“MGG” SERIES ELEVATOR

The most important safety device for this tool is YOU.

Your good judgment is the best protection against

injury.

DO NOT DISCARD –GIVE TO USER Keystone ENERGY TOOLS

⚠WARINING: Do not overload

the elevator. Overloading the

recommended rating could cause

series injury or death.

⚠WARINING: Check the latch for

proper engagement. A

malfunctioning latch could cause

the elevator to unexpectedly

unlatch or not latch at all

resulting in injury or death.

⚠WARINING: Always ensure

that the elevator and bore code

are correct for the tubular it is to

be used on. Failure to use the

proper elevator and bore code

could result in injury or death.

⚠WARINING: To prevent injury

or elevator malfunction, inspect

the elevator bore, latch, hinge

pin, and latch pin regularly for

wear. Failure to inspect these

parts could cause injury or death.

⚠WARINING: Do not use

oversized pipe. Using oversized

pipe could make it difficult or

impossible to properly latch the

elevator.

⚠WARINING: Do not use

undersized pipe. Using

undersized pipe could cause an

inadequate load bearing area

and uneven stress distribution.

Both of which may result in

injury or death.

⚠WARINING: Do not use the

elevator if the latch or latch lock

is malfunctioning. Latch or latch

lock failure, may result in injury

or death.

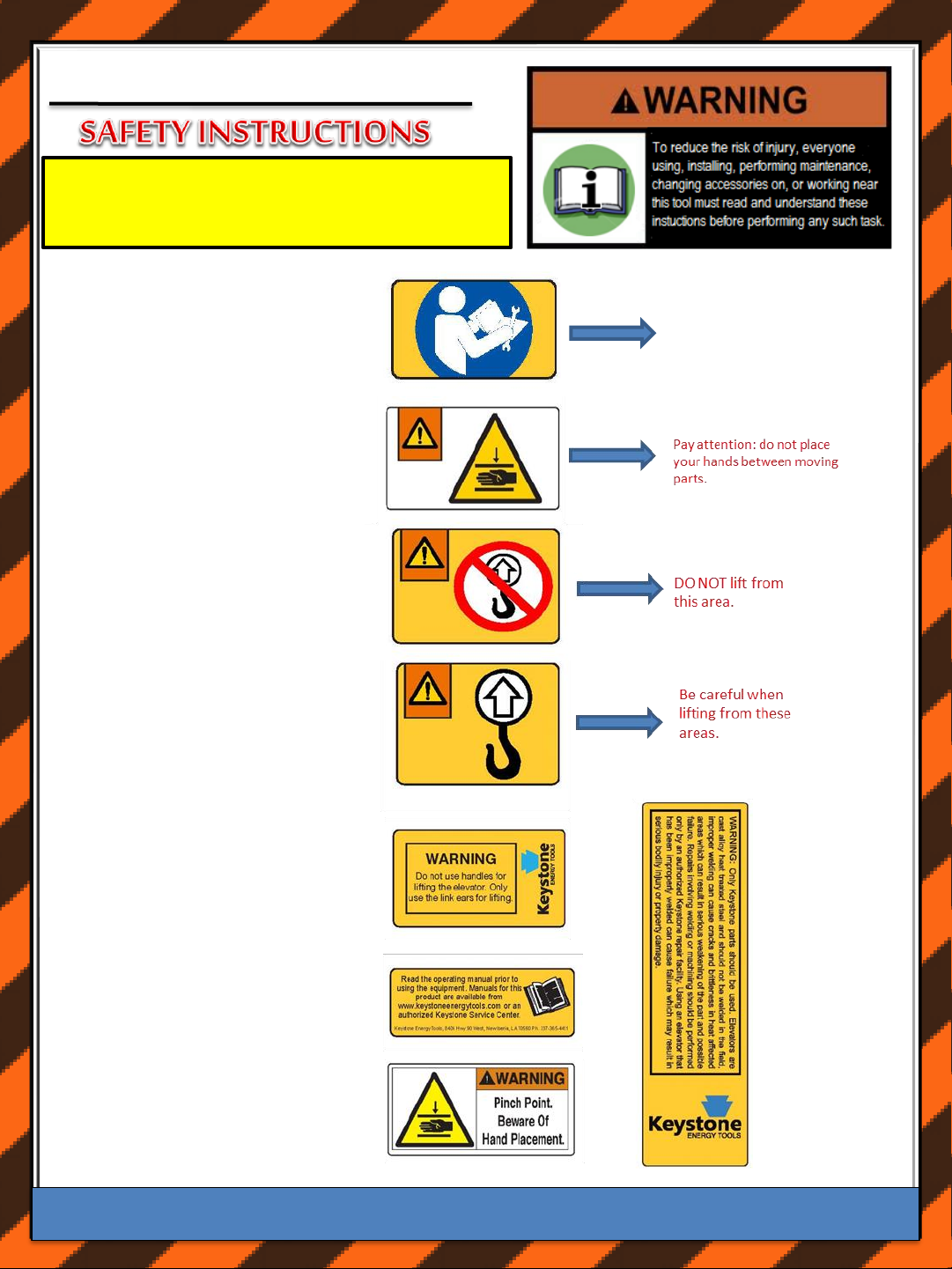

⚠WARINING: All warning labels

attached to the equipment must

be observed. The warning labels

must be present on the tool. Do

not remove the labels. If they are

missing, replacing is mandatory.

