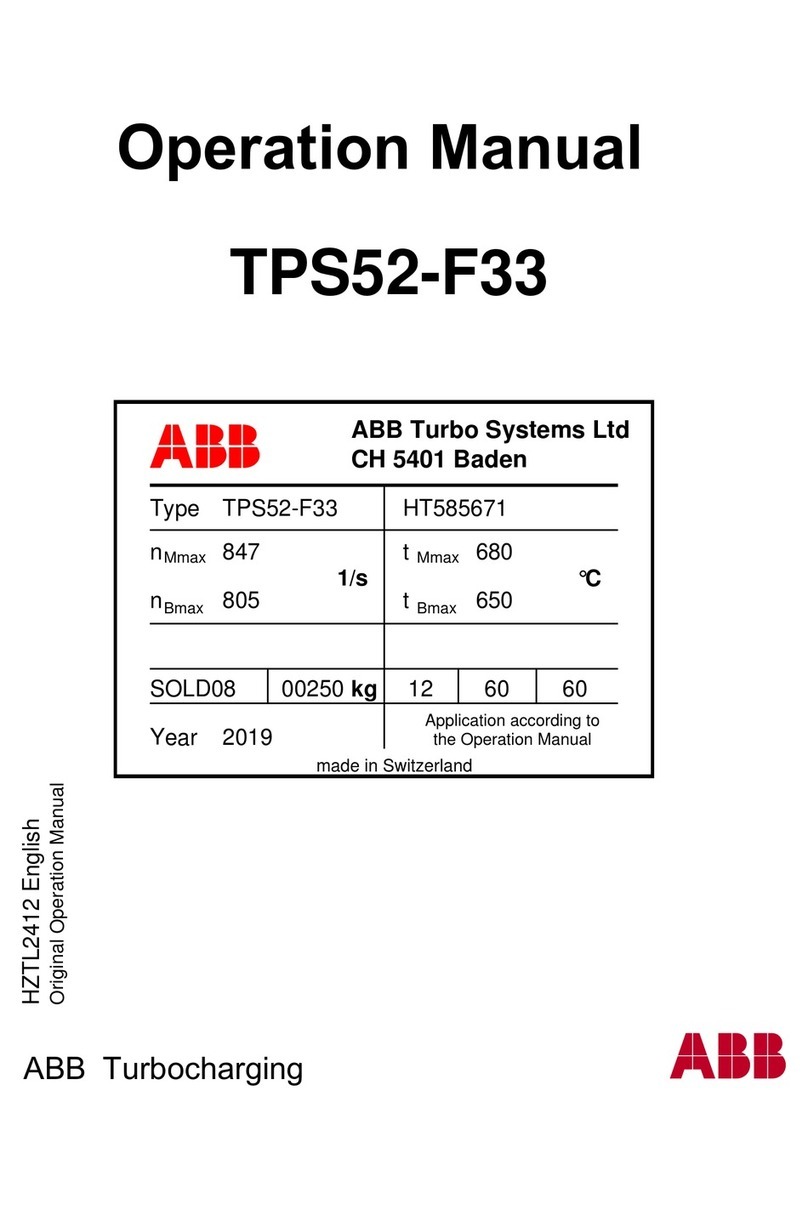

Fig. 1.1: T403 Console with TS410 Tubing Flow Module, TS420 Perivascular Flow Module

and SP430 Transonic Scisense Pressure Amp

2AU-OPR-400Ser-EN,

Rev D

II. T402 & T403 Multi-channel Consoles

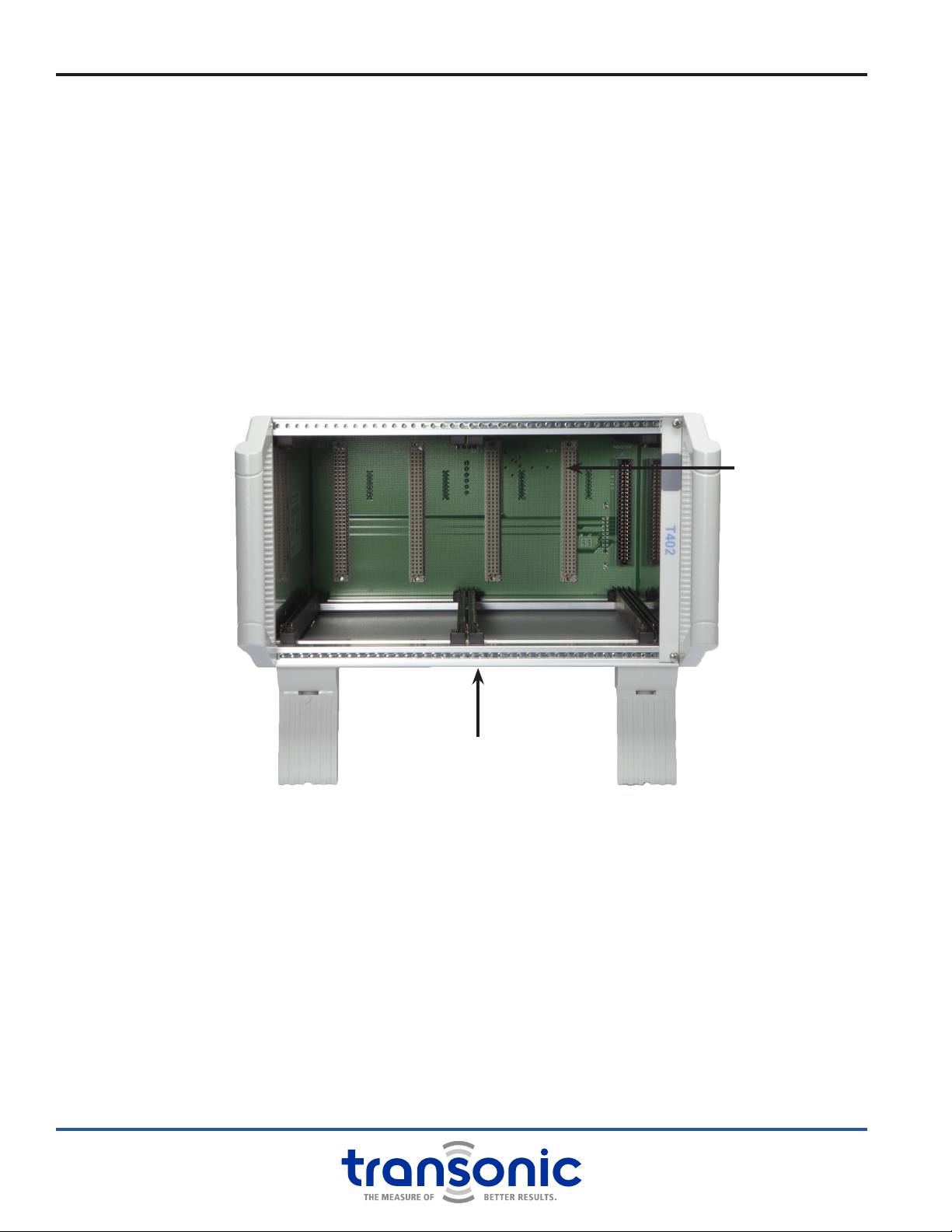

Fig. 2.1: T402 Console without any Modules

All 400-Series Consoles are line powered with convenient carrying handles and tiltable front feet. Consoles

are not stand alone pieces of equipment; a properly connected, compatible Module is required to make

measurements.

A. T402 Multi-Channel Bench-top Console

Four-Bay Console

Holds up to two double-bay wide Modules, one double-bay Module and two single-bay Modules or a

combination.

B. T403 Multi-Channel Bench-top Console

Six-Bay Console

Holds up to three double-bay wide Modules, two double-bay Modules and two single-bay Modules or a

combination.

