Trimax Genuine Parts Stealth S3 Use and care manual

1

SPARE PARTS

INSTRUCTIONS # 47

Date Created: 30/03/2017

Product: Procut S3 (All Models)

Title: Gearbox Pulley Removal and Replacement

SAFETY! Before attempting to make any adjustments or carry out maintenance on the mower, review

the hazard identification table (section 3a of your Operator Manual) and take all necessary precautions.

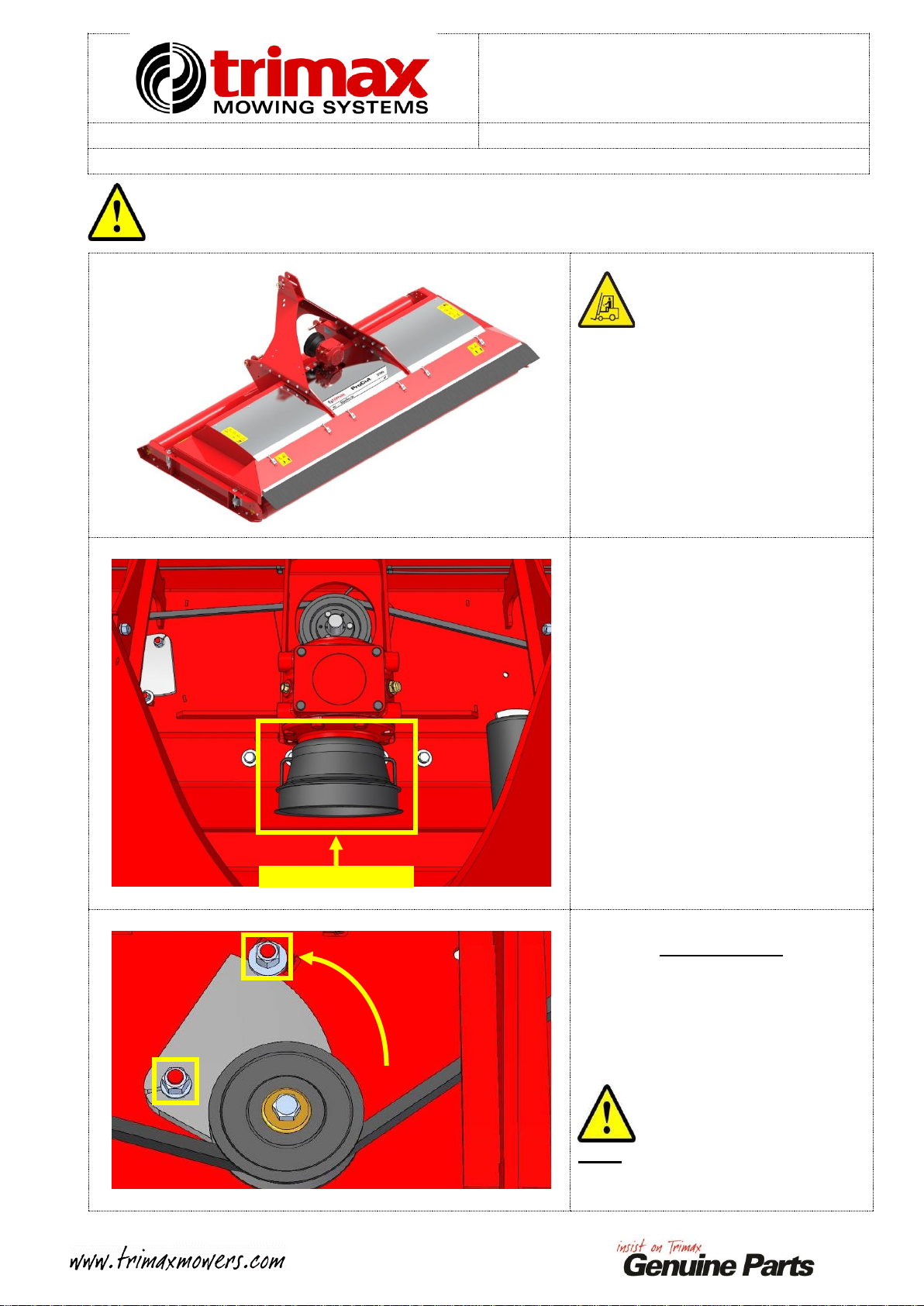

Position the Procut S3 in the work

area.

Unlatch the Covers and remove ALL

M8 Nyloc Nuts and M8 Flat Washers

used to retain the Covers.

Remove ALL Covers and carefully

place to one side.

Remove the P.T.O Cone form the

FRONT of the Gearbox Assembly by

removing the four M8 x 16 Bolts and

M8 Flat Washers.