⚠WARINING: The company

operating the tool is responsible

for issuing work instructions for

safe and proper use of the

equipment.

⚠WARINING: The operating

company is responsible for

verifying that any personnel

operating, servicing, inspecting,

or otherwise involved with the

use of the tool must be properly

trained correctly.

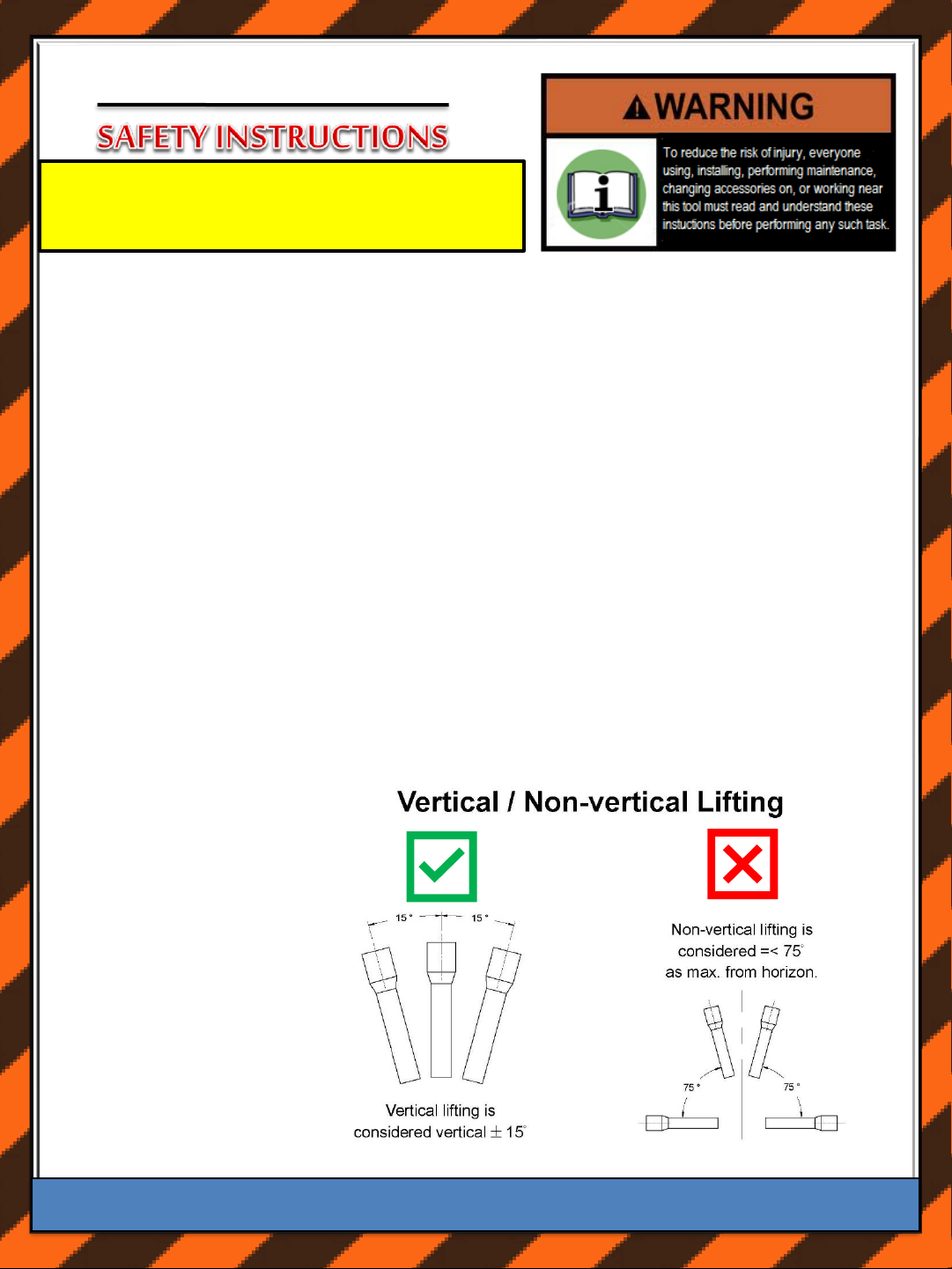

⚠WARINING: The lifting of

vertical pipe is to be performed

carefully and must be monitored.

The picking up of non-horizontal

pipe is dangerous and not

permitted.

Operating Hazards