96-pin DIN connector

Module mounting rails

C. Console Care

It is recommended to keep all Console bays covered during use and storage. Those bays which are not lled

by a Module may be covered with a blank panel cover (available in both single and double width). This will

help keep dust and particulates out of the Console.

Turn the power off before cleaning the Console. Exterior surfaces can be cleaned using a cloth or brush

dampened with soapy water, followed by damp wiping with clear water. For disinfection, the surface can

be damp-wiped with 70% isopropyl alcohol. Do not drip or splash liquids into the Console.

Modules and Consoles exposed to accidental spillage should be unplugged immediately from the power

source. Remove the Module(s). If the spilled uid is potentially corrosive or may leave a residue, carefully

wipe the area of the spill in the Console and the outside of the Module cabinets with a damp cloth

taking care not to ood the internal electronic boards. Compressed air may be used to blow liquid off

components, repeating the rinse and air-blowing as needed.

DO NOT OPERATE THE CONSOLE IN A WET CONDITION; KEEP IT IN A DRY ENVIRONMENT.

AU-OPR-400Ser-EN,

Rev D

3

i. Consoles: Functions & Controls

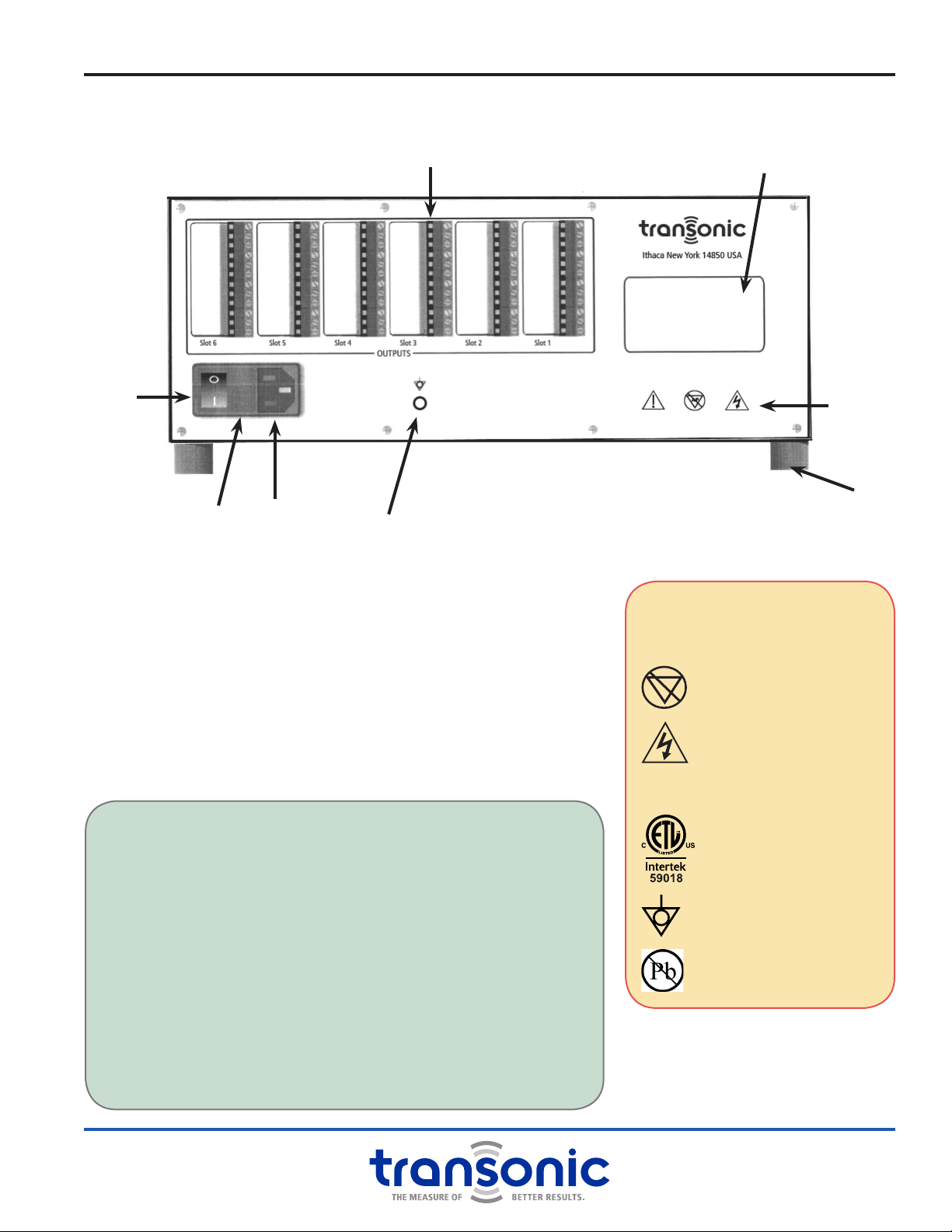

B. Back Panel

POWER ON/OFF SWITCH

Switch power On & Off for the Console and all connected Modules

FUSES

Two user replaceable fuses are located under a protective cover

SCREW TERMINAL BLOCK ANALOG OUTPUTS

12-screw terminal blocks. Outputs dependent on connected

Module. Use general purpose stranded hookup wire to connect

terminals with a data acquisition system.

NOTE: Double-bay wide Modules only use odd numbered slots.

Fig. 2.2: T403 Back Panel

Serial Number and Product

Information Location

Screw Terminal Block Analog Outputs

Power

On/Off

Switch

Fuse

Location Universal

Power Supply Ground Pin

Foot

Legend

WARNINGS/ LABELS

YAttention: Consult

accompanying documents

AP Not category AP equipment

Dangerous Voltage: Service by

trained technicians only

CCE Conformity Mark

ETL Testing Mark: Electrical

Safety Compliance Certication

Equipotentiality pin: Instrument

ground

RoHS Compliant

CHANGING FUSES

The Universal Power Supply is protected from power surges by

two replaceable fuses. These are located on the rear panel of the

Console. Should the Console fail to power on, the fuses may need

to be replaced.

●With the power cord unplugged, gently pry open the tab side of

the black plastic frame to the left of the power switch with a at

screwdriver.

●The cover will open exposing two tabs with arrows. Lift up under

the arrow tabs and pull out the fuse holder.

●If the fuses are blown, replace with 0.8 Amp fast blo fuses

(Bussman # GMA0.8, 250 VAC).

●If the Console still does not power on, contact your local

Transonic®representative.

4AU-OPR-400Ser-EN,

Rev D

iii. Consoles: Specications

WEIGHT/ SIZE

T402 Four Bay Console

●5.21” h x 9.25” w x 12” d

●5.8 lbs

T403 Six Bay Console

●5.21” h x 13.46” w x 12” d

●7.6 lbs

Consoles have side panel handles and tiltable front feet for easy viewing

MODULE COMPATIBILITY

Accepts 400-Series Flow and Pressure Amplier Modules

ELECTRICAL

Console is grounded. If accidentally left ungrounded, line to isolation ground leakage current is less than

50 microamperes.

RoHS COMPLIANT

POWER

AC Input: 100-240 VAC; 50-60 Hz, 50 watts

Fuses: 0.8A fast blo, mfg bussman # GMA0.8, 250 VAC

POWER CORD

USA/Japan: Feller 458-H161 or equivalent

Europe: Feller 199-000 or equivalent

United Kingdom: Feller 209-000 or equivalent

Australia: Feller 198-000 or equivalent

AUDIBLE ALARM

Beeping alarm, non-adjustable volume. Trip level and on/off setting activated through TS410 program.

MODULE CAPACITY

●T402 Four Bay Console: Accepts 2 double-bay, wide Modules of 20 HP width or 4 single bay, narrow

Modules of 10 HP width or a combination of wide and narrow Modules.

