TRC 1000 Series User manual

Service Manual for 1000

Series Strip cutters

Rev 1.1 6/6/22

2

Table of Contents

Safety Information for TRC-1000 Strip Cutters .................................................................................... 4

Specifications....................................................................................................................................... 5

Model Identification............................................................................................................................ 6

Nomenclature ..................................................................................................................................... 7

Setting Up and Using your new TRC 1000 Series Strip Cutters .......................................................... 8

Model HC4 and HC7 Setup............................................................................................................. 8

Start Up Procedures ......................................................................................................................... 8

Keyboard Commands................................................................................................................... 10

Entering A program ....................................................................................................................... 10

Feed Rate ................................................................................................................................... 10

Length ......................................................................................................................................... 10

Cut Time ...................................................................................................................................... 11

How Many................................................................................................................................... 11

Operating Screen....................................................................................................................... 12

Stopping the Machine................................................................................................................... 12

Model CC4 and CC7 Setup ............................................................................................................. 12

Start Up Procedures........................................................................................................................... 13

Keyboard Commands................................................................................................................... 13

Entering a Program........................................................................................................................ 13

Feed Rate ................................................................................................................................... 13

Length ......................................................................................................................................... 14

Cut Time ...................................................................................................................................... 15

How Many................................................................................................................................... 15

Stopping the Machine ............................................................................................................... 15

Model HC4-FS Setup.......................................................................................................................... 16

Start Up Procedures........................................................................................................................... 16

Periodic Maintenance and Repairs................................................................................................. 16

Tools needed:................................................................................................................................. 17

Linear Shafts/Bearings and Air Cylinder shafts:............................................................................ 18

Drive and Tension Rollers ............................................................................................................... 18

Springs:............................................................................................................................................ 20

Drive Belt and Pulleys:.................................................................................................................... 21

Cutting Blades and Cutting Plates ............................................................................................... 22

3

Hot Knife Cutters: ........................................................................................................................... 22

Hot Knife Blade Adjustment .......................................................................................................... 24

Cold Knife Cutters: ......................................................................................................................... 25

Cold Cutter Blade Adjustment ..................................................................................................... 25

Replacing an air cylinder .............................................................................................................. 26

Adjusting the Air Valve .................................................................................................................. 27

Feed Roller Replacement ............................................................................................................. 29

Top Roller Replacement................................................................................................................ 30

Spring Tension Adjustment ............................................................................................................ 30

Drive Belt adjustment..................................................................................................................... 31

Drive Motor Replacement ............................................................................................................ 32

Thermostat, heater cord and heating element testing.............................................................. 33

Heating Element Replacement.................................................................................................... 34

Integrated Cutoff Switch Installation Instructions ........................................................................ 36

Adjusting LCD Contrast ................................................................................................................. 39

Control Panel Calibration.............................................................................................................. 40

Calibration Method 1................................................................................................................. 40

Calibration Method 2................................................................................................................. 40

Replacing Main Fuse ..................................................................................................................... 41

Type 1 .......................................................................................................................................... 41

Type 2 .......................................................................................................................................... 43

Replacing Circuit Board Fuse for Drive Rollers ............................................................................. 43

Troubleshooting ................................................................................................................................. 45

Controller Troubleshooting......................................................................................................... 45

Cutter Troubleshooting .............................................................................................................. 48

Checking for Electrical problems ................................................................................................. 51

Voltage checks with Power to panel........................................................................................... 51

Circuit board removal ................................................................................................................... 52

Control cable test .......................................................................................................................... 52

4

Safety Information for TRC-1000 Strip Cutters

Congratulations on the purchase of your new TRC 1000 Strip cutter. TRC Industries has been

manufacturing and servicing the TRC 1000 series strip cutters since 1993. These cutters are

solidly built, easy to use machines that will last a lifetime with proper care and maintenance.

They are still machines however, and great care must be taken to ensure safe and satisfactory

operation. The following Safety information should be read and understood before attempting

to operate machine. Careless operation can lead to injury and downtime.

1. Make sure the outlet that supplies electricity to your TRC-1000 is properly wired,

grounded and overload protected. We recommend checking with a qualified

electrician when sizing breakers, as your individual needs may vary. The TRC 1000 series

uses less than 10 amps of current.

