TREW 1500 Series Instruction Manual

SERIES 1500

24VDC MOTORIZED DRIVER ROLLER

MDR SPIRAL SECTION

INSTALLATION &

MAINTENANCE MANUAL

1.800.571.8739 poweredbyTREW.com info@trewautomation.com

www.poweredbyTrew.com

1.800.571.8739

REV A MDR Spiral - Installation and Maintenance Manual

TABLE OF CONTENTS

1 - OVERVIEW

Zero Pressure Accumulation (ZPA) 1.1

Standard Zones 1.2

2 - COMPONENTS

Motor Control Card - Auto & Full Control 2.1

Zone Technology 2.2

Motor Control Card Modes of Operation 2.2

Motor Control Card Special Features 2.2

Changing the Operation of the ZPA 2.2

Motor Control Card Circuit Protection 2.2

Motor Control Card Installation Dimesions 2.2

Motor Control Card Replacement 2.2

Motorized Drive Roller (MDR) 2.3

Replacement of MDR 2.3

Carrier Roller 2.6

Replacement of Carrier Roller 2.6

Photo Eye Sensor 2.7

Replacement of a Photo Eye Sensor 2.7

Standard Retro-Reective Photoelectric Sensor 2.8

Standard Background Suppression Diused Photoelectric Sensor 2.9

Drive Belts (O-Bands) 2.10

Replacement of O-Band 2.10

3 - PREVENTIVE MAINTENANCE

Maintenance Precautions 3.2

Inspection 3.3

Replacing Rollers 3.5

Lubrication 3.6

4 - TROUBLESHOOTING

Possible Problems & Solutions 4.1

Troubleshooting Help 4.8

i

i

www.poweredbyTrew.com

1.800.571.8739

REV A MDR Spiral - Installation and Maintenance Manual

1

OVERVIEW

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

OVERVIEW 1

1.1

Zero Pressure Accumulation (ZPA)

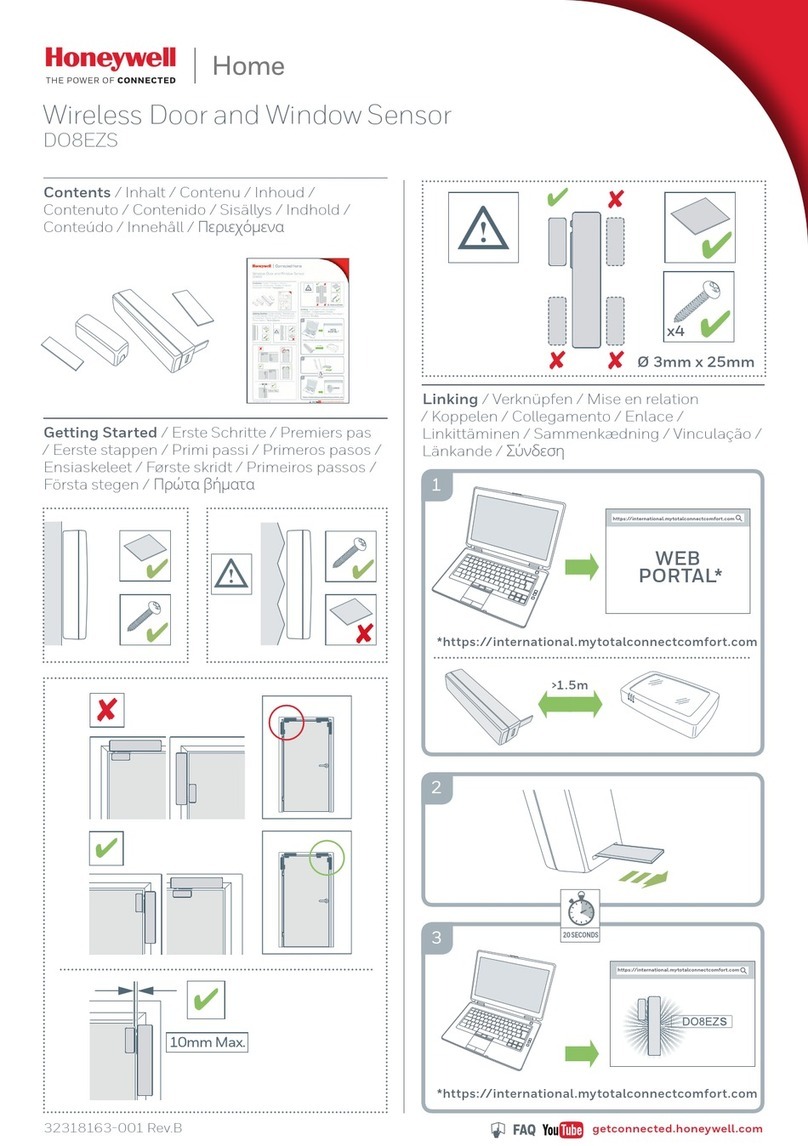

An MDR conveyor with accumulation is composed of several ‘zones’, as shown in the image

below. Each zone is powered by a motorized drive roller (MDR). The MDRs are controlled by

a communications network, allowing the zones to communicate with each other to achieve

the desired accumulation method. The rollers in a zone do not rotate until product has been

detected in the adjacent upstream zone. In other words, the rollers in Zone 2 do not rotate

until the photo eye sensor in Zone 1 detects a product. The rollers in Zone 3 do not rotate

until the photo eye sensor in Zone 2 detects a product.