●T403 Six Bay Console: Accepts 3 double-bay, wide Modules of 20 HP width or 6 single bay, narrow

Modules of 10 HP width or a combination of wide and narrow Modules.

CONSOLE TO MODULE CONNECTION

96-pin DIN connector on proprietary backplane. Thumb-screw to lock into front panel.

SIGNAL OUTPUTS

Back panel screw terminal block receives output signals from Module(s) via DIN 96-pin connection with

Console; 12 output connections per Module, two dedicated for ground; See Module specications for

signal denition and voltage rating. Use with general purpose hookup wire; stranded wire is preferred.

●Wire: UL 1007 or equivalent; 24 - 14 gauge

●Minimum strip length: 6 mm (0.236 inches)

AU-OPR-400Ser-EN,

Rev D

5

iv. Consoles: Directions For Use

A. Installing Modules

INSTALL ONLY MODULES THAT ARE COMPATIBLE WITH TRANSONIC’S 400-SERIES CONSOLES.

●Be sure the power on the Console is turned off.

●Align wide Flow Modules (TS410 & TS420) with right and left upper and lower rails.

●Align narrow Modules (SP430 Pressure Amplier Modules) on either left or right set of upper and lower

rails.

ALWAYS PLACE SP430 MODULES IN ONE OF THE BAYS (SLOT 3, 4, 5 OR 6)

ON THE RIGHT SIDE OF THE CONSOLE TO ENSURE BEST SIGNAL QUALITY.*

●Slide Module into the Console and push gently on upper and lower portion of the front panel to engage

the rear panel 96-pin connector. The Module will click into place so that the Module is slightly recessed in

the Console.

●Lock into place by tightening the thumbscrew.

●Cover any empty Module slots with a blank panel cover from Transonic®. Align the cover holes with the

console top and bottom horizontal rails and screw into place.

B. Removing Modules

Modules may be removed for transfer to another compatible Transonic® Console or for repair by a qualied

electrical technician authorized by Transonic®.

●Turn power off on the back of the Console.

●Loosen the thumbscrew in the lower left corner of the Module until it is un-threaded and free from the

Console, but not removed from the Module.

●Pull gently on the screw and BNC connector to disengage the rear panel 96-pin connector.

●Slide the Module out of the Console.

●It is recommended to cover any vacant Console bays with a blank panel cover to protect the Console.

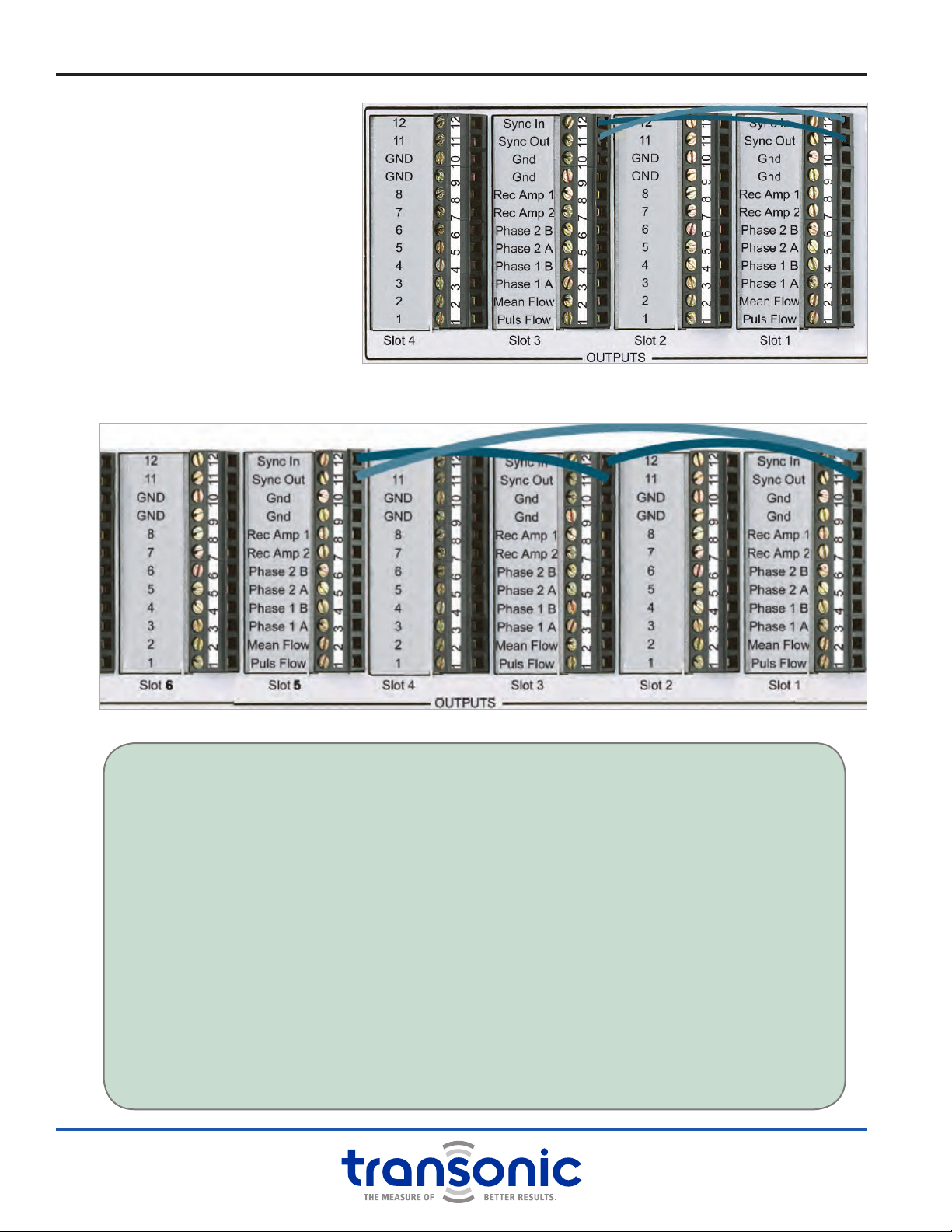

C. Synchronization

The timing of ultrasonic signal bursts for Transonic® Flow Modules and other ultrasonic devices in the

same frequency range should be synchronized to avoid interference between multiple Probes/Sensors

that are within a 20 cm area. Cross-talk between Probe/Sensor signals causes unpredictable errors in ow

measurement such as increases in zero offset and corrupt ow waveforms. No external synchronization is

required for the SP430 Pressure Module.

1. SELF-TRIGGERING

Connect Terminal block pin 11

“Synch Out” to pin 12 “Synch

In” via jumper on same terminal

block. This gives the lowest ow

noise and is selected when a

Flow Module runs by itself, or

multiple Flowprobes/Flowsensors

on multiple Modules run

simultaneously with sufcient

distance (>20 cm) between

Probes/Sensors. NOTE: Flow

Modules are shipped from the

factory in self-trigger mode

unless otherwise specied. Fig. 2.3: Self-triggering Synchronization

6AU-OPR-400Ser-EN,

Rev D

2. SEQUENTIAL TRIGGERING

Interconnect 2 or 3 Flow

Modules on the rear panel with

jumpers between Modules (pins

11 & 12) from “Synch Out” to

“Synch In” as shown (Fig. 2.4)

& (Fig. 2.5). This wiring avoids

the ow offsets that could

result from ultrasonic cross-

talk between adjacent Probes/

Sensors. NOTE: Be careful to

choose the active terminal

connections that correspond to

the installed Modules (TS410 & TS420

use the odd numbered terminal slots).

Fig. 2.4: Sequential Triggering with 2 Flow Modules

Fig. 2.5: Sequential Triggering with 3 Flow Modules

Consoles: Directions For Use

TEST FOR CROSS TALK

(To determine if Modules require sequential triggering)

• Place Flowprobes on vessels or Flowsensors on tubing as they will be used (when < 20 cm apart).

