TREBING + HIMSTEDT SPI 3 User manual

Doc. Version 2.0

SERIAL-PROFIBUS-INTERFACE

SERIAL-PROFIBUS-INTERFACESERIAL-PROFIBUS-INTERFACE

SERIAL-PROFIBUS-INTERFACE | SPI 3

| SPI 3 | SPI 3

| SPI 3

for Fieldbus Devices with Serial Interface

– Sartocheck 4

Doc. Version 2.0 | Mai 2008

Dear customer

This online documentation is designed to help you with engineering, connecting up,

configuration and parameter setting of the SPI 3. Please feel free to contact our

Technical Support department if you need further help:

Trebing & Himstedt Prozessautomation GmbH & Co. KG

Technical Support Dept.

Wilhelm-Hennemann-Str. 13

19061 Schwerin, Germany

Telephone: +49 385 39572-500

Telefax: +49 385 39572-22

E-mail: [email protected]

Homepage: http://www.t-h.de

The information in this online documentation is the property of Trebing & Himstedt

Prozessautomation GmbH & Co. KG. This online documentation or extracts thereof

may only be duplicated or passed on tothird parties following explicit written approval

from Trebing & Himstedt Prozessautomation GmbH & Co. KG. The right is reserved

to make changes to this manual and to the SPI 3 device at any time without prior

notification.

All product names used in this online documentation are trademarks or otherwise

protected by law, even if this is not specifically mentioned.

Table of Contents

Introduction .............................................................................................................. 4

Scope of delivery ........................................................................................... 5

About this online documentation ................................................................... 5

Safety notes ............................................................................................................ 6

Overview of the SPI 3 ............................................................................................... 8

Implementation guideline .............................................................................. 9

Installing the SPI 3 ................................................................................................. 10

Connecting up to Sartocheck 4 ................................................................... 11

Connecting up to the PROFIBUS ................................................................ 11

Starting up the SPI 3 .............................................................................................. 13

SPI 3 Configuration ..................................................................................... 13

Checking the SPI 3 for correct operation ................................................................ 14

Error diagnosis and remedies ................................................................................ 15

Technical specifications ......................................................................................... 17

Appendix ................................................................................................................ 18

Parameters for Sartocheck 4 test runs ........................................................ 18

Common parameters .................................................................................. 18

Test parameters .......................................................................................... 20

Identification data ........................................................................................ 22

Status data .................................................................................................. 22

Test results .................................................................................................. 24

Glossary ................................................................................................................. 29

General Regulations ............................................................................................... 35

Introduction

4

Trebing & Himstedt | SPI 3 | Sartocheck 4

Introduction

The SPI 3 (SERIAL-PROFIBUS-INTERFACE 3) allows a PROFIBUS-DP master to

communicate with a Sartocheck 4 filter test device. This allows the Sartocheck 4 to

function as a real PROFIBUS station, whereby the SPI 3 converts the data to be

exchanged between the PROFIBUS-DP master and the Sartocheck 4 into a format

which is compatible with the other device.

Data are exchanged between the DP master and the SPI 3 in the form of telegrams

through a data channel, the size of which can be configured.

The SPI 3 is easy to install and configure and a separate program for configuration or

parameter setting is not necessary. Configuration is done using the respective

PROFIBUS-DP master.

Features of the SPI 3:

· DP slave at up to 12 Mbit/s

· Does not require special configuration software

· Simple and fast integration in PROFIBUS-DP networks

Example for SPI 3 interface module overview

PLC

Software Tool

SPI 3 | DP Slave

Sartocheck 4

SPI 3

DP Master

(PLC)

Introduction

5

Sartocheck 4 | SPI 3 | Trebing & Himstedt

Scope of delivery

Documentation & Media Kit (optional, not included in delivery)

The documentation & media kit contains this online documentation and the GSD file.

You can download the documentation & media kit from the internet (www.t-h.de). You

need the GSD file for the PLC project.