2. The Cutter Head and Control Panel should be placed on a sturdy table free from

wobble or other movement.

3. Care should be taken with loose fitting sleeves and long hair when around the cutting

unit's feed rollers.

4. Unit should be disconnected from the electrical and air supply before any service work

is performed.

5. Unit should be allowed to cool off for a minimum of 2 hours before any service work is

performed.

6. Only qualified personnel should be allowed to perform maintenance or repairs.

7. Unit should not be operated without air regulator.

8. Material should be removed from cutting unit when not in operation. This prevents

material from overheating, melting, or warping and contacting hot parts of the

machine.

9. Thermostat should be turned to the OFF position when not in operation. The hot knife

blade and block temperature will exceed 900 degrees F.

10. Metal tools absolutely not be used to unjam cutter or knife when unit is connected to

electricity.

11. Bare wires and connections should be immediately repaired or replaced before

operation continues.

12. Only factory recommended replacement parts should be used on the TRC-1000.

5

Specifications

Model

Weight

Dimensions

Power

Requirements

Air

Requirements

TRC 1000 4.5”

Hot cutter

14” x 7” x 14”

120VAC Single

Phase

Min. 40 PSIG

TRC 1000 7”

Hot Cutter

14” x 11” x 14”

120VAC Single

Phase

Min. 40 PSIG

TRC 1000 4.5”

Cold Cutter

14” x 7” x 14”

120VAC Single

Phase

Min 60 PSIG

TRC 1000 7”

Cold Cutter

14” x 11” x 14”

120VAC Single

Phase

Min 60 PSIG

TRC 1000 5”

Alternating

Angle Cutter

18” x 10” x 14”

120VAC Single

Phase

Min. 40 PSIG

TRC 1000

Prepuller

11” x 14” x 8”

120VAC Single

Phase

N/A

TRC 1000 Foot

Switch Cutter

18 lbs.

12” x 8.5” x 10”

120VAC Single

Phase

Min. 40PSIG

Control Panel

(All)

10” x 14” x 6”

120VAC Single

Phase

N/A

35 lbs

35 lbs

40 lbs

35 lbs

50 lbs

25 lbs

7 lbs

6

Model Identification

All the cutters in our first generation of cutting machines (spanning from 1993 until the time of

this publication) are part of the “TRC 1000 Series.” Model numbers beginning with the “HC”

designation are Hot Cutters. Models beginning with the “CC” Designation are cold cutters. The

following digits, either a “4” or a 7” identifies the machine as either a 4.5” or a 7” cutter,

respectively. The next two letters, either a “CS” or “VS” identify the controller unit as either a

Constant Speed or a Variable Speed controller.

Therefore, “TRC 1000 CC4-VS” would identify a 1000 Series Cold Cutter, 4.5” cutter, with a

Variable Speed Controller. Similarly, “TRC 1000 HC7-CS” would identify a 1000 series Hot cutter

in 7” cutting capacity with a Constant Speed Control panel.

It is worth noting that Cutter Heads can be used with either Variable Speed (VS) Controllers or

Constant Speed (CS) Control Panels.

Other Identifiers that may be used include the following:

•AA –Alternating Angle Model

•ICO –Integrated Cutoff Switch Equipped Model

•HT –High Torque Model

•MA –Marking Attachment Equipped Model

TRC Industries has produced more custom machines than we can count. If you have a

question about the specific model you have, or if you are interested in buying a machine

second hand, give us a call and we call help walk you through what features are included.

7

Nomenclature

Throughout this manual we will be referring to sides of the machine as well as its parts. The

diagrams below should be used as a reference to help the instructions in this manual easier to

understand. We will use the terms “infeed side” and “outfeed side” as well as “motor side”

throughout this manual.

Figure 1: The side view of this cold cutter is representative of the HC4, HC7, CC4, and CC7 cutters, with some minor

differences between the hot and cold cutter models. Note the side facing the reader is opposite the motor side of

the cutter.

Outfeed

side

Infeed side

Material Feed Direction

Roller

Tensioner

Handle

8

Setting Up and Using your new TRC 1000 Series Strip Cutters

Model HC4 and HC7 Setup

1. Place control panel and cutter on a flat table with the back of the control panel facing

the side of the cutter. Plug the black heater cord cable from the cutter into the control panel.