There are two types of accumulation release: Singulation release and Slug release. Singulation

release allows one product to be released at a time after the downstream zone has cleared.

Slug release allows a predetermined amount of product to be released at one time after the

downstream zone has cleared. Slug release is typically used in Palletizing or Machine loading

conditions. The type of release to be used is usually determined at design time.

Accumulation begins when a product is forced to remain in Zone 4. The photo eye sensor

in Zone 4 detects the product and turns o the motorized drive roller in Zone 4, stopping all

the rollers in that zone. When a second product is detected by the photo eye sensor in Zone

3, the motorized drive roller in Zone 3 is turned o, stopping all the rollers in that zone.

This accumulation sequence is repeated for each succeeding zone as long as the product

in Zone 4 is forced to remain in position.

When the product in Zone 4 can be released, the motorized drive roller is turned on and the

product moves down the conveyor system. When the product clears the photo eye sensor

in Zone 4, the motorized drive roller in Zone 3 is turned on and the product moves from

Zone 3 to Zone 4. This release sequence is repeated for each succeeding zone as long as

product is not intentionally stopped in any given zone. The subsequent gap between products

is approximately equal to one zone length. This accumulation sequence may be started

anywhere along the length of the conveyor.

The MDR accumulation is a true zero--pressure accumulation (ZPA). This means that

the product being conveyed never comes in contact with any other product; provided

it is dimensionally compatible with the zone (product length is less than the zone length).

