Trillium Roto-Jet R11 Quick start guide

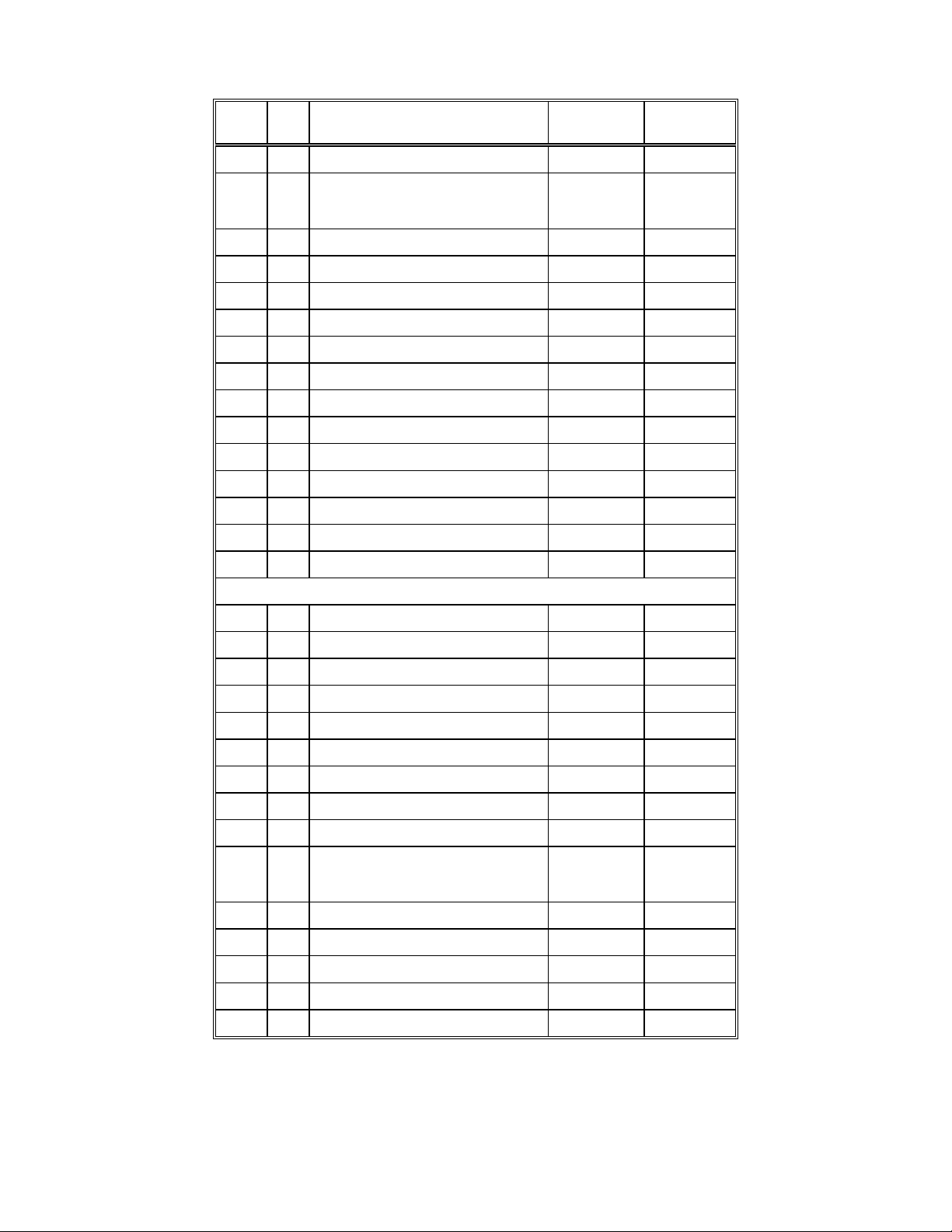

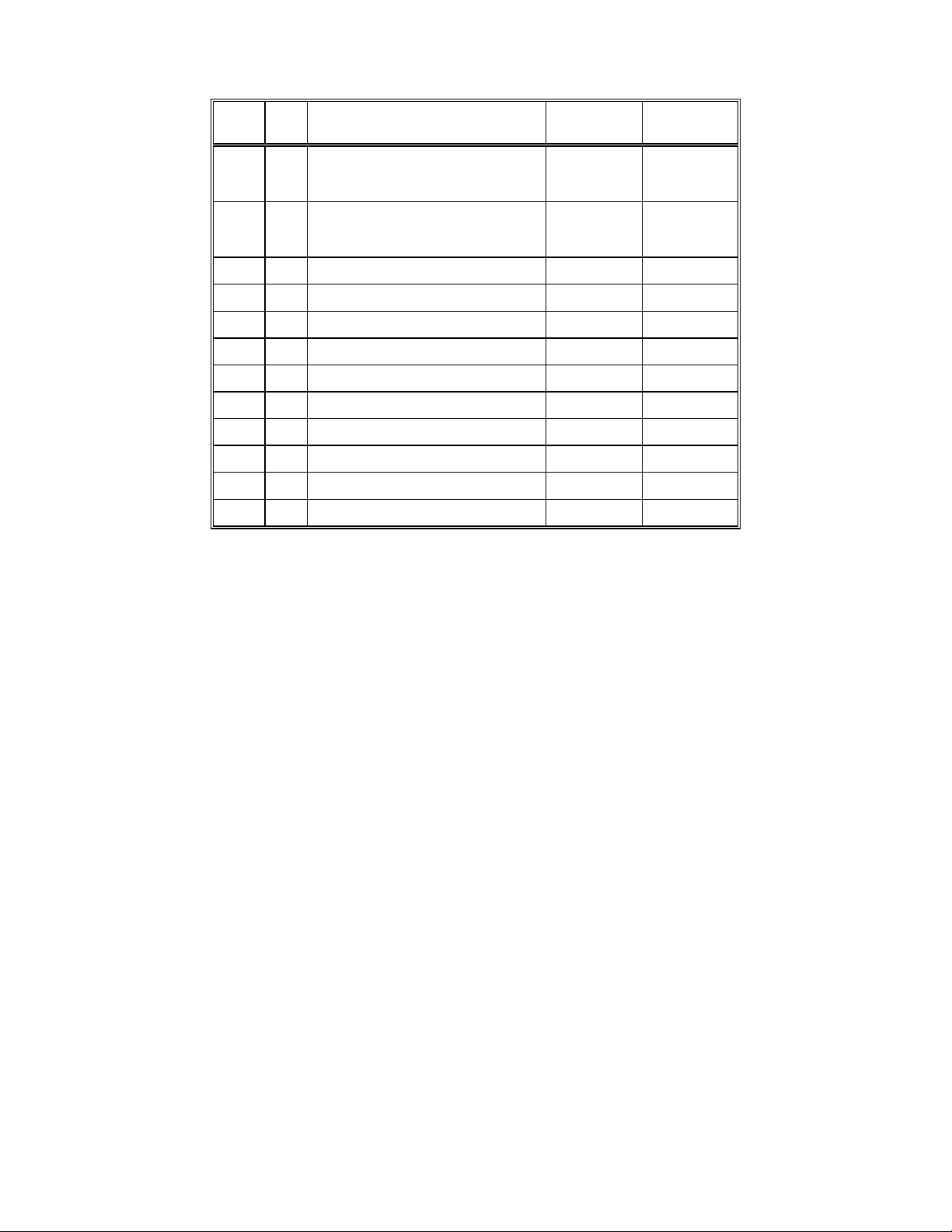

Table of contents

Other Trillium Water Pump manuals

Trillium

Trillium FLOWAY Owner's manual

Trillium

Trillium ROTO-JET VSR 175 Quick start guide

Trillium

Trillium Roto-Jet RO-FT Series Instruction manual

Trillium

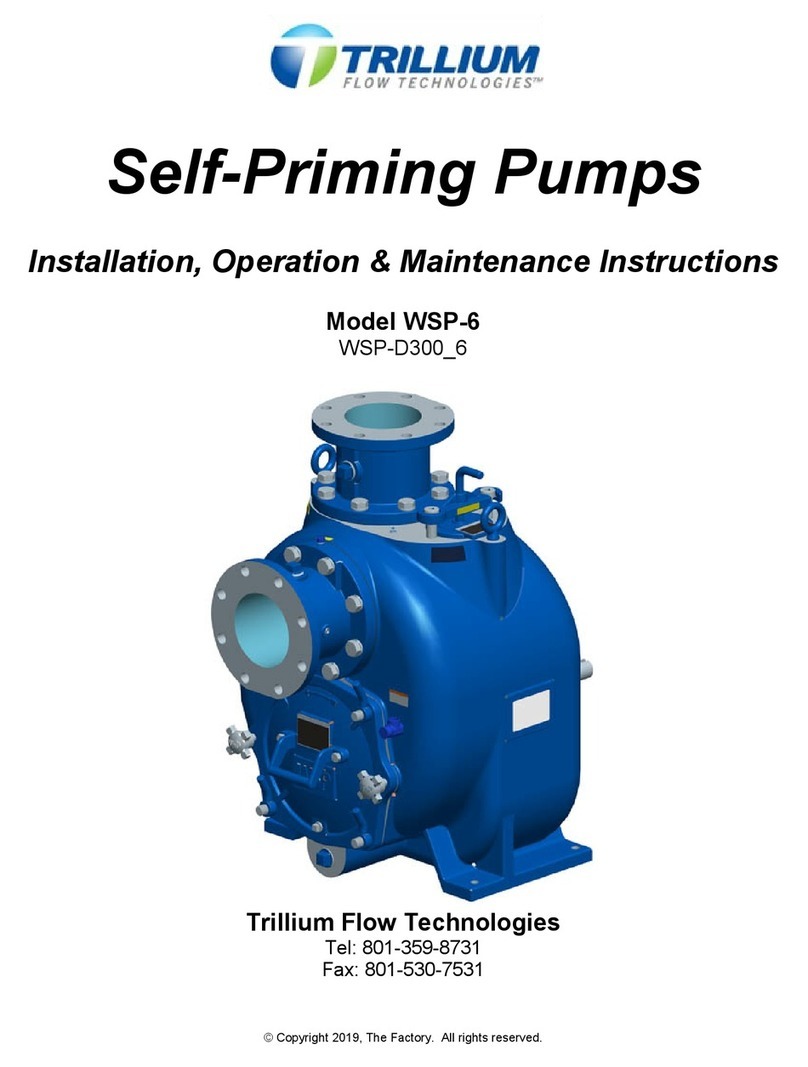