Next, connect the control panel to the cutter using the grey control cable. Plug the power

cord into the fused power receptacle on the control panel and the other end into a standard

120V single phase receptacle.

BE SURE ALL CABLES ARE SECURELY FASTENED BEFORE TURNING ON THE POWER!

2. Connect the air regulator to the cutter head via the press to lock fittings. Set the air

supply pressure at 40 PSI. If connected correctly the blade carrier should move to the up-

stroke position.

3. Set the roll stand on the infeed side of the cutter and line it up with the guides. Place

one plastic disk on the roll stand shaft, then feed webbing roll on to shaft so webbing rolls off

the top side of the roll. Place the other plastic disk on the roll stand and put the roll holder

collar lightly against the disk. tighten the thumb screw lightly. If the webbing does not turn

freely, loosen the roll holder a little.

Start Up Procedures

•While the machine is cold, adjust the guide strips to fit the webbing you are using. Do

not make it too tight as to cause drag on the webbing. The guide strips are there to

simply funnel the material towards the rollers (figure 2).

9

Figure 2: view from the infeed side of the machine, with feed guides visible.

•Turn master switch to the ON position.

•Set the temperature control knob to 3 and allow 10 - 15 min. for the knife to heat up.

The first few times the machine is heated up, the machine may emit the smell of hot oil.

This is normal.

•Feed the webbing through the guides and push it up to the feed rollers and then push

the FEED JOG button on the control panel. This will take the webbing through the feed

rollers. Take the webbing past the rollers an inch or so. You can also put the webbing

through the rollers by pushing down on the black knob and lifting the rollers and

pushing the webbing through.

Note: If your machine is equipped with the optional cutoff switch, you must feed material

under the trip rod before the guides.

NEVER ALLOW THE KNIFE TO BECOME RED HOT AS THIS MAY CAUSE THE WEBBING TO CATCH ON

FIRE.

Use just enough heat to cut the webbing. You will have to experiment with the webbing you

are using to find the exact temperature that works best.

Each cutter

comes

standard with

three sets of

guides, as

seen here.

10

Keyboard Commands

FEED JOG Allows you to manually operate the feed rollers

KNIFE JOG Allows you to manually operate the knife

RE-SET Allows you to clear the machine and start a new program

STOP Allows you to stop the machine and save all data in the memory. The STOP function

Also allows you to clear a data entry while programming –for example, if an incorrect value

was entered for length or cut time.