• Record both average and pulsatile ow from each Probe/Sensor simultaneously.

• Disconnect Probe/Sensor-1 from the Module connector leaving Probe/Sensor-2 in place.

• Observe any changes in average ow value or waveform of Probe/Sensor-2.

• Reconnect Probe/Sensor-1 and continue recording from both Probes/Sensors.

• Disconnect Probe/Sensor-2 from the Module leaving both Probes/Sensors in place.

• Observe any changes in Probe/Sensor-1 average ow value or waveform recording.

• If the following conditions occur, sequential-triggering for the Flow Modules is recommended:

• Shift in average ow baseline when 2 Probes/Sensors are used together compared with each

Probe/Sensor used separately.

• Erratic ow wave pulses or shifts in baseline when both Probes/Sensors are used together.

• Unnatural spikes in the waveform.

• Repeat test after sequential jumpers are in place to conrm synchronization (correction of

previously determined issue).

AU-OPR-400Ser-EN,

Rev D

7

III. TS410 Tubing Flow Module

The TS410 Tubing Flow Module measures a single channel of volume ow using ultrasonic transit-time

technology. The Module operates both Inline and Clamp-on Flowsensors for measuring volume ow in

exible plastic tubing circuits. The Flowsensors can be calibrated for and used with most non-aerated

liquids including but not limited to: blood, saline, water, cell culture, physiological buffers, and blood

analogs such as glycerine/water solutions.

The TS410 Module allows the user

to select precongured calibration

options, change the gain to

recalibrate the Flowsensor on-site,

and set parameters and alarms.

Acoustical velocity phase signals are

also available for ultrasound dilution

measurements.

The TS410 Tubing Flow Module must

be properly installed in a compatible

400-Series Console to function.

See”Installing Modules” on page 5

for installation instructions.

A. Compatible Flowsensors

See Tubing Flowsensor yer (RL-28-y) for more detailed specications.

ME-PXL CLAMP-ON TUBING FLOWSENSORS

Easy to operate, clip-on ME-PXL Flowsensors allow for sterility to be maintained in the ow system by

attaching to the outside of the tubing while measuring ow within (Fig. 3.2). Sensors are sized by OD in

1/16” increments for tubing between 1/8” and 1-1/4” OD. Metric sizes are also available for metric tubing.

PXL-Series Flowsensors can be calibrated and programmed for up to 4 different uid, temperature, tubing,

and ow rate combinations. User must specify calibration parameters at purchase.

ME-PXN INLINE TUBING FLOWSENSORS

Inline Flowsensors splice into the tubing circuit providing high sensitivity and independence from tubing

type (Fig. 3.3). Sensors are sized by ID and are available for tubing between 3/64” to 1” ID. PXN Inline

Sensors can be calibrated and pre-programmed for up to 4 uid, temperature, and ow rate combinations.

User must specify calibration parameters at purchase.

Fig. 3.1: T403 Console with two TS410 Tubing Flow Modules

Fig. 3.2: ME-PXL Clamp-on Tubing

Flowsensor on tubing.

Fig. 3.3: Small ME-PXN Inline Tubing

Flowsensor with exible

tubing ends

Fig. 3.4: Large ME-PXN Inline

Tubing Flowsensor with

rigid barbed ends

8AU-OPR-400Ser-EN,

Rev D

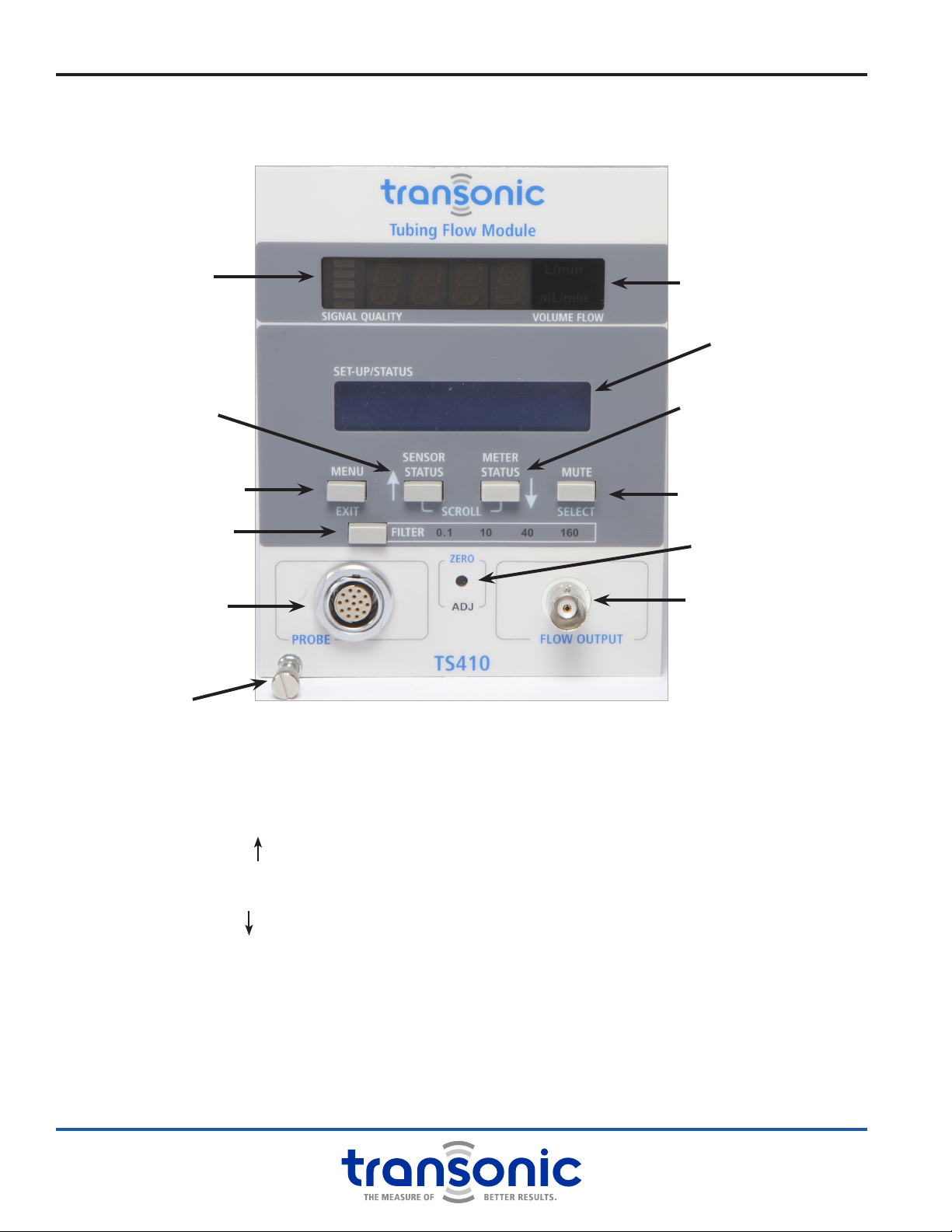

i. TS410 Module: Functions & Controls

A. Front Panel

MENU/ EXIT BUTTON

Enter or exit Menu mode

SENSOR STATUS / SCROLL BUTTON

Displays Sensor calibration and gain

Scrolls up when in Menu mode

METER STATUS / SCROLL BUTTON

Display active Module settings

Scrolls down when in Menu mode

MUTE / SELECT BUTTON

Turns audible alarm on/off

Selects value or enters sub-menu in Menu mode

FILTER SELECTION BUTTON

Sets output lter to 0.1, 10, 40 or 160 Hz

ZERO ADJUST

Adjusts Module to read zero when ow is stopped

PROBE (SENSOR) CONNECTION

Connects Flowsensor or extension cable

BNC FLOW OUTPUT

BNC analog output for mean & pulsatile ow

LED DISPLAY

●Signal quality indicator

●Mean volume ow (mL/min or L/min)

LCD DISPLAY

Module and Sensor settings & Menu mode displays

LED Display

LCD Display

BNC Flow Output

Zero Adjust

Sensor Connection

Menu /

Exit Button

Sensor Status /

Scroll Button

Meter Status /

Scroll Button

Mute /

Select Button

Filter Selection Button

Attachment screw Fig. 3.5: TS410 Front Panel. Blue labels are active when in Menu

mode. White labels are active in Measure and Status modes.