About this online documentation

Please read this online documentation before starting the installation work. It contains

important information on planning your system, connecting up and configuring the

SPI 3 and on parameter setting.

The online documentation uses the following keywords and symbols:

Danger!

Risk of injury to personnel due to electric shock.

Warning!

Risk of damage to equipment.

Note!

Indicates useful tips.

SPI 3 Quick start guide

Safety notes

6

Trebing & Himstedt | SPI 3 | Sartocheck 4

Safety notes

Safety notes for the planning stage

Observe the general rules for PROFIBUS components when planning the SPI 3

installation.

Please observe the following to avoid risk to personnel and damage to equipment and

to ensure that the SPI 3 functions correctly:

Safety regulations – Observe the guidelines in the VDE 0100 regulations for

handling electrical components,

– Observe the applicable safety and accident prevention

regulations.

Assembly personnel The SPI 3 must only be installed or de-installed by qualified

technical personnel with appropriate electrotechnical

qualifications.

PROFIBUS standard Observe the guidelines in the PROFIBUS standard IEC

61158.

Bus cable Bus wiring should only take place using special screened,

twisted pair PROFIBUS cable. The high data transfer rates

can only be guaranteed with the correct cable type.

Cable lengths Refer to the PROFIBUS norm for information on maximum

cable lengths for PROFIBUS.

Terminating resistors Terminating resistors must be used if the SPI 3 is installed at

the beginning or end of the PROFIBUS cable segment. In

this case, you should use PROFIBUS connectors which

contain an integrated terminating resistor. We recommend

use of connectors from ERNI and Siemens. If the bus is

incorrectly terminated, this can lead to errors in data transfer

or to damage to other stations on the bus.

Bus connectors You should only use commercially available PROFIBUS

connectors for connecting the bus. We recommend using

connectors from ERNI and Siemens.

Cable screen Screened cables are less sensitive to interference due to

electromagnetic fields. With screened cables, the

interference currents are led to ground through the

screening rail, which is electrically connected to the case. To

ensure that the interference currents which flow through the

screening do not themselves interfere with other devices, it

is important to provide a low impedance connection to the

protective ground. Observe the following rules for the

screens of the PROFIBUS cable and the serial interface

cable:

– The braiding of the screening should have a degree of

Safety notes

7

Sartocheck 4 | SPI 3 | Trebing & Himstedt

coverage of more than 80 %.

– The screening should include a braided screen and

should not consist solelyof foil screening, since the latter

can be easily damaged by cable tension and pressure.

– To ensure good immunity to interference at high

frequencies as well, the screening of the cable should be

attached to the screening rail at both ends of the cable.

Safety notes for installation and operation of the SPI 3

Please observe the following before connecting up the SPI 3 to avoid risk to

personnel and damage to equipment and to ensure that the SPI 3 functions correctly:

– The SPI 3 is designed as an interface between fieldbus devices with serial

interfaces and the PROFIBUS. Do not use the SPI 3 for any other purpose.

– The SPI 3 may only be installed or de-installed by qualified technical personnel with

appropriate electrotechnical qualifications. When connecting up the SPI 3, you

must observe the guidelines in the VDE 0100 regulations for handling electrical

equipment.

– Always mount the SPI 3 on a suitable top-hat rail.

– The cables used to connect up the SPI 3 should not apply any mechanical forces

to the device.

Danger!

Never open the case of the SPI 3 and do not make any modifications to the

device.

Warning!

Small objects or liquids must not be allowed to enter the case of the SPI 3

(e.g. through the ventilation slots) since this could damage the device.

Never cover up the ventilation slots in the case.

Large temperature differences between the storage location and installation

site can cause condensation to form within the case of the SPI 3, which can

damage the device. If large temperature differences are present, you should

wait at least 3-4 hours after installing the SPI 3 and before switching on the

power.

