VSD2H Variable Speed Drives Data Sheet TA201104 Issue 3, 08-Oct-2013 7

Data Sheet VSD2H

FIRMWARE

Full details of the rmware are diven in the VSD2H Application

Manual TE201103.

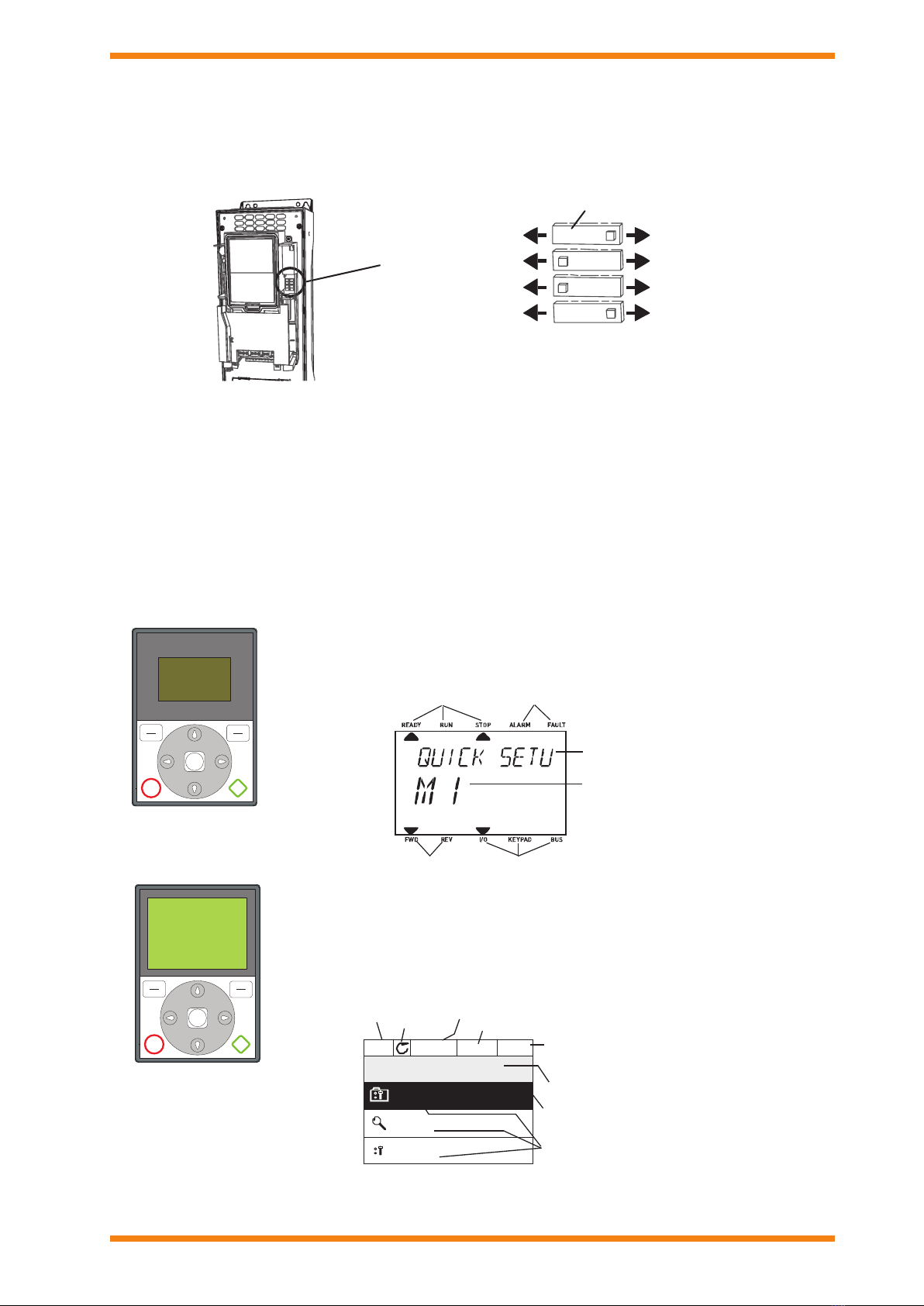

Quick Setup

On initial power up, the Startup Wizard will prompt for:

Language

Daylight saving (Russia/US/EU/off)

Time, Day, Year

Run Startup Wizard (Y/N)

If yes:

Process (pump or fan)

Motor Nominal Speed (range 24 to 19200 rpm)

Motor Nominal Current (range depends on unit)

There are other mini-wizards that can be used for setting the

following:

PID: Three term control for motor or external device by

way of I/O.