Signal Quality

Indicator

AU-OPR-400Ser-EN,

Rev D

9

B. Modes of Operation

C. Filter Settings

To record instantaneous ow: set the ow

output [Filter] to a frequency at least 10

times the rate of ow pulsation. The digital

sample rate for data recording should be

set to a minimum of 3 times the application

frequency.

D. Analog Outputs

Transonic® Flow Modules output analog signals in the range of -5 volts to +5 volts that are compatible

with most A/D (analog-to-digital) converters of Data Acquisition Systems. The back panel analog outputs

generated by the TS410 Module are listed in the table below:

TS410 Module: Functions & Controls

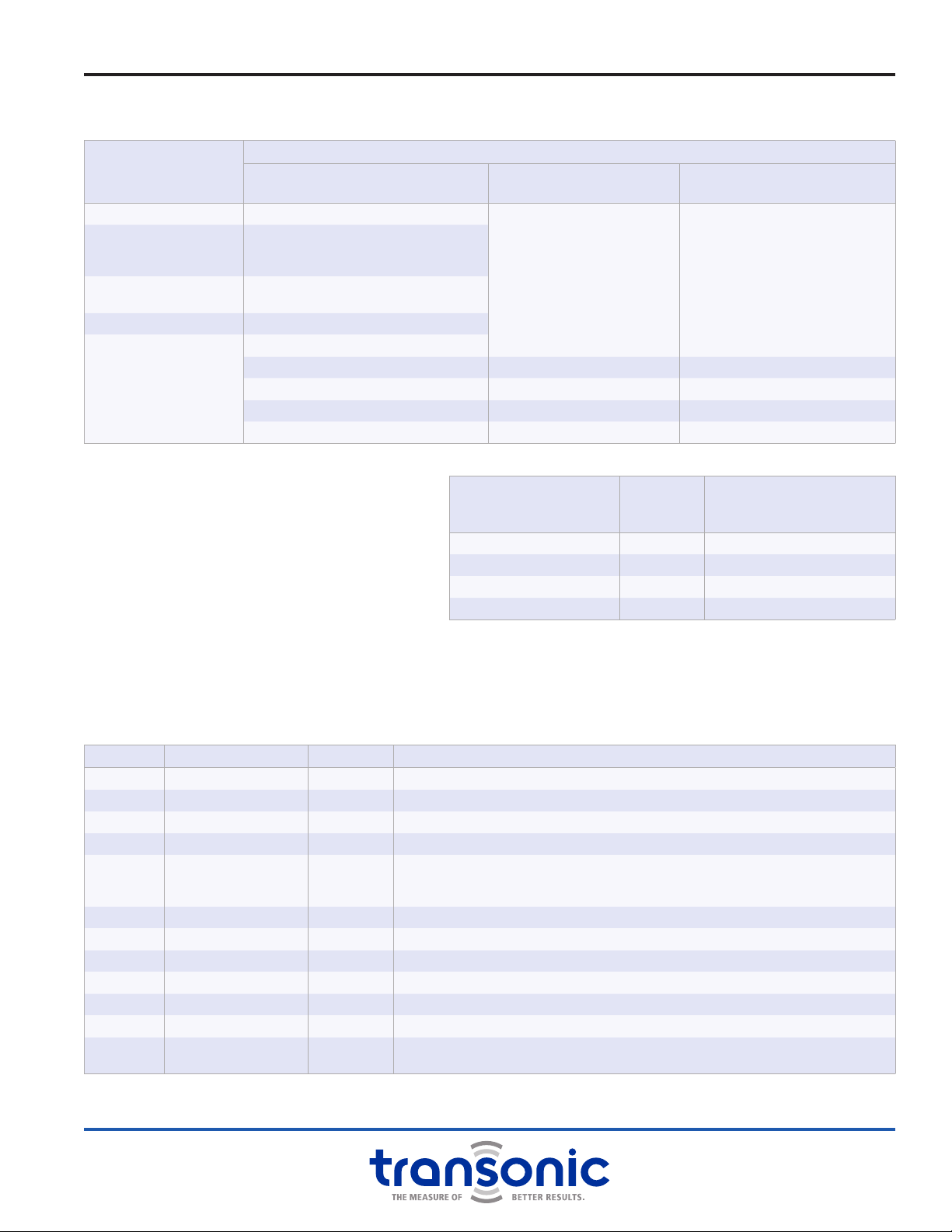

NUMBER TERMINAL NAME VOLTAGE DESCRIPTION

12 Sync In In/Out required for operation; Multi-Module synchronization

11 Sync Out In/Out required for operation; Multi-Module synchronization

10 GND Ground

9GND Ground

8 Rec Amp 1 0 - 4 V Quality of ultrasound transmission for testing Sensor functionality, acoustic coupling

or blockage of ultrasound by air or other impedance mismatch. Can be used in bubble

detection by indicating a drop in signal as air passes through the Flowsensor. 2 V = 100%

7 Rec Amp 2 0 - 4 V Same as Rec Amp 1 for the second pair of transducers. 2 V = 100%

6 Phase 2 B ± 5 V Same as Phase 2 A but offset by +4.5 V or -4.5 V

5 Phase 2 A ± 5 V Same as Phase 1 A but for the second pair of transducers

4 Phase 1 B ± 5 V Same as Phase 1 A but offset by +4.5 V or -4.5 V

3 Phase 1 A ± 5 V Acoustic velocity of uid used in ultrasound indicator dilution studies

2Mean Flow ± 5 V Average volume ow output, ltered at 0.1 Hz

1 Puls Flow ± 5 V Instantaneous pulsatile volume ow output, ltered at 10, 40, or 160 Hz depending on the

Module front panel [Filter] setting. Output defaults to 160 Hz if 0.1 Hz button depressed.

All PXN and PXL Sensors have two pairs of transducers. Flow data is determined from the combination of both pairs while phase and

received amplitude data are separated by transducer pair.

HEART RATE OR

APPLICATION FREQUENCY

LOW PASS

FILTER

SETTING

RECOMMENDED MINIMUM

DIGITAL SAMPLE RATE FOR

DATA ACQUISITION

Average Flow Recording 0.1 Hz 0.3 Hz

Pulsatile to 60 beats/minute 10 Hz 30 Hz

Pulsatile to 240 beats/minute 40 Hz 120 Hz

Pulsatile to 960 beats/minute 160 Hz 500 Hz

MODE

OUTPUTS

LCD DISPLAY

Front Bottom

LED DISPLAY

Front Top

MEAN & PULSATILE FLOW

Front BNC/ Rear Analog

MEASURE Flowsensor model & serial number Bar indicator of signal quality

Average ow in mL/min or L/min

Start-up & error messages

Flow = recorded voltage x scale factor

Bidirectional ow output ± 5 V

SENSOR STATUS

Flowsensor calibration parameters: Fluid

type, temperature, tubing type, tubing

dimensions & % gain if adjusted

METER STATUS Module settings: Invert ow status, 1/4

scale status & active alarm values

MENU: SENSOR CONTROLS Select & change calibration & gain

MENU: METER CONTROLS

Alarm setup

1/4 ow scale Increase ow resolution Scale factor reduced by 1/4

Invert Change sign of ow Reverse signal polarity

Calibrate 0 volt scale 0 mL/min 0 V = 0 mL/min

Calibrate 1 volt scale Scale factor ow value 1 V = scale factor ow

10 AU-OPR-400Ser-EN,

Rev D

ii. TS410 Module: Specications

GENERAL FEATURES

Size: 5.125” h x 4” w x 9.062” d

Weight: 2.3 lbs.

