Evoqua WALLACE & TIERNAN JETPAK User manual

WALLACE & TIERNAN®

ACTIVATED POWDER CARBON

DOSING SYSTEM

INSTRUCTION MANUAL

JETPAK

JETPAK_E.book Seite 1

2 WT.350.210.000.DE.IM.0223

JETPAK

Note

Original manual!

JETPAK_E.book Seite 2

JETPAK Contents

3

Contents

1. Introduction 7

1.1 Documentation 7

1.2 Conventions 8

2. Safety 9

2.1 Intended use 9

2.2 General safety instructions 10

2.3 Safety instructions specific to the JETPAK system 11

3. Description 13

3.1 Structure 13

3.2 Technical data 14

3.3 Requirements to the activated carbon 15

4. Installation 17

4.1 Transport and storage 17

4.2 Unpacking and erection 17

4.3 Mounting the stirrer shaft 18

4.4 Connections 18

4.5 Level measuring 20

4.6 Connection of water supply 20

4.7 Dosage lines 21

4.8 Commissioning 23

4.9 Service menus 25

4.10 Select the language 28

4.11 Settings 29

5. Interfaces 31

5.1 Selecting the interface 31

JETPAK_E.book Seite 3

4 WT.350.210.000.DE.IM.0223

Contents JETPAK

5.2 Connecting PROFINET IO-Device 32

5.3 Connecting PROFIBUS DP 35

5.4 Connecting MODBUS TCP 39

5.5 Changing the IP address of the CPU 42

5.6 Connecting Process Monitoring System (PMS) 46

5.7 Data formats 48

5.8 Reference list 50

6. Operation 53

6.1 HMI Control panel 53

6.2 System scheme 57

6.3 Operator menus 60

6.4 Calculation of the dosage quantity 63

6.5 Replenishing activated carbon 64

6.6 Switching on the dosing points 66

6.7 Switching off dosage 67

6.8 Interruptions to operation 68

6.9 Setting the operational parameters 69

6.10 Weekly switching programme (Timer) 70

6.11 Setting the signal relay 71

6.12 Messages and fault messages 72

6.13 Message buffer 75

6.14 Power failure 75

7. Maintenance 77

7.1 Maintenance and inspection plan 78

7.2 Maintenance by the operator 80

7.3 Confirm maintenance 81

7.4 Delete message buffer 81

JETPAK_E.book Seite 4

JETPAK Contents

5

7.5 Maintenance parts kits 82

7.6 Spares 86

8. Dismantling and disposal 87

9. Typical installation 89

10. Wiring diagrams 91

11. Annex 95

11.1 Requirements to the filter 95

11.2 Dosage diagram 98

11.3 Time sequence of the dosing process 99

12. Declaration of conformity 101

JETPAK_E.book Seite 5

6 WT.350.210.000.DE.IM.0223

Contents JETPAK

JETPAK_E.book Seite 6

JETPAK Introduction 1.

7

1. Introduction

1.1 Documentation

1.1.1 Target groups

This instruction manual is intended to provide assembly, opera-

ting, and maintenance personnel with the information they need

for running and servicing the JETPAK system.

This instruction manual is intended for the operating personnel. It

contains important information which will enable the operator to

run the system in a safe, reliable, trouble-free, and economical

way. Carefully observing these instructions will help to avoid dan-

gers, reduce repair costs and down times, improve the system's

reliability, and prolong its service life.

The entitled „Installation and commissioning“ and „Maintenance...“

chapters are intended exclusively for Evoqua-authorized technici-

ans. These sections contain important information on assembling,

configuring, and commissioning the system and on maintenance

and repair work.

All persons working with the system must have read and unders-

tood the instruction manual, in particular the safety instructions it

contains.

Please consult the table of contents to quickly find the information

you require.

JETPAK_E.book Seite 7

8 WT.350.210.000.DE.IM.0223

Introduction JETPAK

1.

1.2 Conventions

Notes This Instruction manual contains a number of notes with different

priorities marked with symbols.