Place the P.T.O Cone and Fasteners to

one side for later refitment.

ALL MODELS

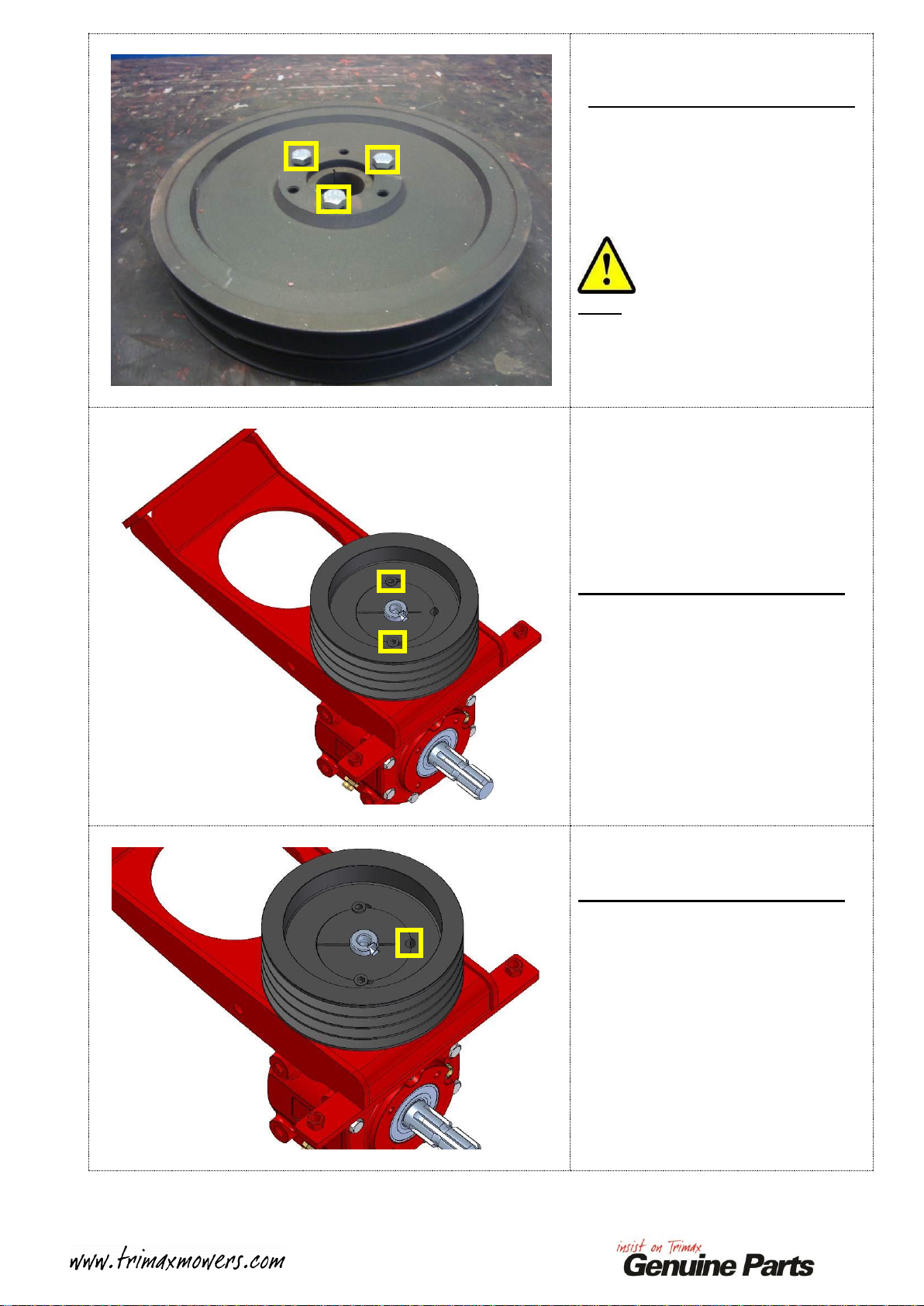

Slacken ALL Idler Mounting Nuts

and pivot the Idlers away from the

Belts to relieve belt tension.

One Idler shown in this example.

Note:

DO NOT remove Idlers!

Remove P.T.O Cone

2

Procut 237 has a special SLOTTED

Idler located near the Gearbox Pulley.

Loosen this Idler by slackening the

Mounting Nut, then unwinding the

M12 x 150 Set Screw.

Note:

DO NOT remove Idlers!

Remove ALL Vee Belts and place to

one side for later re-fitment

Support the weight of the Gearbox

Assembly.

Undo and remove the Gearbox

Mounting Bolts highlighted.

Place the fasteners to one side for re-

use.

