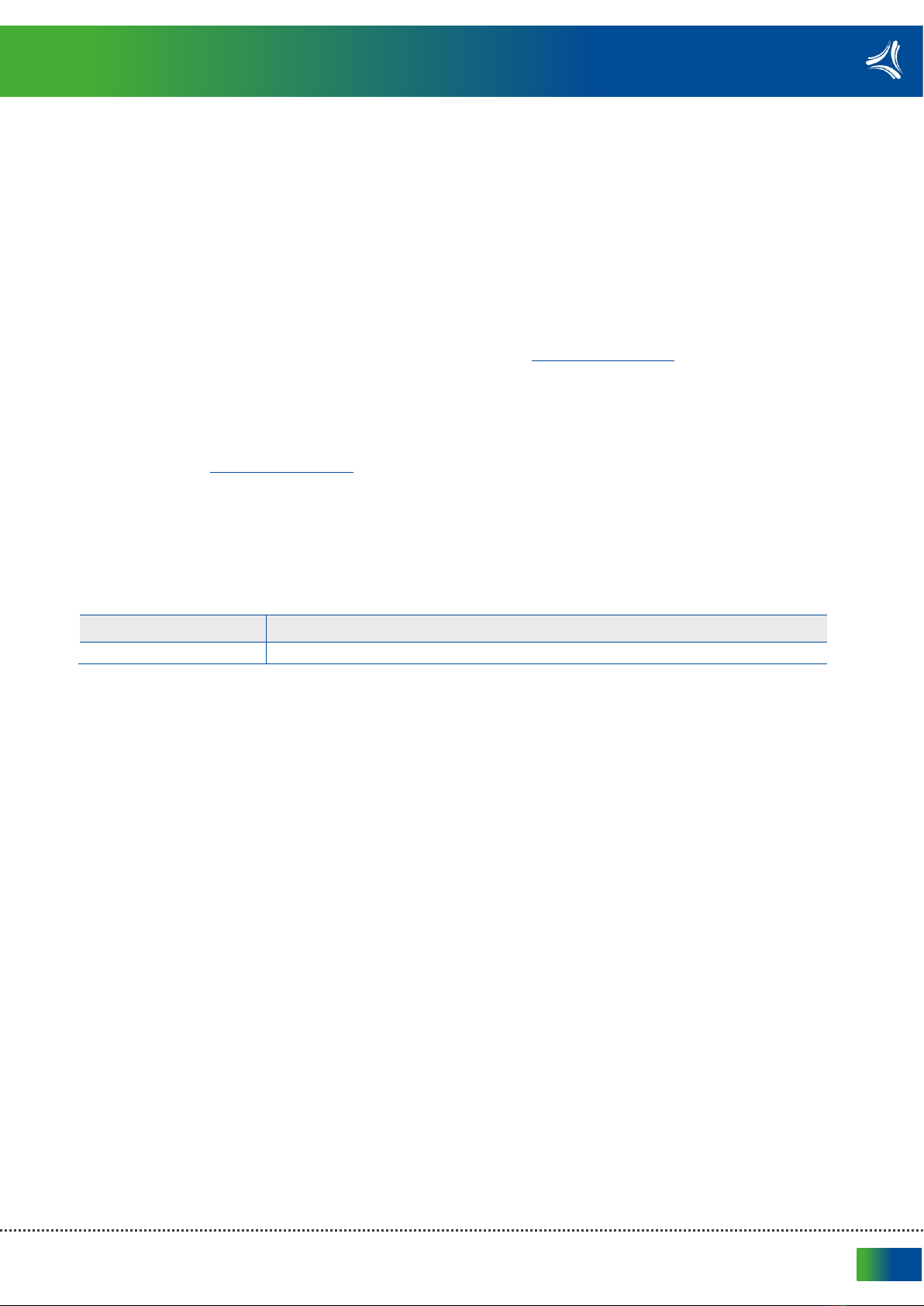

Index

1. LEGAL

INFORMATION

......................................................................................................... 5

1.1.

Warning

notice

system

............................................................................................................................5

1.2. Qualified Personnel ....................................................................................................................................5

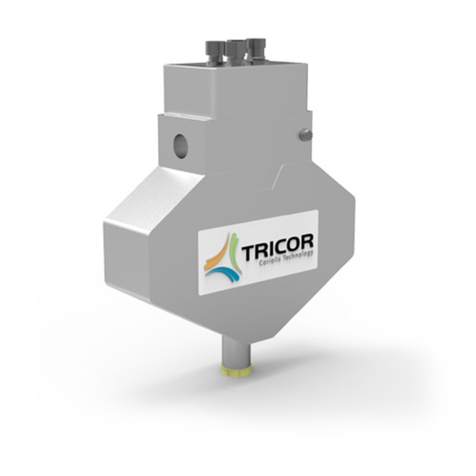

1.3. Proper use of TRICOR products ..................................................................................................................6

