TREVIL 5040 EASYFORM Programming manual

50xx Easyform-ed0811

¥

5040 EASYFORM

5050 EASYFORM AC 7.5kW

5055 EASYFORM AC 15kW

Usage and Maintenance

50xx Easyform-ed0811

50xx Easyform-ed0811 ¥

50xx EASYFORM 3Index

Index

1. Introduction 5

1.1. Content and purpose of this manual 5

1.2. Safety precautions 5

1.3. Manufacturer’s liability 5

2. Description of the machine 6

2.1. How to identify the machine 6

2.2. Technical data 6

3. Installation 7

3.1. Upon receiving the goods 7

3.2. Assembling 7

3.3. Electrical connections 7

3.4. Steam connection (only types without boiler) 7

3.5. Water connection (only types with boiler) 7

3.6. Training of the operator 9

3.7. Compressed air connection (only for models with sleeves tensioning) 9

3.8. Other adjustments 9

4. Operation 10

4.1. Safety precautions 10

4.2. Before starting 10

4.3. Operation 10

4.5. Upon terminating work 10

5. Use of the control board 12

5.1. PROGRAMMING section 12

5.2. PROGRAMMING section - advanced features 12

5.3. MANUAL CONTROLS section 12

5.4. Pressing cycle counter meters 12

6. Maintenance 13

6.1. Maintenance allowed to the user 13

6.2. Maintenance to be carried out by the technician every six months 14

7. Troubleshooting 16

7.1. Solution to common problems, allowed to the user 16

7.2. Solution to failures, for the use of the authorised service center 17

8. Prolonged stop, Transportation or Decommissioning 19

8.1. Prolonged stop 19

8.2. Transportation 19

8.3. Decommissioning 19

9. Technical diagrams 20

10. Spare parts diagrams 29

50xx Easyform-ed0811

50xx Easyform-ed0811 ¥

50xx EASYFORM 5

1. Introduction

1.1. Content and purpose of this manual

This manual contains instructions concerning the installation and

maintenance of pressing equipment in conformity to the present

European Community Directive. Therefore you will find information

on the following subjects:

• Information on machine technical features;

• Instructions on installation and operating of the machine.

• Instructions on maintenance and servicing.

• Technical diagrams

• Exploded views of spare parts

This manual is for installer’s and technician’s use; they will have to

read and understand it carefully before installing, using or servicing

the machine.

This manual should be kept with the machine and read before

operation; in case of loss or damage please ask the builder for a

new copy.

The builder is not responsible for any consequences arising from the

neglecting of all instructions reported in this manual.

The content of this manual is property of the manufacturer. Duplication

of this manual is forbidden.

1.2. Safety precautions

Ignoring the following safety precautions can cause damage either to

people, linen, animals and to the machine.

The following symbols, on the machine and in this manual, advise

about possible risks.

Legend of the safety symbols found on the machine and in this

book:

Warning: live electricity

General warning: follow instructions to avoid damage to

the machine or to people.

Warning: hot surface / burn hazard

Warning: high temperature

Risk of injury to hands of feet

Wear gloves

Wear protective shoes

Wear a helmet

i

Information, notice, advice

Carefully read the entire manual before installing, operating or

servicing the machine.

Installation and maintenance the product described in this manual

must be performed by authorised and qualified technicians who

know the products and are acquainted with standards for installation

of industrial pressing equipment.

The builder is not responsible for external connections not duly

performed.

The product described in this manual must be used only to iron

garments and linen. Any other use is forbidden unless builder

authorizes it in writing.

Do not press fabrics contaminated by dangerous substances such

as explosives, inflammable, etc. Make sure they are rinsed or aired

before ironing.

To prevent fire hazard or explosions do not stand near the machine

with explosive or inflammable products.

Use of the machine is allowed only to professional operators who

have been trained on how to operate the machine. In any case the

use of the machine is forbidden to children under 14 years of age.

Do not remove safety protection devices.

Do not leave machine unattended while in operation.

Do not remove safety symbols from the machine

1.3. Manufacturer’s liability

This manual instructions are not intended to substitute, but only to

combine obligations of current legislation on safety standards.

With reference to information included in this manual, the

manufacturer is not responsible in case of:

• neglect of local safety standards during machine utilisation;

• incorrect installation of the machine;

• neglect or incorrect observance of instructions included in this

manual;

• conection to electric plant having voltage and frequency that

differ from those specified in the technical data tag;

• connection to electric plant non compliant with EC safety

requirement, in particular if the plant lacks grounding, thermal

magnetic protection and differential protection;

• unauthorized changes on the machine;

• utilisation of the machine by unauthorized, untrained or non-

professional operators;

• neglect of maintenance operations;

• use of non original spare parts.

Introduction

50xx Easyform-ed0811

¥

50xx EASYFORM6

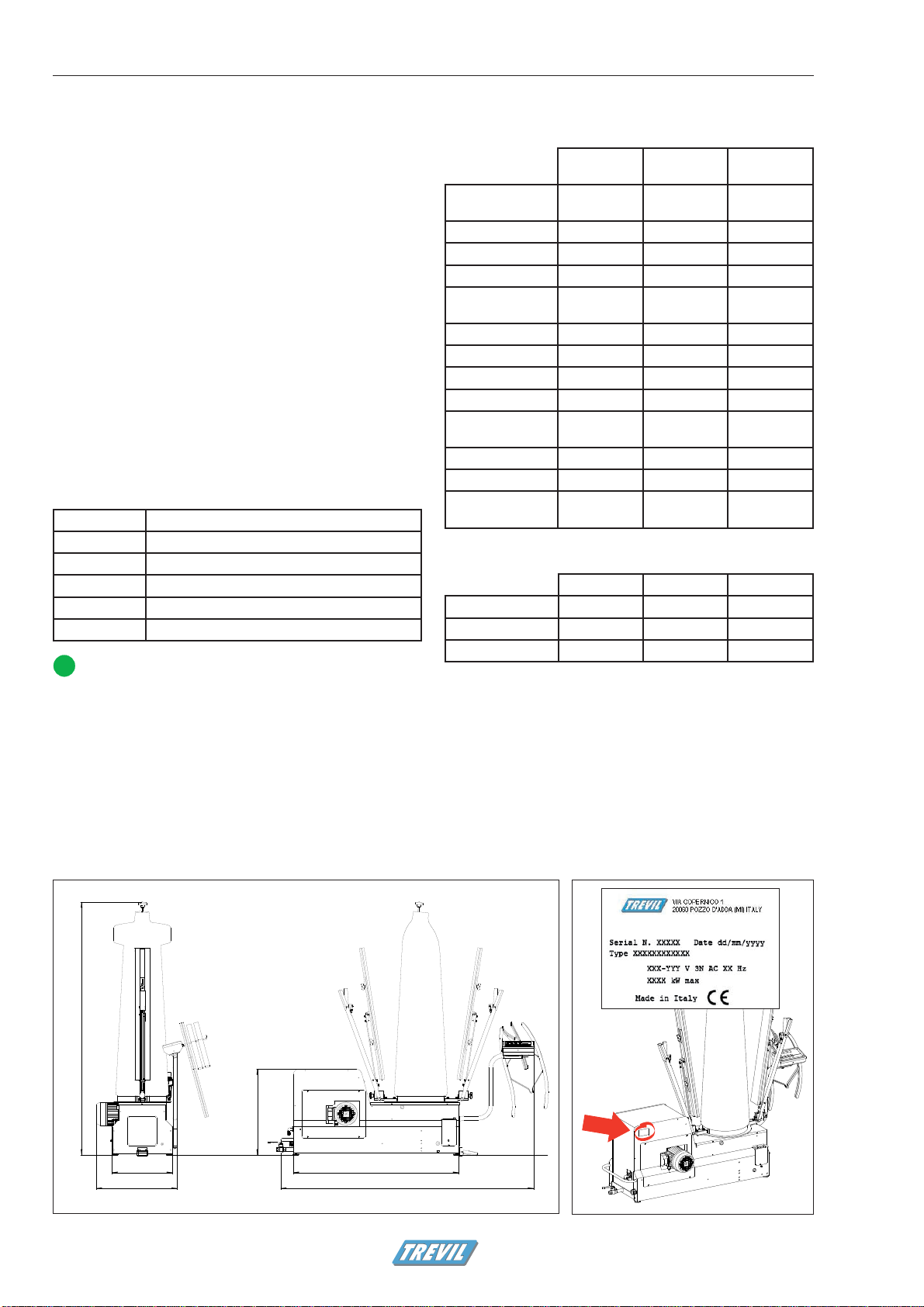

171.5cm (68”)

