Trident CYCLONE Instruction Manual

FEATURES

SUITABLE SURFACES

WWW.TRIDENTPROTECTS.COM 866-951-4293

TECHNICAL DATA SHEET

Surface Enhancement Minimal to slight enhancement with mae nish—the extent is dependent on the surface

Joint Stabilizaon Hardens joint sand which reduces sand washout, weeds and insect infestaon

Surface Protecon

Guards against salt, mild acid, alkali and other corrosives

Provides stain resistance which makes cleaning and maintenance easier

Anfungal lm protecon protects sealer lm from mold, moss and algae

Concrete & Clay Pavers

Natural & Manufactured Stone

MUST TEST FIRST*

Flat and Stamped Concrete

Traverne

Clay Roof Tiles

Segmental Retaining Wall Blocks

Concrete Walls

Exposed Aggregate

Not recommended for marble, granite,

ceramic le and polished, honed or

high gloss surfaces as they do not have

enough surface texture to absorb the

sealer

Cyclone | Page 1 | TDS 113 | Revised Date: 5.1.2020

CYCLONE SEALER

TDS 113

Coverage based on single applicaon. Actual coverage may vary depending on the type, age, condion, joint size and porosity of

the surface, applicaon method and other local condions such as temperature and humidity. For more uniform coverage or if

desired a light second coat may be applied aer the rst coat has dried to the touch.

