PRESTIGE Solo 60, 110, 175 and 250

HX Field Replacement Kit

4

3. In case of insufficient space above the boiler,

remove combustion air inlet piping and boiler

relief valve / air vent assembly from the top of

the boiler. Remove all screws securing the top

jacket panel from the side panels and remove

vent outlet adapter and top jacket panel togeth-

er from the boiler cabinet. Put all items in a safe

place as they will all be reused.

4. Once the vent outlet adapter is removed from the

boiler, it should be inspected for deformation

damage or corrosion.

If there are any signs of deformation, damage or

corrosion on the vent outlet adapter, replace it

immediately. Check condition of flue sensor

mounting, replace vent outlet adapter if necessary.

Failure to comply could result in flue gas leakage

resulting in severe personal injury or death.

Polypropylene Vent Outlet Adapter Removal

1. Dismount the vent outlet adapter from top of boil-

er cabinet by twisting the vent outlet adapter

counter clockwise to disengage the retaining tabs.

Remove the vent outlet adapter by lifting verti-

cally to disengage it from the internal vent pipe.

2. Remove the internal vent pipe from the unit by

lifting vertically upward and out of the boiler

cabinet using a twisting / rocking motion.

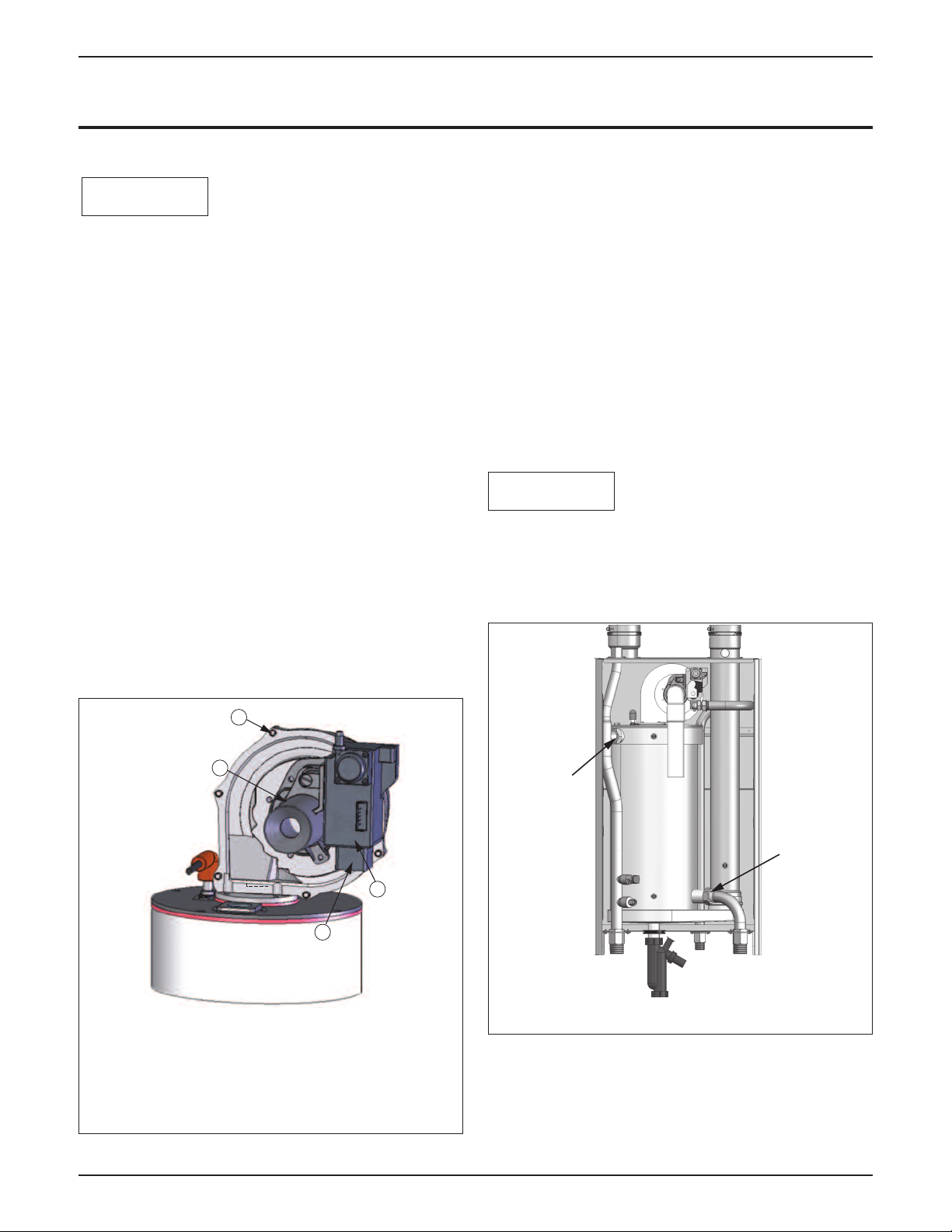

Removal of Electrical Connections (MCBA)

Before disconnecting any wire connections mark and

label all connections and location of the connections.

1. Remove top access panel located above the heat

exchanger on the top jacket panel.

2. Remove ignition cable and green ground wire

from the igniter. (Fig. 6).

3. Disconnect the ignition cable from the CBA

control module and remove air intake pipe from

venturi. (Shown as item 2 in Figs 1-3). Place

the intake pipe and ignition cable aside, DO

NOT discard as they will be re-used.

4. Disconnect the electrical connection(s) for the

blower at the blower housing.

5. Remove the mounting screw and disconnect the

black rectifier plug from the gas valve.

6. Disconnect the grey flat ribbon cable from the

display board at the CBA control module.

7. Disconnect the orange low voltage and high volt-

age wiring terminal strips by unplugging the bot-

tom strips from the upper portion.

8. Remove the retaining screw for control mount-

ing panel and swing open the control mounting

panel. The high voltage and low voltage termi-

nals should pass through the lower cutouts of

the panel to allow movement of the panel.

9. Disconnect the red wire leads from supply tem-

perature sensor (Shown as item 3 in Figs 1-3)

located at the top of the heat exchanger.

10. Disconnect the blue wire leads from return tem-

perature sensor (Shown as item 4 in Figs 1-3)

located at the bottom of the heat exchanger.

NOTICE

WARNING

Ignition

Cable

Igniter

Venturi

Fig. 6: Top of Heat Exchanger