41cm (16”) 112.5cm (44”)

171.5cm (68”)

58.5cm (23”)

55cm (22”)

Figure 2.1 - Machine dimensions Figure 2.2 - How to identify the machine

2. Description of the

machine

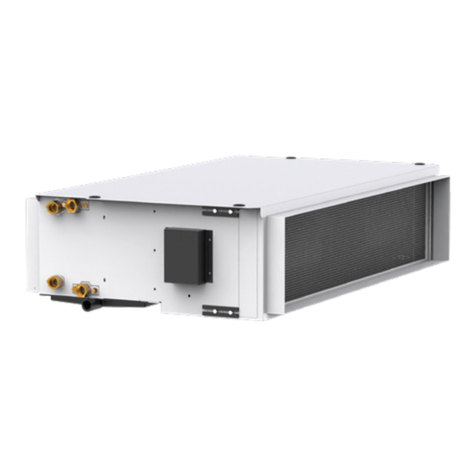

The machine described in this manual is a form finisher for garments

for the upper body.

The form finisher is designed for professional use only in:

• Garment manufacturing industries;

• Large and small Industrial dry cleaners;

• Garment finishing industries.

The form finisher must be utilized only by qualified personnel, who

have been specifically trained on this type of machinery.

The manufacturer does not accept any responsibility for damage

caused to persons or things due to improper, erroneous or

unreasonable utilization of the machine.

2.1. How to identify the machine

The machine is identified by a technical data plate. The plate is found

on the machine cabinet, as shown in picture 2.2. Do not alter or

modify in any way the data on the identification plate. Do not remove

the identification plate.

Description of the data in the identification plate

Serial N 5 digits serial number

Type Product code

V Tension

Hz Frequency (cycles)

kW Power absorption

Date Date of production

i

This manual describes all the versions of the machine. Be-

fore reading the manual identify the version of the ma-

chine you own by reading the machine “type” in the technical

data plate. While reading the manual take into account only

the information related to the version of machine you own.

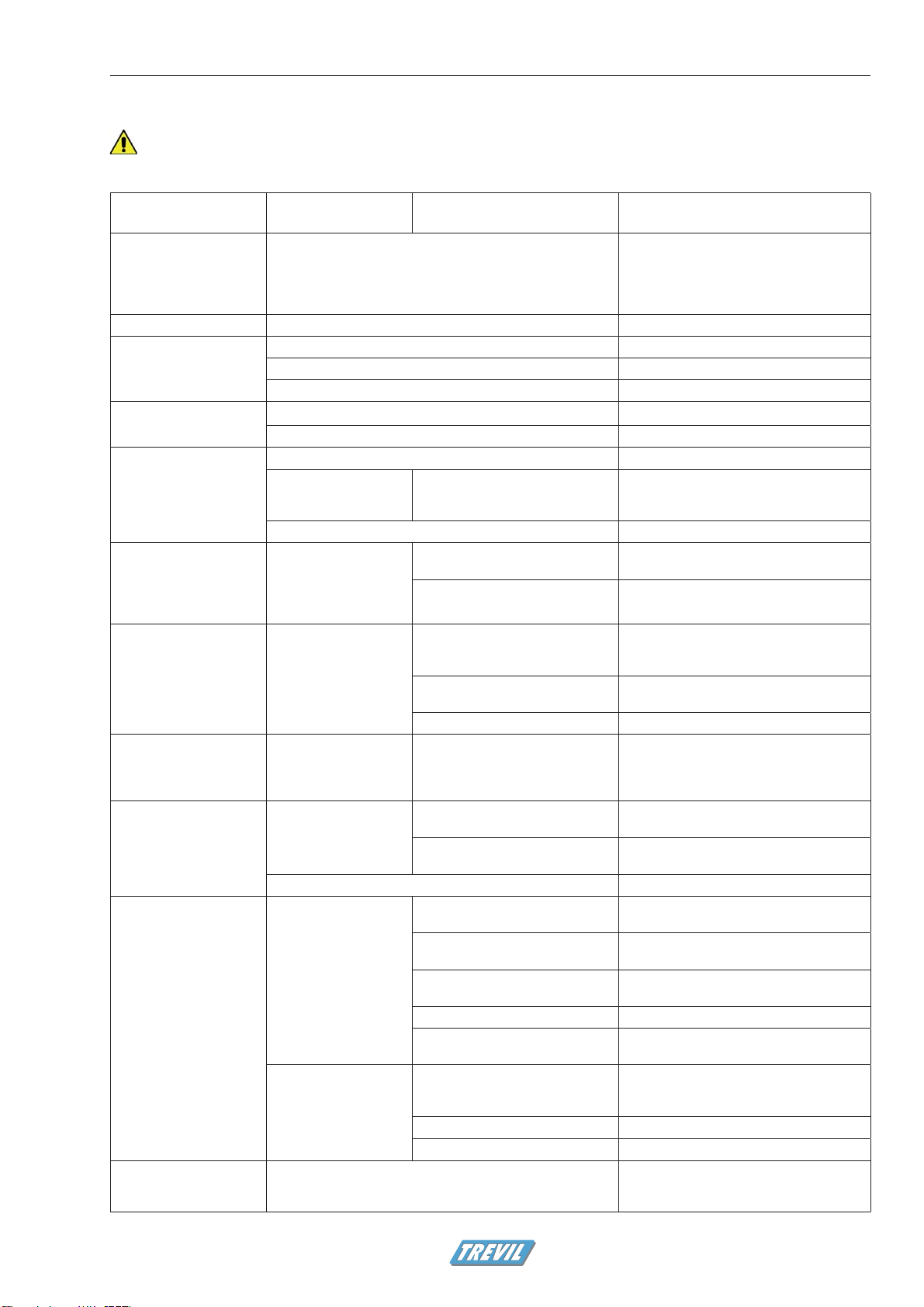

2.2. Technical data

For machine dimensions see Figure 2.1.

5040

5042

5050

5052

5055

5057

Electrical

requirements 400V 50Hz 400V 50Hz 400V 50Hz

Steam inlet 1/2” -- --

Condensate return 1/2” -- --

Steam pressure 600 kPa -- --

Boiler heating

element -- 7,5 kW 15 kW

Water inlet -- 16 mm 16 mm

Boiler exhaust -- 1/2" 1/2"

Pump -- 0,8 kW 0,8 kW

Blower motor 1,5 kW 1,5 kW 1,5 kW

Steam consump-

tion 15-20 kg/h -- --

Weight 105-120 Kg 125-140 Kg 125-140 Kg

Noise

Ambient tempe-

rature 15 - 40 °C 15 - 40 °C 15 - 40 °C

Only for models with sleeves tensioning:

5042 5052 5057

Air inlet 1/4” 1/4” 1/4”

Air pressure 600-700 kPa 600-700 kPa 600-700 kPa

Air consumption 30 nl/min 30 nl/min 30 nl/min

Description of the machine

50xx Easyform-ed0811 ¥

50xx EASYFORM 7

3. Installation

3.1. Upon receiving the goods

The machine is delivered mounted on crate and protected by a plastic

film and, in some cases, by a carboard box.

1. Position the crated machine near to the final location of

installation. The crated machine must be moved using suitable

devices, such as a forklift (Figure 3.1)

2. Unpack the machine and separate cardboard from plastic.

Dispose of carton and plastic according to local regulations.

3. Unscrew the bolts that fix the machine to the crate

4. Move the machine from the crate to its final position.

CAUTION - To avoid damaging the machine, do not move

the machine by grabbing the form or the clamps.

CAUTION - The machine can be moved by

hand by experienced personnel only. Wear

gloves, helmet and protective shoes when moving the ma-

chine.

3.2. Assembling

3.2.1. Packing list

The package contains:

1. Machine body.

2. Form with clamps, pad and cover

3. Set of two sleeve expanders and two manual vent clamps.

4. Instruction manual.

Upon receiving the goods, check that the pakcage contains all the

above listed items.

