KE SERIES

Electric Actuator with worm drive

Installation & Maintenance Manual

7 May 28, 2019

www.atcontrols.com IOM08069

7. Other

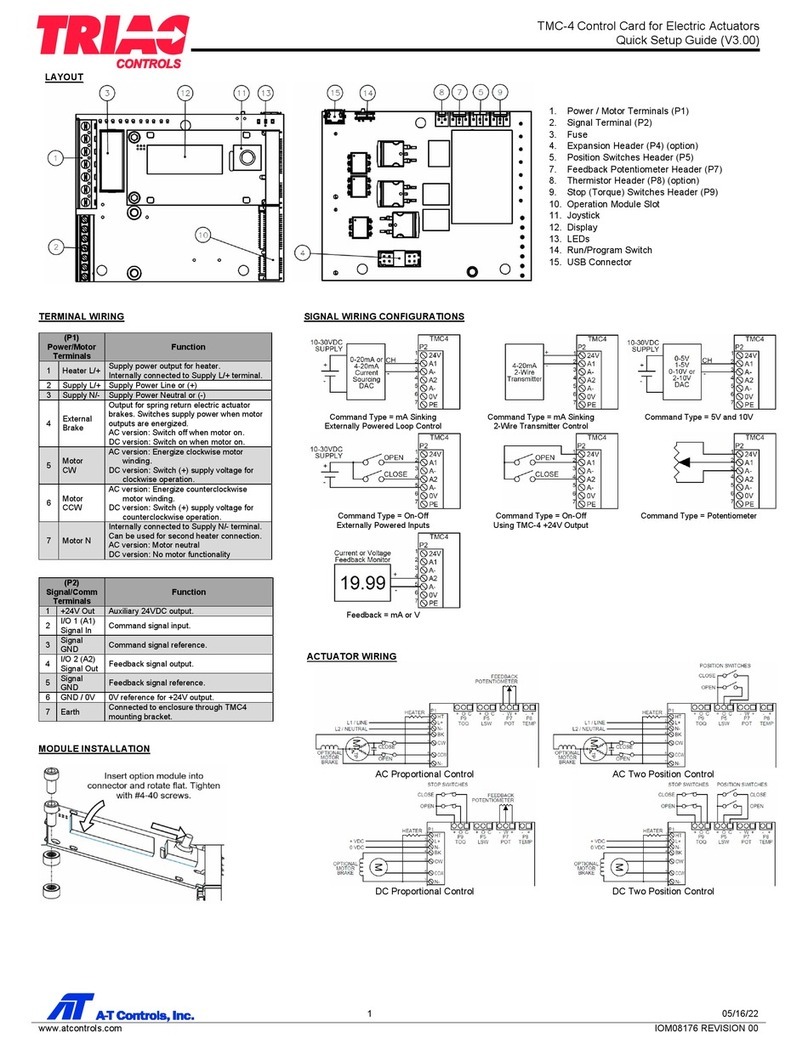

1) The actuator or the brochure shows the reference wiring diagram.

2) Please refer to the specification of Actuator module parts for modulating

instructions.

6. Trouble Shooting

Trouble Cause Solution

Actuator doesn’t

work at all

Check if power is on Power on

Wiring is not correct or is loose

Wire correctly and make

sure wires are tightly

connected

Voltage is too low or motor and

supplied power are different

Check motor power and

supplied power

Coil of motor is damaged Change the motor

Capacitor is damaged Change the capacitor

light doesn’t work

Indicator light is broken Change the indicator light

Micro switch bad action Change Micro switch

The motor does not

stop when it run to

limit position

Micro switch bad action Change Micro switch

The mechanical stop is set before

electrical limit Adjust Mechanical Stop

A-T Controls product, when properly selected, is designed to perform its intended function safely during its useful life.

However, the purchaser or user of A-T Controls products should be aware that A-T Controls products might be used in

numerous applications under a wide variety of industrial service conditions. Although A-T Controls can provide general

guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser / user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of A-T

Controls products. The user should read and understand the installation operation maintenance (IOM) instructions

included with the product, and train its employees and contractors in the safe use of A-T Controls products in connection

with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for

informative purposes only. Because A-T Controls is continually improving and upgrading its product design, the

specifications, dimensions and information contained in this literature are subject to change without notice. Should any

question arise concerning these specifications, the purchaser/user should contact A-T Controls.

For product specifications go to http://download.a-tcontrols.com/

A-T Controls, Inc. • 9955 International Boulevard, Cincinnati, OH 45246 • Phone: (513) 530-5175 • www.atcontrols.com