K1

MOT1

IN1

X1

MOT2

IN2

X2

K1

MOT1

IN1

X1

MOT2

IN2

X2

TO ZONE 2 PHOTOEYE

TO ZONE 2 MOTOR

TO ZONE 4 PHOTOEYE

TO ZONE 4 MOTOR

TO ZONE 3 PHOTOEYE

TO ZONE 3 MOTOR

TO ZONE 1 PHOTOEYE

TO ZONE 1 MOTOR

DOWNSTREAM

CONVEYOR

INTERCONNECTION

UPSTREAM

CONVEYOR

INTERCONNECTION

FLOW

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

OVERVIEW 1

1.2

Standard Zones

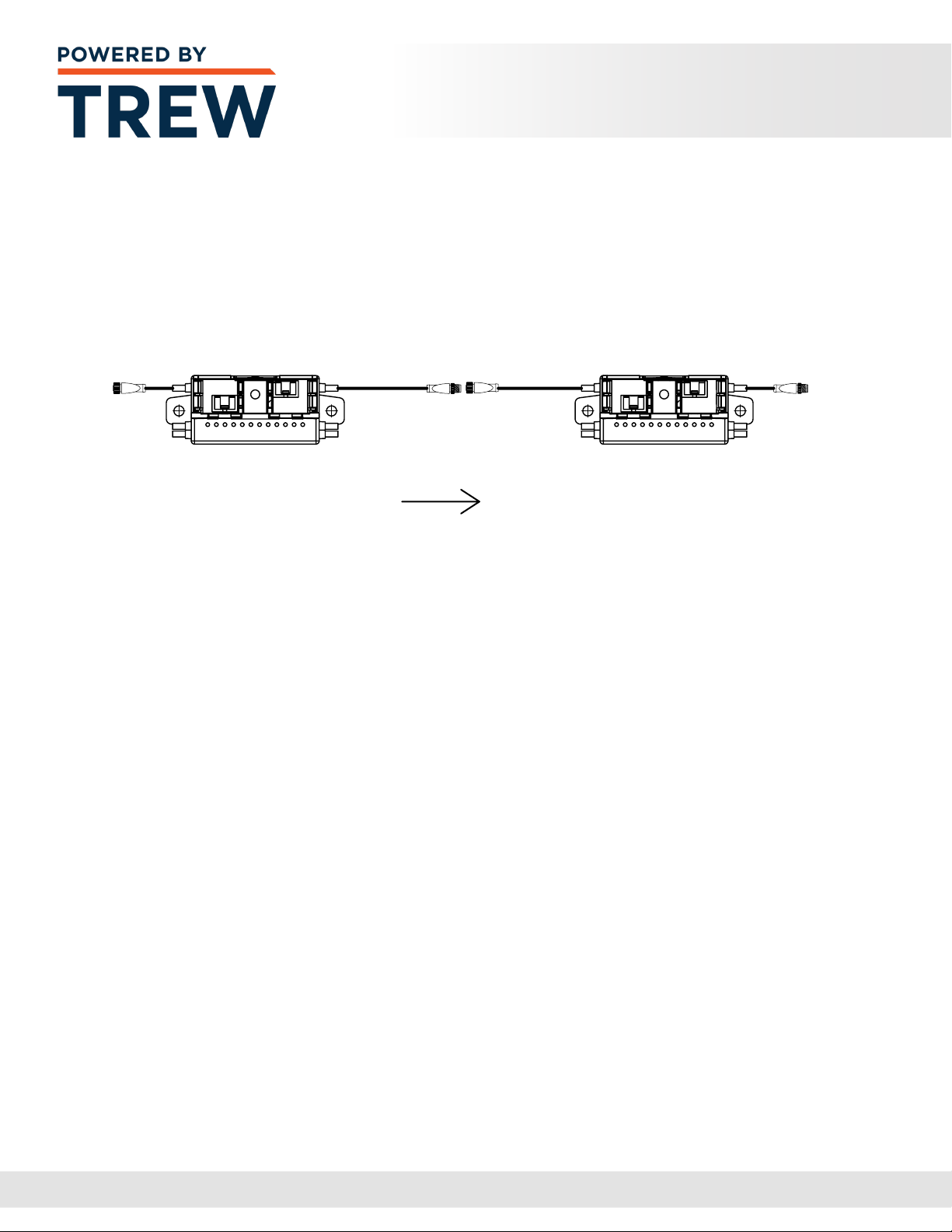

The image below shows a typical zone layout for a standard intermediate zone.

Each zone has one motorized drive roller (MDR), photo eye sensor, reector,

motor control card, and carrier rollers.

www.poweredbyTrew.com

1.800.571.8739

REV A MDR Spiral - Installation and Maintenance Manual

2

COMPONENTS

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

Motor Control Card - Auto & Full Control

The motor control card provides true zero pressure accumulation and other control options

to a conveyor system. Each motor control card manages the functionality of (2) motorized

drive rollers which in turn drives idler rollers using O-rings or other belts. The ZPA motor

control card, MDR and idler rollers, with associated sensors and switches, are assembled

into a short conveyor section - or zone. A logic-controlled, ZPA conveyor is created when a

number of zones are connected together and a four-wire M12 connector links each motor

control card electronically. The MDRs only operate when a package is present and is detected

by a photo-eye. If the downstream zone is empty, the package moves forward. The motor

control card has several design features allowing the integration of workstations, lifts

and turntables into a conveyor design. If the ZPA motor card is to control only (1) motor

(one zone), the seconed zone logic must be turned o with mode 2 (single).

Changing the Operation of the ZPA

Additional control signals can be sent to the motor control cards by using various I/O signals

on its connectors. The logic is passed from board to board through modular RJ-11 telephone

communication cables. By setting rotary switches (S1, S2, S3), you can change its speed,

direction and operating mode, respectively.

Motor Control Card Circuit Protection

The motor outputs are protected by safety fuses with 5A-rated current. They prevent damage

to the motor control chips from back EMF that might be generated by the MDR when it is

rotated by an outside force such as heavy packages arriving at high speed from powered or

gravity-fed conveyors. This is referred to as “over-driving” the MDR. Care should be taken to

minimize over-driving.

2.1

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

Motor Control Card Replacement

1 Turn o and lock out the power supply to the conveyor

2Remove the auxillary power cable from the card

3Remove the drive roller cable connector and the control cable

or com-link from the drive card

4Remove drive card and mounting bracket from the conveyor

5Remove drive card from mounting bracket and inspect for Red LED

6Inspect the original card and observe the jumper and switch settings

7Set the switches and jumpers on the new card to match the old one

8Replace old drive card with spare drive card

9Carefully connect the control cable or com-link and drive roller cable to the card

10 Reconnect the auxillary power cable to the card

11 Unlock the power supply and turn the conveyor on

Before attempting to repair or replace a drive roller, drive card, controller device, or any other

device connected to these components, be sure that power to the controls is locked out to

prevent premature or accidental start-up. Failure to follow this instruction may result in serious

personal injury, and/or equipment damage.

2.2

Note: Only follow motor card bracket steps if applicable, as motor card

brackets are not used on Intermediate Set High.