1.4. Disclaimer of Liability..................................................................................................................................6

2. INTRODUCTION..................................................................................................................... 7

2.1. Purpose of this documentation..................................................................................................................7

2.2. Document history .......................................................................................................................................7

3. COMMUNICATION ................................................................................................................ 8

3.1. Features......................................................................................................................................................8

3.2. Installation in hazardous area ....................................................................................................................8

3.3. Profibus.......................................................................................................................................................8

3.4. Changing Profibus termination at the transmitter cassette.....................................................................10

3.5. Connecting the Profibus (CH1) .................................................................................................................11

3.6. Installation check......................................................................................................................................12

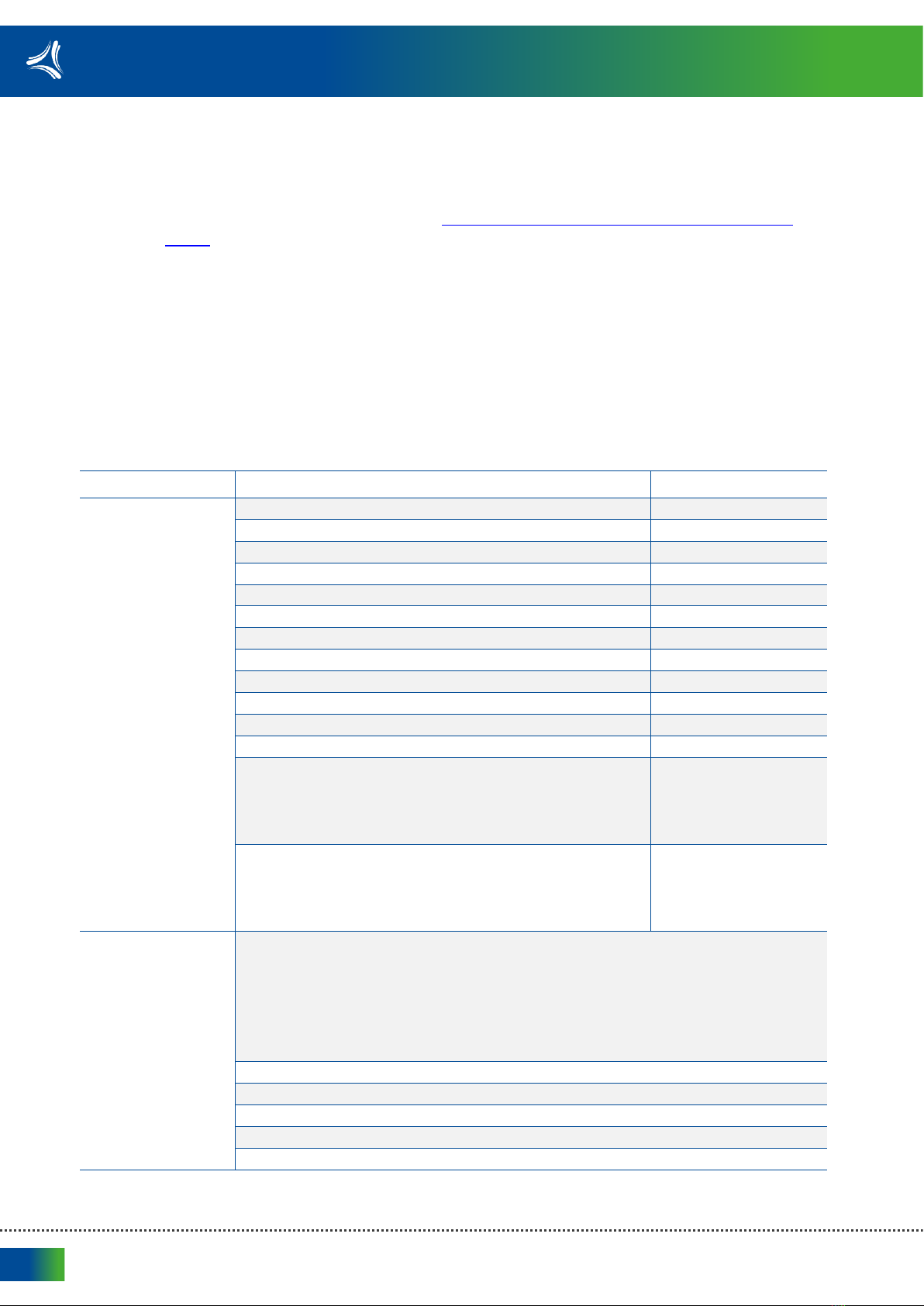

3.7. Cyclic services ...........................................................................................................................................12

