Tricor 225 User manual

TRICOR Systems Inc.

i

Contents

Section Page

1GENERAL DESCRIPTION.................................................................1.1

1.1 Supplied Items .......................................................................................1.1

1.2 Optional Items ........................................................................................1.2

1.3 Serviceable Items ..................................................................................1.2

1.4 Calibration..............................................................................................1.2

2MODEL 225 SETUP ............................................................................2.1

2.1 Equipment Location ..............................................................................2.1

2.2 Power Connection.................................................................................2.2

2.3 Internal Printer ........................................................................................2.2

2.4 External Print / Plot (Option) .................................................................2.3

2.5 TMDAS (Option) ....................................................................................2.5

2.6 PC Configuration...................................................................................2.6

2.6.1 Software Installation...............................................................................2.7

2.6.2 RS232 Connection................................................................................2.8

2.6.3 USB Connection....................................................................................2.9

3MODEL 225 OPERATIONAL PROCEDURES...............................3.1

3.1 Turning On The Model 225 ...................................................................3.1

3.2 Display Contrast ....................................................................................3.2

3.3 Initialization And Testing .......................................................................3.2

3.4 Running A Chocolate Sample ..............................................................3.4

3.5 Menu / Keyboard Operation .................................................................3.7

3.5.1 Passwords..............................................................................................3.8

3.5.2 User ID ....................................................................................................3.8

3.5.3 Print Result Data ....................................................................................3.9

3.5.4 Clear Test Memory..............................................................................3.11

3.5.5 Internal Printer ......................................................................................3.12

3.5.6 External Printer.....................................................................................3.12

3.5.7 Temperature Units ...............................................................................3.13

3.5.8 Set Clock/Calendar .............................................................................3.14

3.5.9 Run Time...............................................................................................3.15

3.5.10 Plot Baseline Temp .............................................................................3.16

3.5.11 History / Status .....................................................................................3.17

3.5.12 LCD Contrast .......................................................................................3.19

3.5.13 CTU Offset Adjust ................................................................................3.19

3.5.14 Cooler Set Point ..................................................................................3.20

Contents (Cont'd)

Section Page

3.5.15 Heater Set Point ..................................................................................3.21

3.5.16 Line Frequency ....................................................................................3.22

3.5.17 Self Test................................................................................................3.22

4CONFIGURATION SOFTWARE .......................................................4.1

4.1 Clock / Calendar Set (Option) ..............................................................4.2

4.2 Preferences............................................................................................4.3

4.2.1 Line Frequency ......................................................................................4.5

4.2.2 Change Password.................................................................................4.5

4.2.3 Sample Run Time (Option) ...................................................................4.6

4.2.4 User Text.................................................................................................4.6

4.2.5 Plot Baseline Temperature (Option) ....................................................4.7

4.2.6 CTU Offset..............................................................................................4.7

4.3 Display....................................................................................................4.8

4.3.1 Result Display Method ..........................................................................4.9

4.3.2 Temperature Units .................................................................................4.9

4.3.3 Internal Printer ........................................................................................4.9

4.3.4 External Printer (Option)......................................................................4.10

4.3.5 Clear Results........................................................................................4.10

4.4 Temperature Control ...........................................................................4.11

4.5 System Status ......................................................................................4.12

4.6 Status Bar.............................................................................................4.12

5CHOCOLATE TEMPER CURVE INTERPRETATION..................5.1

5.1 Temper Curve ........................................................................................5.1

5.2 Qualitative Method.................................................................................5.2

5.3 Analytical Method...................................................................................5.2

5.3.1 CTU and Slope Determination.............................................................5.2

5.3.2 CTU Criteria ...........................................................................................5.5

5.3.3 Slope Criteria.........................................................................................5.5

6TROUBLE SHOOTING.......................................................................6.1

6.1 No Power................................................................................................6.1

6.2 Blank LCD Display................................................................................6.2

6.3 Warning Messages ...............................................................................6.2

6.4 Stored Result Errors..............................................................................6.4

6.5 Temperature Stability............................................................................6.5

6.6 Non-Repeatable Results.......................................................................6.5

TRICOR Systems Inc.

ii

TRICOR Systems Inc.

