Trillium 8-WSP Manual

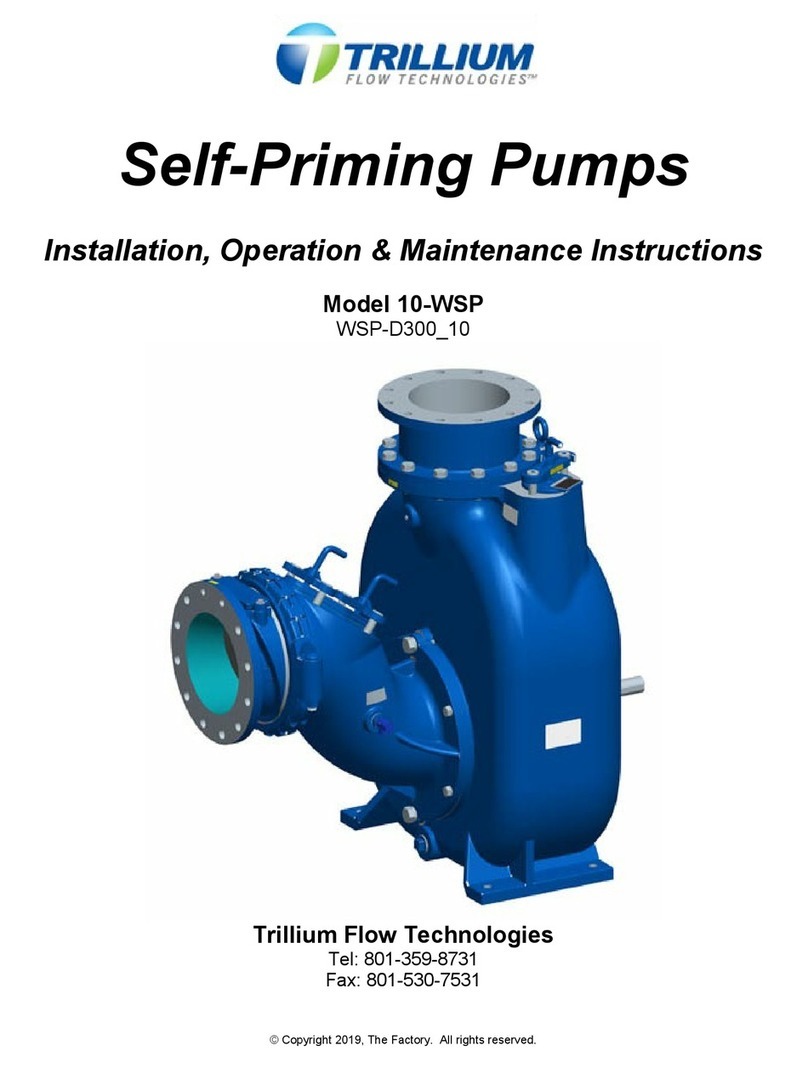

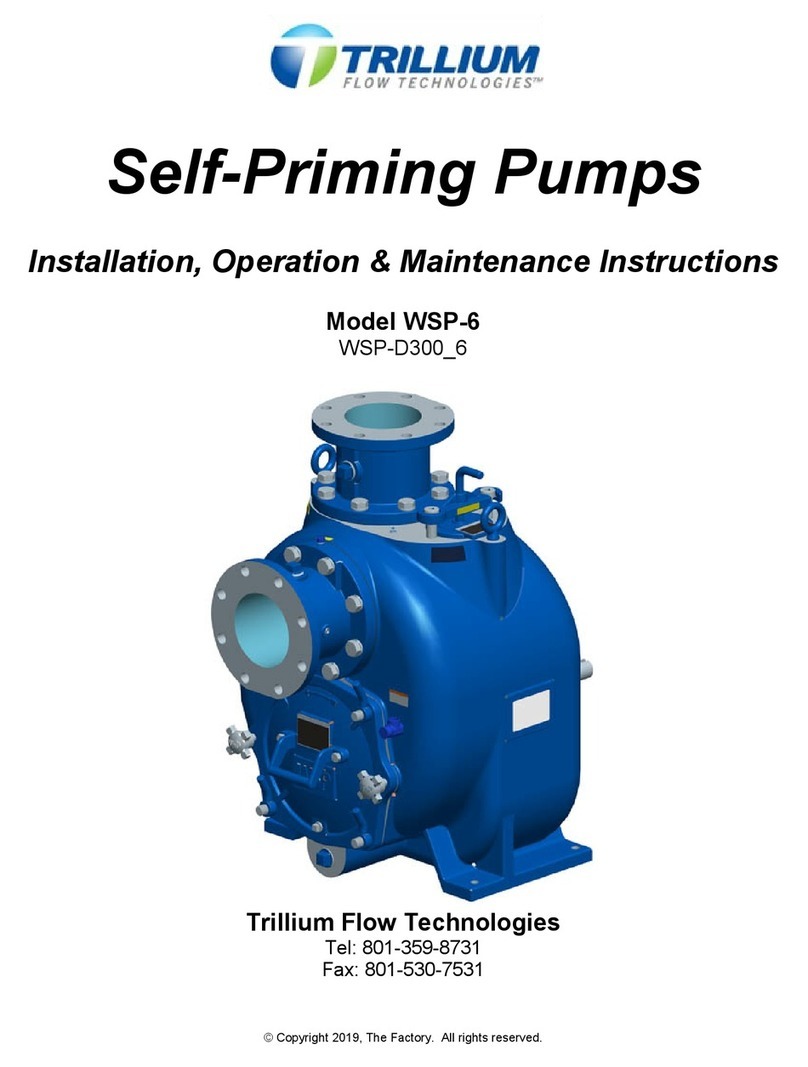

Self-Priming Pumps

Installation, Operation & Maintenance Instructions

Model 8-WSP

WSP-D300_8

Trillium Flow Technologies

Tel: 801-359-8731

Fax: 801-530-7531

© Copyright 2019, The Factory. All rights reserved.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

2

I. INTRODUCTION ................................................................................................ 4

PURPOSE.............................................................................................................. 4

II. SAFETY.............................................................................................................. 5

III. PREVENTIVE MAINTENANCE .................................................................... 13

IV. DISASSEMBLY & REASSEMBLY OF THE PUMP & SEAL ......................... 15

A. REMOVING THE COVER PLATE & WEARPLATE ...................................... 17

B. REMOVING THE SUCTION CHECK VALVE ............................................... 18

C. REMOVING THE ROTATING ASSEMBLY................................................... 18

D. REMOVING THE IMPELLER........................................................................ 21

F. REMOVING & DISASSEMBLING THE SHAFT & BEARING........................ 22

G. DISASSEMBLY OF THE TWO-PIECE BEARING HOUSING....................... 23

H. REASSEMBLING THE TWO-PIECE BEARING HOUSING.......................... 24

I. REASSEMBLING & INSTALLATING THE SHAFT & BEARING................... 24

J. INSTALLING THE MECHANICAL SEAL....................................................... 27

1. Mechanical Seal Installation ...................................................................... 29

2. Cartridge Seal Installation.......................................................................... 30

K. INSTALLING & ADJUSTING THE IMPELLER.............................................. 30

L. INSTALLING THE ROTATING ASSEMBLY ................................................. 32

M. INSTALLING THE SUCTION CHECK VALVE .......................................... 32

N. INSTALLING & ADJUSTING THE COVERPLATE ....................................... 32

V. MAINTAINING THE PRESSURE RELIEF VALVE ........................................... 34

A. Final Pump Assembly ................................................................................... 35

VI. LUBRICATION .............................................................................................. 35

A. Seal Cavity .................................................................................................... 35

B. Bearing Cavity............................................................................................... 35

C. Power Source................................................................................................ 36

VII. TROUBLESHOOTING .................................................................................. 36

VIII. INSTALLATION............................................................................................. 38

A. PUMP DIMENSIONS .................................................................................... 39

B. INSPECTION PRIOR TO INSTALLATION.................................................... 39

C. PUMP POSITIONING ................................................................................... 40

1. Lifting ......................................................................................................... 40

2. Mounting.................................................................................................... 40

3. Clearance .................................................................................................. 41

D. SUCTION AND DISCHARGE PIPING .......................................................... 41

1. Materials.................................................................................................... 41

2. Configuring the Line .................................................................................. 41

3. Pump Connections .................................................................................... 41

4. Gauges...................................................................................................... 41

E. SUCTION LINES........................................................................................... 42