Overview of the SPI 3

8

Trebing & Himstedt | SPI 3 | Sartocheck 4

Overview of the SPI 3

1 Power supply connections

2 PROFIBUS interface

3 Serial interface

4 Stop lever for top-hat rail

5 Turn-switch for PROFIBUS address

6 Display elements

Connections and interfaces

– Power feed

– 24 V Screw terminal for external 24 V power supply

– GND Signal ground terminal

– PE Protective ground terminal

– PROFIBUS interface

– Serial interface (RS232, RS422 or RS485 see label on SPI 3)

Mounting the device

– Stop lever for releasing/fixing the SPI 3 from/on a 35 mm DIN top-hat rail (top-

hat rail not included in delivery)

Operating elements

– Two rotary switches for setting the PROFIBUS address

– Switch for setting the tens value

– Switch for setting the unit value

232

24V

GND

PE

422485

Station

RUN

SERIAL-PROFIBUS-INTERFACE SPI3

PB

TX

x

10

x

1

RX

2

4

3

6

5

1

1

2

3

4

5

Overview of the SPI 3

9

Sartocheck 4 | SPI 3 | Trebing & Himstedt

Indicating elements

LEDs to indicate operating states:

– RUN: lights continuously if supply voltage is present,

flashes in case of errors (see »Error diagnosis and remedies« on page 15)

– PB: lights up if the SPI 3 has been configured by the master and is operational,

flashes in case of errors (see »Error diagnosis and remedies« on page 15)