Copyright© 2004 TRICOR Systems Inc.

All rights reserved

Printed in the United States of America

No part of this publication may be reproduced in any form by any

means without the express written permission of TRICOR

Systems Inc.

The information in this document is subject to change without

notice. TRICOR Systems Inc. makes no representations or

warranties with respect to the contents of this manual and

specifically disclaims any implied warranties of fitness for a

particular purpose. TRICOR Systems Inc. assumes no

responsibility for errors or omissions in this document.

TRICOR Systems Inc.

1650 Todd Farm Drive Elgin, Illinois 60123

Phone (847) 742-5542 • Fax (847) 742-5574

TRICOR Systems Inc.

IMPORTANT

TRICOR’s Mission Statement emphasizes Quality and

Customer Service. Should you encounter any problem with

yourModel225ChocolateTemperMeterordiscrepanciesin

this manual, please let us know at (847) 742-5542.

If TRICOR is made aware or discovers any discrepancies or

problems you will be notified and corrective action will be

taken as soon as possible.

To serve you better we request that primary and alternate

contact names be provided on the enclosed product contact

formandreturnedtoTRICORintheself-addressedenvelope.

This personalized approach will eliminate any delay in

providing you with potentially important information.

TRICOR Systems Inc.

WARRANTY INFORMATION FORM

Customer: ___________________________________________________

Address: ___________________________________________________

___________________________________________________

Please provide the following information for use by our hotline.

•The person(s) to contact with regard to theModel 225 Chocolate Temper Meter

and manual:

Name Telephone No. Email

Primary ____________________ _______________ _______________________

Alternate (1) ____________________ _______________ _______________________

(2) ____________________ _______________ _______________________

(3) ____________________ _______________ _______________________

•The person(s) to contact with regard toNew Product Releases:

Name Telephone No. Email

Primary ____________________ _______________ _______________________

Alternate (1) ____________________ _______________ _______________________

(2) ____________________ _______________ _______________________

(3) ____________________ _______________ _______________________

1.1

TRICOR Systems Inc.

SECTION 1

GENERAL DESCRIPTION

The Model 225 Chocolate Temper Meter provides a much more convenient and

accurate method of determining chocolate temper than the conventional “ice

bath” techniques. The 225 uses a solid-state, thermoelectric cooling unit with

state-o-the-art electronic control circuitry to precisely maintain and regulate the

cooling temperature of the chocolate sample.

The chocolate temperature-sensing probe is maintained at a controlled, fixed

temperature prior to chocolate sample testing to eliminate any errors due to

temperature variations. The 225 is also designed to maintain constant sample

size and temperature-sensing probe depth. These field proven features ensure

accuracy and repeatability in measuring chocolate temper.

The 225 is housed in a small, laboratory enclosure. All controls, indicators and

the internal printer are located on the front panel. The chocolate sample well and

cover door are found on the top of the unit. On the back of the model 225 is the

power entry module with the on/off switch and the RS232 and USB

communication ports.

1.1 Supplied Items

The Model 225 is supplied to the customer along with the following additional

items:

•Power Cord

•RS232 Serial Data Cable and 9-Pin Adaptor

•A spare Roll of Thermal Print Paper for the Internal Printer

•Temper Well Cleaning Tool (attached to Model 225)

•200 Sample Cups

•A CD with Microsoft Windows-Compatible Configuration Software

•Certificate of Calibration for this Model 225

•This Manual

1.2

TRICOR Systems Inc.

