2.0 DELIVERY & RECEIPT OF EQUIPMENT

All equipment is inspected prior to despatch and leaves the factory in

good condition. Upon receipt of the equipment an inspection should be

made and any damage indicated on the delivery note.

Particulars of damage and/or incomplete delivery should be endorsed by

the driver delivering the goods before offloading by the purchaser.

No responsibility will be accepted for damage sustained during the

offloading from the vehicle or on the site thereafter.

All claims for damage and/or incomplete delivery must be reported to

Nuaire within two days of receipt of the equipment.

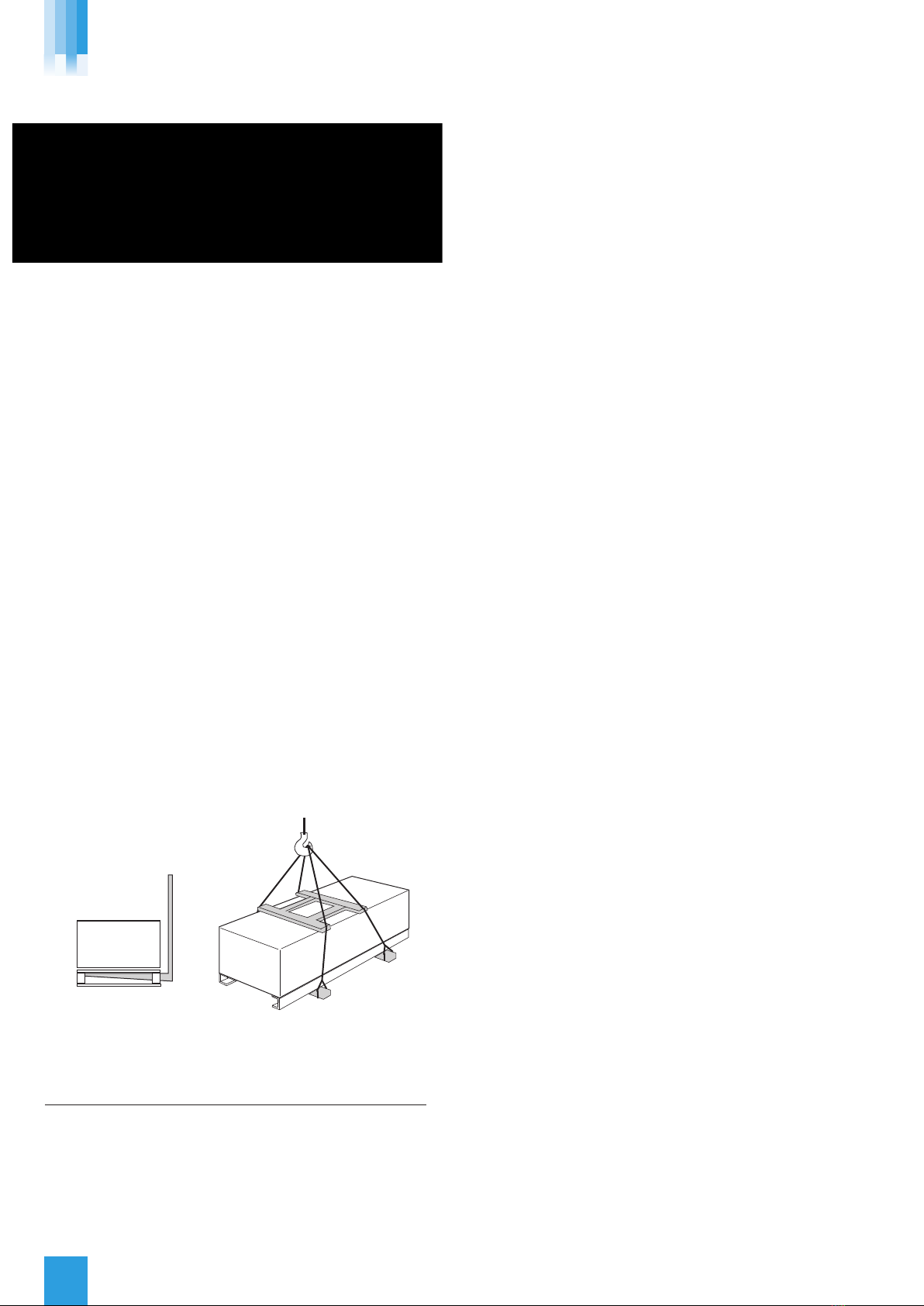

2.1 OFF LOADING AND ANDLING FROM T E

DELIVERY VE ICLE

The weight of the unit modules and palletised items is displayed on the

unit rating plate or on the packaging. Some of the modules have an

‘uneven’ weight distribution, and this will be indicated by labelling

where appropriate. Ensure that lifting and handling equipment is

adequately rated.

Offloading and positioning of the equipment is the responsibility of the

purchaser.

Spreaders should be used when lifting with slings to avoid damage to

the casings. Care must be taken to ensure that slings are correctly

positioned to avoid crushing and twisting of the unit castings.

Where channels and/or support frames are bolted to the underside of

the unit casing, slings or fork-lift arms should be positioned to locate in

the apertures in the channels. If Lifting Eyes have been supplied / fitted

it is recommended that they are used.