– TX: flashes if data is being sent to the serial interface

– RX: flashes if data is being received from the serial interface

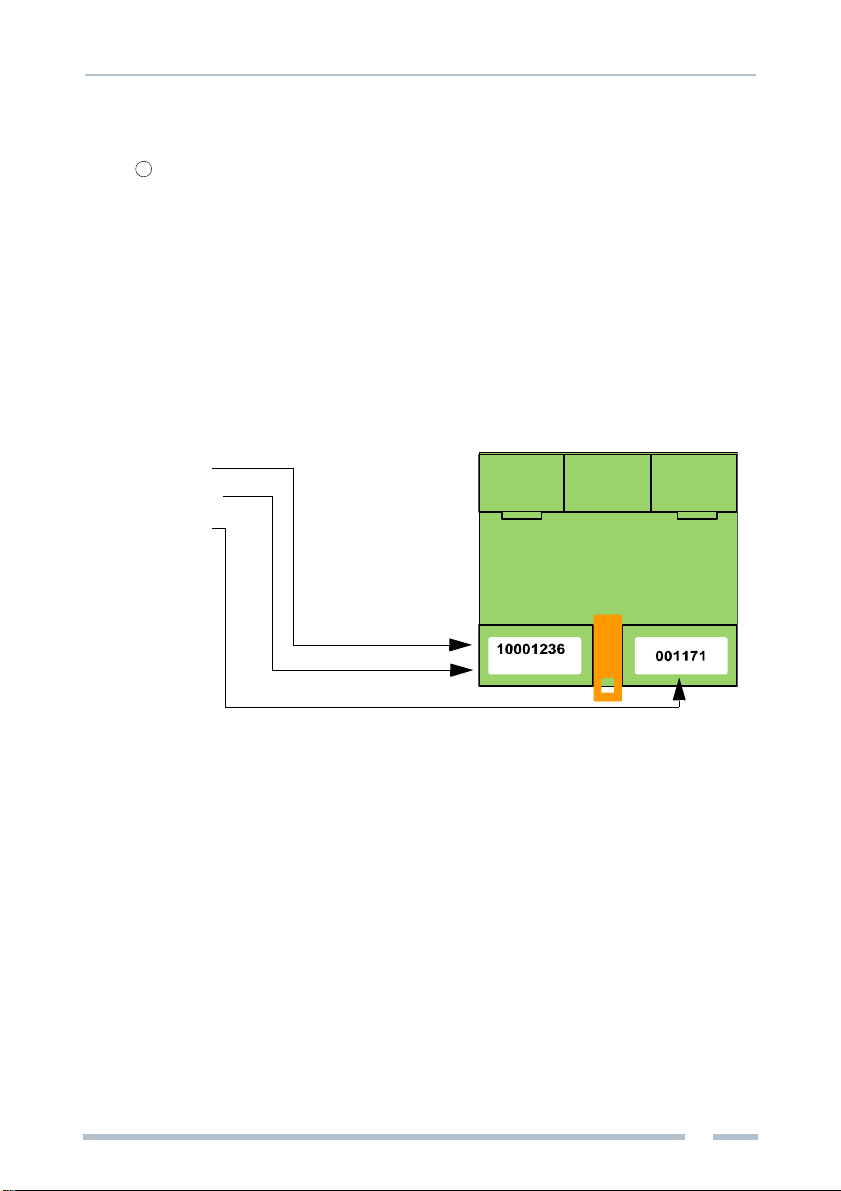

Release

The following information is indicated on the SPI 3 back-panel:

– Article No.

– Release No.

– Serial No.

Implementation guideline

Please procede through the following steps for start-up:

– Mount the SPI 3 (see »Installing the SPI 3« on page 10).

– Connect the SPI 3 to power supply (see »Connecting up the power feed« on

page 10).

– Connect the SPI 3 to the serial field device (see »Connecting up to Sartocheck 4«

on page 11).

– Connect the SPI 3 to the PROFIBUS (see »Connecting up to the PROFIBUS« on

page 11).

– Configure and parameterize the SPI 3 via PROFIBUS configurator (see »Starting

up the SPI 3« on page 13).

6

Release 19

Installing the SPI 3

10

Trebing & Himstedt | SPI 3 | Sartocheck 4

Installing the SPI 3

Mounting the SPI 3

– Place the SPI 3 with the gap onto the top-hat rail and swivel the SPI 3 downward

until the stop lever locks on the top-hat rail.

Warning!

Head space of 5 cm minimum for heat flow is required above and below the

SPI 3.

Dismounting the SPI 3

– Remove the connected supply and signal wires (serial, PROFIBUS, voltage).

– Stick a screwdriver in the slot of the stop lever at the SPI 3.

– Press the screwdriver in the direction of the SPI 3 while at the same time swivelling

the SPI 3 away from the top-hat rail.

Connecting up the power feed

Danger!

Incorrect grounding of the SPI 3 can injure personnel and damage

equipment.

Make sure that the SPI 3 is correctly grounded.

Warning!

Although the SPI 3 is protected against polarity reversal, connecting up the

power feed with incorrect polarity for extended periods can damage the

device. Make sure that the power feed is connected with correct polarity.

– Connect the cables for 24 V power feed, ground and protective ground to the

corresponding screw terminals 24 V, GND and PE.

SPI 3

Top-hat rail

Stop lever

Installing the SPI 3

11

Sartocheck 4 | SPI 3 | Trebing & Himstedt

Connecting up to Sartocheck 4

Note!

To enable communication with the SPI 3, the Sartocheck 4 filter test device

must be version 02.02 or higher.

To ensure that the SPI 3 functions without errors, you should use a screened

cable for connecting to the serial fieldbus device.

– Ensure that the Sub-D connector for the Sartocheck 4 uses the pin assignments

shown in »Technical specifications« on page 17 (connect the cable screen to the

case of the sub-D connector).

– Attach the sub-D connector for the Sartocheck 4 to the serial interface socket on

the SPI 3.

Connecting up to the PROFIBUS

Note!

You should only use commercially available PROFIBUS connectors for

connecting to the bus. We recommend the use ofconnectors from ERNI and

Siemens.

If the SPI 3 is installed at the beginning or end of the PROFIBUS cable

segment, you should use PROFIBUS connectors which contain an integrated

terminating resistor. We recommend using connectors from ERNI and

Siemens.

