4. MANUAL OPERATION............................................................................................................................31

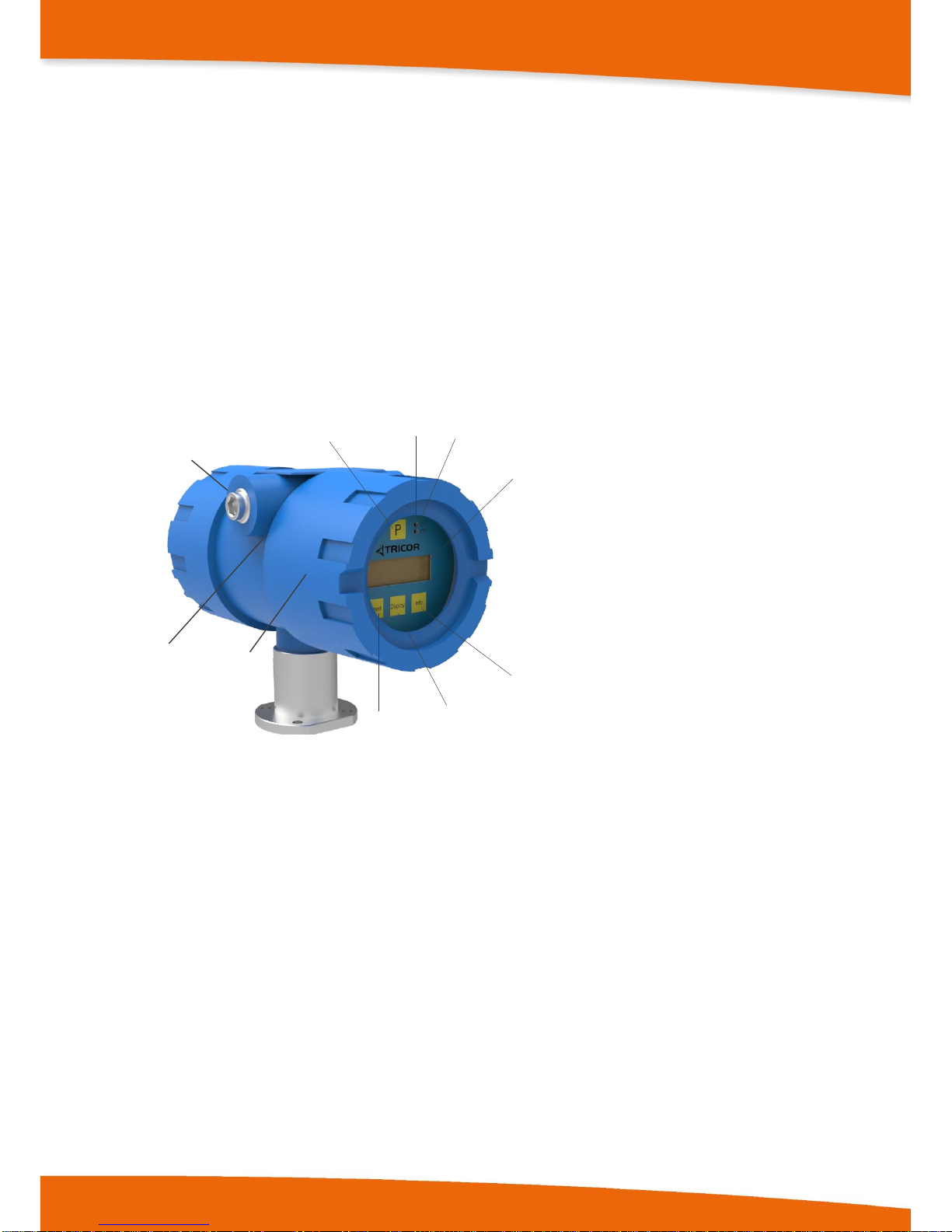

4.1. Power On Sequence and Principles of Manual Control ...........................................................................31