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

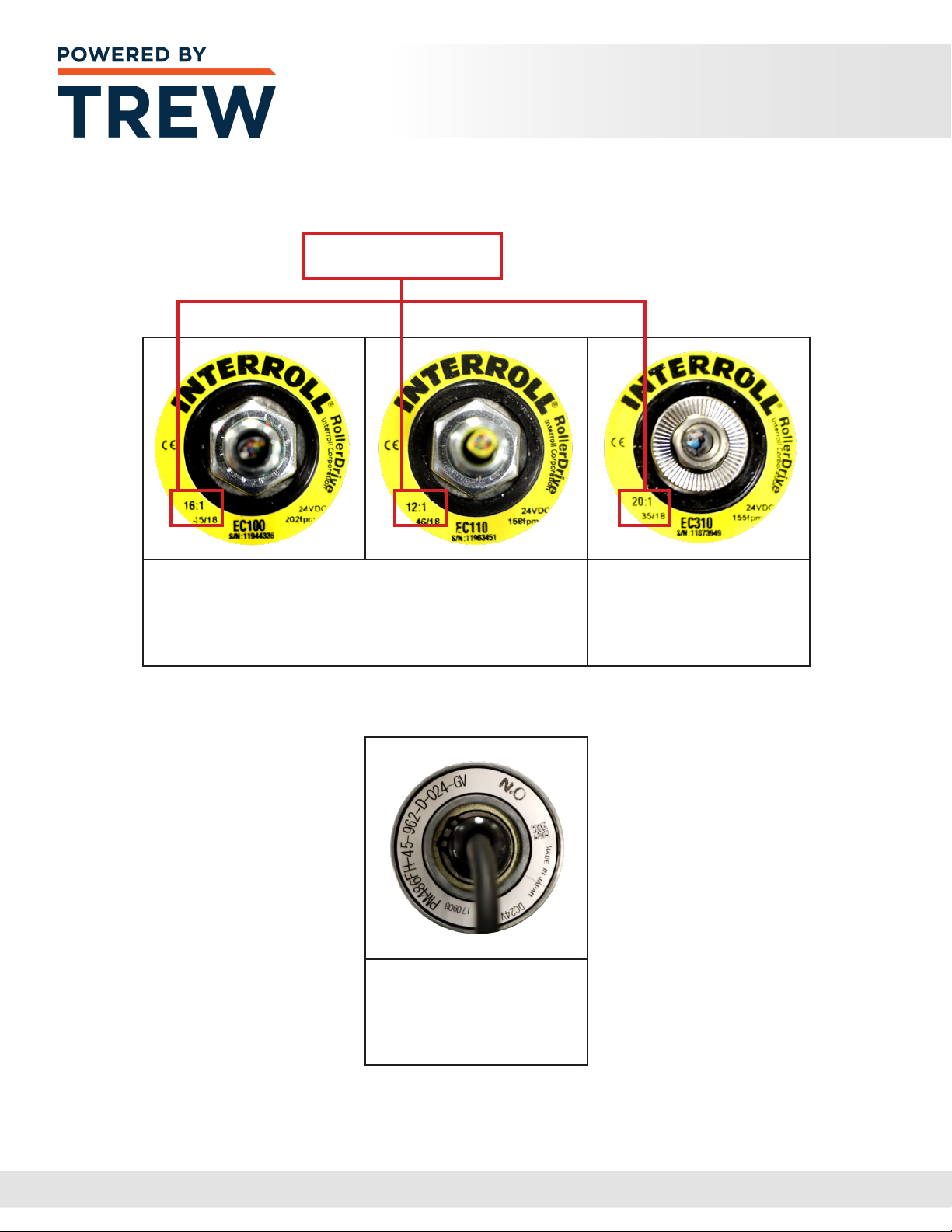

Motorized Drive Roller (MDR)

The motorized drive roller (MDR) is the muscle of the conveyor zone. It provides the torque

and speed required to move the product to the next zone. The MDR has the motor and

gearing encapsulated inside the roller tube.

Replacement of MDR

1 Turn o and Lockout / Tag-out all power to the conveyor section

2Make sure that the Gear Ratio matches that of the roller that is being replaced.

Standard Gear Ratios would include: 16:1, 20:1, 24:1, 36:1, 64:1, and 96:1.

This is important if the conveyor system is comprised of more than one speed

3The replacement roller should include:

aMotorized Drive Roller

bHardware Kit

i. star washers – Qty. 2

ii. motor nut

iii. motor instructions

4Install a star washer on the threaded motor shaft

5Insert the MDR connector into the hex hole and gently pull the cable

extending from the motor through

6Insert the threaded hex shaft into the hex hole. Push the spring loaded idler shaft

inwards and line the roller up with the hole. Release the idler shaft and allow

it to pop into the hole in the frame. The image on Page 2.6 shows an exploded

view of the process

7Install the outer star washer

2.3

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

8The motor nut threads on to the motorized drive roller shaft, and should

be to the proper torque of: See Page 2.5 for Proper Torque Information.

9Tools required to achieve proper torque can be seen below

10 Plug the motor cable into the motor control card

11 Turn on power to the conveyor section

12 Check to see if roller operates by passing your hand in front of the photo eye sensor

of the zone that is being serviced or the photo eye sensor located upstream

with respect to ow

13 If the MDR does not operate review the Troubleshooting Section

These checks must be performed with the power to the conveyor section turned “ON”.

Only qualied electricians should be allowed to perform these checks. Failure to follow

this instruction may result in serious personal injury and/or equipment damage.

2.4

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

EC110 and EC100:

30 ft-lbs +/- 5 ft-lbs

(40.7 N-M +/- 6 N-M)

ITOH:

22.5 ft-lbs +/- 5 ft-lbs

(30.5 N-M +/= 6 N-M)

EC310:

50 ft-lbs +/- 5 ft-lbs

(67.8 N-m +/- 6 N-m)

Gear Ratios Vary.

Proper Torque

2.5

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

Carrier Roller

The carrier roller is used to take the weight of the product and also distributes the torque

generated by the motorized drive rollers via o-belts, chain, timing belts, strip belts,

or full-width belts. Generally, no more than nine carrier rollers per motorized drive roller

are used in each zone.

Replacement of Carrier Roller

1 Turn o and Lockout / Tag-out all power to the conveyor section

2Use an appropriate tool to push in the spring loaded axle on the roller

and free that side of the axle from the frame of the conveyor

3Carefully disengage the opposite end of the roller from the frame.