Picto-

gram Note Meaning

Warning! Danger to life and limb! If the

situation is not handled properly,

death or serious injury may be the

result.

Caution! If this warning is not observed,

medium or slight injury or damage to

the equipment may the result.

Warning! Electrical hazard.

Warning! Risk of injury!

Corrosive substances!

Note These notes assist in the operation

of the system.

JETPAK_E.book Seite 8

JETPAK Safety 2.

9

2. Safety

2.1 Intended use

The plant may be used for the preparation and dosing of a water

and activated carbon suspension for the treatment of swimming,

drinking, cooling, process and waste water. Other or excess use is

not intended.

The operational safety of the system can only be guaranteed if it is

used in accordance with its intended purpose. It may only be used

for the purpose defined in the contract and under the installation,

operating and environmental conditions stated in this operating

manual. No substances (chemicals) may be used other than those

described in this operating manual. All inspection and

maintenance work must be carried out at the prescribed intervals.

Compliance with the intended use also includes reading this

operating manual and observing all the instructions it contains.

The operator bears full and sole responsibility if this unit is put to

any use which does not comply strictly and exclusively with this

intended use.

JETPAK_E.book Seite 9

10 WT.350.210.000.DE.IM.0223

Safety JETPAK

2.

2.2 General safety instructions

Evoqua Water Technologies GmbH attaches great importance to

the safety of all work relating to the system. This was already taken

into account in the design of the system, by the integration of

safety features.

Safety instructions The safety instructions in this documentation must always be

observed. These do not affect the validity of any additional national

or company safety instructions.

Safety instructions printed on

the system

All safety instructions attached to the system must be observed.

They must always be complete and easily legible.

Technical standard The system has been constructed using the best available

technology and according to the accepted safety regulations.

However, danger to the life and limbs of users or third parties or

damage to the system or other property cannot be ruled out if the

system, if the system is used by unqualified persons. Installation

and maintenance, as well as any work that is not described in this

operating manual may only be performed by authorized personnel.

Personnel The operator of the overall system must ensure that only

authorized and qualified technicians can work on or with the

system, and within their specified area of responsibility.

"Authorized and qualified personnel" include:

Operation by the operator, by Evoqua or by personnel who have been trained

and instructed by the service partner.

Installation, Commissioning

and Maintenance level 2

Only Evoqua service personnel or by personnel who have been

trained and authorized by Evoqua.

Electrical work Authorized and qualified electrical technicians

Spare parts / components The trouble-free operation of the system can only be guaranteed,

if original spare parts and components are used in the combination

described in this instruction manual. Otherwise there is a danger

of malfunction or damage to the system.

Modifications and extensions Never attempt to rebuild, modify or extend the system without

written approval from the manufacturer!

Electrical power During normal operation, the control cabinet must remain closed.

Connect cables in accordance with the terminal diagram in chapter

10.

Waste disposal Ensure safe and environmentally-friendly disposal of agents and

replaced parts.

JETPAK_E.book Seite 10

JETPAK Safety 2.

11

2.3 Safety instructions specific to the JETPAK system

Warning of caustic substances!

Danger due to chemicals!

The solution contains sulphuric acid that is dangerous to the skin

and face, particularly the eyes!

During all work involving acid keep an eye-bath close at hand!

To avoid acid burns put on closely sealing protective goggles and

protective clothing before starting any work involving sulphuric

acid.

Avoid splashes and spillages.

Rinse away spilt solution and splashes at once using plenty of

water.

Clean the protective clothing immediately after use.

JETPAK_E.book Seite 11

12 WT.350.210.000.DE.IM.0223

Safety JETPAK

2.

JETPAK_E.book Seite 12

JETPAK Description 3.