1.2 Optional Items

The following are optional items that may be purchased for the Model 225:

•Sample Cups (5000 / box)

•External Printer with Serial Cable Adaptor (plotting option)

•Temper Meter Data Acquisition Software (TMDAS)

•USB Communications Cable

•Calibration / Verification Fixtures

•Optional Software Features

1.3 Serviceable Items

There are no user serviceable parts and no adjustments in the Model 225.

Opening the Model 225 voids the warranty and the Certificate of Calibration.

WARNING

There are dangerous voltages inside the Model 225

which may cause injury or death. Service of the Model

225 should be performed only by a qualified service

technician.

1.4 Calibration

TRICOR Systems recommends a yearly calibration. Two separate calibrations

are performed on Temper Meters. The first is an electronic calibration/

verification of the electronics. This verification can be performed by your internal

personnel provided that they have been given the proper training and the

verification tools have been purchased.

The second part of the calibration is a check of the heat transfer coefficients

between the cooler well and the sample cups. This calibration is performed at

TRICOR using specially crafted tools and procedures to obtain repeatable/

consistent results. This procedure takes 3 days provided that no repairs are

needed and the unit has been scheduled. An electronic calibration is performed

at the same time.

1.3

TRICOR Systems Inc.

1.4 Calibration (Cont'd)

If you would like to schedule your Model 225 to be calibrated at TRICOR

Systems, please call TRICOR’s Contracts Department at (847) 742-5542 for a

Return Material Authorization (RMA#).

2.1

TRICOR Systems Inc.