3.2.2. Mounting the form in place

Refer to Figure 3.2.

1. Loosen screw (A) found on support (B).

2. Insert the form (C) on the support (B).

3. Tighten screw (A).

4. Fit the pad and cover on the form.

5. If the machine is provided with sleeve arms: insert pin (D) into

the slot to block the rotation of the form.

3.3. Electrical connections

WARNING - The electrical connection is to be made by

a licensed electrician only and according to local safety

regulations.

The manufacturer is not responsible for damage or injury caused by

improper installation.

Refer to Figure 3.3.

1. Install a multi-pole switch (circuit breaker) to facilitate installation

and service operations. See table 3.5 for rating and type of

connection.

2. In most countries the circuit breaker should include a

protection against overcurrents (e.g. thermal-magnetic

circuit breaker or fuse). If using a fuse, see power absorbtion

on the identification plate of the machine (see figure 2.2).

In some countries the circuit breaker must include a ground

fault interrupt protection.

3. If the appliance is not provided with power cord, mount a cord

of suitable length. For the choice of the cord type refer to table

3.5.

4. Mount a plug on the power cord, see table 3.5 for rating.

5. Connect the plug to the circuit breaker. The cable should hang

in a gentle curve.

6. Check that the motor is rotating counterclockwise, otherwise

switch two of the three phases wires.

WARNING -The electrical line must be properly grounded

to insure the safety of the operator.

i

INDICATION - If a Ground Fault Interrupt protection is in-

stalled: every month test the safety of the circuit by press-

ing the Test button of the circuit breaker. The protection ought

to trip. If it does not, call a technician immediately, as the safety

of the equipment is impaired.

Table 3.5 - Data for electric connection

Type Plug Power cord

5040

5042

Plug 3P+N+T 400V 3N 10A as

per standard IEC60309

Type H05VV-F

5 x 1mm2

5050

5052

Plug 3P+N+T 400V 3N 25A as

per standard IEC60309

Type H05VV-F

5 x 2,5mm2

5055

5057

Plug 3P+N+T 400V 3N 32A as

per standard IEC60309

Type H05VV-F

5 x 4mm2

WARNING - The power cord can be replaced only by an

authorised service center.

3.4. Steam connection (only types with-

out boiler)

WARNING - The steam connection is to be made by a li-

censed technician only and according to local safety regu-

lations.

Refer to Figure 3.4.

Connect the machine to a steam source with steam pressure at 5 bar

(75 PSI) capable of providing 20 Kg/h (45 lbs/hr) of steam.

The numbers in the figure indicate the follwoing parts (not supplied

with the machine):

1 – Steam line

2 – Condensate return line

3 – Ball valve

4 – Check valve

5 – Steam trap

WARNING - Do not connect the machine to a steam line

having pressure exceeding recommended valuse. Risk of

serious damage to the machine and injury to people.

3.5. Water connection (only types with

boiler)

WARNING - The connection is to be made by a licensed

technician only and according to local safety regulations.

Refer to Figure 3.5.

• Connect the water inlet fitting (1) with the water line.

• install a non-return valve* and a faucet or ball valve on

the water mains

• connect the valve to the water inlet nozzle with a 16mm

diameter tube rated for the pressure of the water mains in

your area*.

*For EU countries: these items must be approved according to

standard EN 61770.

WARNING - Use tap water. Do not add softening

products.

• Connect the boiler discharge fitting (2) to the waste water line.

The tube used for the connection must be suitable to carry hot

water and steam.

Installation

> Continued on page 9

50xx Easyform-ed0811

¥

50xx EASYFORM8

5040: min 10A @ 400V 50Hz

5042: min 10A @ 400V 50Hz

5050: min 25A @ 400V 50Hz

5052: min 25A @ 400V 50Hz

7,5 kW

5055: min 32A @ 400V 50Hz

5057: min 32A @ 400V 50Hz

15 kW

1

2

3

5

4

D

A

B

C

Figure 3.1 - How to move the crated machine

Figure 3.3 - Electrical connection

Figure 3.4 - Steam connection

Installation

Only machine without boiler

(models 5040-5042)

Figure 3.2 - Mounting the form

Choose electric components approved as per

standard IEC60309

50xx Easyform-ed0811 ¥

50xx EASYFORM 9

6bar (90PSI)

6bar (90PSI)

1

2

Figure 3.6- Compressed air connectionm (only for models with sleeves tensioning)

WARNING - The connection to the drainage system

must ensure that no leakage of steam or hot water

occurs during the boiler discharge operation

Thermally insulate the discharge pipes.

If necessary, install tanks or devices that allow hot water to cool

before reaching the drainage system.

3.6. Training of the operator

The technician must instruct the operator on how to perform the boil-

er discharge procedure.

The operator must be advised that:

• during the discharge operation, the boiler expels hot water

mixed to steam;

• the discharge operation can be carried out only if the pressure

in the boiler is below 1 bar;

• the connection of the boiler exhaust to the drainage system

must be kept in good order and must be verified every time

before performing the boiler discharge procedure.

3.7. Compressed air connection (only for

models with sleeves tensioning)

WARNING - The steam connection is to be made by a li-

censed technician only and according to local safety regu-

lations.

Refer to Figure 3.6.

1. Connect the machine to a compressed air source with minimum

pressure 6 bar (90 PSI)

2. Make connections as indicated

3. Set the general pressure regulator on the machine at 6 bar (90

PSI)

WARNING - Do not operate the machine with air pressure

exceeding 6 bar. Risk of damage to the machine.

3.8. Other adjustments

The machine is supplied with the control panel folded against the side

of the the machine cabinet.

Rotate the support of the control panel to bring it in the most

comfortable position.

Figure 3.5 - Water connection

Only machine with boiler

(models 5050-5055-5052-5057)

Installation

50xx Easyform-ed0811

¥

50xx EASYFORM10

4. Operation

The machine described in this manual is a form finisher for garments

for the upper body.

The form finisher is designed for professional use only in:

• Garment manufacturing industries;

• Large and small Industrial dry cleaners;

• Garment finishing industries.

The form finisher must be utilized only by qualified personnel, who

have been specifically trained on this type of machinery.

4.1. Safety precautions

During operation the appliance is under electrical ten-

sion:

• Do not operate machinery with partially exposed or frayed

wiring.

• Never permit water to come into contact with machine:

danger of electrical shock, short-circuiting and damage

to machine may result.

• Do not open the machine cabinet.

The appliance has various parts that reach extremely high

temperatures:

• Do not leave the machine unattended while it is on.

• Keep all flammable substances away from machine, to

avoid risk of fire.

• Do not open machine body.

• Do not replace cover and padding while machine is hot

(wait at least 2 hours after turning it off). Always check

the temperature of the form before proceeding to substi-

tute covers.

The appliance generates hot steam vapors - Stay clear of

steam reflex jet.

