Measurement Considerations

Maintenance

Operating Instructions

Trigger

•Laser and backlight function work

simultaneously when power is on

•Pull the trigger to turn the unit ON. When the

trigger is released it will show HOLD and the

reading will be held

Auto Power Off Function

•After 10 seconds, if the unit is unused, it will

power off automatically

Temperature Scale Selection

•Temperatures are displayed in ether Degrees

Celsius (°C) or Degrees Fahrenheit (°F)

•When the unit is turned on it is set to the

temperature scale last used

•To change the unit of measurement remove

the battery cap and slide switch to desired

scale

Operation

1. Remove the protective cap and push the

trigger. This will turn the unit ON

2. Point the sensor at the object to be

measured

3. Referring to the spot size figure, pull the

trigger and hold until a stable reading is

acquired

4. Replace the cap to extend the life and

protect the sensor

NOTE: Although the field of measurement/view

and the spot almost coincide, actually the field of

measurement corresponds to the diameter for 90%

optical response. The object to be measured needs

to be larger than the diameter (spot of size) by an

adequate margin of at least 2 x larger

Theory of Measurement

Every object emits infrared energy in accor-

dance with its temperature. By measur-

ing the amount of this radiant energy, it is

possible to determine the temperature of the

emitting object.

About Infrared

Infrared radiation is a form of light (electro-

magnetic radiation), and has the property

that it passes easily through air while it is

easily absorbed by solid matter. With an

emission thermometer which operates by

detecting infrared radiation accurate mea-

surement is possible, irrespective of the air

temperature or the measurement distance.

Emission Thermometer Structure

Infrared radiation which has been emitted

from the object is focused upon an infrared

radiation sensor, via an optical system.

This includes a lens which is transparent to

infrared radiation. And 5.3um cut off filter.

The output signal from the infrared radiation

sensor is input to an electronic circuit along

with the output signal from a standard

temperature sensor (Thermopile).

Emissivity

All objects emit invisible infrared energy.

The amount of energy emitted is propor-

tional to the object’s temperature and its

ability to emit IR energy. This ability, called

emissivity, is based upon the material that

the object is made of and its surface finish.

Emissivity values range from 0.10 for a very

reflective object to 1.00 for a black body.

Factory set emissivity value of 0.95, which

cover 90% of typical applications.

If the surface to the measured is covered

by frost or other material, clean it to expose

the surface.

If the surface to be measured is highly

reflective, apply masking tape or matt finish

black paint to the surface.

If the meter seems to be giving incorrect

readings check the front cone. There may

be condensation or debris obstructing the

sensor; clean per instructions in the main-

tenance section.

