Travis Industries, Inc.

Model: Liberty

Report Number:0028WS065E

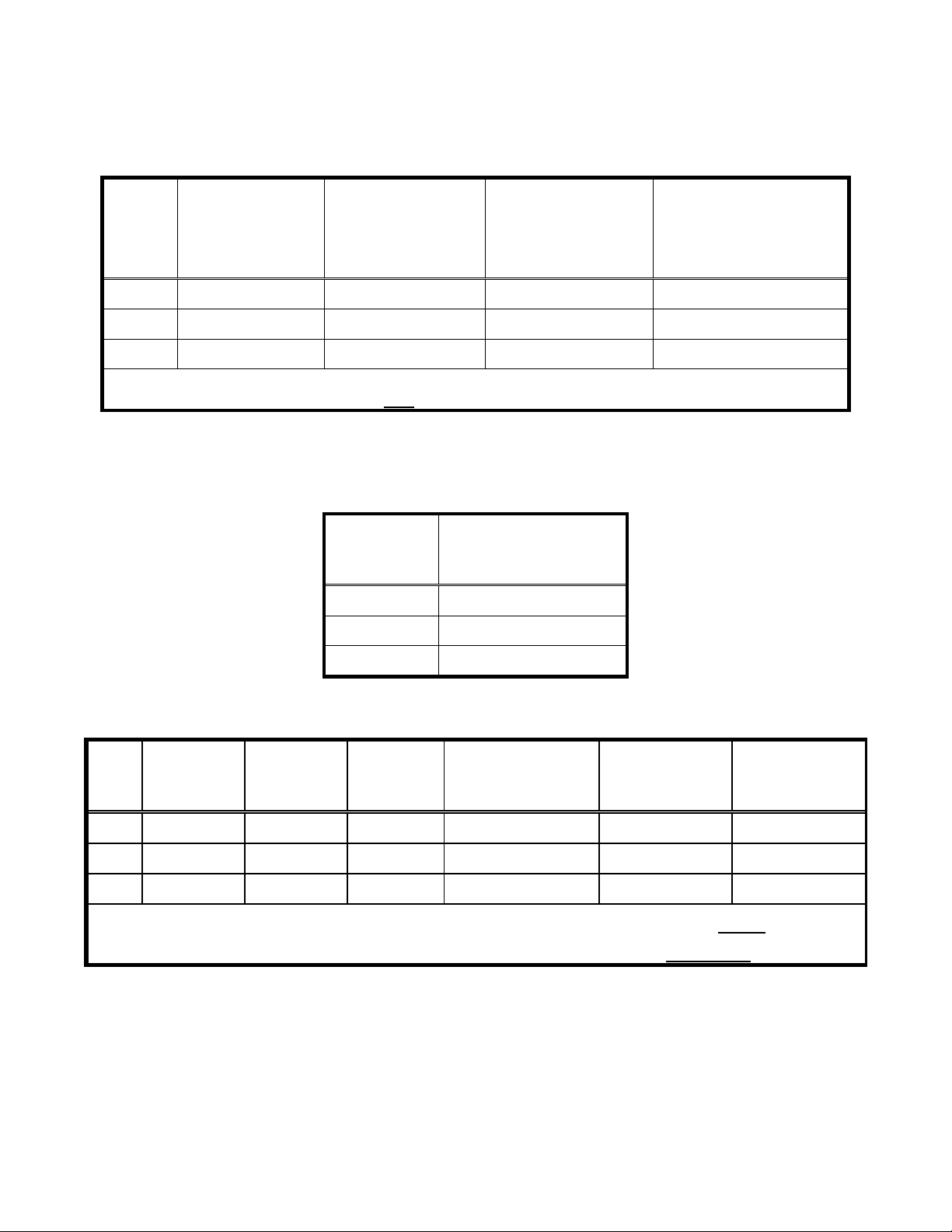

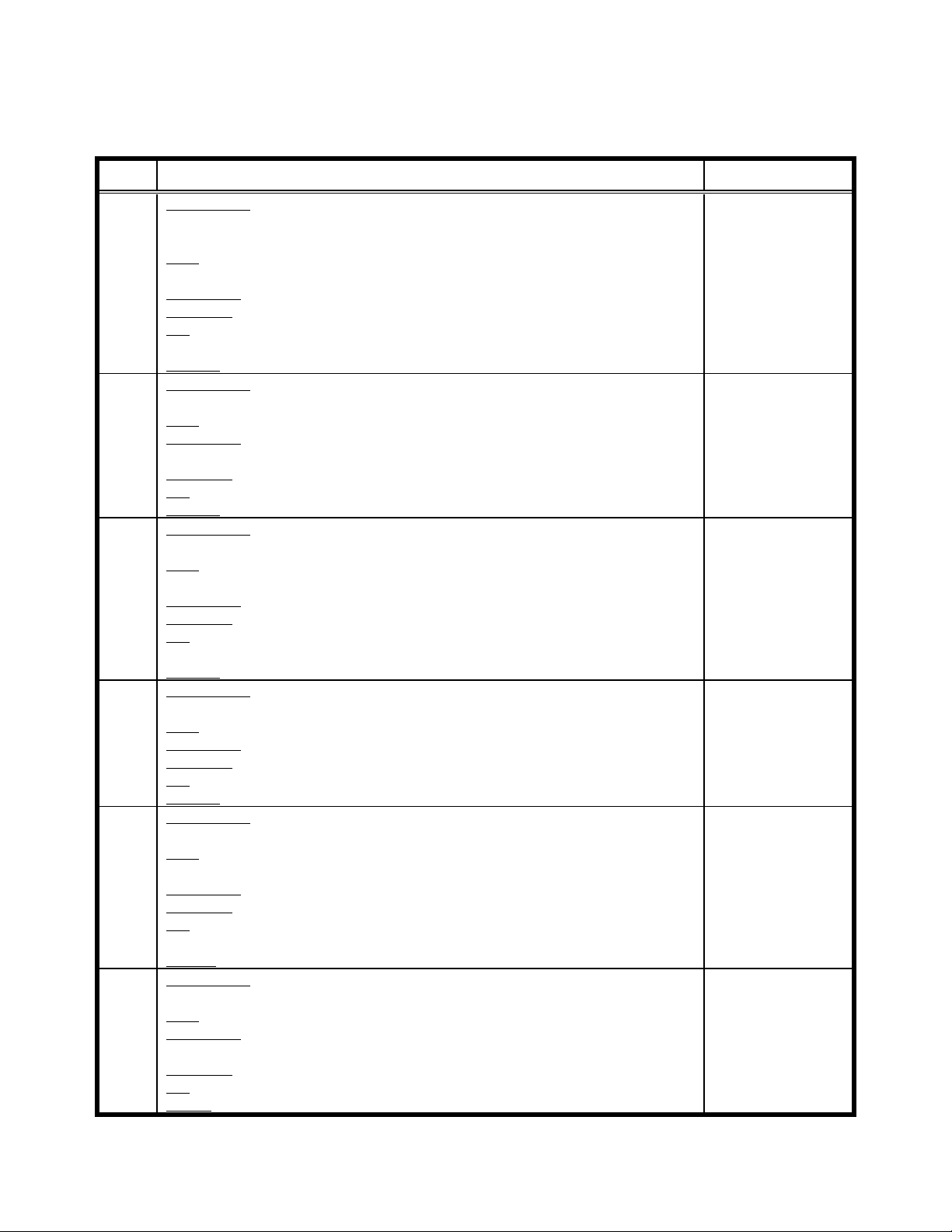

INDIVIDUAL RUN SUMMARIES

Run 1 - Test procedures followed to produce a high burn rate with a primary air setting of

fully open. Observed burn rate was calculated at 4.61 kg/hr. Emissions results

were calculated using particulate sampling from kindling, start-up fuel, and test

fuel load combined (cold to hot). Burn rate, and efficiency were calculated using

data from the test fuel load only (hot to hot). No sampling anomalies occurred,

this test run was determined to be valid for inclusion in the weighted average.

Run 2 - Test procedures were followed to produce a low burn rate with a primary air

setting of full closed. Observed burn rate was calculated at 1.36 kg/hr. Emissions

and efficiency results were calculated using a hot to hot burn cycle, a coal bed

generated by the high burn conducted in test one was used. Prior to starting run 3

a fire box volume drawing was submitted showing a volume larger than that

calculated by the testing laboratory. After review of the document it was agreed

that the larger volume calculated by a computer drawing program was accurate.

This caused one of the fuel load pieces used in the fuel load to be outside the

acceptable weight range. Due to this, test number 2 was considered invalid and

not used in the weighted average.