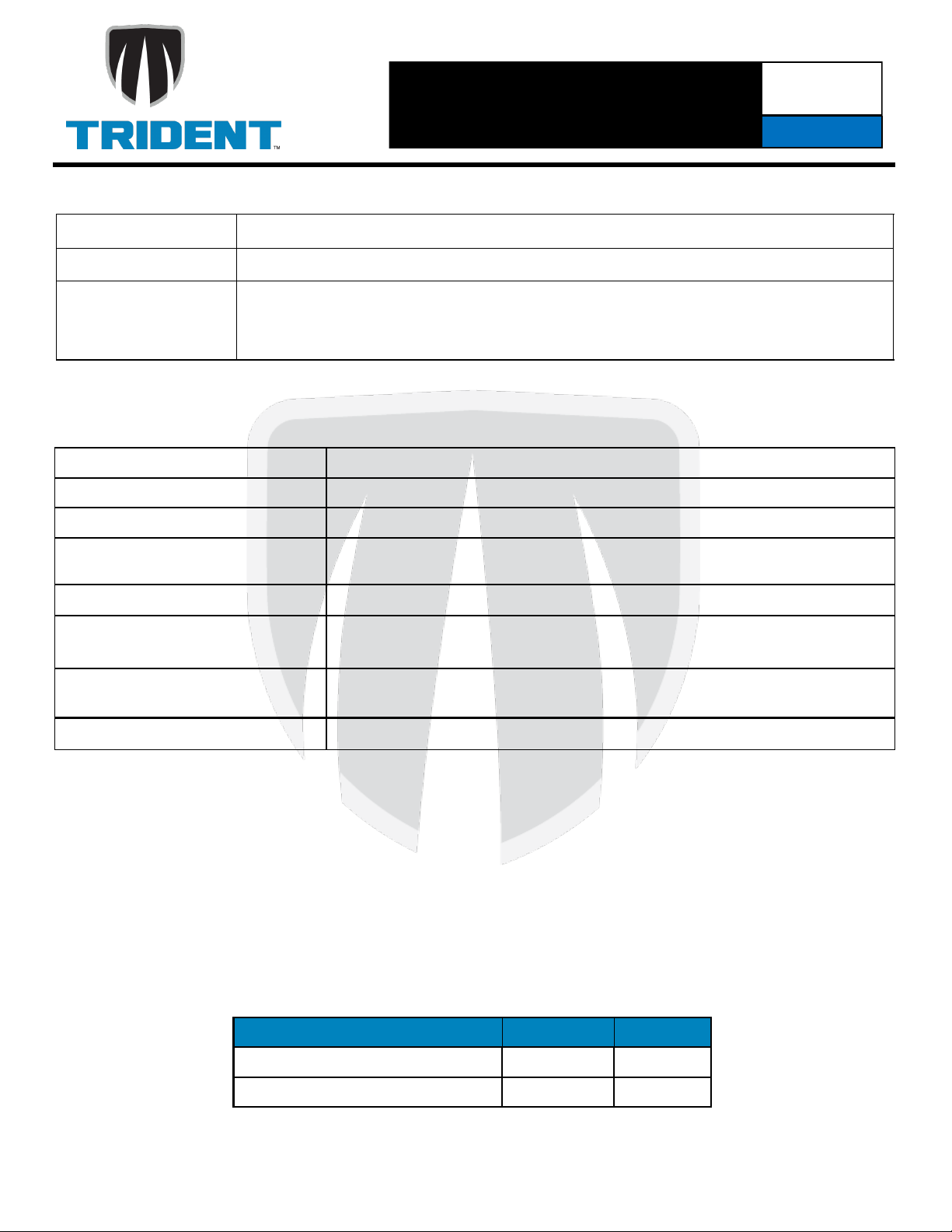

COVERAGE PER GALLON

APPLICATION SQ FEET SQ METERS

Sealing With Joint Stabilizaon 80-120 7.4-11.1

Sealing Only Without Joint Stabilizaon 150-250 13.9-23.2

PURPOSE

PERFORM A TEST IN A SMALL AREA TO VERIFY PERFORMANCE AND APPEARANCE BEFORE APPLYING.

*Due to the variability and physical make-up of natural stone this step is required to verify desired performance and appearance.

Hardens Joint Sand Prevents sand erosion and deters weeds/insects

One Easy Applicaon Protects surface & stabilizes sand joints in one applicaon

Surface Appearance Freshener Locks in a clean, natural look with mae nish

Advanced Single Component, Acrylic

Co-Polymer Formula

Will not yellow under exposure to sunlight

Oers long term durability

Fungal Guard Added anfungal protects sealer lm from mold, moss & algae

Breathable, Immediate Applicaon Will not trap naturally occurring eorescence and/or moisture.

Can be applied on a new, clean and dry surface without waing

Film Forming, Water Based,

LOW VOC Sealer

Consistency of water, milky white in appearance when applied, dries clear

Environmentally friendly, EPA compliant

Temperature Stable Cured sealer is freeze resistant to -60°F (-51°C) and is stable up to 180°F (82°C)

INDUSTRY’S MOST TRUSTED JOINT STABILIZING SEALER FOR OVER 30 YEARS

WWW.TRIDENTPROTECTS.COM 866-951-4293

SURFACE PREPARATION

Test First: Test rst on a small inconspicuous area to determine suitability and if desired results are achievable with this product

on your specic surface.

Clean Surface: Surface should be thoroughly cleaned and prepared with Trident’s cleaners. It should be free of oil, dust, loose

material, and previously applied sealer other than Trident’s Cyclone sealer. Kill and remove growth of any mold, mildew, fungus

or algae. Thoroughly rinse all cleaner residue prior to sealing.

Allow surface to dry for a minimum of 24 hours aer cleaning and/or rain before joint sand installaon or sealer applicaon.

Joint Stabilizaon Preparaon: Paver joints should be no more than 3/4” wide and lled with dry correctly graded joint sand that

meets ASTM C144 standard. Compact surface with vibratory roller or compactor aer sweeping sand into joints to minimize air

voids. Top level of sand should be 1/8” below the boom of chamfer edge or on non-chamfered surfaces 1/8” down from top of

surface.

Prior to sealing, use a leaf blower to remove dust, debris and ne sand parcles from the surface.

Cover/Protect nearby landscape, vehicles and buildings from overspray during applicaon.

APPLICATION CONDITIONS

Apply when day and night temperatures are between 40°F - 95°F.

Allow surface to dry for a minimum of 24 hours aer cleaning and/or rain before sealer applicaon.

Avoid windy condions to keep sealer spray from driing.

NO pre-blending or mixing required. DO NOT DILUTE.

Excessive applicaons can cause surface to become slippery. Some surfaces may require an an-slip addive to increase fricon.

APPLICATION TOOLS

Low pressure, high volume sprayer such as an airless sprayer or hand held pump-up sprayer

Slit foam roller

Foam squeegee for joint stabilizaon

APPLICATION INSTRUCTIONS

Cyclone is designed for a one-coat applicaon but if desired an addional light spray coat can be applied only aer the rst

applicaon has dried to the touch.

Spray & Back Roll Applicaon (no joint stabilizaon):

To apply sealer, hold sprayer nozzle perpendicular to the surface, spray and overlap each spray pass.

Before product dries, back roll with a foam roller to eliminate any pooling and to even out sealer.

Flood Coat & Squeegee Applicaon for Joint Stabilizaon:

Follow coverage guidelines for joint stabilizaon.

Spray sealer to ood joints ensuring proper sand penetraon for stabilizaon.

Use a foam squeegee to direct excess sealer into the joints. On an uneven surface, it is recommended to then back roll with a foam

roller to even out the sealer and eliminate pooling.

DRY TIME

Surface will be dry to the touch in 60 minutes assuming 65-85°F. Low surface or air temperature will extend dry mes.

Protect the surface from dust, rain, condensaon, and trac while drying.