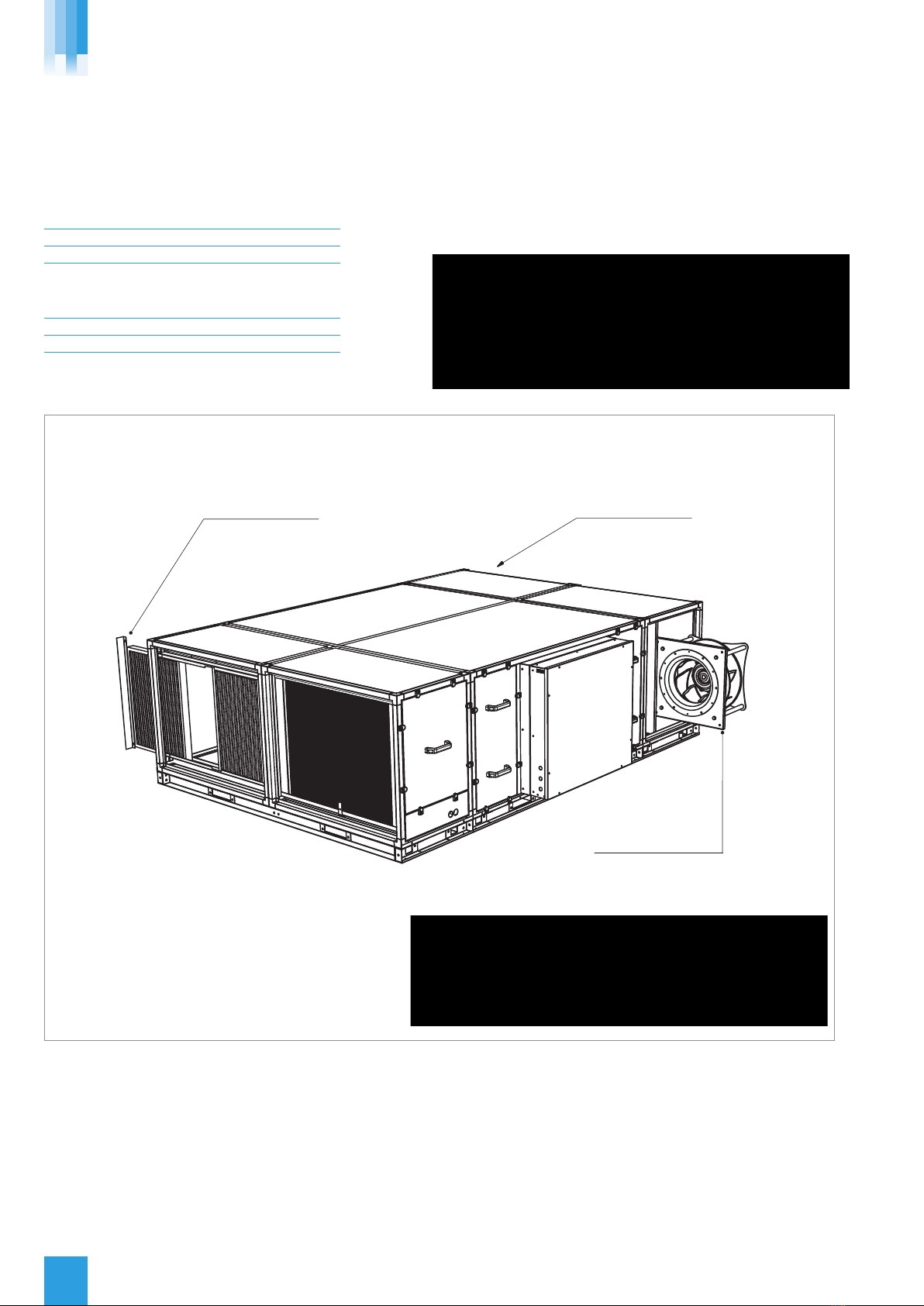

CAUTION: The XBC75 & 85 fan units have an uneven weight

distribution, please refer to the unit labelling before Lifting/

offloading the unit.

