3Fancoil TFCU Series

General information

About this manual

This operation and installation manual enables

operating or service personnel to correctly

install the TROX unit described below, and to

use it safely and eciently.

This operating and installation manual is

intended for use by tting or installation

companies, maintenance technicians,

technical sta, properly-trained persons,

qualied electricians, and climate-control

technicians.

It is essential to read and understand this

manual before starting any work. All safety

indications and instructions described in

this manual must be adhered to in order to

guarantee the working process under the

necessary safety conditions.

All applicable national regulations must be

observed.

The units can only start operating when all

their components are in perfect technical

condition. Damages produced in any of

the elements that comprise the TFCU/

TFCUP units, derived from not observing the

instructions for installation, commissioning

and maintenance, are excluded from the

guarantee by

TROX España.

All components and parts must be replaced

with original TROX TECHNIK spares.

Any changes made on the machinery or any

of its components that have not been explicitly

authorised by TROX España are also excluded

from the guarantee.

All fault or damages shall only be repaired

by specialised personnel, observing the

applicable safety regulations.

This manual must be submitted to the person

in charge of the facilities at the time when the

system is delivered. The system's owner must

keep this manual together with all the system's

documentation. The manual must be available

to be consulted at all times.

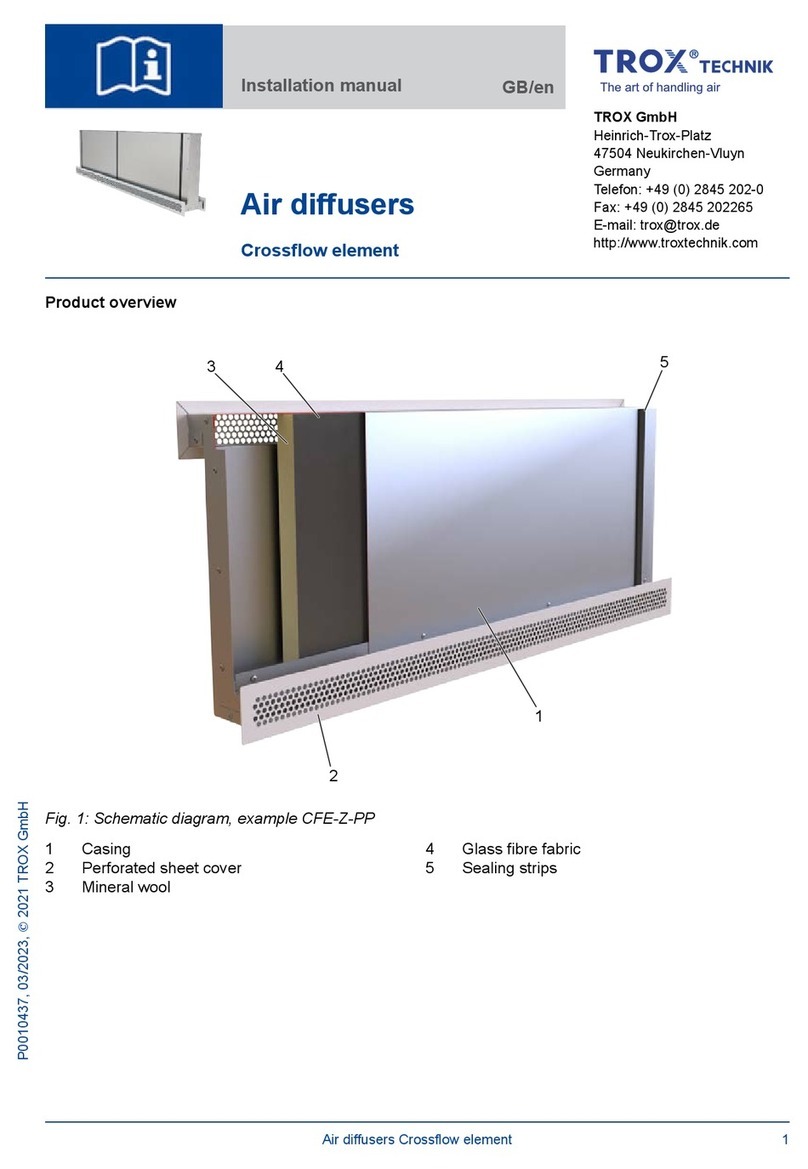

All gures included in this manual are merely

for informative purposes, and may dier from

reality.

Inspection

Upon receiving the unit, this must be visually

inspected in order to detect any damage it

might have suered during transportation.

If there are any defects, this should be noted

on the delivery note, requesting, if necessary,

an inspection by the insurance company

agents or by the carrier. TROX España should

be informed immediately of any defect.

Copyright

This document, including all illustrations,

is protected by copyright and pertains only to

the corresponding product.

Any use without prior consent shall be

considered an infringement of copyright,

and the violator may be held liable for any

damages.

This applies in particular to:

▪ Advertising contents

▪ Copyright contents

▪ Translated contents

▪ Partial copy of the contents

▪ Saving and editing contents in electronic

systems

General information