Pump and Fan Cascade: Cascade control of several

pumps or fans.

Resonance Sweep: For elimination of possible

resonance points in the system.

The Quick Setup menu, mentioned above, enables access to

the parameters most commonly used during installation and

commissioning including access to the Startup, PID, and Pump

and Fan Cascade wizards

Uninterruptible Operation and Energy Saving

Over temperature ride-through: Automatically adjusts

switching frequency and/or speed of the motor to adapt to

unusual increase in ambient. Benet: Uninterruptible operation.

Over temperatureride-through: Automatically adjusts

switching frequency and/or speed of the motor to adapt to

unusual increase in ambient. Benet: Uninterruptible operation.

RTO –Ramp Time Optimizer When problematic areas are

identied in acceleration or deceleration the drive automatically

expands the times needed for this to avoid mechanical stress

to the system. Benet: Decreased mechanical stress to the

system.

Trip free output switching Ensures trip free operation

when an output switch (e.g. safety switch) is operated between

the motor and the VSD. Truly intelligent and highly reliable

function to ensure better functionality than with any other VSD.

Benet: Uninterruptible operation.

Energy Saving function “Flux Optimization”: Flux

Optimization automatically minimizes energy consumption.

Benet: Even 5% increase in energy savings.

Congurable Auto reset function: Auto restart function can

be congured to make VSD restart automatically once fault is

addressed. Benet: Uninterruptible operation.

VFD and Motor Control

Single input control: Analog signal rising edge can be used to

start the device without additional start signal to a digital input.

Benet: Cost and time savings.

Flying start: Ability to get an already spinning fan under speed

control. Benets: Improved performance·. Very important in

clean room production.

Automatic torque boost function: Boosts initial voltage to

start high inertia fans. Benet: Avoids tripping and enables

smooth starts also to high inertia loads.

High Switching Frequency: The VSD2H is capable of

providing the maximum power with high switching frequency.

Benet: Low audible noise from the motor.

Prohibit frequency: Overriding the critical frequencies to

avoid resonance. Can be set with the help of resonance sweep

wizard. Benet: Elimination of resonance.

Maintenance counters/alarms: The drive can be programmed

to notify on upcoming maintenance for the system or the drive

itself. Benet: Reliability

Temperature-controlled fans: Fan stops operating when

not needed Benets: Less audible noise from the VSD itself.

Energy savings.

Advanced HVAC Control

Time based control: With the help of the real time clock and

calendar functionality the drive can be programmed to perform

functions based on time. Benets: Cost savings. Flexibility.

Inbuilt PID controller: Normal and Inverse Regulation, Delta P

regulation with 2 standard pressure transmitters, Feed forward

control, Less wiring since sensor normally close to inverter.

Benet: Cost saving. Faster response to process closed loop.

Sleep Mode: Shutting down the motor, when no demand.

Benet: Energy savings.

Pressure loss compensation: For compensating e.g. wrongly

placed sensor in the system. Benet: Time and cost saving.

Pump Soft ll: Feature to prevent the overpressures when

lling empty pipe work. Benet: Longer lifetime of the system.

Fire override mode: Keeps fan/pump running in case of re.

Benet: Legal requirement.

Pump and Fan Cascade control with full auto-change:

Controls total pumping system with several parallel pumps by

equally sharing the load. Also the master pump can be included

in auto-change loop. Benets: Longer lifetime of the system.·

Cost savings.