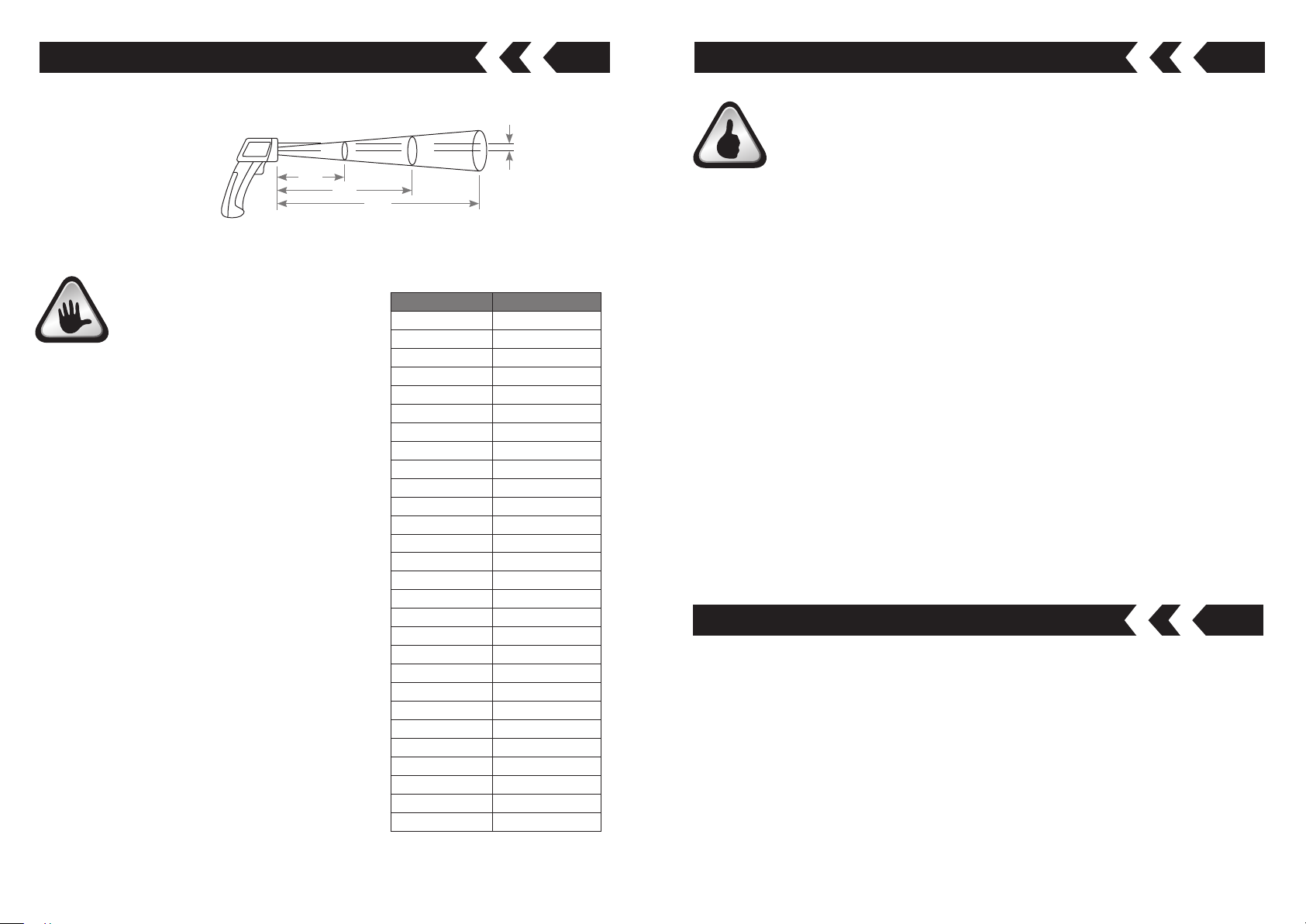

Thermal Emissivity

Substance Thermal Emissivity

Asphalt 0.90 to 0.98

Brick (red) 0.93-0.96

Cement 0.96

Ceramic 0.90-0.94

Charcoal 9powder) 0.96

Chrome Oxides 0.81

Cloth 0.98

Concrete 0.94

Copper Oxides 0.78

Earth 0.92-0.96

Glass 0.90-0.95

Human skin 0.98

Ice 0.96-0.98

Iron Oxides 0.78-0.82

Lacquer 0.80-0.95

Lacquer (matt) 0.97

Lather 0.75-0.80

Marble 0.94

Mortar 0.89-0.91

Paper 0.70-0.94

Plaster 0.80-0.90

Plastic 0.85-0.95

Rubber (black) 0.94

Sand 0.9

Snow 0.83

Textiles 0.9

Timber 0.9

Water 0.92-0.96

Battery Replacement

1. Power is supplied by a 9 volt “transistor”

battery. (NEDA 1604, IEC 6F22).

2. Remove the battery cover by gently sliding

it towards the bottom of the meter.

3. Remove and disconnect the old battery

from the meter and replace with a new

unit. Wind the excess lead length and put

the top of battery toward the lower side of

the battery chamber.

4. Replace the battery cover

5. When battery is installed, the meter

turns on automatically to check the

battery conditions. Power will turn off

automatically after 10 seconds without

operation.

Cleaning

• Periodically wipe the case with a damp cloth

and detergent, do not use abrasives or solvents.