4.2. Before starting

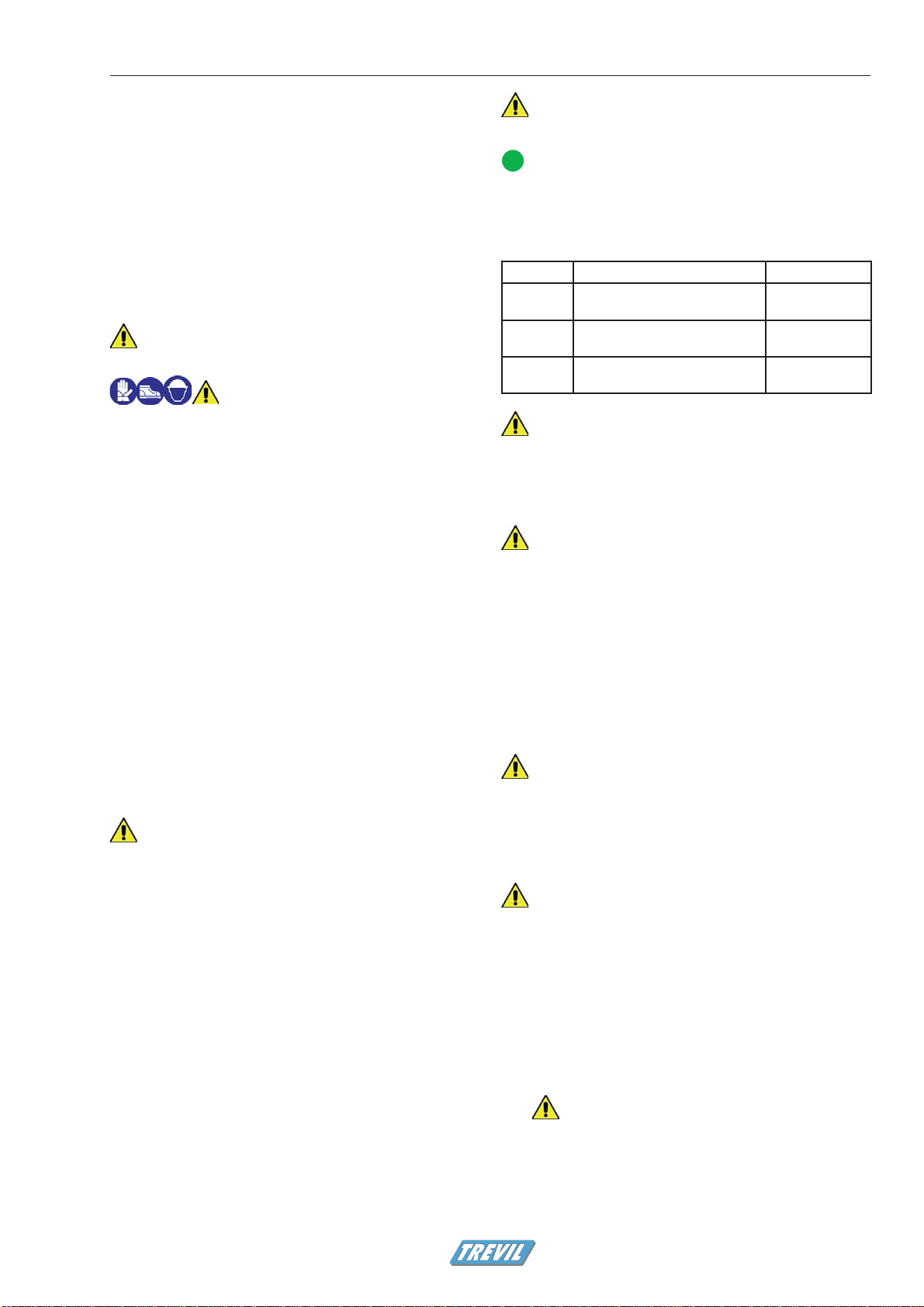

Refer to figure 4.1

4.2.1. Model without boiler

1. Open the steam and condensate return valves.

2. Turn on the main power switch (1).

4.2.2. Model with boiler

1. Open the water feed valve.

2. Check that the boiler discharge valve is closed.

3. Turn on the main power switch (1).

4. Turn on the boiler switch (11).

5. Turn on the heating element switch (12).

6. Only for model 5055: turn on the second heating element (13).

This heating element may be kept off for energy saving if the

machine is to be used for few garments a day. If you realize that

the boiler needs too long to build up pressure, then you can

turn on the auxiliary heating element at any time.

4.3. Operation

Refer to figures 4.1 and 4.2

4.3.1. Settings

1. Adjust the pressure of the front and rear clamps so that they

hold the garment in place during the finishing cycle:

• turn knob (4) clockwise to reduce the pressure;

• turn knob (4) anticlockwise to increase the pressure.

2. Adjust the blowing strength according to the garment: move

lever (5) towards + or - to increase or decrease blowing

strength.

4.3.2 Pressing

1. Use buttons (A) on the control panel to choose the cycle most

suitable to the garment to be finished.

2. Position the garment on the form and adjust shoulder width by

means of knob (9).

3. If needed, change the shape of the bag using the strings.

4. Close the front and rear clamps (8 and 7).

5. Insert sleeve expanders (3) and close any vents with manual

vent clamps (2).

6. Step on the START pedal (6) to start the finishing cycle.

WARNING - The general warning light (14) indicates that

one of the safety protections has tripped. Should it turn on

during usage, turn off the appliance immediately and report to

a service center.

4.5. Upon terminating work

4.5.1. Model without boiler

1. Turn off the power switch (1) and the switch installed on the

mains.

2. Close steam and condensate return valves.

4.5.2. Model with boiler

1. Turn off the power switch (1) and the boiler switches (11-12-

13).

2. Turn off the switch installed on the mains.

3. Close the water feed valve.

Operation

50xx Easyform-ed0811 ¥

50xx EASYFORM 11

"

#

798

23

1

4

6

5

4

13

12

11 14

10

15

Figure 4.2 - Control panel

(A) Program selection buttons

(B) Manual controls section

Operation

Figure 4.1 - Parts of the machine

All models:

(1) ON/OFF switch

(2) Two vent clamps

(3) Two sleeve expanders

(4) Clamps pressure adjustment knob

(5) Blowing strength adjustment lever

(6) START pedal

(7) Rear clamp

(8) Front clamp

(9) Shoulder width adjustment knob

Only models with boiler

(10) Pressure gauge boiler

(11) Main boiler switch

(12) Heating element switch

(13) Second heating element switch

(14) General warning light

(15) Water level lamp

50xx Easyform-ed0811

¥

50xx EASYFORM12 Use of the control board

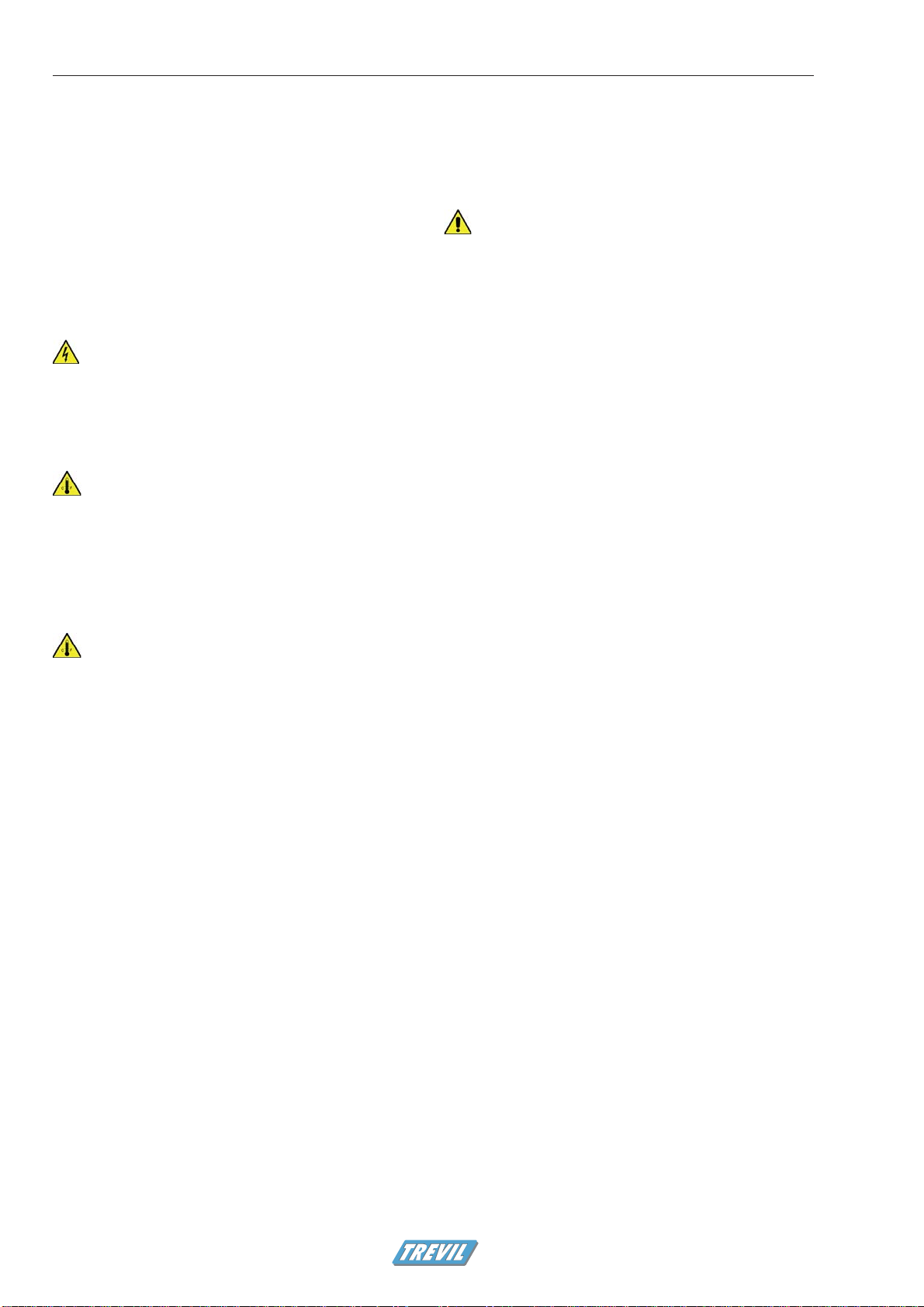

5. Use of the control

board

The microprocessor programmer manages the pressing cycle in all of

its functions. The programmer can store up to 10 programs.