4.1.1. Using the Magnet......................................................................................................................................33

4.2. Setup Guidelines.......................................................................................................................................33

4.2.1. Offset Adjustment .....................................................................................................................................33

4.2.2. Flow Filter .................................................................................................................................................33

4.2.3. CUT OFF ..................................................................................................................................................34

4.2.4. Interaction of the Parameters ...................................................................................................................34

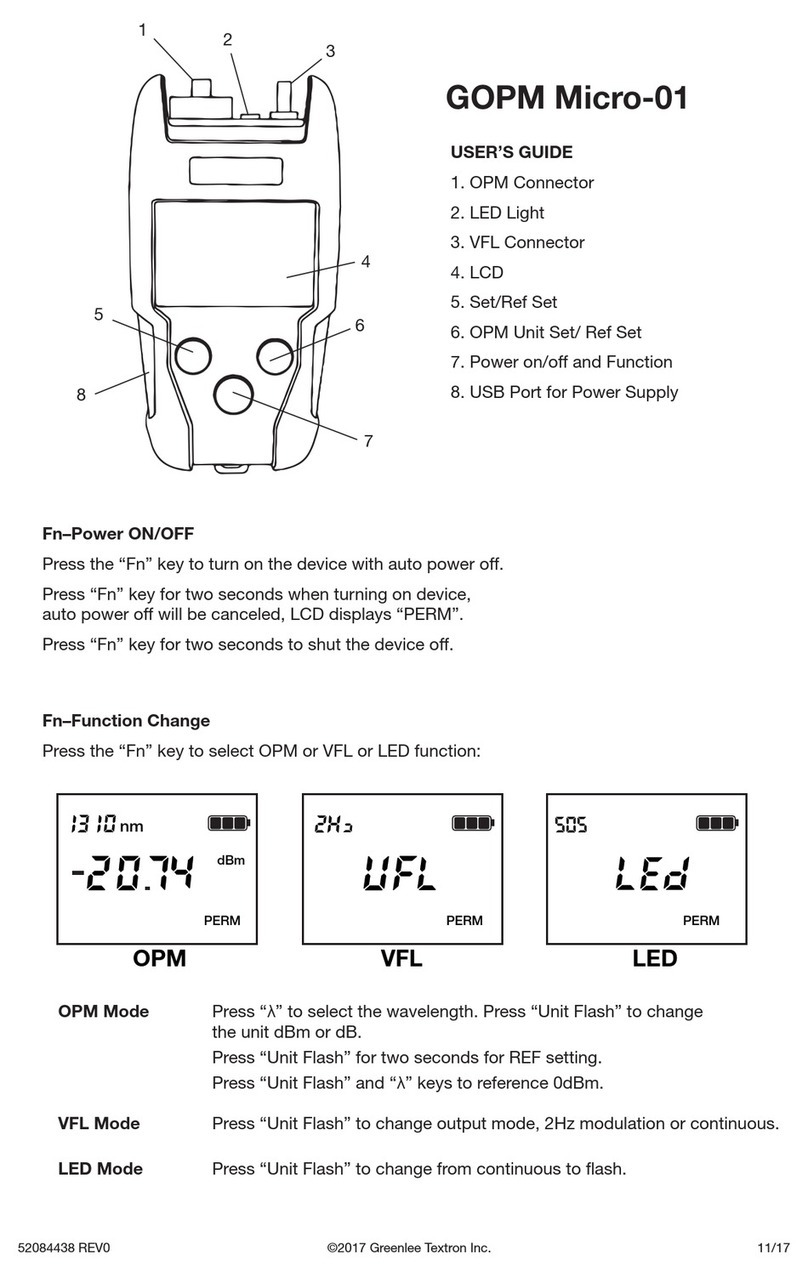

4.3. Measuring Mode.......................................................................................................................................35