Area can be open to foot & vehicular trac in 24 hours depending on site condions.

TECHNICAL DATA SHEET

CYCLONE

Cyclone | Page 2 | TDS 113 | Revised Date: 5.1.2020

TECHNICAL DATA SHEET 100

CLEAN UP

For tools and equipment, use soap and water before product is allowed to dry.

MAINTENANCE

Sealed surfaces should be properly maintained to get the best long-term performance from both the pavement and the Cyclone

sealer.

Keep surface clear of buildup of dirt, grime and stains by rinsing with cold, clean water.

If staining of surface does occur, Trident Sealers are compable with Trident's Cleaners which can be used to remove general

dirness, organic and inorganic stains like oils, food and beverages and mineral deposits from the surface.

Test cleaners in inconspicuous area prior to cleaning.

Be sure to check diluon rates for all cleaners to determine if they are ready to use or to determine appropriate diluon rate

especially for sealed surfaces.

Eorescence should be removed using Trident’s White Water eorescence cleaner and a pressure washer, in conjuncon with

agitaon from a natural ber brush. Care should be taken to ensure that excessive pressure is not ulized, as it may erode joint

sand and could damage the surface itself.

Thoroughly rinse all cleaner o the surface before sealing.

RE-APPLICATION

Re-applicaon may need to be carried out every 2 - 3 years depending on the type of surface and environmental/site condions.

PACKAGING

5 Gallon Pails

55 Gallon Drums

275 Gallon Totes

Store in a cool, well-venlated place

Do not allow to freeze

SHELF LIFE

2 years when unopened and properly stored

VOC CONTENT

< 99 g/L

CYCLONE TECHNICAL DATA SHEET

Cyclone | Page 3 | TDS 113 | Revised Date: 5.1.2020

STORAGE

WWW.TRIDENTPROTECTS.COM 866-951-4293

PRECAUTIONARY INFORMATION

KEEP OUT OF REACH OF CHILDREN

Use in a well venlated area

Wear protecve gloves, clothing, face and eye protecon

Wash thoroughly aer handling

EMERGENCY & FIRST AID MEASURES

IF SWALLOWED: Call a POISON CENTER or physician if you feel unwell.

IF ON SKIN: Wash with plenty of soap and water. Get medical aenon if irritaon occurs. Take o all contaminated clothing

and wash before reuse.

IF IN EYES: Rinse cauously with water for several minutes. Remove contact lenses, if present and easy to do. Connue rinsing.

Get medical aenon if eye irritaon persists.

IF INHALED: Call a POISON CENTER or physician if feel unwell

IN CASE OF FIRE: Use water, water fog, CO2, dry chemical, or alcohol resistant foam to exnguish.

See Safety Data Sheet for complete informaon.

WARRANTY

TECHNICAL DATA SHEET 100

LIMITATIONS

Trident warrants its products to substanally conform to its published specicaons at the me of purchase. The foregoing is the

sole limited warranty applicable to the products. Trident HEREBY DISCLAIMS ALL OTHER WARRANTIES OF ANY KIND OR NATURE,

WHETHER EXPRESS, IMPLIED, OR STATUTORY, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANT-

ABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR ANY OTHER WARRANTY OTHER THAN THE WARRANTY SET FORTH ABOVE.

The user is solely responsible for determining suitability of the products for their parcular use. While the actual applicaon of

this product is out of the control of Trident, it is recommended that the applicaon guidelines be followed completely and

accurately. Trident’s liability for any damage shall not exceed the purchase price of the product used, and it shall have no liability

for consequenal, incidental or punive damages.

3925 Stern Avenue | St. Charles, IL 60174

866-951-4293 | www.tridentprotects.com

TECHNICAL DATA SHEETCYCLONE

Cyclone | Page 4 | TDS 113 | Revised Date: 5.1.2020

Protect sealer from freezing and store in a cool place when not in use. In winter, keep in heated area. This sealer is not

recommended for marble, granite, ceramic le, and polished, honed or high gloss surfaces as they do not absorb the sealer. A test

area is ALWAYS recommended to determine product suitability and compability with your specic surface before use and to

verify if desired results are achievable. Due to the inherent variability of natural stone and clay products, long term performance

may vary. Please consult with Trident prior to sealing if there are concerns. The use of an an-slip addive is recommended for

increased tracon on surface inclines or around consistently wet areas such as pool deck surrounds. Do not use below grade or

where water is always present. Never try to seal wet or damp surfaces. A minimum air temperature of 40° (5°C) must be

maintained for a period of 24 hours prior to applicaon. Air temperature should not exceed 95°F (35°C) during applicaon. Work

should cease in inclement weather (rain or strong wind).

This manual suits for next models

1