13

3. Description

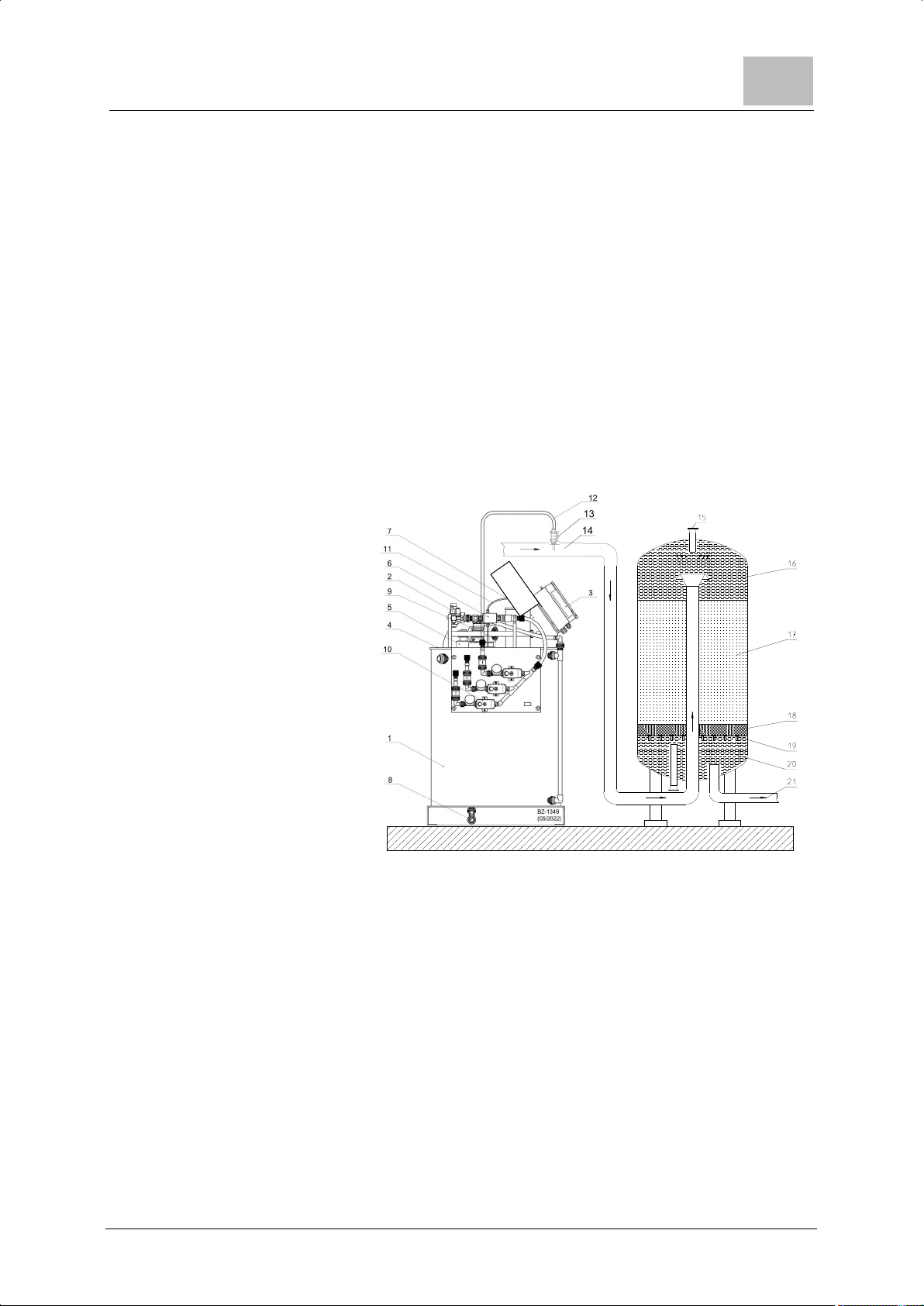

3.1 Structure

The system consists of preparation tank with a stirrer, injector, one

to three dosage lines to move the suspension into the untreated

water pipe and a control panel with the system control.

The items 14 - 21 are not supplied by Evoqua.