The control panel is subdivided into 2 sections:

• PROGRAMMING: allows storage of 10 different work pro-

grams

• MANUAL CONTROLS: allows manual function of main press-

ing functions.

When the machine is switched on the control panel shows the last

program used.

5.1. PROGRAMMING section

5.1.1. Pressing times

The programming section consists of :

• Program number display: from 0 to 9

• STEAM time display: from 00 to 99 seconds

• MIX / PAUSE time display. The two-figure display is shared by

the two functions MIX (mixed steam + air) and PAUSE (pause

between steam and blowing; used e.g. for touch ups)

• AIR time display: blowing time

• 5 programming buttons, as described in the following.

To program a pressing cycle, do as follows:

1. Press the button PROG ( ) on the panel. The STEAM display

and the PROG display begin to flash.

2. Press buttons

or to increase or reduce the steam time.

3. Press the PROG. button ( ) to memorize the steam time.

4. The green light MIX and the display below begin to flash: press

or to set a time of mixed steam + air after steaming, if

needed.

5. Press the PROG. button to memorize the mix time. If you have

memorized a MIX time, go to point 8.

6. If MIX time is zero, the green light PAUSE and the display below

begin to flash: press or to set a pause time between steam

and blowing, if needed (e.g. for touch ups with the iron)

7. Press the PROG. button to memorize the pause time.

8. The AIR indicator starts to flash. Press or to set blowing

time.

9. Press the PROG. button. The display stops to flash. Programming

is finished

If you need to change only one of the times, repeat all steps without

modifying the other times.

Mix and Pause times can be used or not, depending on the needs.

Table 5.1 shows the possible combinations.

5.2. PROGRAMMING section - advanced

features

The PROGRAMMING sections allows adjustment of several param-

eters. Figure 5.3 shows the look of the displays during programming

of advanced parameters.

The status of each function remains stored in the memory associated

to the program in which it was entered.

1. To access advanced programming press and hold the PROG.

button until the letter H appears in the program number dis-

play

2. The STEAM display shows the number of the parameter being

programmed. Please refer to Table 5.2 for description of the

parameters and their status;

3. The AIR display shows a flashing number indicating the param-

eter value. Press or to change parameter value

4. Press PROG. to memorize the value and step forward to the

next function;

5. Press PROG. several times, until the displays return to normal

pressing times visualization.

The settings of the advanced parameters remain stored in the memo-

ry associated to the program in which they were entered.

For example: if the machine is running program number 5 and the

user excludes the photocell, the photocell will remain excluded for

future use of program number 5, even after switching off the ma-

chine.

5.3. MANUAL CONTROLS section

STEAM: Keep pressed to manually steam the garment.

AIR: Press once to start blowing. Press it again to stop blowing. In

order to have manual MIX press STEAM during the blowing

operation.

START CYCLE: Starts the pressing cycle.

END CYCLE: Ends the cycle immediately, interrupts all ongoing

commands, opens

5.4. Pressing cycle counter meters

The machine is equipped with two cycle counters:

• The total counter counts all the pressing cycles carried out by

the machine in its work life and cannot be reset.

• The partial counter can be reset and can be utilized, for exam-

ple, to count the number of garments processed in one day.

Cycle counter - total cycles

• To view the total number of pressing cycles run by the machine

in its life, press and together and hold for 2 seconds.

• The display PROG shows the digit 1 and the other displays

show the number of cycles. This counter cannot be zeroed.

• To exit the counter, press and hold and together and hold

until the displays return to cycle times visualization.

Cycle counter - partial counter

• While the number of total cycles is displayed, press to view

the partial counter.

• The display PROG shows the digit 2 and the other displays

show the number of cycles that the machine has run since the

last time this counter was zeroed.

• Press PROG to zero the partial counter.

• To exit the counter, press and hold and together and hold

until the displays return to cycle times visualization.

50xx Easyform-ed0811 ¥

50xx EASYFORM 13

S

R

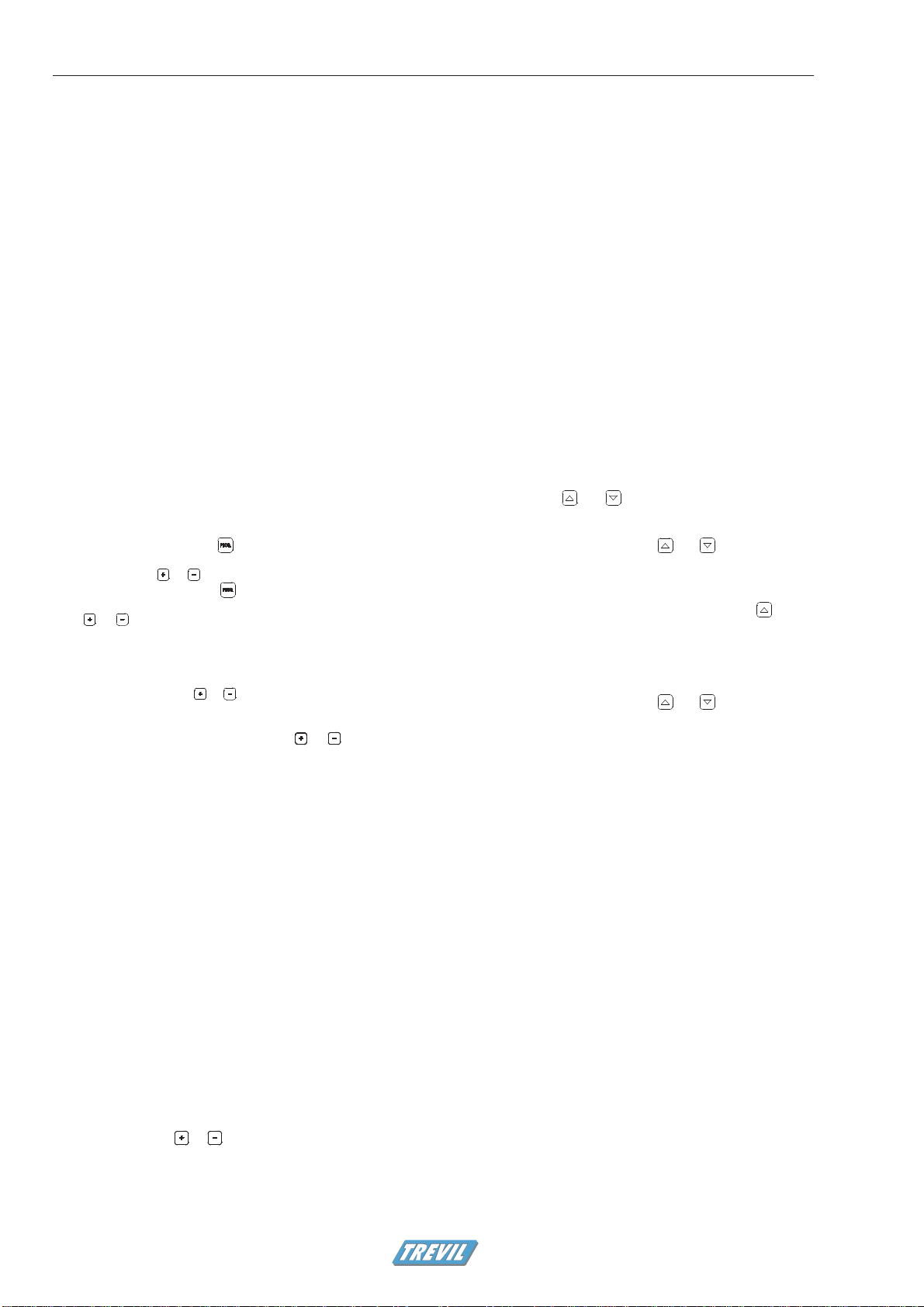

Table 5.1 - Setting mix and pause times

What is your need? What you should do How the displays will look

I do not need mix or pause

times

Set both times at zero Mix and pause lights are off.