Module ts 2 Console bays (20HP) in T402 or T403

Consoles

Power: Derives input power from 400-Series

Consoles. Installation in a Console is required.

RoHS compliant

OPERATIONAL TECHNOLOGY

Ultrasonic Transit-time

FLOWSENSOR COMPATIBILITY

ME-PXL-Series & ME-PXN-Series

SENSOR CONNECTOR

Front panel 16-pin connector. Accepts research

Inline and Clamp-on Flowsensors and extension

cables with male CC16 or CP16 connectors.

AUTOMATIC ADJUSTMENTS

Sensor size identication and corresponding ow

output ranges. Volume ow calibration and serial

number displayed of active Flowsensor.

LED DIGITAL DISPLAY

4-Digit (14 segment) LED displays Flow / Sensor

data / Error Messages

Bar Indicator Light: Displays received signal for

continuous monitoring of Sensor signal quality.

LCD DISPLAY

One line 16-character alpha numeric LCD displays

program parameters, Sensor and Module status,

alarm settings. Default displays Sensor serial

number.

SET-UP/STATUS & PROGRAM PARAMETERS

STATUS MODE: (White labels) Status message

displayed on LCD.

●Sensor Status: Sensor type & calibration

●Meter Status: Active Flow Module settings &

alarm status

●Alarm Mute: Audible alarm on/off toggle

PROGRAM MODE: (Blue labels)

●Sensor Controls: Select pre-programmed factory

calibration options; Adjust Flowsensor gain to

change calibration on-site.

●1/4 Flow Scale: Increases ow gain by factor of 4

for low ow measurements.

●Calibrate Scale: Sets output to 0 and 1 Volt to

calibrate external recording devices with scale

factor ow.

●Invert Flow: Inverts polarity of analog outputs &

ow display

●Alarms Menu: 3 level program to select, set

thresholds, and activate Alarms for “Low Flow”,

“High Flow” and “Received Signal” interruption

FILTER PROPERTIES

●0.1, 10, 40 Hz: 2nd order Butterworth, with a

third passive pole at 160 Hz

●160 Hz: 3rd order Butterworth

ZERO FLOW ADJUST

Recessed momentary push button to zero ow

reading at stopped ow.

FLOW OUTPUT

Front panel BNC output connector & rear panel

terminal block:

●Pulsatile/Average Volume Flow

●Filtering controlled by front panel selectable

lters

●Voltage range: -5 to + 5 volts

●Output resistance: 500 Ohm

●Full Range for Flow: -5 to +5 V (bidirectional

ows, with range of 5 times scale factor ow)

AUTOMATIC DIGITAL SENSOR ID & CALIBRATION

TS410 reads operational data (size, scale &

calibration) programmed in the Sensor’s EPROM.

ULTRASONIC FREQUENCY RANGE

600 KHz to 14.4 MHz; Sensor size dependent

SIGNAL OUTPUTS

8 accessible signals via 400-Series Console’s back-

panel terminal block: Pulsatile Volume Flow; Mean

Volume Flow; Received Signal Amplitude (2);

Phase (4)

SYNCHRONIZATION

Rear panel jumpers select synchronization mode

●Self-Triggering Mode: “SYNC IN” to “SYNC

OUT” jumper on each Module

●Sequential Triggering Mode: “SYNC IN” crossed

to “SYNC OUT” between Modules

AU-OPR-400Ser-EN,

Rev D

11

iii. TS410 Module: Functional Tests

These functional tests are suggested to acquaint a new user with Transonic® TS410 Flow Modules and

Transonic® Tubing Flowsensors and to check for damage incurred during shipment. If the apparatus does

not function as described during this initial operation, please call Transonic®customer service or your

authorized Transonic®provider or sales representative.

A. Flow Module Set-up

1) Verify that the Console’s rear panel synchronization terminals are properly connected (see Console

synchronization instructions, page 5).

2) Connect Console power cord to grounded power receptacle. NOTE: Do not operate unless Console is

electrically grounded via supplied power cable.

3) Turn on power switch on back panel of Console.

a) Digital Display will scroll “TSI ✓” and display “NO.PR.” The LCD will read “TS410 Flowmeter.” Pressing

[Menu] and [Status] buttons will change the LCD display to “No Sensor.” NOTE: No parameters

may be changed without a connected Sensor.

4) Connect a Tubing Flowsensor to the front panel mounted self-aligning 16-pin connector. The digital

display will scroll Sensor size and series and signal coupling status “No Sig.” (no signal) until liquid is

present in the Flowsensor. The LCD will display Sensor serial number.

a) When liquid is present in the Flowsensor, the digital display will report average volume ow in

milliliters/minute or liters/minute. Acoustic signal quality is displayed by the number of illuminated

bars on the digital display and can be continuously monitored for the presence of air, or change in

Flowsensor performance.

B. Flowsensor Zero Offset

1) Connect a Flowsensor to the Tubing Flow Module and insert/clamp-on to the tubing circuit. Allow about

5 minutes for the Sensor to stabilize.

2) Press [Sensor Status] to view the active calibration parameters.

a) If the calibration parameters on the display do not match the system conditions use the [Menu] to

choose the correct calibration combination. Incorrect calibration parameters may result in a high or

unstable zero offset.

3) With the tubing lled with uid and the ow stopped the ow reading should be zero or close to zero. If

there is zero offset, it may be nullied by depressing the [Zero Adj] button using a pointed instrument

such as the tip of a pen or pencil. The LED Display will ash “Zero Adj” for about 10 seconds and the

“Adj” light will be illuminated to indicate that the offset has been adjusted. NOTE: Once the zero offset

has been adjusted, it cannot be adjusted again unless the Sensor is disconnected or the Module turned

off. Unplugging the Sensor or turning off the Module will cause the zero offset to reset.

SIGNAL STRENGTH SIGNAL QUALITY BAR DISPLAY “REC AMP” VOLTAGE

FROM REAR PANEL

over 80% Good 5 bars lit over 0.8 V

60% to 80% Good 4 bars lit

proportional reading

30% to 60% Good 3 bars lit

20% to 30% Low 2 bars lit

10% to 20% Low 1 bars lit

under 10% No Signal no bars lit under 0.1 V

12 AU-OPR-400Ser-EN,

Rev D

TS410 Module: Functional Tests

C. User Adjusted Gain

The user may adjust the calibration gain if using different uids, temperatures or variables from the pre-

programmed calibrations.

1) Set up the tubing calibration system with the desired parameters.

2) Choose the calibration setting which most closely matches the system setting.

3) Nullify the zero offset as described in “Flowsensor Zero Offset” on page 11.

4) Preform a multi-point calibration to create a calibration curve and determine the % correction required.

Flowsensor calibration instructions are found in RL-34-tn.

5) [Select] “User Adj Gain” to alter the factory calibration by percent (%) according to the results from

the previously performed calibration. NOTE: This new calibration gain will be stored in the Flowsensors

EPROM and becomes the default calibration until reset to factory default of 100%. Calibration selections

which have user adjusted gains have a % symbol next to them in the “Sensor Controls” menu and a *

star indicating that they have been adjusted.

D. Calibrating a Data Acquisition System

The calibration reference signals are located in the [Menu] (see ”Program Menu” on page 13 for Menu

setup diagram). [Select] “Meter Controls” then [Scroll] to “Calibrate Scale” and press [Select]. The “0

Volt Scale” and “1 Volt Scale” settings are provided to generate 0 and 1 Volt reference scale signals for

calibrating a data acquisition system.