For requirements concerning the filter refer to the annex.

1 Suspension tank

2 Flow through assembly

3 Operating panel with main

switch

4 Filling hole

5 Stirrer

6 Injector

7 Level sensor

8 Drain

9 Suction line

10 Diaphragm valve

11 Vent line with solenoid valve

12 Dosing line

13 Injection point with ball

valve

14 Unfiltered water inlet

15 Filter ventilation

16 Untreated water

17 Filter layer

18 Support layer

19 Filter nozzles

20 Pure water

21 Pure water outlet

JETPAK_E.book Seite 13

14 WT.350.210.000.DE.IM.0223

Description JETPAK

3.

3.2 Technical data

Capacity

Dimensions (W x D x H) 1.10 m x 0.85 m x 1.5 m

Space 1.5 m x 1.5 m

Weight, installed, empty

operative

approx. 56 kg (with 3 dosage lines)

approx. 516 kg

Tank volume 460 ltr up to overflow

Usible volume 300 ltr

Remaining volume 20 ltr, cannot be pumped out

Electric connection 1/N/PE, AC 230 V 50 Hz, 1 kVA

Fuse max. 10 A

Operating water potable water

min. 6 bar (g)

700 ltr/h

Counter pressure at the point of

application

max. 1.5 bar (g)

System of protection IP 54

Ambient temperature 5 ... 40°C

Humidity without condensation

Concentration 20 g/ltr 30 g/ltr 40 g/ltr

Desired concentration

in the brute water Circulation max.

0.5 g/m³ 2200 m³/h 3300 m³/h 4400 m³/h

1.0 g/m³ 1100 m³/h 1650 m³/h 2200 m³/h

1.5 g/m³ 730 m³/h 1100 m³/h 1460 m³/h

JETPAK_E.book Seite 14

JETPAK Description 3.

15

3.3 Requirements to the activated carbon

• Only moistened and acidic powdered activated carbon

(to EN 12903 (potable water), EN 15977 (swimming pool

water), DIN 19643-2)

• Surface >900 m2/g, calculated by BET

• Low fluctuations in quality depending on production

• Grain size distribution to be adhered to accurately

(to DIN 19643-2):

• Only a low proportion of oversize particles (specially larger

than 1 mm)

• Absence of foreign substances

• Filled into bags or cardboard with 3 kg weight portion of dry

carbon.

Note

Suspensions which are produced with water vapour-activated

powdered carbon can react in a strongly alkaline manner. This re-

sults in partial or entire precipitation of the hardening constituents

in the suspension water.

Through a reduction in the pH value to below pH 2 by the use of

sulphuric acid, the precipitation of hardening constituents and ger-

mination can both be prevented.

The necessary quantity of acid is already added to the moistened

and acidic powdered activated carbon that should be used.

It is known that most adsorption processes are not negatively af-

fected by a low pH value, but in fact tend to be assisted.

Warning of caustic substances!

Danger due to chemicals!

The solution contains sulphuric acid that is dangerous to the skin

and face, particularly the eyes!

During all work involving acid keep an eye-bath close at hand!

To avoid acid burns put on closely sealing protective goggles and

protective clothing before starting any work involving sulphuric acid.

Avoid splashes and spillages.

Rinse away spilt solution and splashes at once using plenty of wa-

ter.

Clean the protective clothing immediately after use.

Grain size range Percentage mass

of sieve fraction

> 0.071 mm < 25%

< 0.045 mm > 50%

JETPAK_E.book Seite 15

16 WT.350.210.000.DE.IM.0223

Description JETPAK

3.

JETPAK_E.book Seite 16

JETPAK Installation 4.

17

4. Installation

4.1 Transport and storage

• Protect the system from tilting during transport and storage.

• Remove the transport fixing devices only on arriving at the ins-

tallation site.

• Load the system with an elevating truck or forklift.

• No pilot points are provided for lifting by crane.

• Cover the system if it is to be stored out in the open for any

period of time.

• Protect system from penetration by damp and frost.