SECTION 2

MODEL 225 SETUP

2.1 Equipment Location

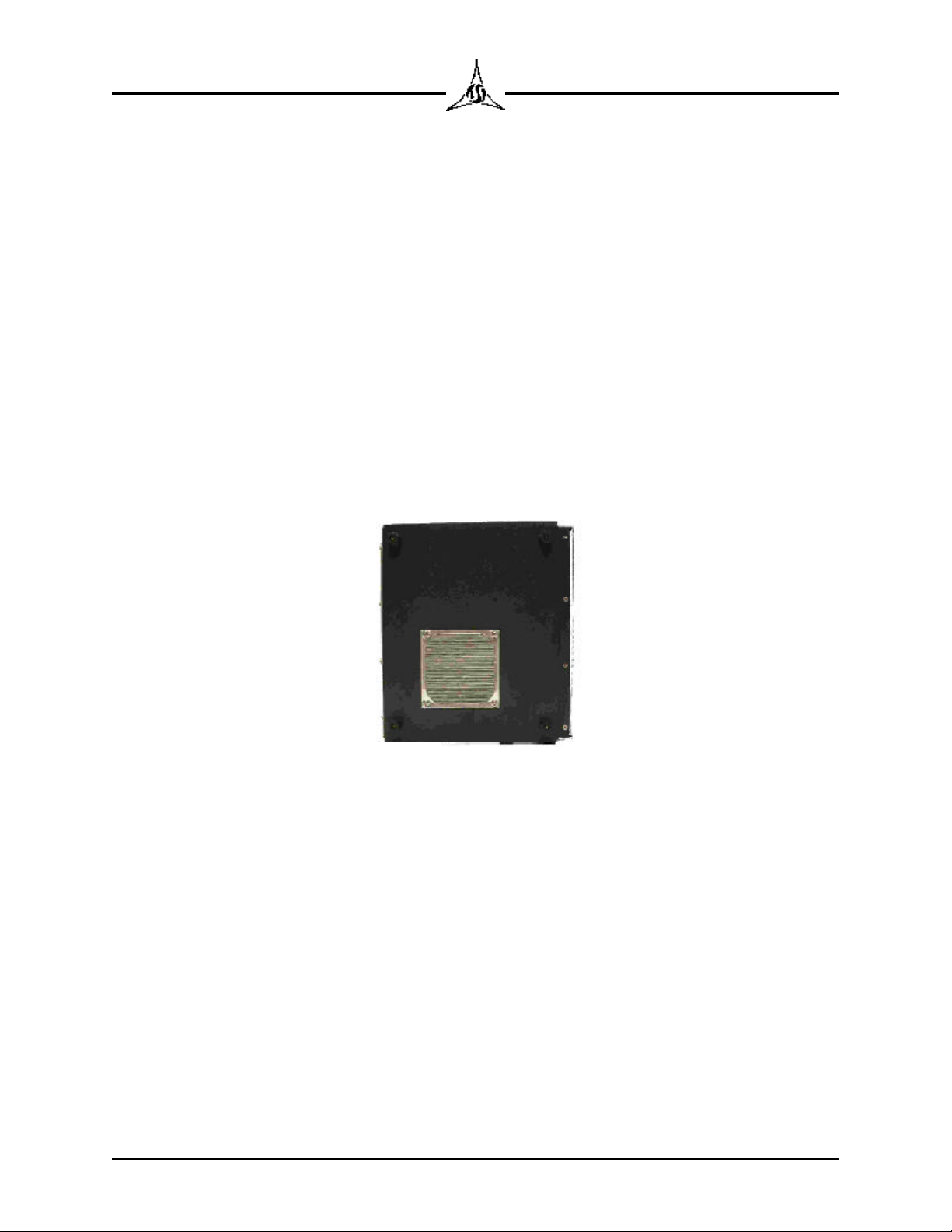

The Model 225 uses a thermoelectric cooler to generate the cold temperature

well. To obtain the temperature reduction, a great amount of forced air must be

passed through the unit to remove the heat produced in the cooler. It is ideal that

the 225 be located in a spot where relatively cool, clean and dry air may pass

through the unit. The intake port on the bottom of the unit (shown below) as well

as the exit ports on the back must be kept unobstructed. Do not place papers

under the unit. The paper will be drawn up against the intake restricting air flow.

If the intake becomes clogged, the screen can be removed for cleaning by

removing the 4 screws which hold it to the base cover.

Figure 2.1 Bottom View Showing Fan Intake

The repeatability and precision of the chocolate temper is affected by the length

of time it takes to get the chocolate sample from the source to the Model 225

temperature well and to get the sample door closed. It is recommended that the

unit be placed in close proximity to the chocolate so that this transfer can be

minimized. If excessive cooling takes place before the measurement process

begins, inaccurate result may result.

The Model 225 is a precision measurement instrument. It is important that a

clean, uninterrupted supply of electrical power be provided to the unit. If

unexpected problems occur, please verify your power source or move the Model

225 to a location where good power is assured. Noise filtering and transient

suppression may be beneficial.

2.3

TRICOR Systems Inc.

2.3 Internal Printer (Cont'd)

To install the thermal print paper, grasp the latching clips on the translucent

printer paper supply door. Squeeze the clips and fold the door down. If the

remains of the previous roll of paper are still in the printer, remove this spool.

Unwrap a new roll of paper and cut or tear the end so that the paper is free to

spool off of the roll. Insert the paper roll into the printer opening with the loose

paper end coming over the top of the roll from the back side. Snap the door

closed being sure to align the paper so that it is centered below the tear-off

metal teeth. If the power is turned on, the “Feed” button can be pressed to

advance the paper.

The internal printer can be tested by holding the “Feed” button down while the

Model 225 is powered up. The printer will print several inches of text and

graphic symbols.