Trillium WSP-6 Guide

Trillium

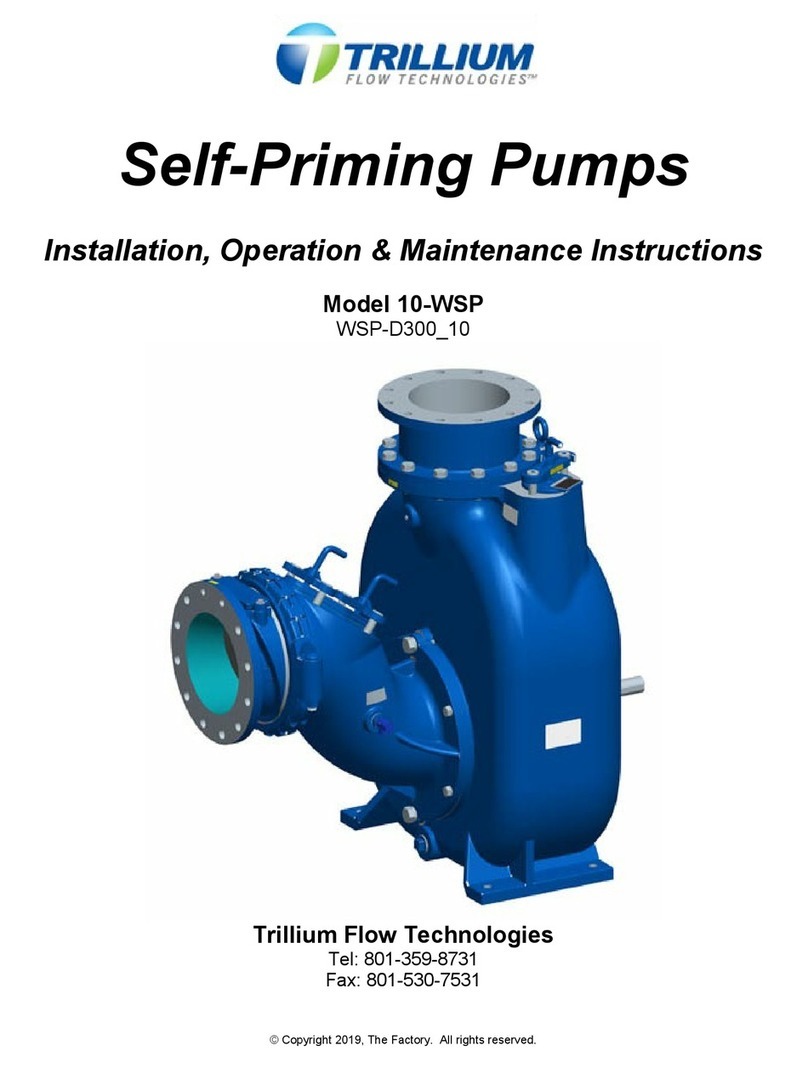

Trillium 10-WSP Guide

Trillium

Trillium ROTO-JET RO III 4x3 Quick start guide

Trillium

Trillium ROTO-JET RGA III 2x2 Quick start guide

Trillium

Trillium 8-WSP Manual

Popular Water Pump manuals by other brands

Grundfos

Grundfos CR Service instructions

I.VA.CO.

I.VA.CO. ICP Series Installation and operating manual

Pentair

Pentair MYERS SP33 Series Installation, Operation & Parts Manual

GORMAN-RUPP

GORMAN-RUPP 10 SERIES Installation, operation and maintenance manual

DAB

DAB DRENAG 1400 Series Instruction for installation and maintenance

Casella

Casella Vortex 3 user manual

STA-RITE

STA-RITE DP233110V owner's manual

GÜDE

GÜDE MIDI 40012 Translation of original operating instructions

Veeder-Root

Veeder-Root Red Jacket Maxxum Big-Flo Quick-Set Series Installation, operation & service manual

Pentair

Pentair Hydromatic SP50 owner's manual

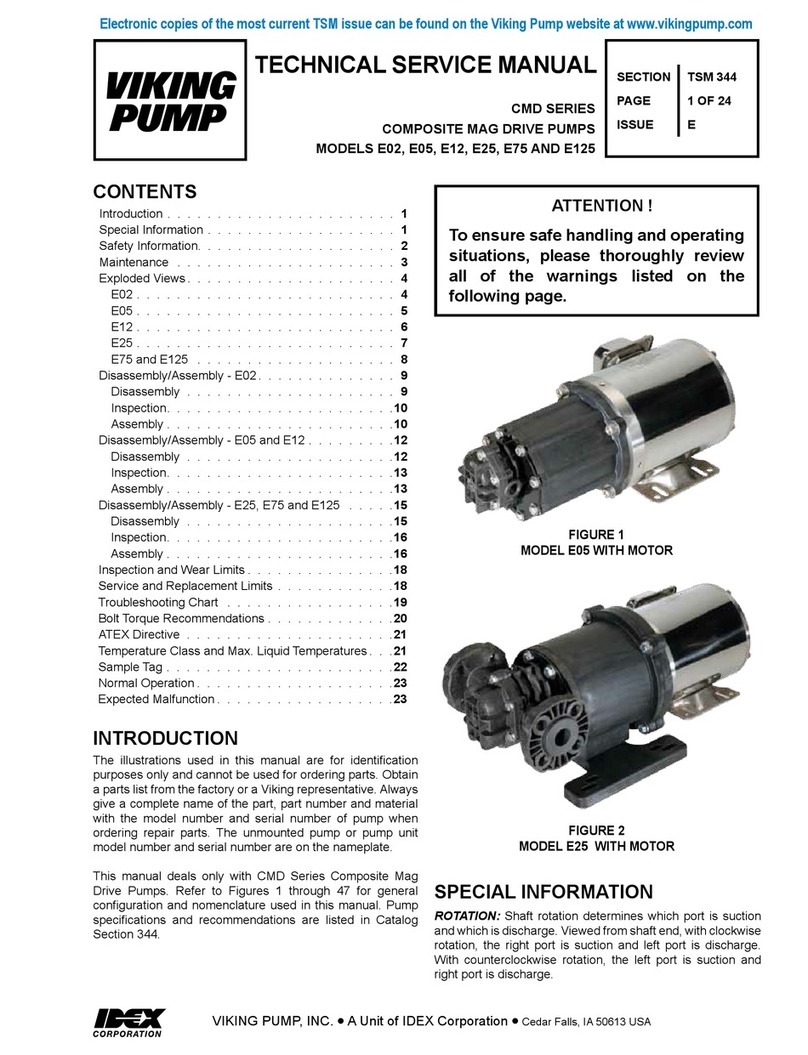

Viking pump

Viking pump CMD-E02 Series Technical & service manual

OTC

OTC 2510A PARTS LIST & OPERATING INSTRUCTIONS