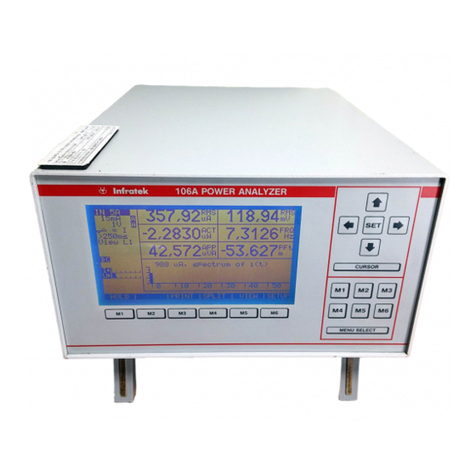

4.3.1. Function of the Pushbuttons.....................................................................................................................35

4.3.2. Display Selection ......................................................................................................................................35

4.3.3. Display Resolution....................................................................................................................................35

4.3.4. Resetting the Batch (TOTAL-) Value........................................................................................................35

4.3.5. Event Logging...........................................................................................................................................36

4.3.6. Totalizer ....................................................................................................................................................40

4.4. Offset Adjustment .....................................................................................................................................40

4.5. Control Mode ............................................................................................................................................41

4.5.1. Function of the Pushbuttons.....................................................................................................................41

4.5.2. Submenus in the Main Menu....................................................................................................................42

4.5.3. ZERO OFFSET Menu...............................................................................................................................42

4.5.4. DISPLAY Menu.........................................................................................................................................43

4.5.5. SETUP Menu............................................................................................................................................50

4.5.6. SETUP PARAMETER Menu ....................................................................................................................51

4.5.7. SETUP FILTER Menu...............................................................................................................................55

4.5.8. SETUP IN/OUTPUTS Menu.....................................................................................................................56

4.5.9. SETUP DATA CONFIGURATION Menu..................................................................................................64

4.5.10. SETUP RESET TOTAL Menu..................................................................................................................65

4.5.11. SETUP CLEAR LOGS Menu....................................................................................................................66

4.5.12. I/O-TEST Menu.........................................................................................................................................66

4.5.13. SERVICE Menu ........................................................................................................................................68

5. REMOTE OPERATION............................................................................................................................69

5.1. Serial RS485 Interface..............................................................................................................................69

5.1.1. Electrical Connection of RS485 Interface.................................................................................................69

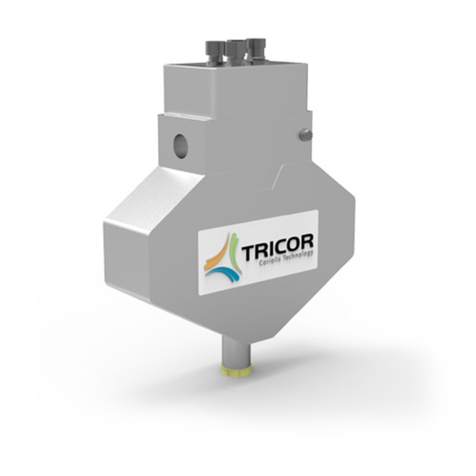

5.1.2. Usage of the TRICOR Configurator..........................................................................................................69

5.1.3. RS485-Interface-Protocol .........................................................................................................................69

5.2. HART®.......................................................................................................................................................70

5.2.1. Electrical Connection for HART®..............................................................................................................70

5.2.2. Device Description File for HART®Interface Protocol..............................................................................70

5.3. Foundation Fieldbus®................................................................................................................................70

5.3.1. Electrical Connection for Foundation Fieldbus®.......................................................................................70

5.3.2. Device Description File for Foundation Fieldbus®Interface Protocol.......................................................70

6. SERVICE AND MAINTENANCE..............................................................................................................71

6.1. Maintenance .............................................................................................................................................71

6.2. Trouble Shooting.......................................................................................................................................71

6.3. Changing the Fuses..................................................................................................................................72