1) Connect the data acquisition system to either the front or rear analog outputs.

2) Follow the data acquisition provider instructions for a 2-point calibration.

3) For reference point “zero” (0 volts), [Select] “0 Volt Scale” and record the output voltage. NOTE: A star

(*) appear when the signal is active. NOTE: In the “Calibrate Scale” menu either “0 Volt Scale” or “1 Volt

Scale” is always active. Exiting the menu deactivates the calibration signal.

4) For reference point “1 volt”, [Scroll] to “1 Volt Scale” and press [Select] and record the voltage. The

value of the 1 volt reference signal is the Sensor scale factor that is displayed on the LED display of the

Module. NOTE: The Flow Module can read up to ve times the scale factor value.

5) If the scale is changed (Standard Flow vs. 1/4 Scale Flow) during the experiment, the 1 volt reference scale

value in the data acquisition system must be reset. The voltage range for the Flow Module remains the

same, but the scale factor changes. Repeat the calibration sequence above whenever the ow range

setting has been changed.

AU-OPR-400Ser-EN,

Rev D

13

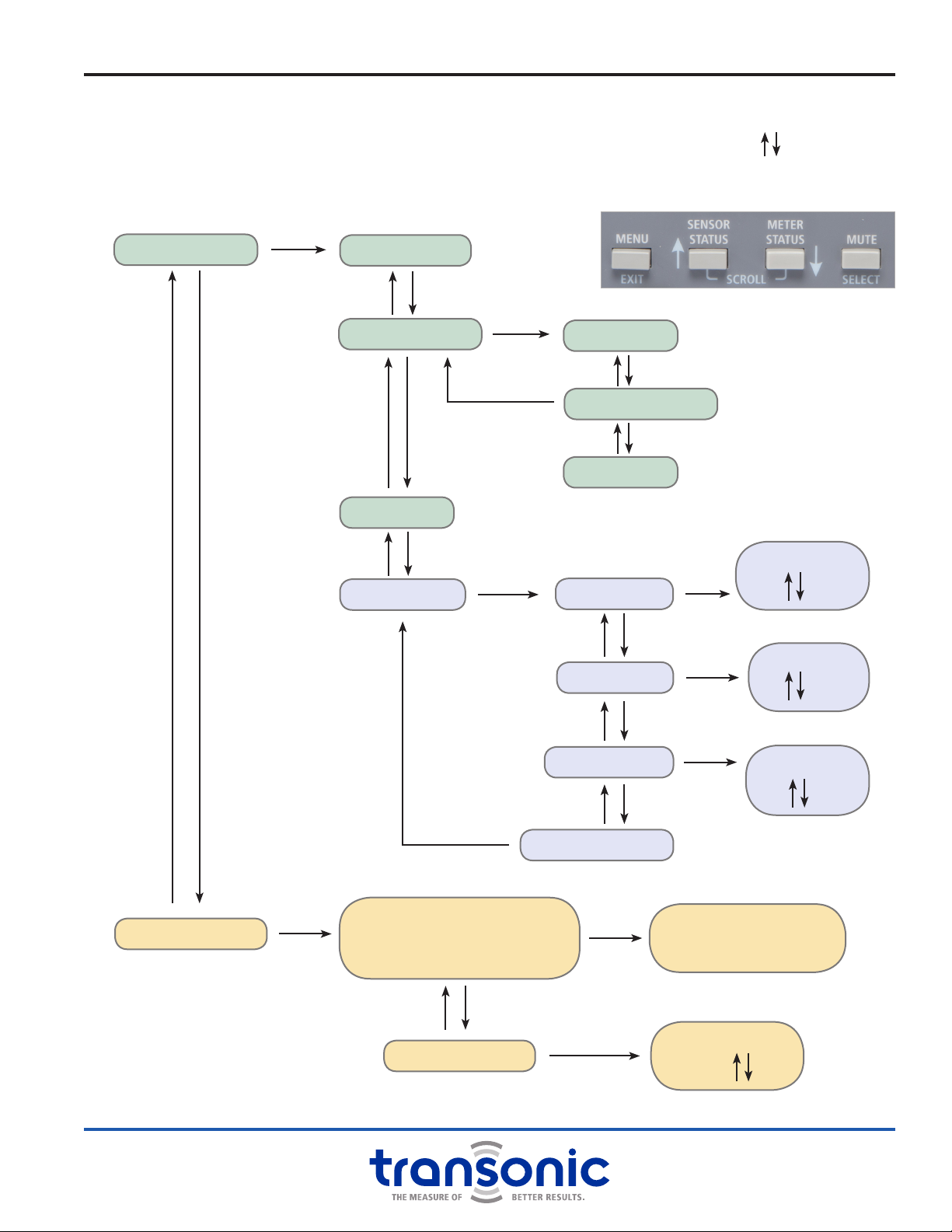

METER CONTROLS

SENSOR CONTROLS

1/4 FLOW SCALE

CALIBRATE SCALE

INVERT FLOW

ALARMS MENU

“CALIBRATION CHOICES”

(Up to 4 factory programmed)

USER ADJ. GAIN

Display selection

& select as active

calibration

SENSOR GAIN

100%

0 VOLT SCALE

1 VOLT SCALE

TO METER OPTIONS

LOFLO ALARM

LO FLOW

min

HIFLO ALARM

HI FLOW

max

REC SIG ALARM THRESHOLD

%

TO METER OPTIONS

A. Program Menu

Press [Menu] to enter the program, this makes the blue button labels active. Use arrows to [Scroll]

through menus and to set values for alarms and gain (pressing and holding scrolls faster). Press [Select]

to enter menus or toggle settings on and off. A star (*) indicates that a selection is made/active. Return to

Measure mode at any point using the [Exit] button.

iv. TS410 Module: Directions For Use

[Select] on*

[Select] on*

[Select] on*

[Select] on*

[Select] on*

[Select] on*

[Select] on*

[Select] on*

14 AU-OPR-400Ser-EN,

Rev D

TS410 Module: Directions For Use

B. Alarms Menu

The TS410 has 3 alarm settings: Low Flow, High Flow and Received Signal. Alarm threshold values are set in

the Program mode. Use the [Scroll] buttons to adjust the threshold from the default value. Default values

are scaled by Sensor size. Alarms are turned on/off in the Program mode using [Select]. NOTE: A star (*)

indicates an alarm is set.

ALL ALARMS TURN OFF AND RESET TO DEFAULT VALUES WHEN SENSOR IS DISCONNECTED OR MODULE TURNED OFF.

When an alarm condition is met, the LCD will ash alarm messages for the specic condition. The LCD

will continue to ash until the condition ends. The message will continue to be displayed on the LCD (not

ashing) to show that the condition occurred. Clear the LCD by pressing any button. NOTE: The button

pressed will also perform its regular function in addition to clearing the LCD screen.

NOTE: The alarm can be re-triggered if the condition is met again without having to reset the alarm in the

program mode. If more than one alarm is set and triggered simultaneously (ie low ow and received signal)

a joint alarm message is displayed. If more than one alarm is triggered sequentially only the most recent

alarm message will be displayed.

If the audible alarm is turned on, an alarm will sound a non adjustable beeping when the condition is met.

The audible alarm will stop if the condition ends. Press the [Mute] button to disable (or enable) the audible

alarm.

NOTE: The mute button is a toggle ON/OFF and must be reset to sound if muted.

LOW FLOW ALARM “LOFLOW”

The low ow alarm is activated when the pulsatile ow signal is lower than the set threshold level. Default

value is minimum ow value (negative ow not zero ow) that the Sensor is specied to detect.

HIGH FLOW ALARM “HIFLOW”

The high ow alarm is activated when the pulsatile ow signal is higher than the set threshold level.