ENTER Allows you to enter program data

Entering A program

Feed Rate

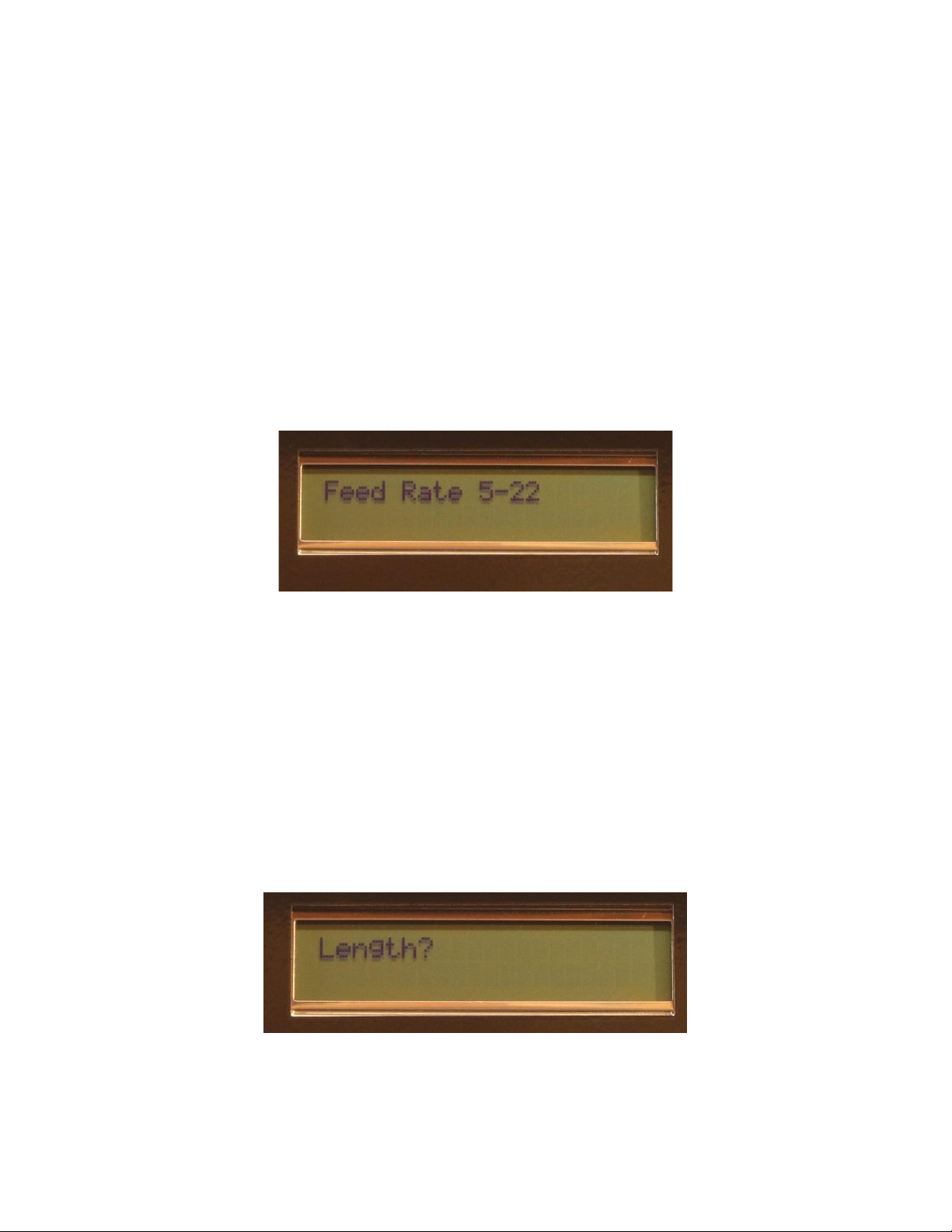

Figure 3

When the control panel is turned on the loading screen and version number will be displayed.

The next series of prompts will be cut settings. The first prompt will be for feed rate. "FEED RATE

5-22 " (figure 3) will appear on the LCD. This will determine how fast the material will feed

through the machine, in inches. While our machines can feed up to 22 inches per second, the

speed required to run the machine successfully will largely be determined by the material

being cut. We recommend starting somewhere in the middle and working up if necessary.

Older machines may not have variable speed, in which case this prompt will be omitted. Type

in the desired speed and press ENTER.

Length

Figure 4

11

The Next prompt will be for length(figure 4). Type in the desired length and press ENTER. For

example, 15 inches will be typed in as “15”. For decimal values, use the “*” key. For example,

15.5 inches would be typed as “15*5”

Cut Time

Figure 5

Next, “Cut Time?” will appear on the LCD (figure 5). This is amount of time in seconds the blade

will stay in the down position for. The maximum time that most cutters can cut for is 2.4

seconds, but this varies depending on chip version. We recommend starting at 0.5 seconds an

increasing as necessary. A decimal can be entered by pressing the “*” key. Cut times will vary

with the thickness of the webbing and some trial and error is necessary to get the proper cut

time. 1" medium weight poly pro webbing will cut in about .75 seconds or 3/4 of a second.

How Many

Figure 6

This is the number of pieces that you want to cut (figure 6). After typing in a number and

BEFORE you push the Enter key you will want to insert the material through the feed guides,

pushing it up to the feed rollers. Press and hold the FEED JOG button until material advances

past the hot knife about 3". Press the KNIFE JOG button and cut off the webbing. This will give

you a fresh cut to start with.

Now with the correct piece count entered in press ENTER and the machine will start cutting.

When the number of pieces that were entered have been cut the machine will stop. If you

wish to run the same program again just push ENTER and it will run the same program again,

while maintain a running count of both program runs.

12

Operating Screen

Figure 7: screen during operation.

The operating screen will be displayed during operation (figure 7). The operating screen

displays the following:

Top left: Programmed Part length, in inches

Top right: Programmed cut time, in seconds

Bottom: Running total of programmed parts cut so far

Stopping the Machine

To stop the machine during operation and not lose the data you have entered, push the STOP

button and hold it down until the machine stops.