To ensure that the SPI 3 functions without errors, you must ground the

screen of the PROFIBUS cable.

– Ensure that the PROFIBUS connector uses the pin assignments shown in

»Technical specifications« on page 17.

– Attach the PROFIBUS connector to the PROFIBUS interface socket on the SPI 3

and secure the connector with the retaining screws.

Setting the PROFIBUS address

Note!

The SPI 3 only updates its PROFIBUS address during a restart. Set the

PROFIBUS address on the SPI 3 before switching on the power, or turn off

the power briefly after changing the PROFIBUS address.

You should only use addresses between 01 and 99.

3

2

Installing the SPI 3

12

Trebing & Himstedt | SPI 3 | Sartocheck 4

– The PROFIBUS address is set with the two rotary switches.

Example: In order to set the PROFIBUS address 68, turn the rotary switch for the 10’s

to 6, and the rotary switch for the units to 8.

Bus terminating resistor

Terminations of a PROFIBUS network must each be terminated with a bus

terminating resistor. Use standardized plugs with integrated terminating resistors.

Figure: Bus termination configuration for PROFIBUS (see PROFIBUS Norm)

Note!

Please observe the following when using the depicted passive terminating

resistor: Is the feeding voltage (+5 V) supplied by the device (SPI 3), the

PROFIBUS is shorted via the resistors when the device is disconnected

from voltage. PROFIBUS communication can be interrupted or completely

break down until the device is re-energized.

Use active resistors to avoid this problem, as in this case the terminating

resistors are fed with +5 V and GND independently from the device.

1 390 ΩPull-up resistance from Pin 3 to positive supply voltage at Pin 6

2 220 ΩCable terminating resistor between Pin 3 and Pin 8

3 390 ΩPull-Down resistor from Pin 8 to data reception potential at Pin 5

+5 V DC/DC

(Pin 6) Data+

(Pin 3) Data–

(Pin 8) GND DC/DC

(Pin 5)

[1] [2] [3]

Starting up the SPI 3

13

Sartocheck 4 | SPI 3 | Trebing & Himstedt

Starting up the SPI 3

To start up the SPI 3, you need to configure the device. Configuration is done via

PROFIBUS configurator (PLC programming tool).

– Start the PROFIBUS configurator of the DP master (PLC programming tool).

– Load the »THDP0091.GSD« GSD file for the SPI 3 into the configurator (GSD by

download: www.t-h.de).

– Configure the SPI 3 as described in the configurator online help or user manual.

Select the respective module »SartoCheck« or »SartoCheckExt« for the extended

version 2.0 for configuration. Do not parameterize this module with special user

parameters.

SPI 3 Configuration

During configuration with the PROFIBUS configurator, you are asked to select a

module from the menu. The »SartoCheck« or »SartoCheckExt« module can be used.

Note!

The described module SartoCheck is valid for the SPI 3 release 17 and hig-

her. The described module SartoCheckExt is valid for the SPI 3 release 19

and higher.

Module selection depends on the respective SPI 3 application. All further

modules (not described herein) cannot be used for SPI 3 application with

Sartocheck 4.

Module Name I/O Field Data transfer protocol

SartoCheck 39 Byte Input

21 Byte Output xBPI2

SartoCheckExt 44 Byte Input

21 Byte Output xBPI2

Checking the SPI 3 for correct operation

14

Trebing & Himstedt | SPI 3 | Sartocheck 4

Checking the SPI 3 for correct operation

Several checks should be run before using the SPI 3 for data transfer.

Checking SPI 3 power feed

– At this stage, do not attach either the PROFIBUS interface or the serial interface.

– Switch on the power feed for the SPI 3.

The RUN LED should light continuously. If this is not the case, there is a fault in the

24 V power feed. Refer to »Error diagnosis and remedies« on page 15 for details of

how to locate the fault.

Checking PROFIBUS communication

– Connect up the PROFIBUS interface cable.