1. Fittings ....................................................................................................... 42

2. Strainers .................................................................................................... 42

3. Sealing....................................................................................................... 42

4. Suction Lines in Sumps ............................................................................. 43

5. Suction Line Positioning ............................................................................ 43

F. DISCHARGE LINES ..................................................................................... 45

1. Siphoning................................................................................................... 45

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

3

2. Valves........................................................................................................ 45

3. Bypass Lines ............................................................................................. 45

G. WSP™ AUTOMATIC AIR RELEASE VALVE (WSP™ ARV) ........................ 47

1. Theory of Operation................................................................................... 47

2. WSP™ Air Release Valve Installation ....................................................... 49

H. ALIGNMENT ................................................................................................. 50

1. Coupled Drives .......................................................................................... 51

2. Spider Insert-Type Couplings .................................................................... 51

3. Non-Spider Type Couplings....................................................................... 51

4. V-Belt Drives.............................................................................................. 52

IX. OPERATION ................................................................................................. 53

A. PRIMING....................................................................................................... 53

B. START-UP .................................................................................................... 54

C. OPERATION................................................................................................. 54

1. Lines with a Bypass................................................................................... 54

2. Lines Without a Bypass ............................................................................. 55

3. Leaking...................................................................................................... 55

4. Liquid Temperature and Overheating ........................................................ 55

5. Strainer Check........................................................................................... 56

6. Checking the Pump Vacuum ..................................................................... 56

D. STOPPING.................................................................................................... 57

1. Preserving the Pump in Cold Weather ...................................................... 57

E. CHECKING THE BEARING TEMPERATURE .............................................. 58

X. TECHNICAL DATA........................................................................................... 59

A. 8” WSP Curve ............................................................................................... 59

B. 8” WSP General Arrangement Drawing ........................................................ 60

C. 8” WSP Sectional Drawing and Parts List ..................................................... 61

D. WSP™ Air Release Valve Drawing and Parts List........................................ 67

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

4

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

I. INTRODUCTION

Warning levels applying to the safe installation, operation and maintenance of all

sizes of WSP™ Self-Primer (WSP) pumps can be located at the beginning of this

manual. You must refer to the manual accompanying your power source before

attempting to begin operation since Weir Specialty Pumps has no control over or

special knowledge of the power source to which you will connect these pumps.

You have made a wise decision in your purchase of a WSP™ Self-Primer (WSP)

pump, and we thank you for your business. To learn how to install and operate your

pump safely, read this manual carefully. Failure to follow the enclosed instructions

may result in damage to the pump or personal injury. The WSP™ Self-Primer Pump

Installation, Operation, and Maintenance manual was created to help you maximize

the pump’s performance while achieving the longest life possible.

Your pump is a centrifugal, self-priming model featuring a semi-open impeller and

suction check valve. The pump is designed with external shimless adjusters for

setting the wear plate to impeller clearance. It pumps liquids containing large,

entrained solids as well as slurries. Its basic material is ductile iron with a cast steel

impeller and a steel wearplate.

For questions about the pump or its application not covered in this manual or other

documentation included with the unit, please contact your WSP™ distributor, or write

to:

Weir Specialty Pumps

P.O. Box 209

Salt Lake City, UT 84110-0209

Phone: (801) 359-8731

Contact the power source manufacturer’s local dealer or representative for

information or technical assistance on your power source before attempting

installation or operation of this Weir Self-Primer Pump.

PURPOSE

This manual is designed for all levels of users from a novice to an experienced

operator. It provides employees with known procedures requiring extra attention as

well as providing information on unsafe situations that could damage the equipment

and/or be dangerous to the operator. While Weir Specialty Pumps is providing you

with this information, we cannot anticipate or provide detailed precautions for every

situation that could occur during maintenance of the unit.

It is your responsibility, as the owner and/or maintenance person, to be sure you

always use safe and established maintenance procedures and that any procedures

not included in this manual are performed only after ensuring you are not

compromising either personal safety or your pump’s integrity by such practices.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

5

IMMEDIATE HAZARDS WHICH WILL RESULT

IN SEVERE PERSONAL INJURY OR DEATH.

THESE INSTRUCTIONS DESCRIBE THE

PROCEDURE REQUIRED AND THE INJURY

WHICH WILL RESULT FROM FAILURE TO

FOLLOW THE PROCEDURE.

HAZARDS OR UNSAFE PRACTICES WHICH

COULD RESULT IN SEVERE PERSONAL

INJURY OR DEATH. THESE INSTRUCTIONS

DESCRIBE THE PROCEDURE REQUIRED

AND THE INJURY WHICH COULD RESULT

FROM FAILURE TO FOLLOW THE

PROCEDURE.

HAZARDS OR UNSAFE PRACTICES WHICH

COULD RESULT IN MINOR PERSONAL

INJURY OR PRODUCT OR PROPERTY

DAMAGE WHICH COULD RESULT FROM

FAILURE TO FOLLOW THE PROCEDURE.

II. SAFETY

The installation, operation and maintenance warnings for all sized WSP™ Self-

Primer (WSP) Pumps follows:

PLEASE STUDY THESE INSTRUCTIONS CAREFULLY BEFORE PUTTING THE

PUMP INTO SERVICE. ADHERENCE TO THESE INSTRUCTIONS IS NECESSARY

TO ENSURE THAT OPERATOR SAFETY AND SATISFACTORY PUMP OPERATION

ARE NEVER COMPROMISED. OPERATING PERSONNEL MUST READ AND

UNDERSTAND THESE INSTRUCTIONS BEFORE ANY ATTEMPT TO SERVICE THE

PUMP IS MADE.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN SEVERE INJURY.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

6

WHEN A MANUAL SHUT-OFF VALVE IS INSTALLED IN A BYPASS LINE, IT MUST

REMAIN OPEN DURING OPERATION. CLOSING THE MANUAL SHUT-

OFF VALVE

COULD CAUSE A PUMP, WHICH

HAS LOST PRIME, TO CONTINUE TO OPERATE

WITHOUT REACHING PRIME. THIS COULD CAUSE DANGEROUS OVERHEATING OF

THE PUMP AND POSSIBLY RUPTURE THE PUMP CASING.

BEFORE SERVICING, ALLOW SUFFICIENT TIME FOR THE OVERHEATED PUMP TO

COMPLETELY COOL. ONCE THE PUMP HAS

COMPLETELY COOLED, DRAIN THE

LIQUID FROM THE PUMP BY REMOVING THE CASING DRAIN PLUG. WHEN

REMOVING THE DRAIN PLUG, USE CAUTION. FAILURE TO DO SO MAY RESULT IN

INJURY. PLATES, COVERS, GAUGES, OR FITTINGS MUST NOT BE REMOVED FROM

AN OVERHEATED PUMP. LIQ

UIDS IN THE PUMP CAN REACH BOILING

TEMPERATURES AND PRESSURE INSIDE THE PUMP CAN CAUSE PARTS TO BE

EXPELLED VIOLENTLY.

BEFORE SERVICING, ALLOW SUFFICIENT TIME FOR AN OVERHEATED PUMP TO

COMPLETELY COOL. ONCE THE PUMP HAS COMPLETELY COOLED, DRAIN THE

LIQUID FROM THE PUMP BY REMOVING THE CASING DRAIN PLUG. WHEN

REMOVING THE DRAIN PLUG, USE CAUTION. FAILURE TO DO SO MAY RESULT IN

INJURY. PLATES, COVERS, GAUGES, OR FITTINGS MUST NOT BE REMOVED

FROM AN OVERHEATED PUMP. LIQUIDS IN THE PUMP CAN REACH BOILING

TEMPERATURES AND VAPOR PRESSURE INSIDE THE PUMP CAN CAUSE PARTS

TO BE EXPELLED VIOLENTLY.

WHEN PERFORMING EQUIPMENT MAINTENANCE OR IF THE PUMP IS TO

REMAIN OUT OF SERVICE FOR A PERIOD OF TIME, THE EQUIPMENT

ELECTRICAL SERVICE MUST BE DISCONNECTED WITH AN APPROVED

LOCKOUT AND KEY. FAILURE TO LOCK OUT THE EQUIPMENT MAY RESULT IN

INJURY.

1. IF OVERHEATED, THE PUMP MUST BE ALLOWED TO COMPLETELY

COOL BEFORE ATTEMPTING ANY PROCEDURES.

2. CHECK THE TEMPERATURE BEFORE OPENING ANY COVERS,

PLATES, OR PLUGS.

3. ENSURE THAT SUCTION AND DISCHARGE VALVES ARE CLOSED.

4. SLOWLY AND CAREFULLY VENT THE PUMP.

5. DRAIN THE PUMP.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

7

ONCE THE PUMP HAS BEEN POSITIONED, ENSURE THAT ALL PUMP AND PIPING

CONNECTIONS ARE TIGHTENED, SECURED, AND SUPPORTED PROPERLY.

ALL GUARDS AND PROTECTIVE DEVICES MUST BE INSTALLED BEFORE THE PUMP

IS STARTED. CONTACT WITH UNGUARDED BELTS, SHEAVES, OR COUPLINGS

COULD RESULT IN INJURY.

PLATES, COVERS, GAUGES, PIPE PLUGS, OR FITTINGS MUST NOT BE

REMOVED FROM AN OVERHEATED PUMP. VAPOR PRESSURE WITHIN THE

PUMP MAY CAUSE PARTS TO BECOME DISENGAGED AND EJECTED WITH

GREAT FORCE, CAUSING POTENTIAL SEVERE INJURY TO PERSONNEL.

ALWAYS ALLOW THE PUMP TO COOL BEFORE SERVICING ANY EQUIPMENT.

DO NOT OPERATE PUMP WITH BOTH SUCTION AND DISCHARGE VALVES CLOSED

OR WITH SUCTION OR DISCHARGE BLOCKED BY CLOGGING – THIS COULD CAUSE

DAMAGE AND IS DANGEROUS. THESE PUMPS ARE TO BE USED FOR LIQUID

SERVICE ONLY. EXCESSIVE PRESSURE CAN CAUSE MALFUNCTION LEADING TO

INJURY.

PUMP LIFTING EYES ON THE SELF-PRIMING PUMP ARE ONLY DESIGNED TO

HANDLE THE WEIGHT OF THE BARE PUMP. BEFORE LIFTING, ENSURE THAT

ALL SUCTION AND DISCHARGE HOSES AND PIPING HAVE BEEN REMOVED

FROM THE PUMP, AND THE PUMP IS FREE FROM ANY BASE OR DRIVER.

EQUIPMENT LIFTING DEVICES SUCH AS CHAIN, LIFTING EYES, HOOKS, ETC.,

MUST BE APPROVED BY LOCAL, STATE, OR FEDERAL SAFETY CODES.

HOIST AND CRANES MUST BE ADEQUATELY SIZED TO LIFT RATED LOADS.

FAILURE TO USE APPROVED LIFTING DEVICES MAY RESULT IN INJURY.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

8

ENSURE THAT THE BYPASS LINE IS DIRECTED BACK INTO THE WET-

WELL OR TANK

TO PREVENT HAZARDOUS SPILLS AS SOME LEAKING (1 TO 5 GALLONS [3.8 TO 19

LITERS] PER MINUTE) WILL OCCUR WHEN THE VALVE IS IN THE FULL-

CLOSED

POSITION.

WHEN CHECKING ALIGNMENT YOU MUST FIRST DISCONNECT THE POWER

SOURCE.

YOUR PUMP HAS BEEN ENGINEERED TO PUMP LIQUIDS THAT CONTAIN SOLIDS OR

SLURRIES. AT NO TIME SHOULD THE LIQUID BE VOLATILE

, CORROSIVE, OR

COMBUSTIBLE. FAILURE TO DO SO C

OULD DAMAGE THE PUMP OR RESULT IN

INJURY.

AFTER THE PUMP CASING HAS BEEN FILLED, REINSTALL AND TIGHTEN THE FILL

PLUG. FAILURE TO OPERATE THE PUMP WITHOUT ALL CONNECTION PIPING

SECURELY INSTALLED COULD CAUSE LIQUID IN THE PUMP TO BE FORCED OUT

UNDER PRESSURE AND MAY RESULT IN INJURY.

PRIO

R TO WORKING ON THIS PUMP, ALWAYS LOCK OUT OR DISCONNECT THE

PUMP FROM ITS POWER SOURCE. IT MUST REMAIN INOPERABLE DURING REPAIRS.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

9

NO PERSON SHOULD ATTEMPT TO OPEN OR SERVICE THIS PUMP BEFORE

BECOMING THOROUGHLY FAMILIAR WITH ALL THE PROCEDURES OUTLINED

IN THIS MANUAL.

1. PLEASE STUDY THESE INSTRUCTIONS CAREFULLY.

2. WHEN PERFORMING EQUIPMENT MAINTENANCE, THE EQUIPMENT

ELECTRICAL SERVICE MUST BE LOCKED OUT WITH AN APPROVED

LOCKOUT AND KEY.

3. IF THE PUMP HAS OVERHEATED, ALLOW SUFFICIENT TIME FOR THE

PUMP TO COMPLETELY COOL BEFORE ATTEMPTING TO OPEN OR

SERVICE THE PUMP.

4. CAREFULLY CHECK THE TEMPERATURES BEFORE OPENING ANY

COVERS, PLATES, OR PLUGS.

5. CLOSE THE SUCTION AND DISCHARGE VALVES.

6. CAREFULLY AND SLOWLY VENT THE PUMP.

7. DRAIN THE PUMP.

PUMP LIFTING EYES ON THE SELF-PRIMING PUMP ARE ONLY DESIGNED TO

HANDLE THE WEIGHT OF THE BARE PUMP. BEFORE LIFTING, ENSURE

THAT ALL SUCTION AND DISCHARGE HOSES AND PIPING HAVE BEEN

REMOVED FROM THE PUMP, AND IT IS FREE OF ANY BASE AND DRIVER.

EQUIPMENT LIFTING DEVICES SUCH AS CHAIN, LIFTING EYES, HOOKS, ETC.,

MUST BE APPROVED BY LOCAL, STATE, OR FEDERAL SAFETY CODES.

HOIST AND CRANES MUST BE ADEQUATELY SIZED TO LIFT RATED LOADS.

FAILURE TO USE APPROVED LIFTING DEVICES MAY RESULT IN INJURY.

BEFORE USING ANY CLEANING SOLVENTS CAREFULLY READ AND FOLLOW ALL

PRECAUTIONS PRINTED ON THE SOLVENT CONTAINER. CLEANING SOLVENTS ARE

KNOWN TO BE TOXIC AND FLAMMABLE AND ARE ONLY TO BE USED IN WELL-

VENTILATED AREAS AWAY FROM EXCESSIVE HEAT, SPARKS, AND FLAMES.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

10

PRESSURE WITHIN THE PUMP MAY CAUSE PARTS TO BECOME DISENGAGED

AND EXPELED VIOLENTLY, CAUSING POTENTIAL SEVERE INJURY TO

PERSONNEL. ALWAYS ALLOW THE PUMP TO COOL BEFORE SERVICING.

THIS PUMP SHOULD ONLY BE OPERATED IN THE DIRECTION SHOWN ON THE

ARROW ON THE PUMP BODY AND ON ANY ACCOMPANYING DECALS.

SERIOUS DAMAGE COULD OCCUR TO THE PUMP ASSEMBLY IF BOTH LIFTING EYES

ARE NOT UTILIZED DURING LIFTING AND MOVEMENT OF THE UNIT. ONLY LIFT THE

PUMP WITH THE LIFTING EYES.

IN HIGH DISCHARGE HEAD APPLICATIONS THE DISCHARGE THROTTLING VALVE

MUST BE GRADUALLY CLOSED BEFORE THE PUMP IS STOPPED.

BYPASS LINES MUST BE SECURED AGAINST BEING DRAWN INTO THE PUMP

SUCTION INLET WHEN RETURNED TO A WET WELL.

ALIGNMENT ADJUSTMENT IN ONE DIRECTION MAY DISRUPT ALIGNMENT

ADJUSTMENT IN ANOTHER DIRECTION. CHECK EACH PROCEDURE AFTER

ALTERING ALIGNMENT.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

11

PUMP PERFORMANCE INCLUDING SPEED AND OPERATING CONDITIONS ARE

REQUIRED TO BE WITHIN THE RANGE SHOWN ON THE MANUFACTURER’S PUMP

PERFORMANCE CURVE.

THIS PUMP SHOULD ALWAYS BE OPERATED WITH LIQUID IN THE PUMP CASING.

WHEN OPERATING THE PUMP DRY, THE PUMP WILL NOT PRIME.

DISASSEMBLY OF THE SHAFT AND BEARING IS NOT RECOMMENDED IN THE FIELD.

PERFORM THESE OPERATIONS

ONLY IN A PROPERLY EQUIPPED SHOP BY

QUALIFIED TECHNICIANS.

IT IS RECOMMENDED THAT THE BEARING BE CLEANED AND INSPECTED IN PLACE

TO PREVENT DAMAGE DURING REMOVAL FROM THE SHAFT. WE HIGHLY

RECOMMEND REPLACEMENT OF THE BEARINGS ANYTIME THE SHAFT AND

BEARINGS ARE REMOVED.

BEARINGS MUST BE KEPT IN AN ENVIRONMENT THAT IS FREE OF ALL DIRT AND

FOREIGN MATERIAL. FAILURE TO DO SO WILL RESULT IN A SHORTER BEARING

LIFE. THE BEARINGS SHOULD NEVER BE SPUN DRY AS THIS MAY SCRATCH THE

BALLS OR RACES AND WILL CAUSE PREMATURE BEARING FAILURE.

NEVER PRESS OR HIT AGAINST THE OUTER RACE, BALLS, OR BALL CAGE DURING

BEARING INSTALLATION ONTO THE SHAFT. PRESS THE INNER RACE ONLY.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

12

PUSH AGAINST THE OUTER RACE DURING INSTALLATION OF THE BEARINGS INTO

THE BEARING BORE. NEVER STRIKE THE BALL CAGE OR BALLS.

ANY TIME THE OLD SEAL IS REMOVED FROM THE PUMP A NEW SEAL ASSEMBLY

SHOULD BE INSTALLED. DURING REASSEMBLY WEAR PATTERNS ON THE

FINISHED FACES CANNOT BE REALIGNED. PREMATURE SEAL FAILURE WILL

RESULT FROM USING AN OLD SEAL.

OPERATION AT TEMPERATURES ABOVE 160OF (71OC). IS NOT RECOMMENDED FOR

THIS SEAL. THIS PUMP SHOULD NOT BE USED AT HIGHER OPERATING

TEMPERATURES, WITHOUT CONSULTING THE FACTORY.

WHEN REUSING AN OLD SEAL, DO NOT ATTEMPT TO SEPARATE THE

ROTATING PORTION OF THE SEAL FROM THE SHAFT SLEEVE. DURING USE

THE RUBBER BELLOWS WILL BOND TO THE SLEEVE AND ATTEMPTING TO

SEPARATE THEM WILL DAMAGE THE BELLOWS.

BEFORE REINSTALLING THE IMPELLER, COMPLETELY CLEAN THE SHAFT AND

IMPELLER THREADS. THE SMALLEST AMOUNT OF DIRT ON THE THREADS COULD

CAUSE THE IMPELLER TO SEIZE ON THE SHAFT, WHICH, IN TURN, MAKES FUTURE

REMOVAL DIFFICULT IF NOT IMPOSSIBLE WITHOUT SHAFT AND IMPELLER

DAMAGE.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

13

INSTALLATION AND OPERATION OF THE PUMPS AND ASSOCIATED EQUIPMENT

MUST BE IN ACCORDANCE WITH ALL NATIONAL AND LOCAL CODES, AS WELL AS

INDUSTRY STANDARDS.

REGULARLY OBSERVE THE CONDITION OF THE BEARING LUBRICANT FOR SIGNS

OF RUST OR MOISTURE, ESPECIALLY IN AREAS WHERE VARYING HOT AND COLD

TEMPERATURES ARE TYPICAL.

III. PREVENTIVE MAINTENANCE

Wear on the pump is affected by any number of pump applications. Abrasive

qualities due to specific applications as well as the pressure and the liquid

temperature being pumped will all cause pump wear. This section provides basic

practices and recommendations for preventive maintenance on your WSP™ Self-

Primer pump.

Following a consistent preventive maintenance schedule will help maintain peak

performance and an extended life from your WSP™ Self-Primer pump.

If you have questions about your current or proposed application, contact your

WSP™ distributor or the Weir Specialty Pump factory.

The key to a quality preventive maintenance program is continuous record keeping.

Always note changes in suction and discharge gauge readings if your pump includes

such gauges. If there are changes between regular inspections, it may indicate

some type of dysfunction that can be corrected before damage to your system or

total failure happens. Document any wearing parts during inspections for later

comparison. Make note in your records whether certain parts fail during the same

duty cycle so the part can be checked and replaced before it fails. This helps reduce

unscheduled down time.

Inspect wearing parts at 250 hours to ascertain the wear rate when implementing

new applications. Later inspections should be completed at designated times noted

on the following chart. Be aware that critical applications must be inspected more

frequently.

THIS SPACE INTENTIONALLY LEFT BLANK

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

14

Preventive Maintenance Guide

Daily

Service

Owner

Status

Notes

Check the following:

Check the overall condition of the pump

Notice: Hardware for tightness

Are there any leaks?

Is there unusual vibration?

Monitor and record the gauge readings

Are the speed and flow normal?

Weekly

Service

Owner

Status

Notes

Check the following:

Bearing oil level in the sight gauge

Notice if the bearing oil is cloudy. If the

oil is cloudy, drain and replace.

Seal oil level and condition. If the oil is

cloudy, drain and replace.

Monthly

Service

Owner

Status

Notes

Check the following: If your pump is

driven by V-Belts

Check tightness

Alignment of belts

Tension belts

Check the following: If your pump is

direct drive with a coupling

Inspect the coupling for signs of:

− Wear

− Misalignment

− Loose fasteners

Check the following: If your pump

has an Air Release Valve

Inspect and lubricate

Semi Annually

Service

Owner

Status

Notes

Check the following:

Adjust impeller to wear plate clearance

Adjust impeller to seal plate clearance

Inspect, clean and lubricate air release

valve

Annually

Service

Owner

Status

Notes

Check the following:

Piping for:

− Leaks

− Loose fasteners

Bearing oil:

− Drain and replace

Seal oil:

− Drain and replace

Note: Service interval based on an intermittent duty cycle equal to approximately 4000

hours annually. Adjust schedule as required for lower or higher duty cycles or extreme

operating conditions.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

15

IV. DISASSEMBLY & REASSEMBLY OF THE PUMP & SEAL

Review all warnings before performing installation and follow the directions on all

tags, labels, and decals attached to the pump very closely.

Your pump requires minimum service due to its rugged, low maintenance design.

Should you need to inspect or replace wearing parts, follow these instructions. They

match the sectional views and the list of appropriate parts.

Instructions in this manual are intended to inform the operator about any procedures

that need extra attention. It will also make note of procedures that could damage

equipment or cause danger to the operator and/or other employees. This manual

will not anticipate or provide in-depth precautions for every possible situation that

could happen during maintenance or repair of the WSP™ Self-Primer Pump. As

always, it is the owner’s and maintenance staff’s duty to be sure that safety and

established maintenance procedures and processes are used. Any procedures or

processes not noted in this manual should only be completed after determining that

personal safety and equipment integrity is not harmed.

A number of servicing functions may be completed by draining all the liquid from the

pump and removing the cover plate assembly. Before making significant repairs,

disconnect the power source and piping. The following instructions require complete

disassembly.

Before disassembly, determine the material type and configuration of the pump if

unknown. The first set of characters in the pump name describes the size and model

of the pump (8-WSP is an 8” self-primer). Use the following key to determine the

materials used in the pump from the remaining characters in the pump name.

THIS SPACE INTENTIONALLY LEFT BLANK

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

16

* This letter indicates a Ductile Iron pump case with a Hi-Chrome Cover Plate. A Hi-

Chrome case is not available.

For example, 8-WSP-BBBBB-B1-BLG is a stainless pump with a stainless ANSI

flange, stainless hardware, nitrile o-rings, and Type 2 tungsten carbide seal.

If an “X” is present in the materials code, please contact the factory providing the

pump serial number for assistance in determining the material type and configuration

of the pump.

Prior to working on the pump, lock out or disconnect its power source. It must

remain inoperable during repairs. Next, shut all the valves in both discharge and

suction lines.

PRIOR TO WORKING ON THIS PUMP, ALWAYS LOCK OUT OR DISCONNECT THE

PUMP FROM ITS POWER SOURCE. IT MUST REMAIN INOPERABLE DURING REPAIRS.

To take apart and repair the power source, refer to the documentation supplied with

your power source, or contact your local power source representative.

Digit 1

Digit 2

Digit 3

Digit 4

Digit 5

-

Digit 6

-

Digit 7

Digit 8

Digit 9

Case / Cover Plate

Seal

Plate Wear Plate

Bearing

Housing Impeller - Flanges - Hardware O-rings Seal

A – DI

A - CI

A - Steel

A - DI/CI

A - Steel

-

A1 - CI ANSI

-

A - Steel

L - Nitrile

F - Type 2 SC

B – SS B - CD4

B – SS

8 & 10” – CD4

B – SST/CI

2” – CD4/CI B - CD4 - A2 - CI DIN - B - Stainless M - Buna G - Type 2 TC

*C – HiCr

(DI/HiCr) C - HiCr

C – HiCr

ONLY 8” & 10” C – HiCr/CI C - HiCr - A3 - CI JIS N - Viton H - Type 9 SS

D – Mangabraze

Except 8”

D – DI

3” ONLY

A4 - CI NPT

P - Kalrez I - Type 9 TT

E - DI

A5 - CI BSP

B1 - SS ANSI

B2 - SS DIN

B3 - SS JIS

B4 - SS NPT

B5 - SS BSP

X - Other

X-

Other X - Other X - Other X - Other

X - Other

X - Other X - Other X - Other

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

17

NO PERSON SHOULD ATTEMPT TO OPEN OR SERVICE THIS PUMP BEFORE

BECOMING THOROUGHLY FAMILIAR WITH ALL THE PROCEDURES OUTLINED

IN THIS MANUAL.