In the event of an emergency, simply turn the master power switch to the off position.

By using the STOP button, you will save the program and the count. To start the program again

just push ENTER and it will continue with the program you had entered. When you use RESET or

the master switch you will lose the program, meaning you will have to follow the prompts

again and enter the desired program values in again.

When finished with machine operations, simply turn thermostat and master switch off and

allow to cool. Remove material from machine to prevent material from melting.

Model CC4 and CC7 Setup

1. Place control panel and cutter on a flat table with the back of the control panel facing

the side of the cutter. Next, connect the control panel to the cutter using the grey control

cable. Plug the power cord into the fused power receptacle on the control panel and the

other end into a standard 120V single phase receptacle.

BE SURE ALL CABLES ARE SECURELY FASTENED BEFORE TURNING ON THE POWER!

13

2. Connect the air regulator to the cutter head via the press to lock fittings. Set the air

supply pressure at 60 PSI. If connected correctly the blade carrier should move to the up-

stroke position.

3. Set the roll stand on the infeed side of the cutter and line it up with the guides. Place

one plastic disk on the roll stand shaft, then feed webbing roll on to shaft so webbing rolls off

the top side of the roll. Place the other plastic disk on the roll stand and put the roll holder

collar lightly against the disk. tighten the thumb screw lightly. If the webbing does not turn

freely, loosen the roll holder a little.

Start Up Procedures

•Adjust the guide strips to fit the webbing you are using. Do not make it too tight as to

cause drag on the webbing. The guide strips are there to simply funnel the material

towards the rollers.

•Turn master switch to the ON position.

•Feed the webbing through the guides and push it up to the feed rollers and then push

the FEED JOG button on the control panel. This will take the webbing through the feed

rollers. Take the webbing past the rollers an inch or so. You can also put the webbing

through the rollers by pushing down on the black knob and lifting the rollers and

pushing the webbing through.

Note: If your machine is equipped with the optional cutoff switch, you must feed material

under the trip rod before the guides.

Keyboard Commands

FEED JOG Allows you to manually operate the feed rollers

KNIFE JOG Allows you to manually operate the knife

RE-SET Allows you to clear the machine and start a new program

STOP Allows you to stop the machine and save all data in the memory. The STOP function

Also allows you to clear a data entry while programming –for example, if an incorrect value

was entered for length or cut time.

ENTER Allows you to enter program data

Entering a Program

Feed Rate

14

Figure 8

When the control panel is turned on the loading screen and version number will be displayed.

The next series of prompts will be cut settings. The first prompt will be for feed rate. "FEED RATE

5-22 " will appear on the LCD. This will determine how fast the material will feed through the

machine, in inches. While our machines can feed up to 22 inches per second, the speed

required to run the machine successfully will largely be determined by the material being cut.

We recommend starting somewhere in the middle and working up if necessary. Older

machines may not have variable speed, in which case this prompt will be omitted. Type in the

desired speed and press ENTER.

Length

Figure 9

The Next prompt will be for length. Type in the desired length and press ENTER. For example, 15

inches will be typed in as “15”. For decimal values, use the “*” key. For example, 15.5 inches

would be typed as “15*5”

15

Cut Time

Figure 10

Next, “Cut Time?” will appear on the LCD. This is amount of time in seconds the blade will

cycle for. The maximum time that most cutters can cut for is 2.4 seconds, but this varies

depending on chip version. We recommend starting at 0.5 seconds an increasing as

necessary. A decimal can be entered by pressing the “*” key. Cut times will vary with the

thickness of the webbing and some trial and error is necessary to get the proper cut time.

How Many

Figure 11

This is the number of pieces that you want to cut. BEFORE you push enter on How many, you

will want to insert the material through the feed guides, pushing it up to the feed rollers. Press

and hold the FEED JOG button until material advances past the cold knife about 3". Press the

KNIFE JOG button and cut off the webbing. This will give you a fresh cut to start with.

Now with the correct piece count entered in press ENTER and the machine will start cutting.

When the number of pieces that were entered have been cut the machine will stop. If you

wish to run the same program again just push ENTER and it will run the same program again,

while maintain a running count of both program runs.