3.8. Acyclic communication.............................................................................................................................13

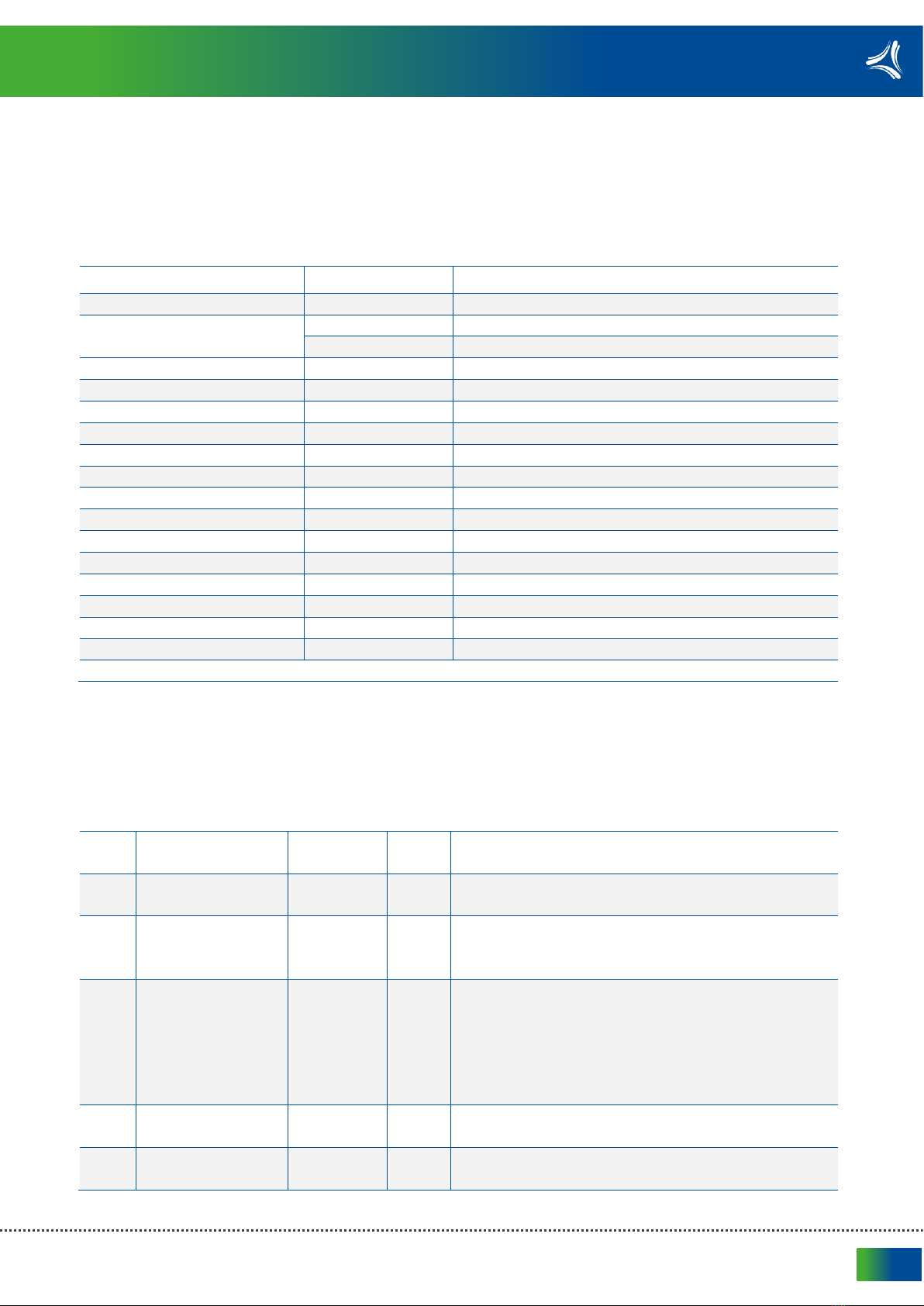

3.8.1. Slot 0, Physical Block.................................................................................................................................13

3.8.2. Slot 1: Analog Input block –Mass flow.....................................................................................................18