Make sure the axle is not pinched on the frame causing damage during removal

4Remove the disengaged roller entirely from the frame section

5Carefully maneuver the roller to allow the drive belts to be removed

from the grooved end of the roller. Set old roller aside

6 Install new roller by rst maneuvering grooved end through the drive belts,

ensuring the belts are aligned in the appropriate grooves

7Insert the axle of the replacement roller through the conveyor frame

8Use an appropriate tool to push in the spring loaded axle and lower

the roller into position, aligning the axle with the hex hole in the conveyor frame

9Unlock and turn on the power to the conveyor section

2.6

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

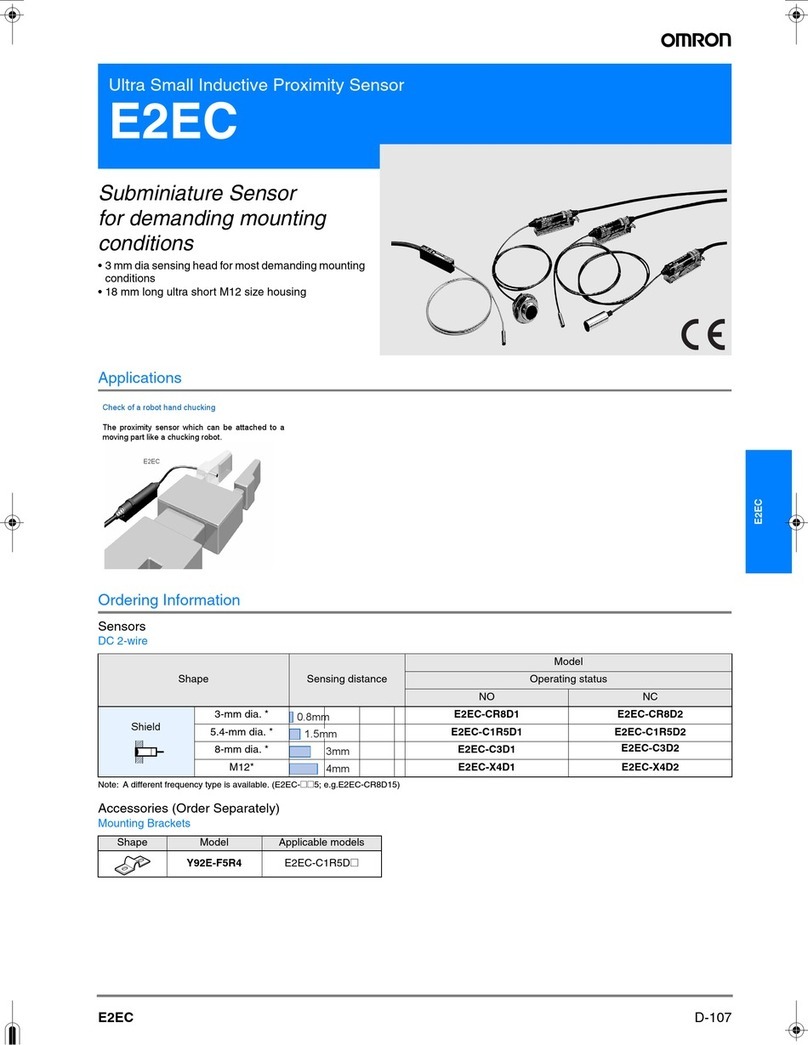

Photo Eye Sensor

A photo eye sensor is used to sense the presence of the product. Two styles of photo

eye sensors are used on standard Conveyor: Retro-Reective Photoelectric Sensor

& Background Suppression Diused Photoelectric Sensor.

Replacement of a Photo Eye Sensor

1 Turn o and Lockout / Tag-out all power to the conveyor section

2Locate end of Photo Eye Sensor cable and unplug from the roller drive card

3Carefully remove cable from any holes in conveyor frame.