Run 3 - Test procedures followed to produce a high burn rate with a primary air setting of

fully open. Observed burn rate was calculated at 4.88 kg/hr. Burn rate was

calculated using data from the test fuel load only (hot to hot). No sampling

occurred during this test, it was conducted to generate a coal bed for test number

4.

Run 4 - Test procedures were followed to produce a medium high burn rate with a

primary air setting of 0.125”(1/8”) open. Observed burn rate was calculated at

1.74 kg/hr. Emissions and efficiency results were calculated using a hot to hot

burn cycle, a coal bed generated by the high burn conducted in test three was

used. No sampling anomalies occurred; this test run was determined to be valid

for inclusion in the weighted average.

Run 5 - Test procedures followed to produce a high burn rate with a primary air setting of

fully open. Observed burn rate was calculated at 5.73 kg/hr. Burn rate was

calculated using data from the test fuel load only (hot to hot). No sampling

occurred during this test; it was conducted to generate a coal bed for test number

6.

Run 6 - Test procedures were followed to produce a low burn rate with a primary air

setting of full closed. Observed burn rate was calculated at 1.18 kg/hr. Emissions

and efficiency results were calculated using a hot to hot burn cycle, a coal bed

generated by the high burn conducted in test one was used. No sampling

anomalies occurred; this test run was determined to be valid for inclusion in the

weighted average.