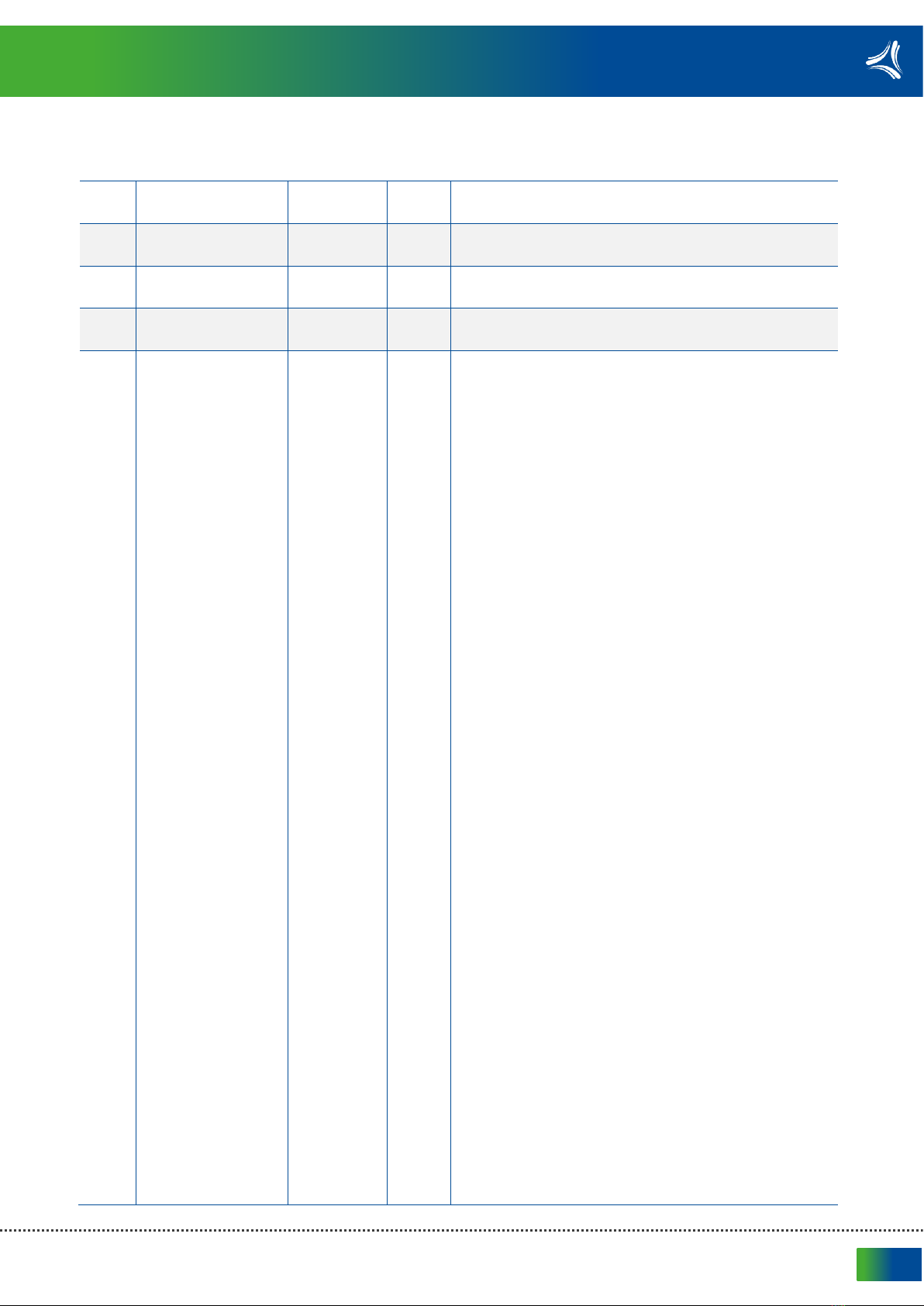

3.8.3. Slot 1: Transducer Block ...........................................................................................................................19

3.8.4. Slot 2: Analog Input block –Density.........................................................................................................29

3.8.5. Slot 3: Analog Input block –Medium temperature..................................................................................30

3.8.6. Slot 4: Totalizer block 1.............................................................................................................................30

3.8.7. Slot 5: Totalizer block 2.............................................................................................................................33

3.8.8. Slot 6: Analog Input block –Volume flow.................................................................................................36

3.8.9. Slot 7: Analog Input block –Fractional flow A block ................................................................................36

3.8.10. Slot 8: Analog Input block –Fractional flow B block ................................................................................37

3.8.11. Slot 9: Analog Input block –Fractional flow % A block.............................................................................38

3.8.12. Slot 10: Analog Input block –Fractional flow % B block...........................................................................38

3.8.13. Slot 11: Analog Input block –Standard volume flow ...............................................................................39

3.8.14. Slot 12: Analog Input block –Frame temperature ...................................................................................40

3.8.15. Slot 12: Analog Input block –Frame temperature ...................................................................................40

3.8.16. Slot 13: Totalizer block 3...........................................................................................................................41

3.8.17. Slot 14: Control commands (Manufacturer Specific) ...............................................................................44

3.8.18. Dosing block, Slot 15.................................................................................................................................45