Note the routing path of the cable

4Remove fasteners from the Photo Eye Sensor mounting bracket

and remove Sensor from conveyor

5Install new Sensor at the same location as the old sensor

6Route the new Sensor cable through the same path as the old sensor cable

7Install Sensor cable plug into the roller drive card

2.7

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

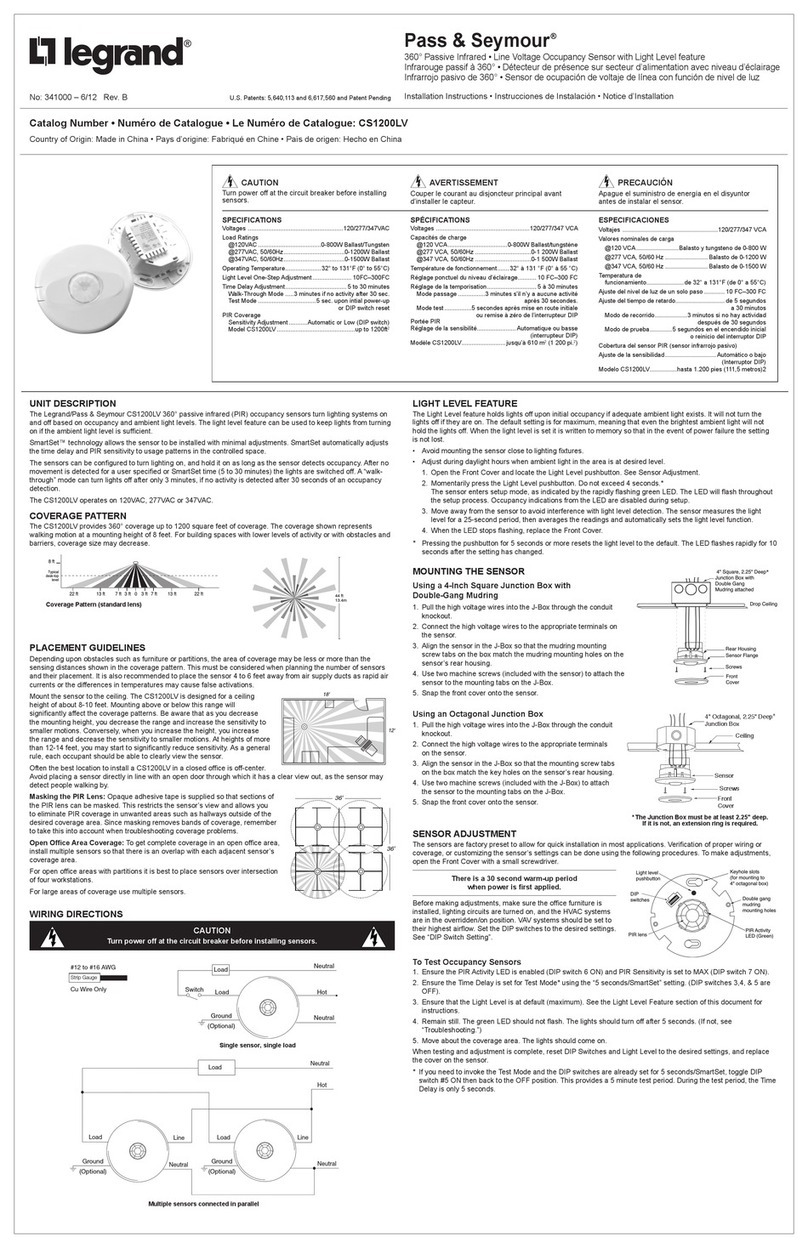

Standard Retro- Reflective Photoelectric Sensor

The image and diagram below displays the cable connection types for the Tru-Vue ML17

series photoelectric sensors - 3.5m sensing range - Polarized retro-reective mode -

PNP Dark-Operated Sensor.