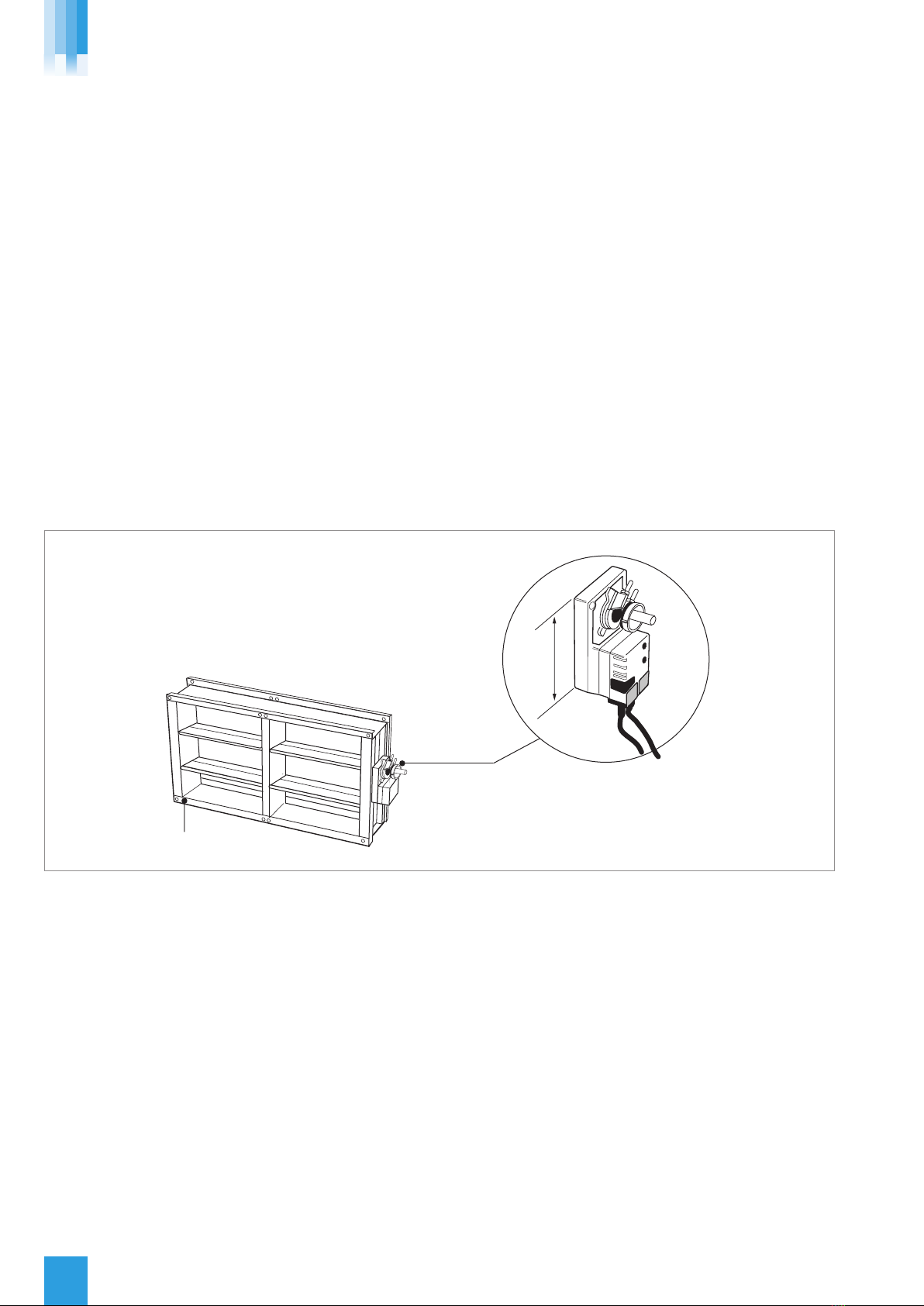

Figure 4: Lifting.