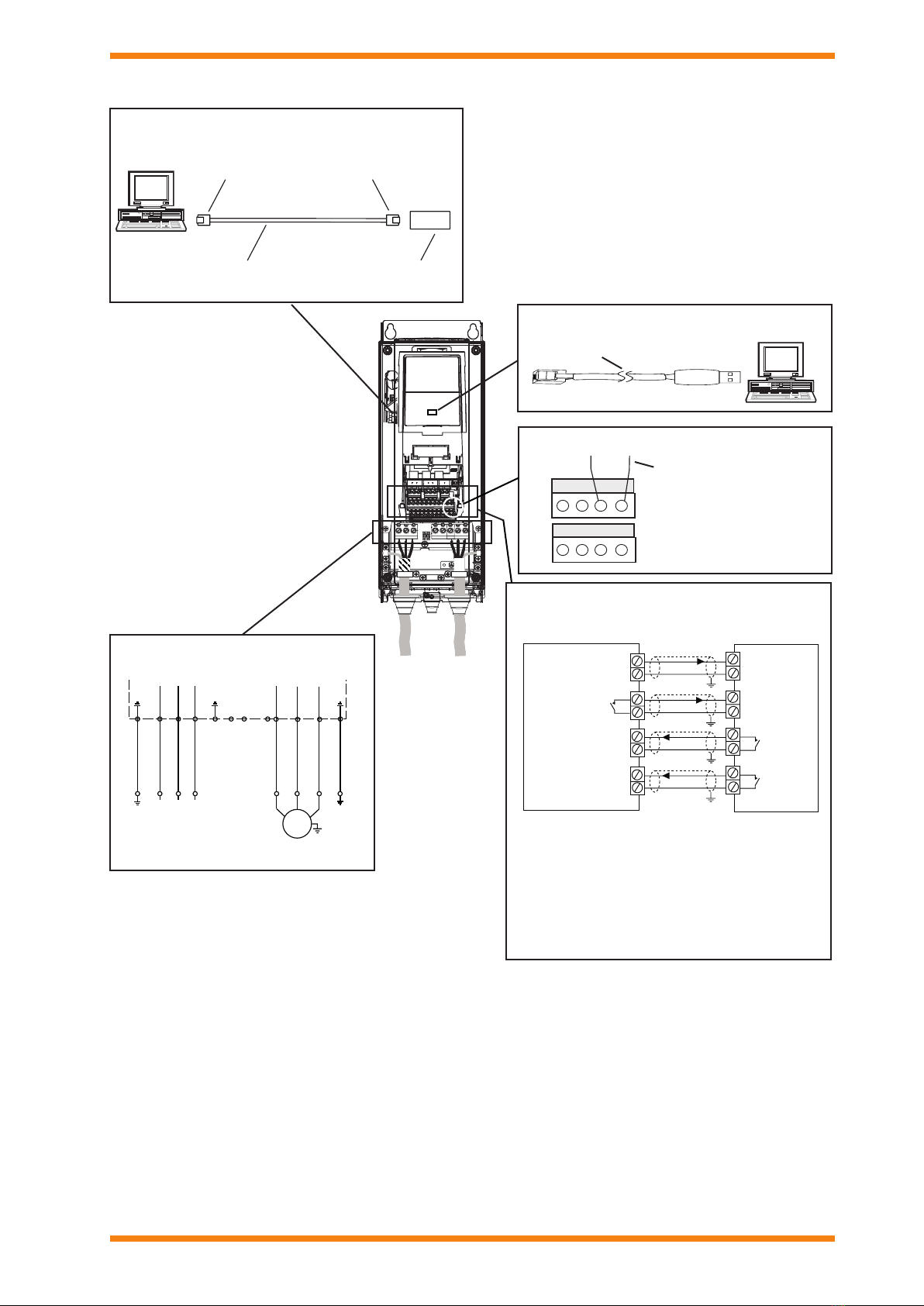

SOFTWARE

Windows based PC utility tools are available for making the use

of the Trend VSD2H as easy and convenient as possible. The

tools facilitate installation, commissioning, and maintenance.

The software is self-documenting from its integral help le. The

minimum requirement for using the software is a PC and a USB

to RS485 interface cable (e.g. ACC/VSD2H/USB-PC/CABLE,

3 m), to be connected to the RS485 terminal behind the control

panel. The software tools are available as a download from

Partnernet.

Drive Care PC Tool: The Drive Care tool is easy-to-use

commissioning software for the control of the VSD2H. It enables

the following:

Setting up parameters with the PC

Saving Settings to the PC

Creating commissioning documentation

Comparing paramters settings

Monitoring view with graphics

Diagnostics

Controlling the drive from the PC

This tool also includes the Loader tool which enables the

downloading of rmware or applications.

Note that the drive conguration can be loaded from one drive

into the advanced commissioning keypad (ACC/VSD2H/

GRAPHIC DISPLAY), and downloaded into another drive.