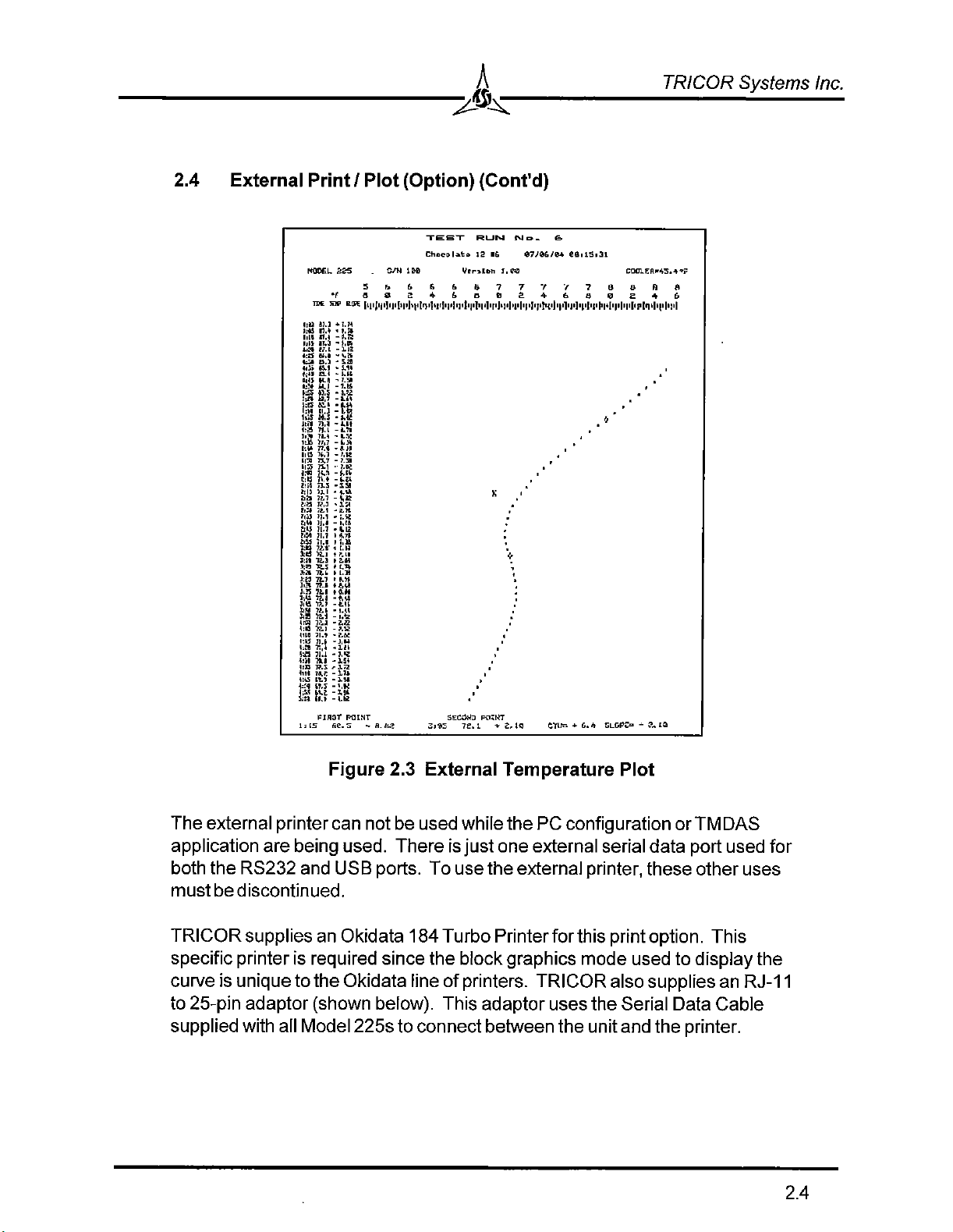

2.4 External Print / Plot (Option)

The external printing is an optional feature that must be purchased. This feature

creates a full page time / temperature graph of the chocolate sample. This

allows easy visualization of tempering problems.

2.5

TRICOR Systems Inc.

2.4 External Print / Plot (Option) (Cont'd)

Figure 2.4 Printer Adaptor

To attach the external printer to the Model 225, plug the Printer Adaptor into the

25-pin D connector on the back of the Okidata 184. Tighten the thumb jacks.

Plug one end of the RJ-11 flat cable (telephone cable) into the Printer Adaptor.

