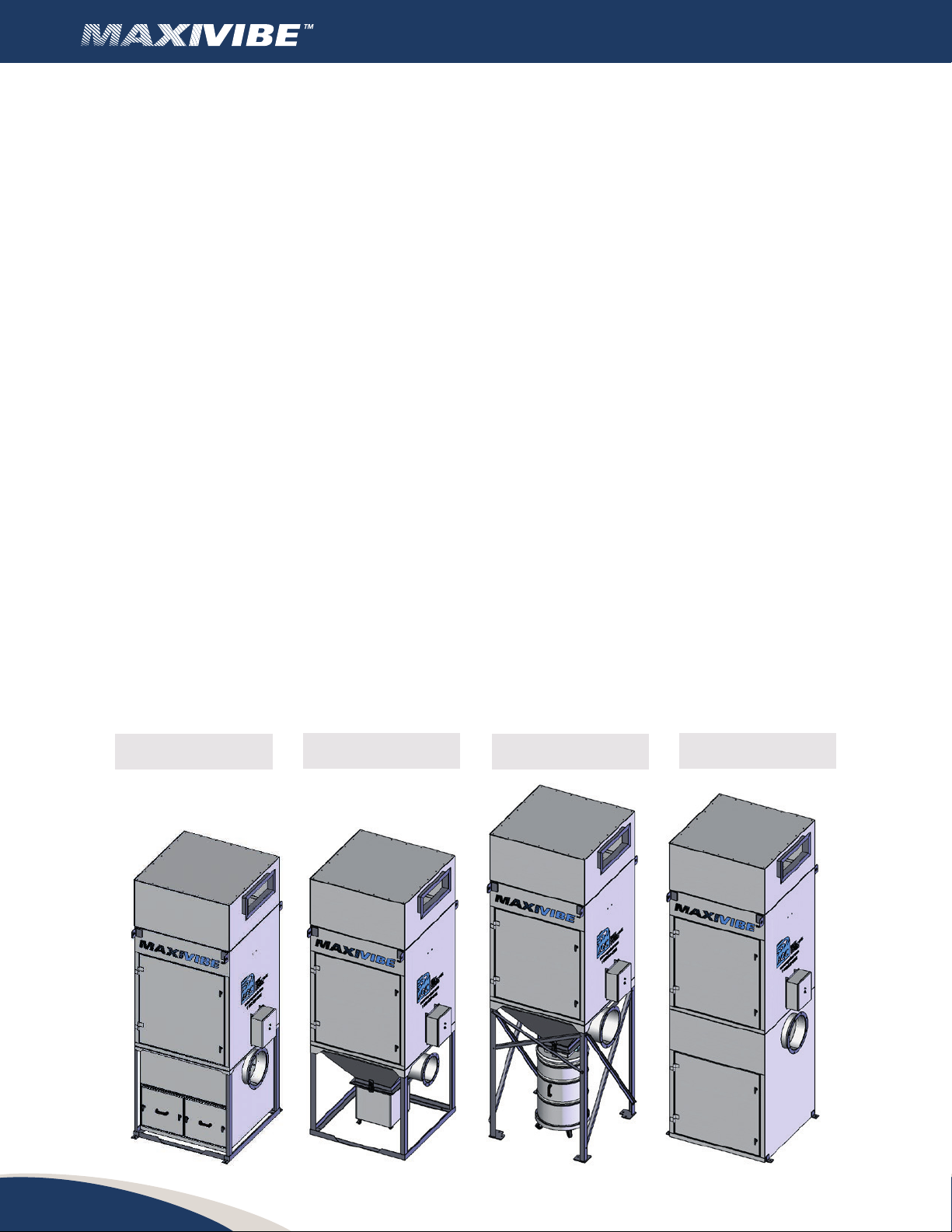

Shaker type dust collector

22

INDEX

................................................. 3

................................ 3

................................................. 4

3.1 Each MAXIVIBE units include...................................... 4

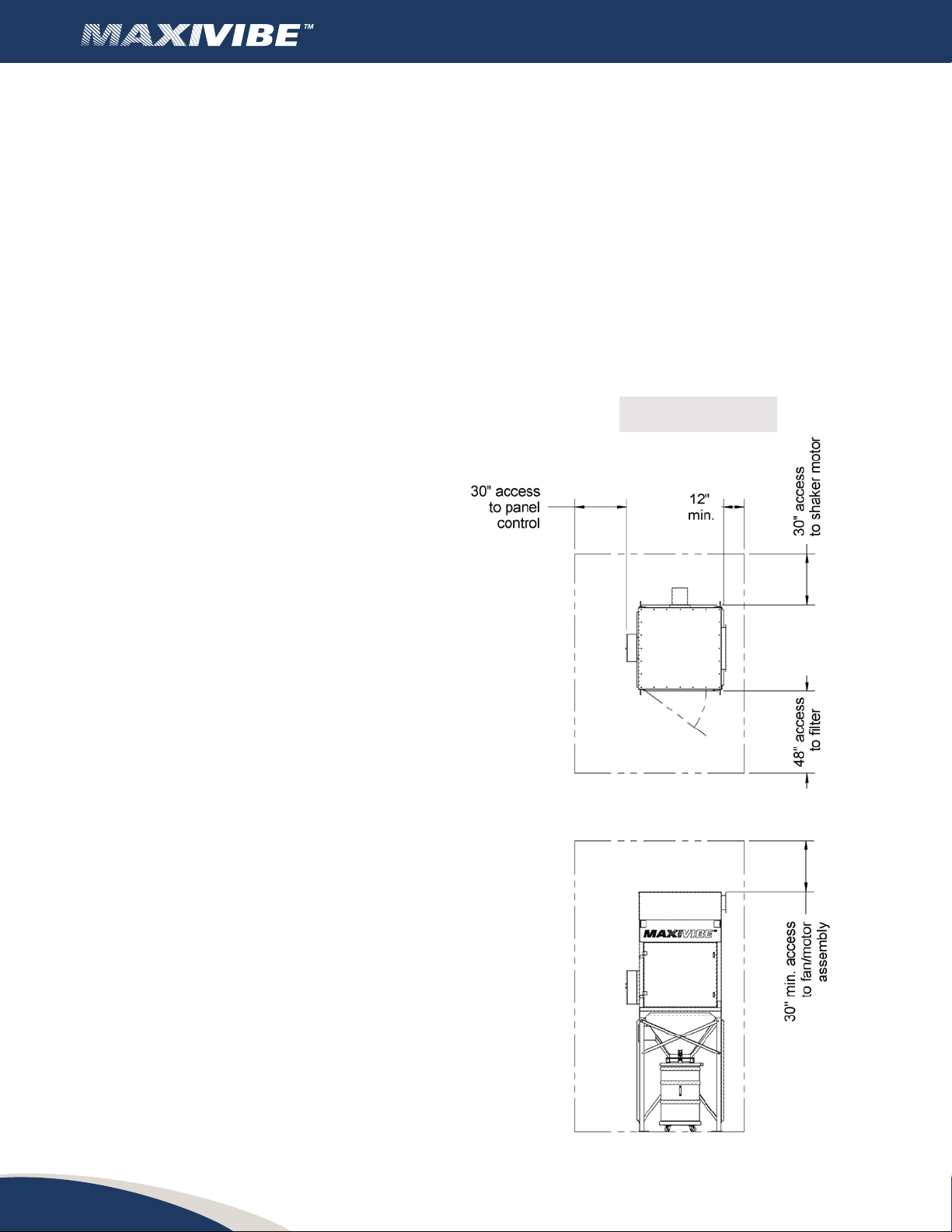

.................................................. 5

................................................. 5

.................................. 5

6.1 Automacshaker(oponal) ...................................... 5

6.2 Manualshaker ................................................. 5

.................................................. 6

7.1 Inspeconofthematerial ....................................... 6

7.2 Areaofinstallaon .............................................. 6

.................................................... 7

8.1 Necessarytools ................................................ 7

8.2 Fing......................................................... 7

.......................................... 9

.............................................. 11

.................................................... 11

11.1 Checklist ..................................................... 11

11.2 Shakersystem.................................................. 11

11.3 Electricalconnecon ............................................ 11

......................................... 12

12.1 Starngtheunitwithanewlterenvelope ......................... 12

12.2 Normalstart-up ................................................ 12

12.3 ShungtheunitOFF ............................................ 12

.............................................. 12

13.1 Workers/Sta .................................................. 12

13.2 Electricalcomponents ........................................... 12

13.3 Explosivedusts ................................................. 12

13.4 Anchors ....................................................... 13

13.5 Interiorinstallaon.............................................. 13

13.6 Processescreangsparks ........................................ 13

................................................. 13

14.1 Replacingthelterenvelope ..................................... 13

14.2 Installaonofthelterenvelope .................................. 14

14.3 Controlpanel .................................................. 15

14.4 Programminginstrucons ........................................ 15

............................................... 15

................................... 16

.............................................. 16

.................................................... 19

.......................................... 20

................................................. 20

............................................... 20