Stopping the Machine

To stop the machine during operation and not lose the data you have entered, push the STOP

button and hold it down until the machine stops.

In the event of an emergency, simply turn the master power switch to the off position.

By using the STOP button, you will save the program and the count. To start the program again

just push ENTER and it will continue with the program you had entered. When you use RESET or

the master switch you will lose the program, meaning you will have to follow the prompts

again and enter the desired program values in again.

16

When finished with machine operations, simply turn the master switch off.

Model HC4-FS Setup

1. Place cutter on a flat table.

2. Route footswitch to a safe comfortable place on the floor. Foot switch can be secured

with carpet tape or similar double-sided tape.

3. Next hook up the air regulator to your air supply and set the pressure at 40 PSI.

4. Plug the power cord into a 120V outlet.

Start Up Procedures

1. Turn master switch to ON position

2. Set the temperature control knob to 3 and allow 10 - 15 min. for the knife to heat up.

NEVER ALLOW THE KNIFE TO BECOME RED HOT AS THIS MAY CAUSE THE WEBBING TO CATCH ON

FIRE.

Use just enough heat to cut the webbing. You will have to experiment with the webbing you

are using to find the exact temperature that works best.

3. Place material across cutting plate. KEEPING HANDS CLEAR OF KNIFE!

4. When material is in desired position, with HANDS CLEAR, depress footswitch until knife

passes through material. Release the foot switch after blade has passed through material.

5. When you are through with the machine turn the Temperature control to OFF and

switch the Master Switch OFF.

Periodic Maintenance and Repairs

17

Your TRC 1000 Series Strip Cutter will last a long time with proper care and maintenance. You

will need a few simple tools to properly maintain and service your new TRC 1000 Series cutter.

Tools needed:

•SAE Allen wrenches. "T" handle and Ball driver styles are recommended. Sets typically

sold at hardware stores with wrenches from 0.050" –3/8" will be suitable.

•Combination end wrenches 1/4" - 9/16"

•Small and medium flathead screwdriver

•Small and medium phillips head screwdrivers

•3/16" Hex driver for jack screws

For advanced users or those who wish to fully diagnose, test, and repair circuitry on their

machine, the following will also be required:

•Volt/Ohm multimeter with continuity tester

•Pencil tip style soldering iron

•rosin core solder

•Wire strippers/crimpers

•Small angle cutting wire cutters

Again, not everyone who buys a TRC Industries 1000 series cutter will need the items in the

second list; those who choose to do advanced work on their machines, including circuit

board repairs should only do so if familiar with circuitry, and at their own risk.

As a note, most of the TRC-1000 series strip cutters are made of aluminum. While 6061-T6 is a

superb material for manufacturing rugged machines, it has its limitations. Use caution when

tightening screws and bolts, to avoid stripping the threaded holes. Also, due to a chemical

reaction between aluminum and steel, it is sometimes difficult to break loose screws before

removing them. We advise using penetrating oil in order to remove stuck bolts before

attempting to remove by force.

Simple lubrication and adjustment will prevent premature wear and tear. The following areas

should be carefully maintained on a regular basis:

18

Linear Shafts/Bearings and Air Cylinder shafts: keep clean of dust, lint and other

foreign substances. These points should also be lubricated periodically with a light weight oil,

such as sewing machine oil.

Drive and Tension Rollers:Remove any melted materials stuck onto rollers (figure 12), as

well as any strings or pieces of fabric wrapped around the rollers when safe to do so. Having

foreign materials stuck to your rollers will cause abnormal feed lengths. Guide boxes guides

should be moved periodically such that material feeds through the machine over different

parts of the roller. Alternating the contact point of the roller and material will help the rollers

last as long as possible and prevent wear spots from forming on the rollers.

Oil linear

bearings

here

19

Figure 12: Rollers in poor condition. Top: melted plastic stuck onto bottom roller (part AM4-7a). Bottom: Top Roller

(AM4-6a) split from heat. The heat guards on this machine were removed, and heat was left on without machine

running, leaving the roller to face the heater block on this side until the rubber degraded. The top roller can be

repaired; the bottom one cannot.