2.8

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

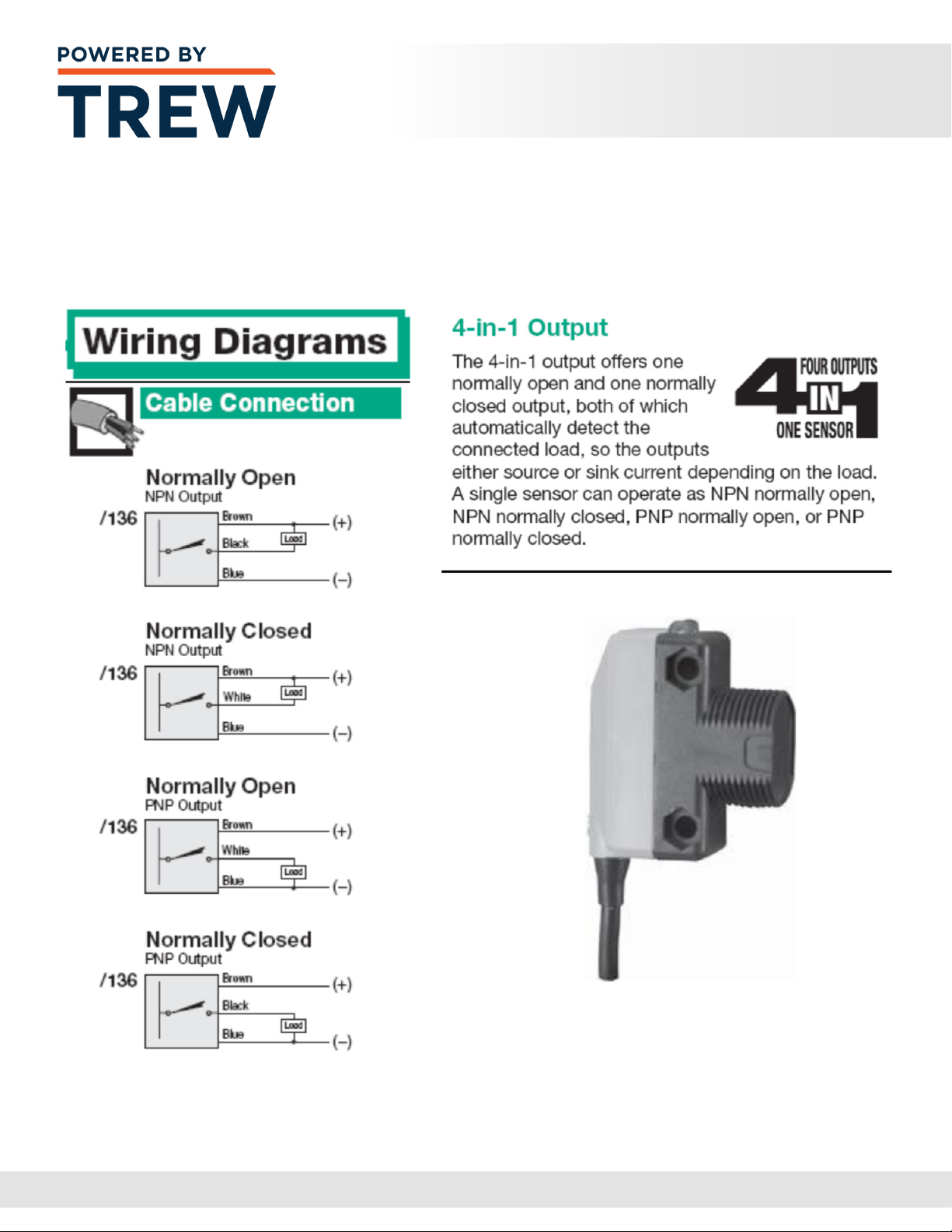

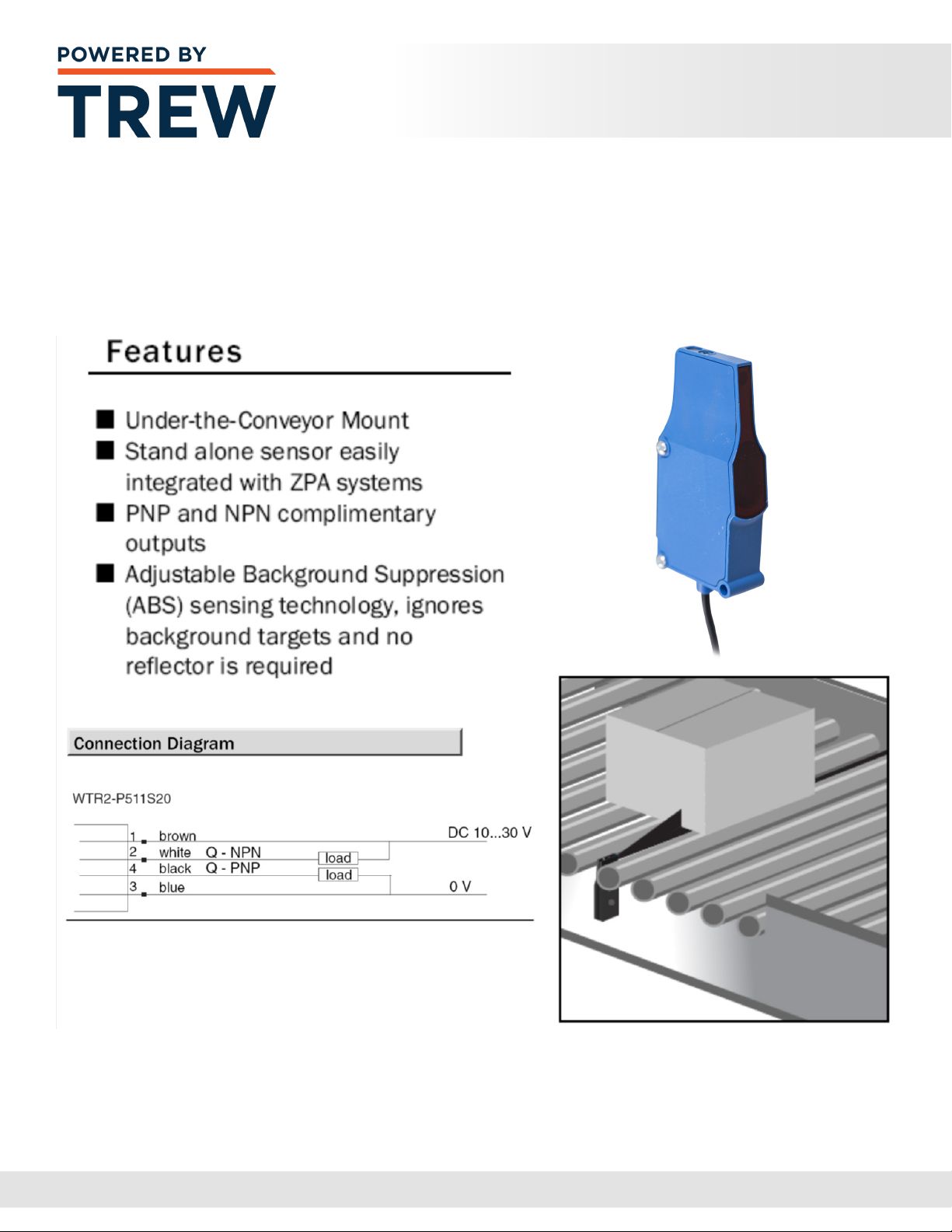

Standard Background Suppression Diffused

Photoelectric Sensor (SICK)

The image and diagram below displays the connection diagram for the WTR series

photoelectric sensors – 90mm sensing range – Background Suppression Diused-4-in-1

output N.O./N.C. - 2m cable.