The displays show no numbers.

I need only a mix time, no

pause

Set mix time at the desired value.

Mix light is on.

Pause light is off.

The two displays show mix time (8 seconds and 12

seconds in the example).

I need only a pause time,

no mix

Set mix time at zero. Set pause time at

the desired value.

Mix light is off.

Pause light is on.

The two displays show pause time.

Maintenance

6. Maintenance

6.1. Maintenance allowed to the user

6.1.1. Every week

• Clean machine body with a soft non abrasive cloth.

WARNING: Do not use aggressive detergents or sol-

vents that may ruin machine parts

• Verify visually that steam, condensate and compressed air

connections do not leak

• Verify that visible electrical cabling and air and steam

connection tubing are in perfect working order

• Verify that pads and covers are in good condition. If they show

any sign of deterioration replace them immediately. Pressing

quality may decrease dramatically if pads and covers are dirty

or damaged.

• Clean the filter (only types with boiler)

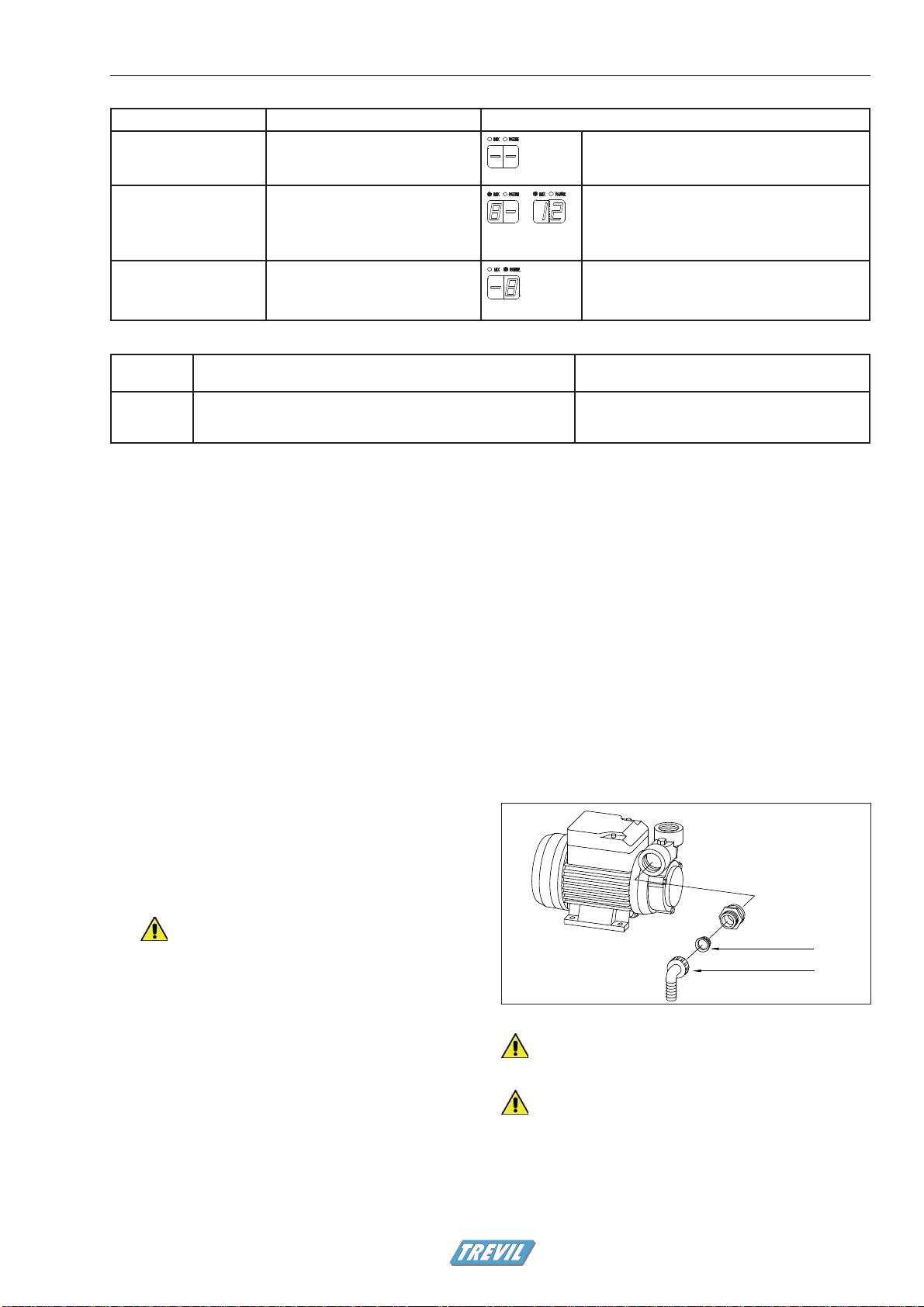

Refer to Figure 6.1

• Close the connections to the water source.

• Remove the elbow fitting (R).

• Clean the fitting.

• Remove the filter (S).

• Carefully clean the filter.

• For types with boiler: once a week, after finishing ironing, dis-

charge the boiler following the instructions at the following

paragraph.

WARNING: Do not run a machine that does not look in

proper order

INDICATION: always ask for original spare parts. Non

original parts may damage to the machine or decrease

its safety

6.1.2. Boiler discharge procedure

The boiler discharge is a delicate procedure, that may be dangerous

if carried out in improper way.

Figure 6.1 - Water filter cleaning (only machine with built-in boiler)

Table 5.2 - Advanced programming parameters

Parameter

number

Parameter description Meaning of the number in the display AIR

(press + or - to change the value)

01 Manual steam time. Duration of steam output when pressing the

steam button in the manual controls section. The factory pre-set time

is 0 seconds.