The other end plugs into the RJ-11 jack on the back of the Model 225. Be sure

that nothing is attached to the USB jack on the Model 225.

Install tractor feed paper according to the Okidata 184 Printer Manual. Align the

paper perforation at the tear off edge of the viewing window. Be sure to follow

all instructions provided by Okidata regarding setup of this printer. The shipping

restraints holding the print head must be removed. Connect AC power to the

printer.

NOTE

The Okidata 184 must be ordered with the correct line

voltage input for your region of the world. The printer

does not contain a “universal” power supply nor a line

voltageselector. TRICORisnotresponsiblefordamages

caused by operating the Okidata 184 at the wrong line

voltage.

2.5 TMDAS (Option)

The Temper Meter Data Acquisition Software (TMDAS) is a Windows

application that accepts and interprets the external printer output from the 225,

plots smooth curves for display/printing and saves the data to a file where

multiple results can be analyzed. The TMDAS application and the external

printing feature of the Model 225 are both options that must be purchased.

2.6

TRICOR Systems Inc.

2.5 TMDAS (Option) (Cont'd)

Refer to the TMDAS manual for discussion of installing the software and

attaching the Model 225 to the PC. The discussion below, concerning PC

Configuration also describes the attachment of the Model 225 to a PC.

2.6 PC Configuration

The Model 225 is supplied with a Windows application that is used to configure

features. Not all the features shown in this manual are available on all Model

225 units. Some features are common to all units, while others are provided

only when originally purchased with the unit. A list of features which can be

configured is shown below:

•Set Real Time Clock/Calendar (Option)

•Set Power Line Frequency

•Adjust Sample Run Time(Option)

•Set User Text

•Extended Temperature Plotting(Option)

•Change CTU Offset

•Set Password

•Select CTU or Slope/Temperature

•Select Temperature Units

•Enable/Disable Internal Printer Auto-Print

•Enable/Disable External Printer Auto-Print (Option)

•Change Cooler Reference Temperature(Option)

•Change Heater Reference Temperature(Option)

Some, but not all of these features can also be changed using the menu on the

Model 225 itself. The Configuration Application does make setting these

features easier and more intuitive. See section 3 for menu descriptions.

2.7

TRICOR Systems Inc.

2.6.1 Software Installation

To install the configuration application, follow the procedure below:

NOTE

Youmusthaveadministratorprivilegestoproperlyinstall

this software on Windows NT, 2000 and XP.

1. Insert the installation CD into the CD-ROM drive of the PC.

2. If the auto-run feature does not work, navigate to the root directory

folder of the CD. Double click the file “SETUP.EXE”.

3. It is recommended that you accept the default installation options

provided by the install program. Simply press the “Enter” key to

accept the choices.

4. The program can be run by going to theStart menu and selecting

Programs | Model225 | Model225 Configure. The application

software can be run without the Model 225 attached, but the

operations are limited until there is communications established

between the PC and the unit.

5. If the USB connection is to be used on the Model 225, leave the

installation CD in the drive and skip down to section 2.6.3.

The communications between the PC and the Model 225 is handled over either

an RS232 serial port or a Universal Serial Bus (USB) port. The application

software will automatically attempt to find the unit if it is attached. Once

communications is established the buttons and the controls on the Configuration

dialog will become active. The choice of communications port is dependant on

the type of hardware resources available on the PC. Both methods provide the

same level of performance. Review the connection discussion below for proper

connection of the 225 to the PC.

2.8

TRICOR Systems Inc.

2.6.1 Software Installation (Cont'd)

Figure 2.5 Serial and USB Connectors on Back of Model 225

2.6.2 RS232 Connection

The cabling required to communicate between the PC and the Model 225 is

provided. It consists of a 9-pin adaptor which attaches to the serial port of most

recent PCs. This adaptor accepts one end of the flat cable with RJ-11

connectors. The other end of the cable is plugged into the Model 225. The

black “phone” jack on the back of the unit is intended for the serial

communications.