– Switch on the power feed for the SPI 3 (RUN-LED lights up).

– Start the DP master which has previously been configured for the SPI 3.

The PB LED should light continuously. If this is not the case, there is an error in the

PROFIBUS communication. Refer to »Error diagnosis and remedies« on page 15 for

details of how to locate the fault.

Checking serial interface communication

– Connect up the PROFIBUS interface cable and the serial interface cable.

– Switch on the power feed for the SPI 3 (RUN-LED lights up).

– Start the DP master which has previously been configured for the SPI 3 (PB-LED

lights up).

The RUN LED should light continuously. If it does not light, or it only flashes, there is

an error in the communication with the serial device. Refer to »Error diagnosis and

remedies« on page 15 for details of how to locate the fault.

If no errors were detected, the SPI 3 is ready for use. During data transfer, the TX or

RX LEDs will flash (see »Indicating elements« on page 9).

Evaluating PROFIBUS diagnosis telegrams

In case of communication failures (PROFIBUS), the SPI3 sends a diagnosis telegram

on DP master request. The diagnosis telegram contains general PROFIBUS

diagnosis data (see PROFIBUS Norm).

You can evaluate the diagnosis telegram through the DP master and/or a PROFIBUS

diagnosis tool (e.g. the PROFIBUS Scope).

Error diagnosis and remedies

15

Sartocheck 4 | SPI 3 | Trebing & Himstedt

Error diagnosis and remedies

If errors are detected, the pattern of flashing of the PB and RUN LED’s on the SPI 3

can be used for error diagnosis. The LED’s can flash with the following patterns:

Note!

If the PB LED (PROFIBUS) is off, the RUN LED is on continuously and no

longer indicates a valid LED code. Accordingly, the RUN LED can only be

used for diagnosis when the PB LED is lit.

The PROFIBUS diagnosis and error statuses are reset when the error is no

longer present or when the slave gets new parameter and configuration

values.

LED off LED short LED medium LED long LED on

LED off LED is ¾ off ¼ on LED is ½ off ½ on LED is ¼ off ¾ on LED always on

PB LED code Status Significance Remedy

PB LED off Correct data transfer

rate could not be

determined

– No PROFIBUS master in

the network – Connect up the DP master

– Check the wiring

PB LED short DP master available – A master is available but

communication is not

taking place with SPI 3

– Check address setting on

the SPI 3

PB LED

medium Incorrect configuration – Configuration telegram

faulty – Use only the module »Sar-

toCheck« from GSD file

PB LED on Data exchange OK – Data exchange is currently

taking place – SPI 3 working correctly

Error diagnosis and remedies

16 Trebing & Himstedt | SPI 3 | Sartocheck 4

Note!

If errors occur during communication, the DP master runs a PROFIBUS

diagnosis. Evaluation of this diagnosis depends on the used DP master.

When using a bus monitor (e.g. the PROFIBUS Scope), you can also

evaluate diagnosis telegrams.

RUN LED

code Status Significance Remedy

RUN LED off

PB LED off SPI 3 not ready – 24 V supply not present – Check external power

supply

– Check the wiring

RUN LED off

PB LED on Sartocheck 4 is not

connected – no connection to

Sartocheck 4 – Check the wiring to

Sartocheck 4

RUNLED

medium Interface error – Error on xBPI2 protocol – Check version of

Sartocheck 4

(02.02 or higher)

RUN LED on Communication OK – Sartocheck 4 communica-

ting correctly with the SPI 3 – SPI 3 working correctly

Technical specifications

17

Sartocheck 4 | SPI 3 | Trebing & Himstedt

Technical specifications

Electrical data

Nominal supply voltage V DC 24 (20.4…28.8)

Current consumption mA 200

Galvanic isolation, PROFIBUS

interface V DC 500

Ambient conditions

Operating temperature °C 0…60

Case

Protection class IP 20

Dimensions W × H × D mm 75 × 75 × 53

Weight g 136

PROFIBUS interface

Interface type RS 485

Data transfer rate Bit/s 9,600; 19,200; 93,750; 187,500; 0.5M; 1.5M; 3M; 6M; 12M,

automatic detection of the data transfer rate

Pin assignment Sub-D connector Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Screen

Unused

B-line

Request to Send (RTS)

Ground for 5 V (M5)

+5 V (galvanically isolated P5)

Unused

A-line

Unused

Serial interface

Interface type RS 232

Data transfer rate Bit/s 9,600

Data frame Bit 8

Parity odd

Pin assignment Sub-D connector Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Screen

TXD (out)

RXD (in)

Unused

GND

+5 V

CTS (in)

RTS (out)

Unused

Other

Certifcates CE

Connectable field devices units 1

15

69

15

69

Appendix

18

Trebing & Himstedt | SPI 3 | Sartocheck 4

Appendix

Parameters for Sartocheck 4 test runs

Mapping of serial data from Sartocheck 4 to PROFIBUS DP is structured as follows:

– Data for output:

· common parameters

· test parameters

– Data for input:

· identification

· status data

· test results

Note!

To enable communication with the SPI 3, the Sartocheck 4 filter test device

must be version 02.02 or higher.

Common parameters

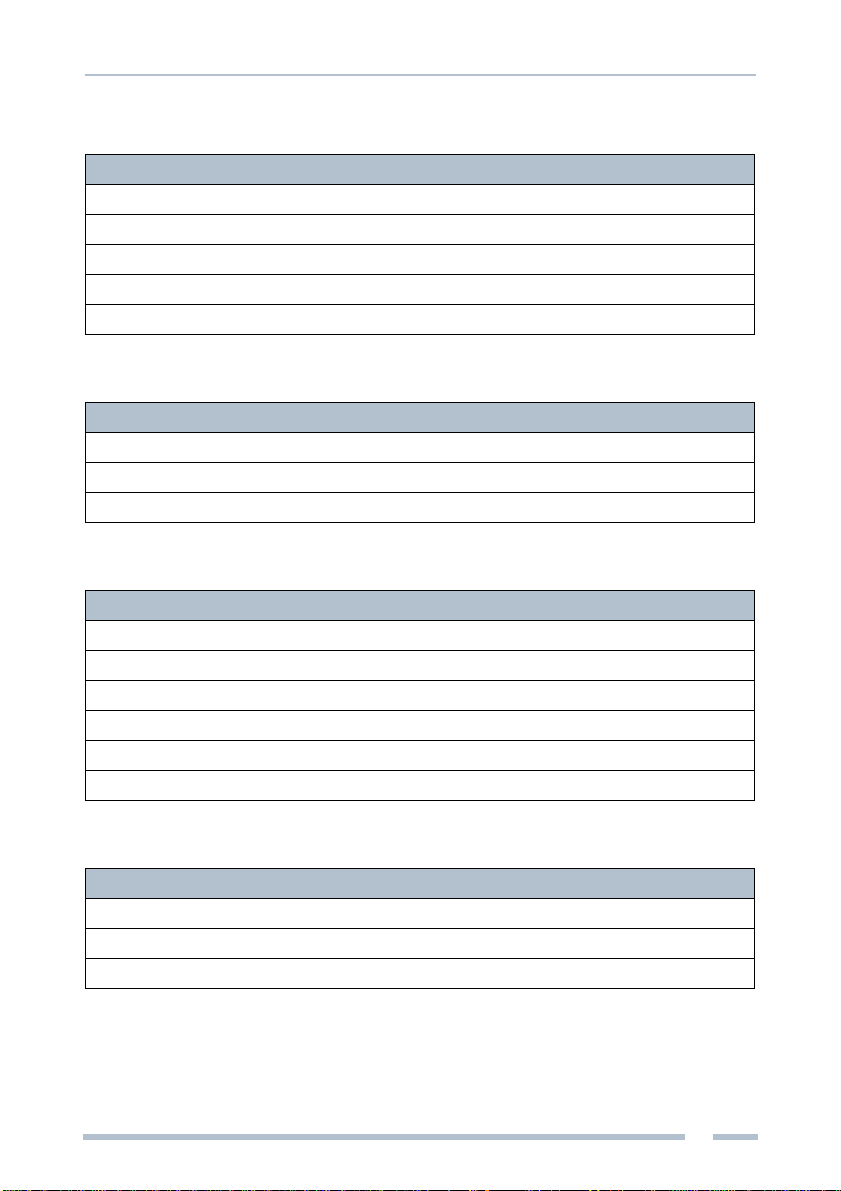

Offset Name Internal name Type Unit Visualization

0 Command

(see table 2 on

page 19)

BYTE – Command

1 TestMethod

(see table 4 on

page 19)

eMethod BYTE – Test method

2 TestOptions

(see table 5 on

page 19)

BYTE – –

3 NetVolumeValue vVolumeNet_ml REAL ml –

Table 1: Common parameters

Appendix

19

Sartocheck 4 | SPI 3 | Trebing & Himstedt

Value Bit Description Visualization

0 No change No change

1 Start Filter Test Start filter test

2 Abort Filter Test Abort filter test

3 Clear Alarm Clear alarm

4 Clear Ready Clear ready

Table 2: Common parameters »Command« for SartoCheck

Value Bit Description Visualization

0 No change No change

1 Start Filter Test Start filter test

2 Abort Filter Test Abort filter test

Table 3: Common parameters »Command« for SartoCheckExt

Value Bit Description Visualization

0 DIF Diffusion Test Diffusion Test

1 BPT Bubble Point Test Bubble Point Test

2 WIT Water Intrusion Test

3 PDT Pressure Drop Test

4 WFT Water Flow Test

5 VOL Volume Test

Table 4: Common parameters »TestMethod«

Value Bit Description Visualization

0 Use external Pressure Sensor

1 Use external Venting Mode –

2 WITFillExternal –

Table 5: Common parameters »TestOptions«

Appendix

20

Trebing & Himstedt | SPI 3 | Sartocheck 4

Test parameters

Test parameters depend on the kind of test. Each new test activates the respective

parameter sets. Only parameters required for the selected test are sent.

Diffusion Test – DIF

Bubble Point Test – BPT

Offset Name Internal name Type Unit Visualization

7 DIFTestPressure prPressureTest REAL mbar Test pressure

11 DIFStabTime tTimeStabilization_min WORD min –

13 DIFTestTime tTestDuration_min WORD min Test time

15 DIFDiffusionMax dDiffusionMax_mlmin REAL ml/min Limit value

Table 6: Test parameters DIF

Offset Name Internal name Type Unit Visualization

7 BPTMinFactor cBPMultiplier REAL – –

(Range

0,1…1,0)

11 BPTMaxPressure prBPMax REAL mbar –

15 BPTTestClass

(see table 8 on

page 20)

eTestClass BYTE – Test class

16 BPTMinPressure prBPMin REAL mbar Limit value

Table 7: Test parameters BPT

Value Bit Description Visualization

0 Small Filter Housing Small

1 Standard Filter Housing Standard

2 Large Filter Housing Large

Table 8: Bubble Point Test »BPTestClass«

Other manuals for SPI 3

4

This manual suits for next models

6

Table of contents

Other TREBING + HIMSTEDT Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Iron Ether

Iron Ether Divaricator owner's manual

Roland

Roland SoundCanvas SC-55 owner's guide

Deluge

Deluge Synthstrom Audible instruction manual

Roland

Roland MKS-30 owner's manual

Philips

Philips dynalite AntumbraButton PA6BPA installation instructions

Honeywell

Honeywell IF-LON2 Product Manual and Mounting Instructions