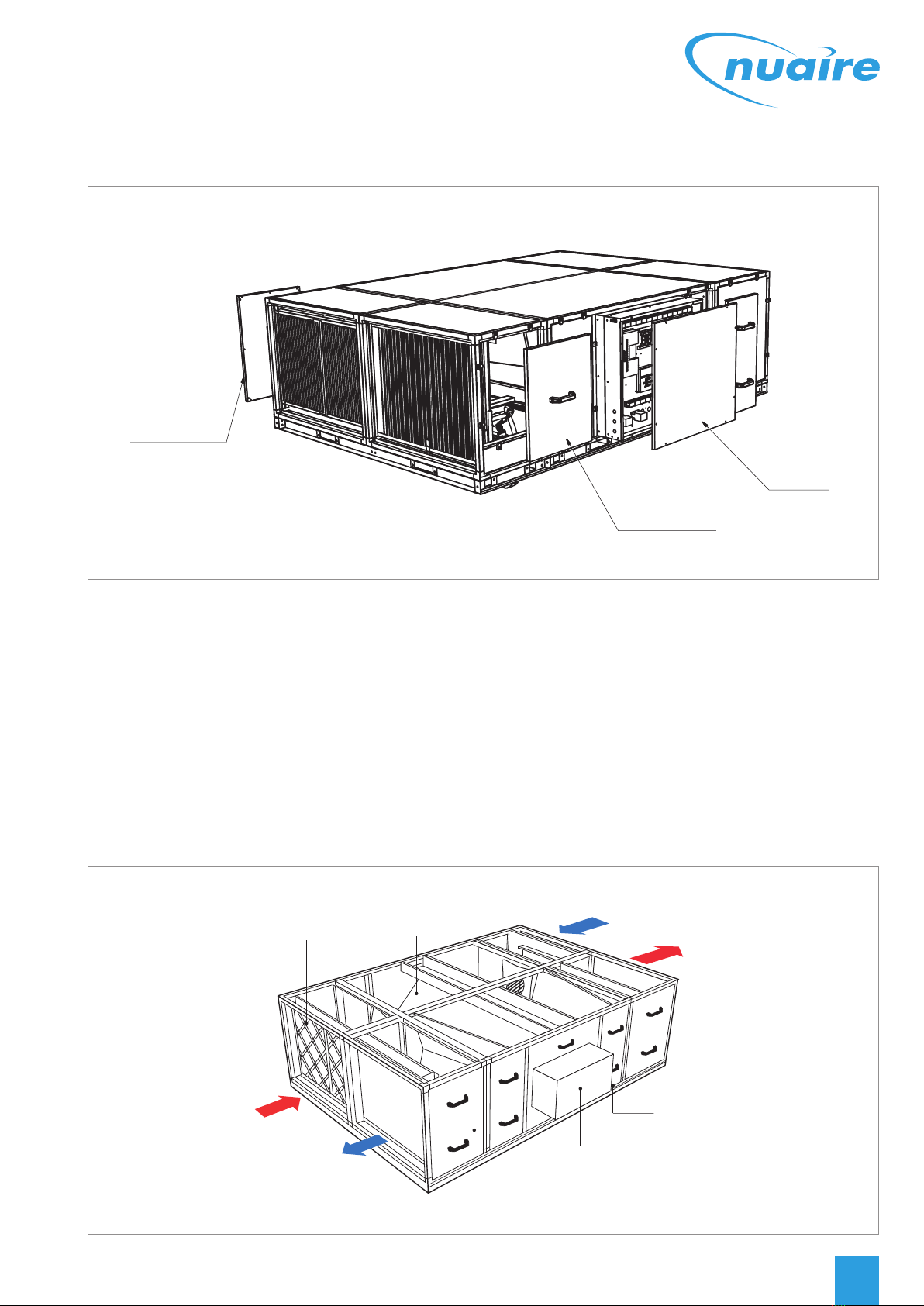

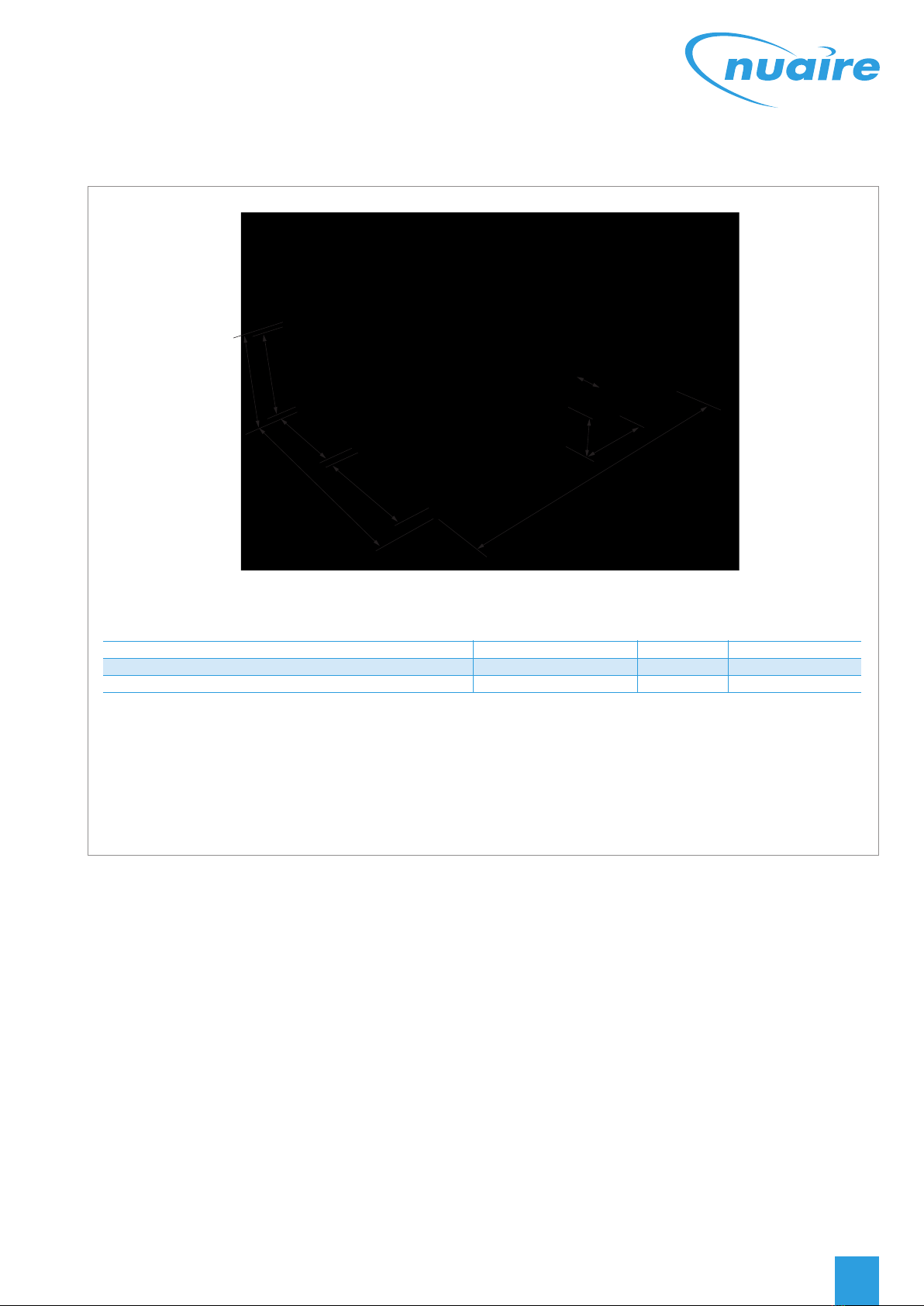

XBOXER XBC unit sections will be delivered to site in the number of

sections shown below.