Time of manual steam in seconds

50xx Easyform-ed0811

¥

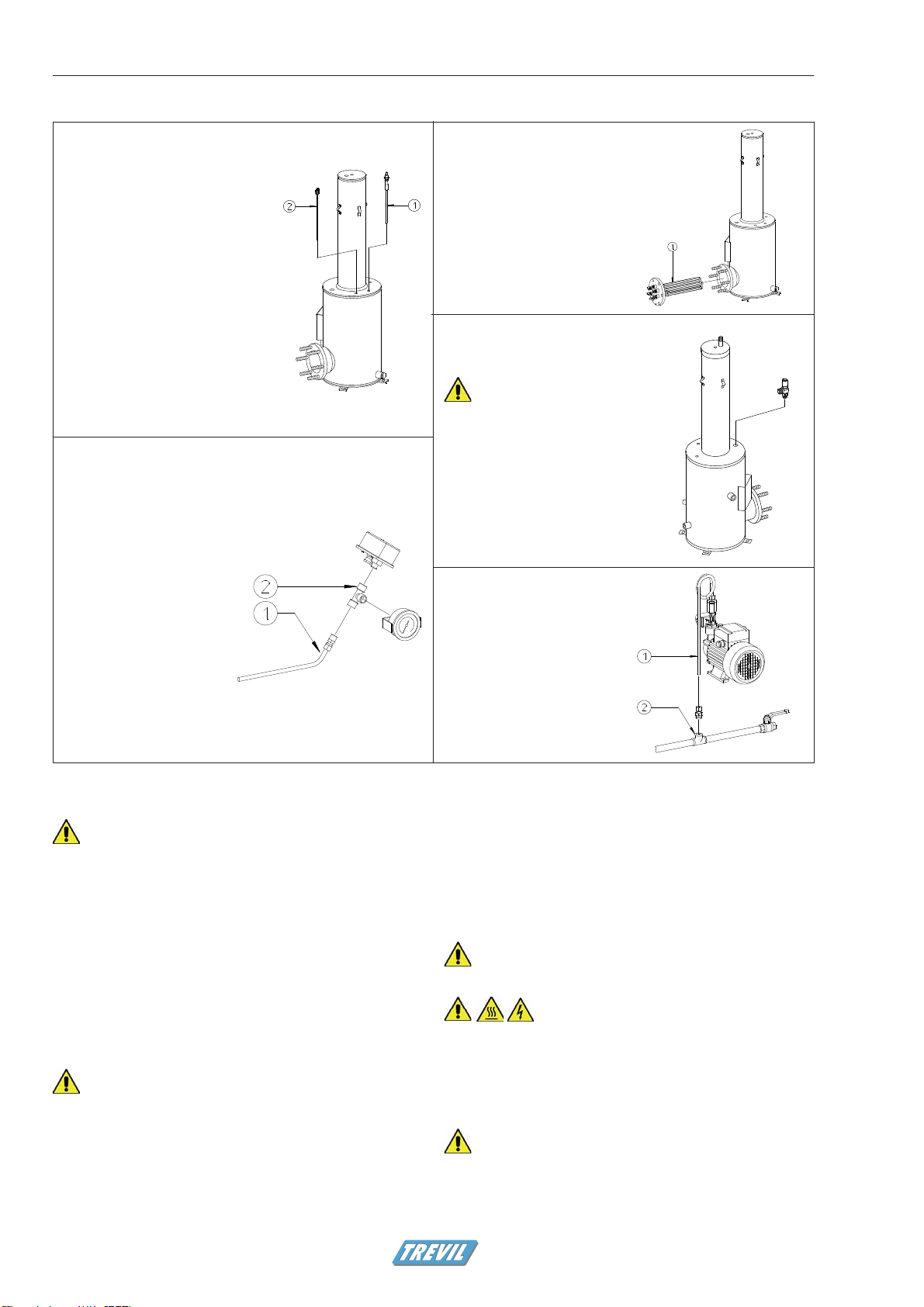

50xx EASYFORM14

Pressure switch, pressure gauge

• Clean the tube 1

• Clean the fitting 2

Safety valve

• Unscrew the safety valve 1

Use caution when handling

the safety valve: do not alter

the setting

• Clean the fitting and the hole

from scaling

Level probes

• Remove level probes 1 and 2

• Remove scaling from the level

probes

Water inlet

• Remove water inlet tube

1

• Clean from scaling

• Clean the water inlet

fitting 2

Heating element

• Unscrew the bolts and

remove the heating

elements flanche

• Clean the heating

elements from scaling

Table 6.1 - Maintenance of the boiler group (only for machine with built-in boiler)

Maintenance

WARNING - Only properly trained operators can dis-

charge the boiler.

If you have doubts about the boiler discharge procedure, ask the

technician to explain it again.

If you feel that the connection of the boiler exhaust to the drainage

is not in good order, do not discharge the boiler and call the techni-

cian.

Boiler discharge procedure :

1. Verify that the connection to the drainage system is firm and

intact;

2. Wait for the pressure in the boiler to be under 1 bar;

3. Lift the metal frame and slowly open the boiler discharge

valve;

4. When the discharge is finished, close the discharge valve and

block it with the metal frame.

WARNING - The boiler discharge procedure is safe only if

the following conditions are verified:

• the boiler discharge valve is safely and firmly connected

to the permanent drainage system

• the pressure displayed by the gauge is lower than 1 bar

6.1.3. Every six months

Call the authorised technician to perform the maintenance operations

described in the following paragraph.

6.2. Maintenance to be carried out by the

technician every six months

WARNING: The maintenance operations described in this

chapter must only be carried out by qualified personnel.

WARNING for the technician:

Before any kind of maintenance or control intervention:

• Disconnect the machine from electricity, air and steam

• Discharge air pressure from the pneumatic circuit by opening

the valve at the air inlet (only for models with sleeves tension-

ing)

• Make sure that all the parts of the machine have cooled down

For types with boiler:

the pump is equipped with a self-

the pump is equipped with a self-

restoring protection.

restoring protection.

Always disconnect power from the

Always disconnect power from the

appliance before servicing the pump: it may restart abruptly.

appliance before servicing the pump: it may restart abruptly.

50xx Easyform-ed0811 ¥

50xx EASYFORM 15

6.2.1. Electrical circuit maintenance

• Verify that electrical connections are properly tightened and do

not show oxidation;

• Verify tightening of solenoid valve coils;

• Verify state of cable and electrical wiring conditions.

6.2.2. Steam circuit maintenance

Model without boiler

• Verify that steam and condensate return connections are

properly tightened and do not leak

• Verify that steam valve is in good working order and does not

present leakage

Model with boiler

• Follow instrucions in table 6.1 for the maintenance of the boiler

group

• Verify that all connections are properly tightened and do not

leak

• Verify that the steam valve is in good working order and does

not present leakage

6.2.3. Air circuit maintenance (only for models

with sleeves tensioning)

• Verify that valves and cylinders do not show any loss of air.

6.2.4. Other controls

• Check that fan blades are free of dirt and lint deposits.

Use only Original spare parts.

50xx Easyform-ed0811

¥

50xx EASYFORM16 Troubleshooting

7. Troubleshooting

7.1. Solution to common problems, allowed to the user

Refer to Table 7.1 for solutions to the most common malfunction situations.

WARNING - DO NOT SERVICE THE APPLIANCE WITHOUT PROPER ADVICE - In event of a malfunction not anticipated in

the table or if the suggested remedy does not solve the problem, do not operate the machine. You must contact a service

center immediately.

Table 7.1 - Troubleshooting common problems (user)

Problem Possible cause What the user should do

The machine does not

start

No power to the machine Check there is power in the plant

Check connection to the plug

Turn on the main power switch

No steam from the ma-

chine

Steam time set to zero Adjust the steam time

The steam feed valve is closed Open the steam feed valve

Blowing is too weak Lever on the lowest position Shift the lever (5 - Figure 4.1) towards the + sign

Fan does not function

(no blowing)

The blowing time is set at zero Enter programming and set a blowing time

The boiler does not

reach working pressure

(Models 5050, 5055,

5052, 5057)

The heating elements are off Turn on the heating elements switch

The boiler is off Turn on the boiler by means of switch

The boiler reaches

working pressure too

slowly (Models 5055,

5057)

The second heating element is off Turn on all the heating elements. When working pressure has been reached,

unnecessary power can be turned off

The pump is working

but no water gets into

the vessel (Models

5050, 5055, 5052,

5057)

There is no water / the water

delivery valve is closed

Turn off the machine

Make sure that the water is reaching the machine

When the problem is removed, turn on the machine

The filter is dirty Clean the filter

The water inlet system is dirty It is time to call the technician for periodic maintenance

Too much water into

the boiler (Models

5050, 5055, 5052,

5057)

The level probe of the boiler is

dirty

It is time to call the technician for periodic maintenance

The boiler is turned on

but it does not work

(Models 5050, 5055,

5052, 5057)

The appliance has blocked be-

cause water is not reaching in it

Check that the water delivery valve(s) are open

Check that the valves between the tank and the boiler are open

Check that there is water into the line

When the cause has been removed, turn off and then on again the unit to

remove the protection

The sleeve arms do not

move (Models 5042,

5052, 5057)

Air pressure is too low Set the general pressure at 6bar

The sleeve arms are excluded Remove the exclusion by pushing button EXCL ARMS on the control panel,

When the light is off, the arms are activated.

50xx Easyform-ed0811 ¥

50xx EASYFORM 17Troubleshooting

7.2. Solution to failures, for the use of the authorised service center

WARNING - This chapter is for the exclusive use of an authorised technician. For maintenance and replacement of compo-

nents always refer to a service center.