4.2 Unpacking and erection

Requirements of the site of installation:

• Carrying power at least 500 kg

• Frost-free

• Protected from rain or moisture

• Sink for drainage and overflow

The stirrer shaft has been removed for transport and is packed se-

parately.

1 Remove packaging foil and transport fixing devices.

Take note of small components.

2 Check system for damage, foreign substances and soiling and

clean if necessary.

3 Push the system off the pallet on to the prepared space, bring

into the correct position and check that it is resting horizontally.

4 Fix the system to the floor. Fixing material is included.

JETPAK_E.book Seite 17

18 WT.350.210.000.DE.IM.0223

Installation JETPAK

4.

4.3 Mounting the stirrer shaft

1 Open the filling hole of the tank.

2 Fix the stirrer shaft to the stirrer motor (see figure).

3 Fix the screws A with the Allen key 3 mm..

4.4 Connections

4.4.1 Mains connection

Also refer to the technical data in chapter 3.2 and the wiring dia-

grams enclosed.

Warning of dangerous voltage!

Risk of injury due to electric current!

Electrical work on the system may only be performed by qualified

electricians.

In the case of all work on the system take into consideration the

following:

• This Instruction Manual,

• The national regulations on the Erection of Power Installations

with Nominal Voltages below 1000 V,

• Regulations for the "Coordination of Works” and/or the corres-

ponding national and regional installation and safety regulati-

ons.

• Safety regulations at the installation site:

A

JETPAK_E.book Seite 18

JETPAK Installation 4.

19

• Get instructions from the operator!

• Harmonise your work with the surroundings.

• Use only licensed and properly functioning tools and measu-

ring equipment, and personal protection devices.

• The system must be properly earthed. No freely accessible

part of the system may be under mains voltage or any other

dangerous voltage.

• Once the system is connected, work may only be carried out

on the system when the pre-fuse has been removed or the

main switch on the system is secured in the OFF position

using a lock.

• If work has to be carried out on the appliance when switched

on, on no account touch the electrical contacts. One hand

must always be free away from live or earthed parts of the sys-

tem.

1 Check the mains for correct voltage and fuse.

2 Connect the system with a flexible cable 3x1,5 mm².

Install either a stationary connection to the mains supply or

connect the mains cable via a not exchangeable 3-pole CEE

plug (blue).

Install the wiring according to the nominal current of the fuse.

4.4.2 External release contacts

The system provides terminals for external release contacts to

stop dosage during filter cleaning etc. For each dosing line there is

one release contact.

At delivery the terminals are shortened. For details refer to the wi-

ring diagrams.

Note

During dosage of activated powder carbon, flocculant dosage

should not be switched off.

As long as hygiene parameters are met, it is not necessary to add

activated powder carbon and flocculant after pool closure until the

next morning.

JETPAK_E.book Seite 19

20 WT.350.210.000.DE.IM.0223

Installation JETPAK

4.

4.5 Level measuring

Installed is a non-contact, contiuously measuring ultrasonic level

sensor. The limit levels have been programmed at the factory and

cannot be changed.

4.6 Connection of water supply

1 Connect the system to process water (potable water quality).

Attention!

Water temperature must not exceed the ambient temperature.

Otherwise condensation and deposits of carbon in the tank can oc-

cur.

Note

Pay attention to the regulations for installations.

If necessary install a backflow preventer.

Tighten the plastic unions by hand only.

4.6.1 Connecting process water input

1 Connect the system to pipe or hose

(connection EN ISO 228-1 - G½).

Max. inlet pressure 25 bar (g).

Min. inlet pressure 6 bar (g).

2 Secure with fitting hose brackets if a hose is used.

Level Height Reaction

EMPTY approx. 50 mm Failure

MIN approx. 150 mm Tank is filled

MAX approx. 760 mm Filling is stopped

OVERFLOW approx. 895 mm Failure

JETPAK_E.book Seite 20

Table of contents

Other Evoqua Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual