CONTENT

1 SAFETY INSTRUCTIONS...................................................................................................................................................... 3

2 SAFETY PRECAUTIONS ...................................................................................................................................................... 4

3 WARRANTY INFORMATION ................................................................................................................................................ 5

4 TERMINOLOGY ..................................................................................................................................................................... 6

5 GENERAL ADVICE ............................................................................................................................................................... 7

5.1 RESPONSIBILITIES ........................................................................................................................................................ 7

5.2 IDENTIFICATION PLATE ................................................................................................................................................ 7

5.3 SPRING ........................................................................................................................................................................... 8

5.4 STORAGE ........................................................................................................................................................................ 9

5.5 HANDLING ....................................................................................................................................................................... 9

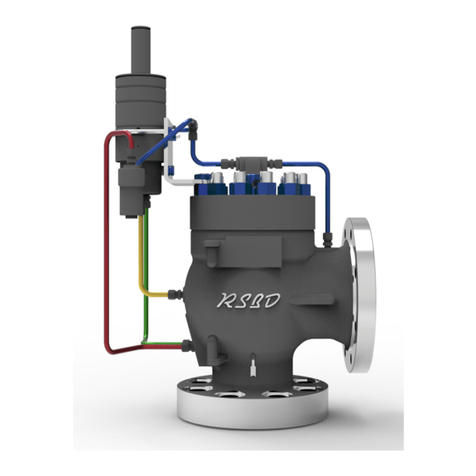

6STARFLOW BASICS ............................................................................................................................................................. 10

6.1 DESCRIPTION ................................................................................................................................................................. 10

6.2 FEATURES AND NOMENCLATURES...................................... ............................................................................................ 11

7INSTALLATION ..................................................................................................................................................................... 13

7.1 GENERAL ........................................................................................................................................................................ 13

7.2 INLET PIPING .................................................................................................................................................................. 13

7.3 OUTLET PIPING .............................................................................................................................................................. 14

7.4 INSTALLATION ON THE PROTECTED EQUIPMENT ............................................................................................................ 14

7.5 OUTLET MANIFOLD DESIGN ......................................................................................................................................... 14

7.6 RECOMMENDATIONS .................................................................................................................................................... 15

7.7 OUTDOOR INSTALLATION ............................................................................................................................................ 15

7.8 INDOOR INSTALLATION ................................................................................................................................................ 15

7.9 SPECIAL CASE OF STEAM ............................................................................................................................................ 15

8MAINTENANCE..................................................................................................................................................................... 17

8.1 DISASSEMBLY ................................................................................................................................................................ 18

8.2 LAPPING .......................................................................................................................................................................... 22

8.3 ASSEMBLY ...................................................................................................................................................................... 25

9TESTING ................................................................................................................................................................................ 27

9.1 RECOMMENDATIONS .................................................................................................................................................... 27

9.2 SET PRESSURE AND ADJUSTMENT ON LINES................................................................................................................. 28

9.3 MANUAL LIFTING DEVICE ............................................................................................................................................. 33

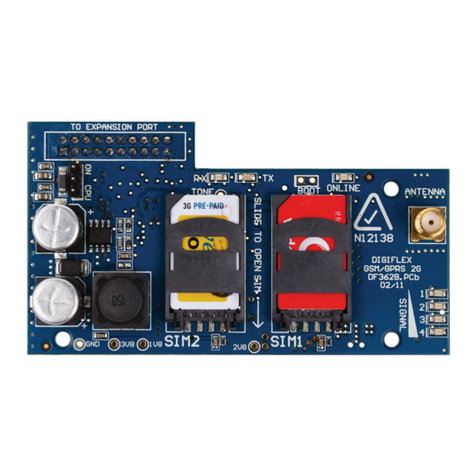

9.4 CALIBRATION CHECK WITH ONLINE TESTING DEVICE ..................................................................................................... 34

9.5 VALVE SEALING ............................................................................................................................................................. 34

10 MAINTENANCE..................................................................................................................................................................... 34

11 TROUBLESHOOTING ........................................................................................................................................................... 35

12 SPARE PARTS ...................................................................................................................................................................... 36

13 DISMANTLING....................................................................................................................................................................... 36

14 GENUINE PARTS .................................................................................................................................................................. 37

15 CODIFICATION ...................................................................................................................................................................... 38

1|

SARASIN-RSBD

STARFLOW SAFETY RELIEF VALVE

TM

TM