2.9

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

COMPONENTS 2

Drive Belts (O-Bands)

MDR conveyor utilizes drive belts to connect individual rollers together to create a Zone.

The drive belts can be O-bands or V belts, depending upon load and speed requirements

of the conveyor.

Over time the drive belts can exhibit wear. O-bands in particular can wear or stretch,

eventually allowing excessive slippage in the roller groove. When this happens,

the rollers in the zones may not rotate and inadequately convey packages.

Replacement of O-bands is quick and easy.

Replacement of O-Bands

1 Remove the roller having the aected O-band, following procedures

for roller removal discussed earlier in this manual

2 Remove the (2) adjacent rollers. At this point, the aected O-band can be removed

3Place new O-bands over the grooved end of the roller(s)

and re-install the rollers

2.10

www.poweredbyTrew.com

1.800.571.8739

REV A MDR Spiral - Installation and Maintenance Manual

3

PREVENTATIVE

MAINTENANCE

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

PREVENTATIVE MAINTENANCE 3

The satisfactory performance and reliability of this equipment is dependent upon a procient

preventive maintenance (PM) program with scheduled equipment inspections under normal

operating conditions.

Accurate records of maintenance and repairs will help to identify problem areas and

repetitive problem patterns. It is imperative that adequate records be kept in connection

with the preventive maintenance program. These records should contain the date of

inspection, inspection results, equipment services, repair history, part replacement history,

and any other information that will help to make maintenance process more ecient and

accurate. It is recommended that each conveyor have its own record. Properly kept, the

conveyor record sheet will form a mechanical history of the equipment covered.

Preventive maintenance consists of regular service (lubrication, adjustments, cleaning, etc.).

In addition, it consists of ”keeping your eyes, ears, and nose open.” Use your eyes to see

potential component failure. Use your ears to listen for abnormal or louder than normal noises.

Use your nose to smell a motor running abnormally warm in time to prevent its burnout.

These sights, noises, and smells can be indicators of lack of lubrication, misalignment,

or other potential trouble. Ignore them and you will be replacing a shaft, motor, or whatever

does go out when a component is lacking proper preventive maintenance.

Only qualied maintenance specialists should maintain the mechanical, electrical and

pneumatic portion of the conveyor.

3.1

Before performing any maintenance or lubrication services, follow

the lockout/tagout procedure in the Safety section to ensure that the

equipment is safe to work on. Failure to follow this instruction may

result in serious personal injury and/or equipment damage.

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

PREVENTATIVE MAINTENANCE 3

Maintenance Precautions

1When testing operating performance, do not start the equipment until all operations

and maintenance personnel are notied and clear of the unit being tested

2Be certain that required safety guards are never removed without authorization

3Never run the equipment under production conditions without safety guards in place

4Do not make any equipment repairs, while the conveyor is running

5Keep hands, hair and clothing clear of any moving parts

6Never attempt to clear load jams, while equipment is running

7Always use appropriate tools when making repairs or adjustments

8Observe all warning labels and follow plant safety rules

9Make sure all connectors are secure and all wires are free from interference,

obstruction, and any moving parts

Cleaning and Inspection

Generally, there are many reasons for cleaning:

1To allow heat to dissipate (motors and gearboxes)

2To prevent wear on moving parts

3To prevent binding

4For proper operation

5Operating personnel will most likely treat clean equipment with more care

3.2

You must read and understand these precautions completely before operating, setting up,

running, or performing maintenance on the equipment. Failure to follow this instruction may

result in serious personal injury and/or equipment damage.

REV A MDR Spiral - Installation and Maintenance Manual

www.poweredbyTrew.com

PREVENTATIVE MAINTENANCE 3

Any prescribed cleaning schedule should be modied as experience is gained. A thorough

inspection should be performed while cleaning problem areas.

The total value of inspection procedures is determined largely by the consistency and

regularity of the schedule. A denite interval of inspection must be established and obeyed.

This is usually easier to accomplish if a ”round robin” system of inspection is used. It is

recommended that a general inspection that will ensure a thorough examination of each

component and assembly contained in the system be done at least once for each thirty

day period of operation. Results of these general inspections should be documented

in the conveyor record of the unit inspected.

The probability of mechanical/electrical problems increase during periods of heavy usage,

so an additional inspection immediately before and after a these periods is recommended.

Daily Inspection

Walk the entire length of conveyor system and observe the following:

1With the conveyor running, listen for abnormal noises that could indicate:

• Worn bearings in rollers, motors, reducers, etc.

• O-Belt making contact due to misalignment or improper adjustment

2With the conveyor shut down, look for the following:

• Strings or other foreign material wrapped around bearings,

shafts, or rollers. Remove all foreign material immediately

• Shavings or belt dust under conveyor that would indicate misaligned

or damaged components

• Oil leakage that would indicate faulty bearings or seals in rollers,

motors, reducers, etc.

3Check pneumatic regulators for proper setting and listen for air leaks

3.3

Other manuals for 1500 Series

1

Table of contents

Other TREW Accessories manuals