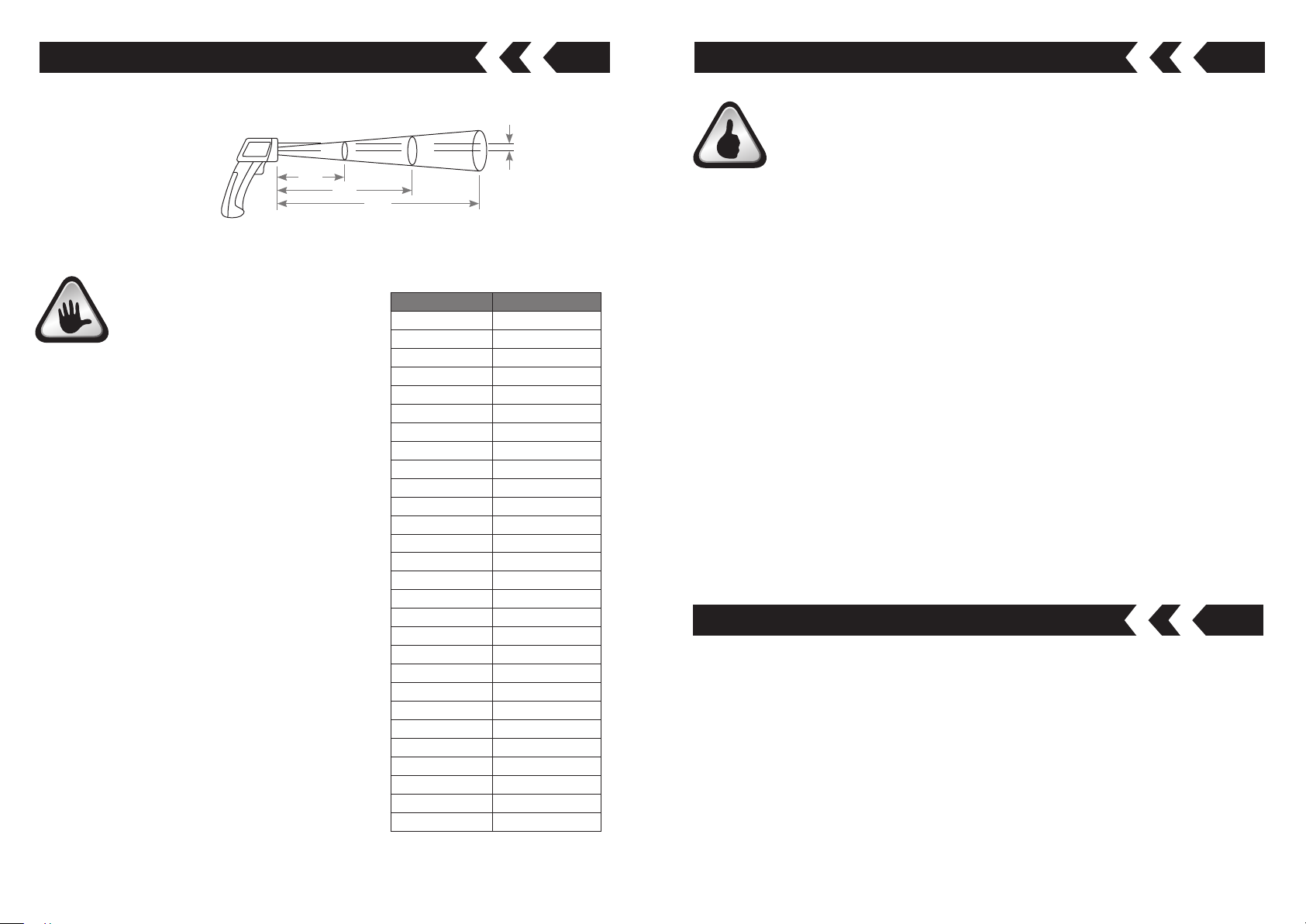

Spot size increases with distance from the probe tip as shown

250

25Ø 50Ø 100Ø

16

500

1000

Distance to object (mm)

Diameter of spot (mm)

Laser

Marker