Figure 2.6 RS232 Serial Cable

2.9

TRICOR Systems Inc.

2.6.2 RS232 Connection (Cont'd)

The cable provided is a standard “telephone” cable. If a longer cable is

required, a standard cable may be used as long as it is a 6-conductor cable.

Four-conductor cables will not work with the external printer.

WARNING

Thoughtheserialcablemaybethesameasthoseused

for telephone communications, the interface is not a

modemconnection. DonotplugtheModel225orthe9-

pin adaptor into a telephone network. They are

incompatible. Damage to the Model 225 or PC may

result.

2.6.3 USB Connection

The Model 225 may communicate with the PC using a USB interface. A

standard AB USB cable is required (not supplied). These cables have a length

limited by the USB specification. Extension cables violate the USB

specification and TRICOR Systems will not support equipment operated using a

USB cable longer than 6 feet.

IMPORTANT

DonotconnecttheModel225withtheUSBcabletothe

PCuntilinstructed to doso,below. If you arenotready

with the proper software, you may create difficulties

when connecting in the future.

USB is not supported (directly) by Windows 95, and may have incompatibilities

with early versions of Windows 98 and Windows NT 4.0. These are limitations

of the operating systems and not the Model 225.

For the USB communications to function, software drivers must be installed on

the PC. These drivers are provided on the installation CD that is provided. If

you have already installed the application software and have removed the CD

from the drive, you can prevent the auto-run installation from running again by

holding down the left shift key for several seconds while inserting the CD. If the

auto-run starts, simply cancel the operation.

2.10

TRICOR Systems Inc.

2.6.3 USB Connection (Cont'd)

With the Model 225 turned off, attach the unit to the PC using a USB cable. Be

sure Windows has started and is up and running. Turn on the power to the

Model 225. Within a few short seconds the Windows operating system should

recognize that new hardware has been attached. The dialog will prompt you to

load new software for this hardware. Navigate to the root directory of the CD

ROM drive. Press the next button to install the drivers. Depending on the

version of the operating system you may be asked to re-boot the PC. Follow the

directions provided by the operating system.

Run the Configuration application. It will search through all the available

resources on the PC in an attempt to find a connection to the Model 225. The

status bar of the application shows in the lower-left corner the communication

channel being used or currently searched.