Slacken this

Nut first

Then

unwind the

Set Screw

3

Lift the Gearbox Assembly clear of

the Procut and place on a bench.

Remove ALL Lifting Equipment

from the Gearbox Assembly.

Flip the Gearbox Assembly over to

the position shown.

Note:

Place the Gearbox Assembly on

cardboard or rubber to minimise paint

damage!

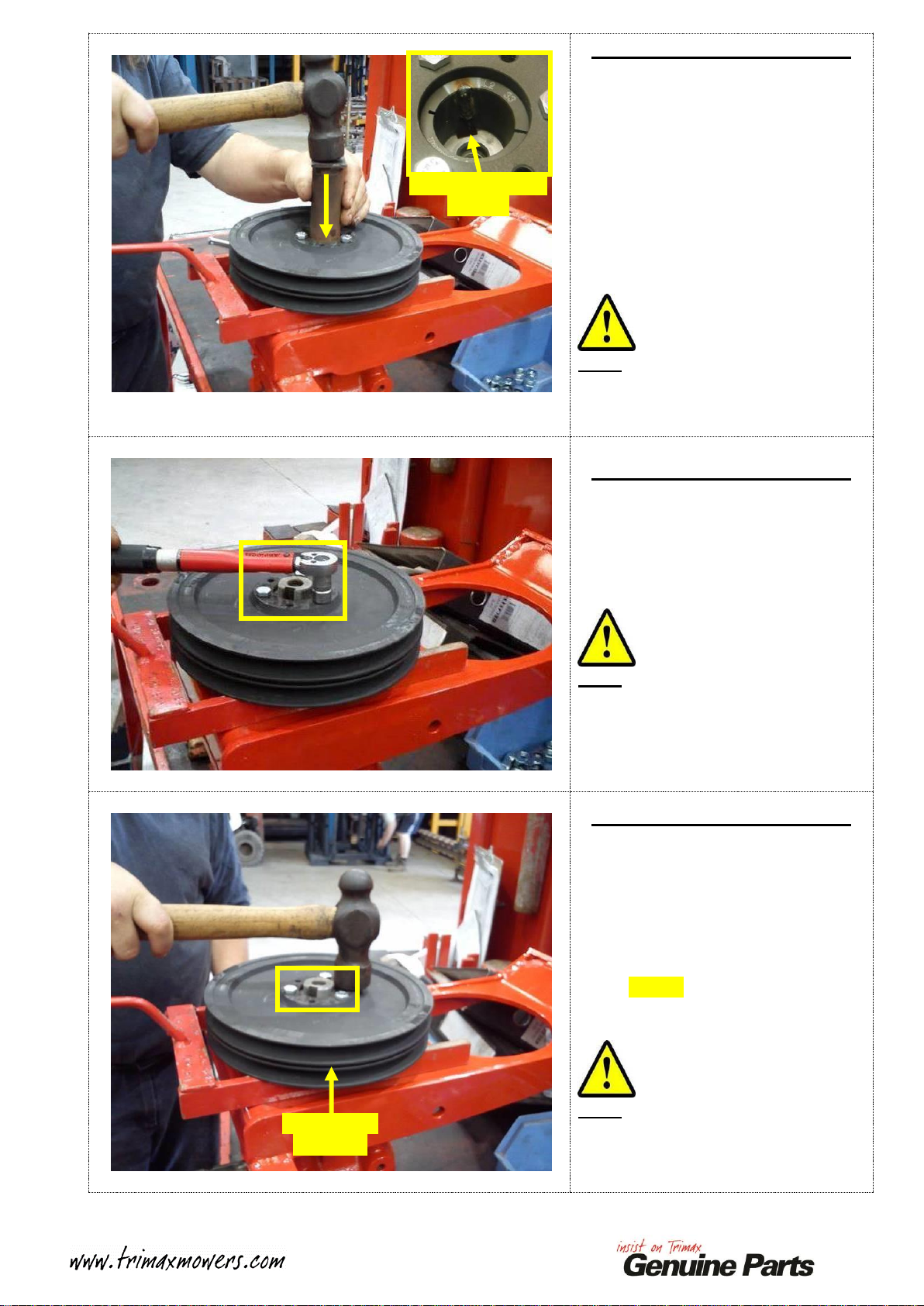

PROCUT 178 and 210 Only:

Slacken the three M8 x 40 Bolts

highlighted.

Tap the heads of each of the Bolts

with a Hammer.

This will separate the Pulleys off the

Biloc Bush.

Remove the M8 x 40 Bolts.

Remove the first Pulley.

4

PROCUT 178 and 210 Only:

Insert a Flat Bladed Screwdriver in

the Slot in the Biloc Bush.