1. PLEASE STUDY THESE INSTRUCTIONS CAREFULLY.

2. WHEN PERFORMING EQUIPMENT MAINTENANCE, THE EQUIPMENT

ELECTRICAL SERVICE MUST BE LOCKED OUT WITH AN APPROVED

LOCKOUT AND KEY.

3. IF THE PUMP HAS OVERHEATED, ALLOW SUFFICIENT TIME FOR THE

PUMP TO COMPLETELY COOL BEFORE ATTEMPTING TO OPEN OR

SERVICE THE PUMP.

4. CAREFULLY CHECK THE TEMPERATURES BEFORE OPENING ANY

COVERS, PLATES, OR PLUGS.

5. CLOSE THE SUCTION AND DISCHARGE VALVES.

6. CAREFULLY AND SLOWLY VENT THE PUMP.

7. DRAIN THE PUMP.

A. REMOVING THE COVER PLATE & WEARPLATE

Remove the pump casing drain plug. Drain the pump before attempting to maintain

or repair the unit. Once the cover plate assembly is removed, the wearplate

becomes accessible and is easy to maintain. When service or repair is completed,

clean, inspect and reinstall the drain plug.

After removing the hand nuts, use the adjuster knobs; pull (or use jackbolts to

remove) the cover plate and assembled wearplate from the pump casing.

To determine how much wear has taken place, rest the wear plate on top of the

impeller and measure the gap as shown in Figure 1. If more the 1/8th inch out of flat,

the wear plate should be replaced (Figure 1).

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

18

Figure 1

Disengage the hardware to remove the wearplate then inspect it and replace if it is

badly gouged or worn.

Carefully inspect the O-rings in the back cover and replace if worn or damaged.

B. REMOVING THE SUCTION CHECK VALVE

Remove the check valve pin. Pull the complete assembly from the suction flange by

reaching through the back cover opening. Once this is completed, service, inspect

and replace the check valve assembly.

NOTE: Additional check value disassembly is not needed. It must be replaced as a

complete unit since individual parts are not sold separately.

C. REMOVING THE ROTATING ASSEMBLY

To service the rotating assembly without disconnecting the suction or discharge

piping, remove the power source. This will provide clearance for servicing.

To prevent seal cavity oil from escaping when the impeller is loosened, remove the

seal cavity drain plug, and drain the oil in the seal cavity before loosening the

impeller.

With the rotating assembly still attached to the pump casing, loosen the impeller.

When done, clean, inspect and reinstall the drain plug in the seal cavity.

Wedge a block of wood between the impeller vanes and the pump casing prior to

removing the stainless steel impeller screw.

Install the impeller shaft key before installing a lathe dog on the drive end of the

shaft. When installing the lathe dog, be sure the “V” notch is positioned over the

shaft key.

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

19

While the impeller rotation still has a block (Figure 3), use a piece of long, heavy bar

to lever against the arm of the lathe dog in a counterclockwise direction (You should

be facing the drive end of the shaft.). Be very careful and avoid damaging either the

keyway or the shaft. Once the impeller is dislodged, take out the lathe dog, the wood

block and the key.

NOTE: The rotating assembly may be removed through the coverplate opening if

desired.

Figure 2

WSP™

DATA SHEET WSP™ SELF-PRIMER PUMPS WSP-D300_8

Rev. 3 01/09/20

© 2019 The Factory

20

Figure 3

Remove hardware attaching the rotating assembly to the pump casing. Use the

jackbolts to detach the rotating assembly by pulling directly away from the pump

casing, then tag and tie the rotating assembly shims to simplify reassembly.

NOTE: If you prefer, a tool for disassembly may be obtained from Weir Specialty

Pumps. Should you select this option, follow all instructions included in the

package. You may construct a tool that is similar if you use a ½-inch pipe

made of schedule 80 steel or malleable iron with a standard tee connection

(Figure 4). All threads should be ½-inch NPT. Do not build the tool

beforehand.

Figure 4

Table of contents

Other Trillium Water Pump manuals

Trillium

Trillium FLOWAY Owner's manual

Trillium

Trillium Roto-Jet RO-FT Series Instruction manual

Trillium

Trillium Roto-Jet R11 Quick start guide

Trillium

Trillium ROTO-JET RO III 4x3 Quick start guide

Trillium

Trillium 10-WSP Guide

Trillium

Trillium WSP-6 Guide

Trillium

Trillium ROTO-JET RGA III 2x2 Quick start guide

Trillium

Trillium ROTO-JET VSR 175 Quick start guide

Popular Water Pump manuals by other brands

KNF

KNF N860 TRANSLATION OF ORIGINAL OPERATING AND INSTALLATION INSTRUCTIONS

Honeywell

Honeywell CBU142 installation instructions

Rothenberger

Rothenberger RODIA-VAC Instructions for use

Grundfos

Grundfos MTR instructions

BREWFERM

BREWFERM Pump'in 018.600.15 user guide

Shinhoo

Shinhoo LPA Series Installation and operating instructions