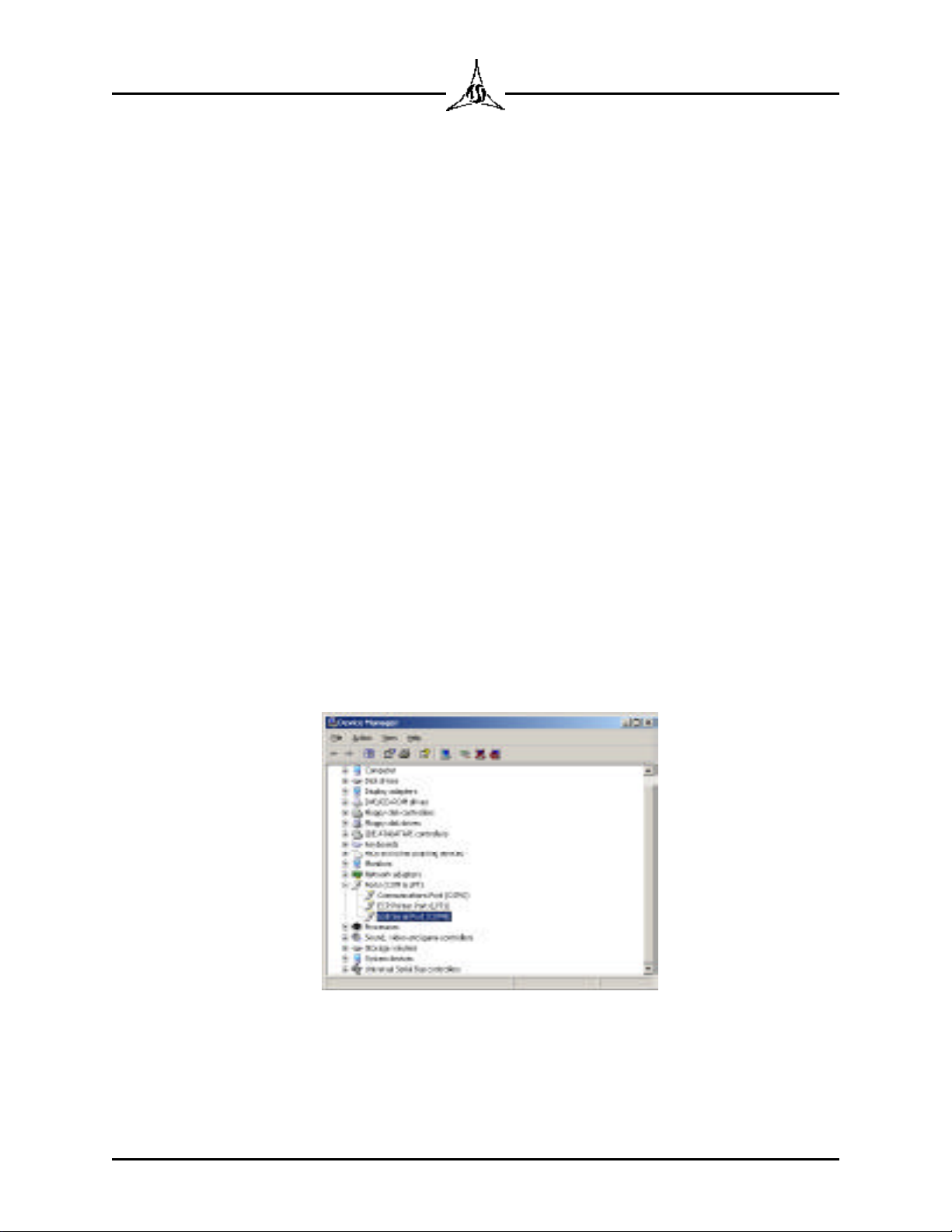

If there is trouble installing the USB drivers, the most likely cause are legacy

RS232 serial ports on the PC conflicting with the USB port designation. To

correct this problem, open the Windows Device Manager from the Control Panel

System folder. The newly installed USB connection should show up as a serial

port as shown below. Note, the port resource will not appear in this list if the

Model 225 is not attached and turned on. Be sure to close the Configuration

application.

Figure 2.7 Newly Installed USB Port

2.11

TRICOR Systems Inc.

2.6.3 USB Connection (Cont'd)

The currently selected COM channel is appended after the port name. This

channel selection should not be less than COM3. If it is, double click to edit the

port properties. Choose the Port Settings tab and press the Advanced button.

Figure 2.8 USB Port Settings

Change the port channel setting to some other value greater than COM4. Use

the Com Port Number drop down list box to choose the channel. Never select a

channel that is the same as an RS232 com port on the PC. Press the OK

buttons to back out with the new settings.

Figure 2.9 Advanced Port Settings

Turn off the Model 225 and reboot the Windows operating system. Wait for

Windows to again restart. Turn on the Model 225. Verify that the Configuration

application can communicate with the Model 225. The channel should match

that set in the driver configuration dialog. If problems persist, please call

TRICOR for assistance.

Table of contents

Other Tricor Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser RIA15 operating instructions

ABB

ABB Aztec 600 user guide

Secomam

Secomam UviLine Connect Series operating manual

Fluidwell

Fluidwell F011-A user manual

VOLTCRAFT

VOLTCRAFT SL-300 instruction manual

Aquametro Oil & Marine

Aquametro Oil & Marine CONTOIL DN15 Mounting and operating instructions