XBOXER XBC Central Ventilation Unit No. of sections 1

The unit will be labelled with the direction of air flow.

The direction convention must be observed during assembly.

The unit may only be operated in its intended horizontal

installation plane.

The unit must be fully levelled during installation (this is essential to

ensure that condensate drains correctly).

See page 7. for dimensions and weights.

2.3 STORAGE

The equipment must be stored in a dry, internal location. Ductwork

connection apertures shall be sealed against the ingress of dust, water

and vermin. If the storage period is to exceed two months, contact

Nuaire for guidance on the appropriate “mothballing” procedures.

Do not stack units, modules or components.

3.0 ERECTION AND ASSEMBLY

Units must be installed in accordance with good industry practice.

These units may only be mounted horizontally and must be fully

levelled in the horizontal plane.

The units are heavy, and should be mounted using the fixing brackets

supplied or other suitable methods of support.

The supporting structure must be assessed for structural suitability.

If these units are being fitted into a ceiling void a suitable support

structure must be provided under each unit, the baseframe provided is

‘NOT’ suitable for this purpose.

Heat recovery components and modules that incorporate cooling coils

may produce condensation during use.

An insulated drip tray and condensate pump is provided.

The drain connection must be connected to a suitable drainage point.

(See fig 9, page 9 for details).

CONDENSATE PU P ALAR

The condensate pump incorporates an alarm function. If the water level

in the condensate tray exceeds a maximum level (for example, as a

result of the discharge tube becoming blocked or frozen), the alarm

contact will open. This contact is internally connected to the heat

exchanger bypass actuator, and the unit will automatically be placed

into bypass mode, preventing further condensate production. Unit

operation will otherwise be unaffected.

CONDENSATE PU P SPECIFICATION

Maximum flow rate = 50 L/

Maximum head = 20m Vertical, 100m orizontal

Pipe Connection size (Low Pressure Condensate

connection) XBOXER XBC = 8 mm

LPHW Coils, if fitted, are tested during manufacture to 16 Bar (using

dry compressed air). Coil and valve assemblies are similarly tested to

10 Bar. Operation of standard equipment is rated at PN6, if the

intended system requires higher operating pressures; please contact

the Nuaire Technical department for advice.

Electrical connections to the unit shall be made in accordance with the

appropriate product (see below); and installation wiring diagrams, and

shall use appropriately sized and rated cables.

Only the prepared apertures in the unit casing may be used for cable

entry. Do not drill or cut the unit casing for this purpose. Cable access

points are provided at the ends of the control enclosure.

If the control is rotated to aid connection of cables, please ensure that

sufficient flexibility is provided in the final connection run.

NB to avoid conflict with the unit access panels, it is recommended

that electrical and plumbing service connections to the unit are run at

90 degrees to the main air flow axis.

Control circuit connections must be segregated (i.e. routed separately)

from power connections.

The unit rating label shows the maximum electrical load of the

equipment. Connections to the unit may include single phase supply

connections, and a variety of control circuits.

Only the prepared apertures in the unit casing may be used for cable

entry. Do not drill or cut the unit casing for this purpose.

The equipment must be earthed and earth-bonded.

Means of local isolation for maintenance purposes are generally

required (by others). Ensure that all mains connections are isolated.

029 2085 8200

6

Safety first! – before commencing any work ensure:

• That all appropriate risk assesments have been carried

out, and the required safety measures have been taken

• That you understand the work required

• That you are trained and competent to carry it out

XBOXER XBC ECOS ART2 (NT) ODELS

Palletised.

Slings via spreaders fitted to unit with base frame.