Table 7.2 - Solution to failures

Symptom Components likely to

be involved

Possible cause Controls to be carried out

The programming panel

cannot be activated /

The programming panel

switches on but the machi-

ne doesn’t start

The control card has failed Replace the card

No steam from machine The solenoid valve has failed Replace the solenoid valve

Fan does not function Protection tripped Reset protection

The electromagnetic switch has failed Replace the electromagnetic switch

Motor burnt out Replace the motor

Inadequate ventilation Fan blades has failed Check and replace

Fan is dirty Clean fan

Water leakage during

steam operation

Steam trap failed or dirty (Models 5040, 5042) Replace or clean the steam trap

High water level (Models

5050, 5055, 5052,

5057)

The electic circuit between board and

probes is faulty

Clean the probes

The control board has failed (Models 5050, 5055, 5052, 5057) Replace the card

The pump works, water

gets into the boiler but

overflows fron the safety

valve exhaust. (Models

5050, 5055, 5052, 5057)

The level control board

does not receive the

signal that the level has

been reached

The electic circuit between board and

probes is faulty

Check connections and wires

The control board has failed Replace the board

The pump works but water

does not reach the boiler.

After 4 minutes the unit

turns into protection mode

(Models 5050, 5055,

5052, 5057)

There is no water or the

water flow is too low

Problems of the water line (no

service, closed valves, interruptions

or leaks, ...)

Verify that water reaches the unit in proper

quantity.

Filters or connections are dirty Clean water intake connections and filters as

per instructions in table 6.1

The pump solenoid valve has failed Replace the solenoid valve

The pump is always on,

the heating elements are

on (Models 5050, 5055,

5052, 5057)

The pump does not re-

ceive the signal to stop

The level control board of the boiler

has failed

Replace the board

The pump does not work

(Models 5050, 5055,

5052, 5057)

The pump does not re-

ceive the signal to start

Electric circuit between control board

and pump is interrrupdes

Check connections and wires

The level control board of the boiler

has failed

Replace the board

The pump has failed Replace the pump

There is water in the boiler

but heating elements do

not turn on (Models 5050,

5055, 5052, 5057)

The heating elements do

not receive the signal to

heat

Pressure switch or relative circuit have

failed

Check the circuit and/or replace the pressure

switch

Safety thermostat or relative circuit

have failed

Check the circuit and/or replace the safety

thermostat

The level control board of the boiler

has failed

Replace the board

The coil of the contactor has failed Replace the contactor

The circuit that drives the heating

elements has failed

Check the electric connections of the contactor

coils

No electricity to the heat-

ing elements

The electric circuit that carries

electricity to the heating elements is

interrupted

Check that the fuses are intact

Faulty element Replace the element

Faulty contactor Replace the contactor

The sleeve arms do not

move (Models 5042, 5052,

5057)

The solenoid valve has failed Replace the solenoid valve

50xx Easyform-ed0811

¥

50xx EASYFORM18

50xx Easyform-ed0811 ¥

50xx EASYFORM 19

Figure 8.2. - How to pack the machine for transportation

Figure 8.1. - How to screw the machine to the crate

Machine stop

Disposal of Waste Electric and Electronic

Equipment (WEEE) in the European Union

This symbol on the product or on its packaging indicates that this

product is subject to separate collection and recycling.

It is your responsibility to dispose of your waste equipment by

handing it over to a designated collection point for the recycling

of waste electrical and electronic equipment. The separate collec-

tion and recycling of your waste equipment at the time of disposal

will help to conserve natural resources and ensure that it is re-

cycled in a manner that protects human health and the environ-

ment. For more information about where you can drop off your

waste equipment for recycling, please contact the dealer where

you purchased the product.

8. Prolonged stop, Tran-

sportation or Decommis-

sioning

The following explanation refers to all models, follow only the instruc-

tions relating to the model you own.

8.1. Prolonged stop

In case of prolonged stop of the machine:

1. Model with boiler: discharge the boiler.

2. Close air connections (models with sleeves tensioning).

3. Close steam (models without boiler) or water (models with

boiler) connection.

4. Disconnect from electrical power.

5. Discharge the pressure in the air circuit (models with sleeves

tensioning).

6. Discharge residual condensate.

7. Clean the cabinet and the grids from dust and lint.

8. Protect the form so that the covers do not get dirty.

8.2. Transportation

In case the machine must be moved, follow the instructions below.

1. Model with boiler: discharge the boiler.

2. Close air connections (models with sleeves tensioning).

3. Close steam (model without boiler) or water (model with boiler)

connection.

4. Disconnect from electrical power.

5. Discharge the pressure in the air circuit (models with sleeves

tensioning).

6. Discharge residual condensate.

7. Disconnect all connections (water/steam, air, ...).

8. Clean the cabinet and the grids from dust and lint.

9. Move the machine to a crate of suitable size.

10. Screw the machine to the crate, using suitable brackets (Figure

8.1).

11. Fold any protruding elements (such as the control panel).

12. Protect the form so that the covers do not get dirty.

13. Wrap the machine in cellophane or bubble plastic.

14. If necessary, cover the whole machine with a cardboard box

and tighten it to the crate.

8.3. Decommissioning

At the end of its life the machine must be properly dismantled and its

parts must be disposed of according to local regulations.

1. Model with boiler: discharge the boiler.

2. Close air connections (models with sleeves tensioning).

3. Close steam (model without boiler) or water (model with boiler)

connection.

4. Disconnect from electrical power.

5. Discharge the pressure in the air circuit (models with sleeves

tensioning).

6. Discharge residual condensate.

7. Disconnect all connections (water/steam, air, ...).

8. Move the machine to a crate of suitable size.

9. Screw the machine to the crate, using suitable brackets (Figure

8.1).

10. Fold any protruding elements (such as the control panel).

11. Give the machine to a specialized recycling center for proper

separation and reciclyng of all materials (painted steel, stainless

steel, copper, plastic, cloth).

50xx Easyform-ed0811

¥

50xx EASYFORM20

EV ELETTROVALVOLA

VAPORE SOLENOID VALVE

STEAM ELEKTRODAMPFVENTIL ELECTROVANNE

VAPEUR ELECTROVÁLVULA

VAPOR

FL FILTRO

CONDENSATORE CAPACITOR FILTER KONDENSATFILTER FILTRE CONDENSATEUR FILTRO

CONDENSATORE

FS FUSIBILE FUSE SICHERUNG FUSIBLE FUSIBLE

IM INTERRUTTORE

MACCHINA MACHINE SWITCH MASCHINESCHALTER INTERRUPTEUR

MACHINE INTERRUPTOR

MÁQUINA

PM PEDALE START STARTPEDAL STARTPEDAL PEDALE START PEDAL START

RT RELE' TERMICO THERMAL RELAY THERMORELAIS RELAIS TERMIQUE RELÉ TÉRMICO

VT MOTORE VENTILATORE BLOWING MOTOR GEBLÄSE MOTEUR VENTILATEUR VENTILADOR

VT1 CONTATTORE COMANDO

VENTILATORE BLOWING MOTOR

CONTACTOR SWITCH SCHALTSCHÜTZ GEBLÄSE CONTACTEUR

COMMANDEVENTILATEUR CONTACTO MANDO

VENTILADOR

SC

(Cod.0221417) SCHEDACOMANDO

MACCHINA MACHINE CONTROL

BOARD STEUERUNGSKARTE DES

MASCHINE CARTE COMMANDE

MACHINE TARJETAMANDO

MÁQUINA

Part Descrizione Description Beschreibung Designation Descripción

ELECTRIC DIAGRAM - SCHEMA ELETTRICO ed 4806

Part of: 5040 - EASYFORM 50Hz (without boiler)

400V 50Hz

Diagrams

9. Technical diagrams

The diagrams in this chapter are for the excludive use of the authirized assistance center.

Do not perform maintenance on the machine if not authorized in writing by the Manufacturing Company.

This manual suits for next models

5

Table of contents

Popular Industrial Equipment manuals by other brands

SUHNER

SUHNER Abrasive expert ROTOset 25-R manual

Trox Technik

Trox Technik TFCU Series Operation and installation manual

Busch-Jaeger

Busch-Jaeger Busch-Wachter DualLINE 6813/11 Series operating instructions

ITW

ITW Simco Ion Conveyostat Installation and operating instructions

Keystone

Keystone MGG operating manual

Jäger

Jäger KS2-16/80 manual