Default value is maximum ow value (positive ow) that the Sensor is specied to detect.

RECEIVED SIGNAL ALARM “REC SIG ALARM”

The Received Signal Alarm is activated when the acoustic signal falls below the set threshold. This alarm can

be used as a gross bubble alarm or detector. The signal amplitude will fall or be interrupted by air or gas

bubbles in the ow circuit. Default value is 0%.

C. Use of Clamp-on Flowsensors

SENSOR SELECTION

Flowsensor size and calibration is determined by the OD of the tubing on which it will be used. Each

Transonic® Clamp-on Tubing Flowsensor is custom calibrated for use on particular tubing (silicone rubber,

latex, polyurethane, or polyvinyl chloride {PVC}). Use on tubing other than specied generally yields

inaccurate measurements and may cause erratic zero baseline drift.

SENSOR CALIBRATION

Flowsensors are precalibrated for a particular tubing and liquid at a certain temperature (see Flowsensor’s

calibration certicate). Recalibration is necessary for accurate measurements at other temperatures or in

other liquids. If a more precise zero baseline than that specied is needed, the Module must be zeroed by

stopping the ow momentarily.

AU-OPR-400Ser-EN,

Rev D

15

SITE SELECTION

The Flowsensor should be applied on straight tubing segments, about 10X the ID from side branches to

produce measurements within its accuracy specications. The best application site for the Flowsensor is

a point well below the highest elevation of the tubing (where gas bubbles might lodge). The Flowsensor

will deform the tube slightly. If the tubing site becomes permanently deformed at one clamping position,

choose another site to achieve better ultrasonic (acoustic) coupling.

TUBING PREPARATION

Apply a layer of petroleum jelly, or silicone grease over the tubing surface to enable ultrasonic transmission

between tube and Sensor. NOTE: Water-based ultrasonic gels should not be used for coupling Clamp-on

Tubing Sensors since they dry out and may build up on the transducer faces. This can cause additional

offset in the measurement and decrease signal quality.

SENSOR APPLICATION

To apply the Flowsensor to tubing, open the Flowsensor's hinged lid, insert lubricated tubing into the

sensing cavity, and close the lid. Fit should be tight, with the full tubing cross section contacting all inner

surfaces of the sensing window. Once the tubing is lled with the liquid to be measured, Flowsensor

operation and signal quality can be conrmed on the Module. Check that the signal quality bars are

illuminated. Low signal quality may indicate that an air or gas bubble is lodged in the tube. Since gas

bubbles block ultrasonic transmission, tilt the tubing and Flowsensor vertically before operating the

Module to ush any bubbles from the sensing window.

FLOW MEASUREMENTS

If using a data acquisition system, calibrate the system prior to beginning measuring. The digital display

presents the average volume ow value in mL/min or L/min. Choose the appropriate [Filter] setting for

average or pulsatile applications.

INVERT FLOW

The arrow on the Sensor points in the direction of positive ow. If the Sensor is installed backwards the

Invert function can change the polarity of the ow outputs without changing the Sensor position. Under

the [Menu], [Select] “Invert Flow” to change the display and outputs to the correct polarity.

LOW FLOW (1/4 SCALE)

Under the [Menu], [Select] “1/4 Flow Scale” to increase the ow gain by a factor of four and increased

sensitivity at low ow rates. The maximum value at the low ow scale is ve times the 1 volt scale value.

Before switching to “1/4 Flow Scale” check to ensure that peak pulsatile ows will not be cut off as this will

cause inaccurate readings. NOTE: When changing the ow scale be sure to recalibrate the data acquisition

system as the 1 volt scale value will change.

CLEANING & STERILIZATION

A Clamp-on Tubing Sensor may be cleaned by wiping with a solution of soap and water (60°C, 140°F).

Because no physical contact is required between the liquid under observation and the Flowsensor,

sterilization is not usually necessary. Standard cold (ethylene oxide) gas sterilization may be used (≤ 60°C,

140°F). The sterile-tubing Flowsensor can be damaged by saline immersion or wet storage and should not

be boiled, autoclaved, or sterilized by cold liquid sterilization.

TS410 Module: Directions For Use

16 AU-OPR-400Ser-EN,

Rev D

D. Use of Inline Flowsensors

SENSOR SELECTION

Flowsensor size is determined by the tubing with which it will be used. Inline Flowsensors are sized based

on the ID of the system tubing.

SENSOR CALIBRATION

Flowsensors are precalibrated for a particular liquid at a certain temperature (see Flowsensor’s calibration

certicate). Recalibration is necessary for accurate measurements at other temperatures or in other liquids.

If a more precise zero baseline than that specied is needed, the Module must be zeroed by stopping the

ow momentarily.

SITE SELECTION

The Flowsensor should be inserted into straight tubing segments about 10X the ID from side branches to

produce measurements within its accuracy specications. The best application site for the Flowsensor is a

point well below the highest elevation of the tubing (where gas bubbles might lodge).

SENSOR APPLICATION

Inline Flowsensors splice into exible tubing circuits. Larger Sensors (4-25PXN) with barbed ends insert into

the tubing. Tubing clamps may be used in high pressure applications to ensure a secure t. Small Sensors (1-

3PXN) with exible tubing ends may be spliced in using a rigid piece of tubing or expanded over the circuit

tubing (see RL-31-tn for PXN installation instructions).

Once the tubing & Sensor are lled with the liquid to be measured, Flowsensor operation and signal quality

can be conrmed on the Module. Check that the signal quality bars are illuminated. Low signal quality may

indicate that an air or gas bubble is lodged in the Sensor. Since gas bubbles block ultrasonic transmission,

tilt the tubing and Flowsensor vertically before operating the Module to ush any bubbles from the

sensing window.

FLOW MEASUREMENTS

If using a data acquisition system, calibrate the system prior to beginning measuring. The digital display

presents the average volume ow value in mL/min or L/min. Choose the appropriate [Filter] setting for

average or pulsatile applications.

INVERT FLOW

The arrow on the Sensor points in the direction of positive ow. If the Sensor is installed backwards the

Invert function can change the polarity of the ow outputs without changing the Sensor position. Under

the [Menu], [Select] “Invert Flow” to change the display and outputs to the correct polarity.

LOW FLOW (1/4 SCALE)

Under the [Menu], [Select] “1/4 Flow Scale” to increase the ow gain by a factor of four and increased

sensitivity at low ow rates. The maximum value at the low ow scale is ve times the 1 volt scale value.

Before switching to “1/4 Flow Scale” check to ensure that peak pulsatile ows will not be cut off as this will

cause inaccurate readings. NOTE: When changing the ow scale be sure to recalibrate the data acquisition

system as the 1 volt scale value will change.

CLEANING & STERILIZATION

An Inline Tubing Sensor may be cleaned by wiping with a solution of soap and water (60°C, 140°F). The

inside of PXN Flowsensors may be cleaned with a soft brush. Care should be taken to avoid scratching the

inside surface of the tube. Standard cold (ethylene oxide) gas sterilization may be used (≤ 60°C, 140°F).

The tubing Flowsensor can be damaged by wet storage and should not be boiled, autoclaved, or sterilized

by cold liquid sterilization. NOTE: Do not use alcohol on small (1-3PXN) Flowsensors as it will damage the

exible tubing.

TS410 Module: Directions For Use

This manual suits for next models

5

Table of contents

Other Transonic Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Jct

Jct JES-360Ex operating manual

Grundfos

Grundfos PS.R.05-17 instructions

GSi

GSi DMC Design III Series owner's manual

NCMT

NCMT MAKINO A100-5XR-CD Operator's manual

Gorlitz

Gorlitz GO 68HD Series Operating & maintenance instructions

PCB Piezotronics

PCB Piezotronics 1630-03C Installation and operating manual