20

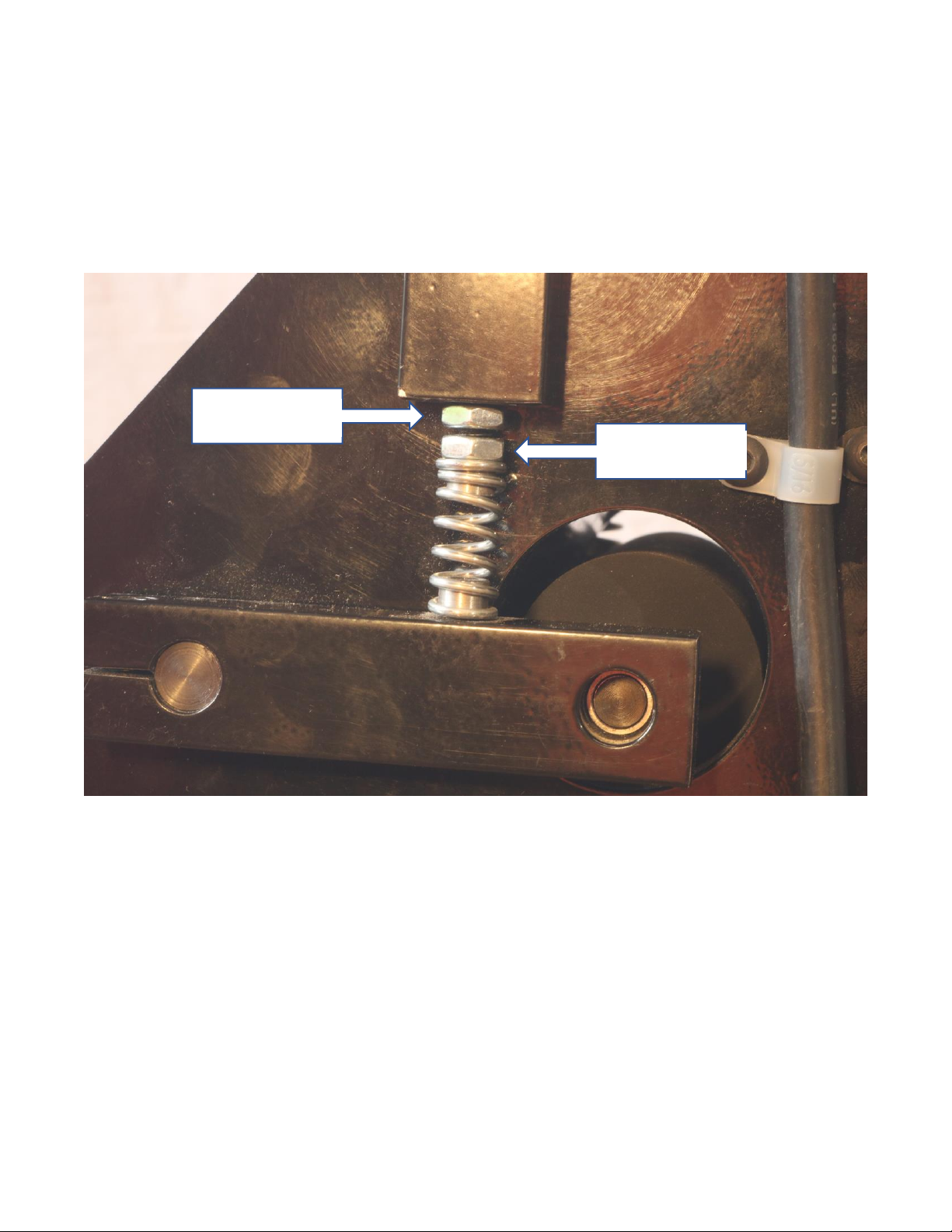

Springs: Depending on the model of TRC 1000 that you are operating, there will be springs to

tension to top roller as well as the knife blades. Proper tension on the top roller will allow

optimum grip of the material without creating excessive drag and premature bearing failure.

Too little pressure will cause material slippage. Finding the right amount of pressure will likely be

a matter of trial and error. Different types of material, as well as different thicknesses, may

require adjustment to run correctly.

Figure 13: Side view of the roller tensioner assembly

Jam Nut

Adjustment

nut

This manual suits for next models

7

Table of contents