Carefully lever the Bush open

slightly.

Slide the Bush up and off the Gearbox

Output Shaft.

Remove the second Pulley.

PROCUT 178 and 210 Only:

Clean the Taper in the centre of

BOTH Gearbox Pulleys using White

Spirits and a Clean Cloth.

Clean the Welded 33mm Biloc Bush

using White Spirits and a Clean

Cloth.

One Pulley is shown opposite.

PROCUT 178 and 210 Only:

Lay one Pulley as shown and fit the

Welded 33mm Biloc Bush into the

Pulley with the LONG side of the

taper facing DOWNWARDS as

shown opposite.

Insert Flat Screw

driver here to

lever bush open

slightly

Long side of Biloc

Taper MUST face

DOWNWARDS!

5

PROCUT 178 and 210 Only:

Fit the Second Pulley over the

Welded 33mm Biloc Bush.

Fit the three M8 x 40 bolts into the

Pulley.

Note:

DO NOT tighten the M8 x 40 bolts at

this stage!

PROCUT 237 and 290 Only:

Remove the two Grub Screws

highlighted.

PROCUT 237 and 290 Only:

Re-insert one of the Grub Screws in

the hole highlighted.

Gradually tighten until the Pulley

separates from the Taper Lock Bush.

Continue to tighten this Grub Screw

to drive the Taper Lock Buch

upwards.

6

PROCUT 237 and 290 Only:

Insert a Flat Bladed Screwdriver in

the Slot in the Biloc Bush.

Carefully lever the Bush open

slightly.

Slide the Bush up and off the Gearbox

Output Shaft.

Remove the Pulley.

IMPORTANT:

Apply MINIMAL leverage while

removing the Taper Lock Bush,

otherwise cracking can occur through

the thinnest section of the Taper Lock

Bush!

PROCUT 237 and 290 Only:

Clean the Bore in the Centre of the

Pulley, the Taper Lock Bush and the

Gearbox Output Shaft with White

Spirits and a clean cloth

Re-assemble the Pulley as shown with

MEDIUM STRENGTH THREAD

LOCKING COMPOUND applied to

the Grub Screws.

Leave the Grub Screws loose at this

stage.

Place two Spacers onto the Gearbox

Mounting Plate in the locations

shown opposite. These will be used to

set the spacing of the Pulley.

There are TWO different

measurements used:

•Procut 178 and 210 require:

27mm (1 1/16”) Spacers

•Procut 237 and 290 require:

10mm (3/8”) Spacers

Insert Flat Screw driver here

to lever bush open slightly

Leave empty, used for pulley

removal ONLY

Grub screws with MEDIUM STRENGTH THREAD

LOCKING COMPOUND applied

Spacer

Spacer

7

Procut S3 178 and 210 only:

Re-fit the Gearbox Pulley

Assembly onto the Output Shaft.

Lightly tap the Gearbox Pulley

Sub-assembly down until it is hard

against the 27mm (1 1/16”) Spacers.

A section of steel tube with an I.D

40mm (1 9/16”)is an ideal drift for

this task.

Note:

Ensure the weld in the Biloc Bush

aligns with the Keyway in the Output

Shaft! see inset for detail.

Procut S3 178 and 210 only:

Tighten the three M8 x 40 bolts

gradually and evenly.

Once nipped up, torque to 25Nm

(18ft/lbs).

Note:

The M8 x 40 bolts MUST be

tightened evenly to ensure a

consistent gap between the two

Pulleys!

Procut S3 178 and 210 only:

Tap the Pulley with a Hammer

between the bolts and re-torque to

25Nm (18ft/lbs). This ensures that the

Pulley is securely mounted.

Stripe the heads of the M8 x 40 Bolts

with a Yellow Paint Marker.

Remove the Spacers.

Note:

Check gap between Pulleys is

consistent around the circumference

of the Pulley! Reset the Pulley if not!

Weld aligned with

Keyway

Check gap is

consistent

8

Procut S3 237 and 290 only:

Fit the Gearbox Pulley

Sub-assembly onto the Output Shaft.

Align the Key in the Output Shaft

with the Keyway in the Gearbox

Pulley Assembly.

Lightly tap the Gearbox Pulley

Sub-assembly down until it is hard

against the 10mm (3/8”) Spacers.

Fully tighten.

Procut S3 237 and 290 only:

Torque the Grub Screws to 90Nm

(66ft/lbs)

Tap around the Bush with a Hammer,

this will ensure that the Bush is seated

squarely in the Bore

Re-torque the Grub Screws to 90Nm

(66ft/lbs) This ensures that the Pulley

is securely mounted.

Note:

It may be necessary to prevent the

Gearbox from rotating, an old P.T.O

Yoke can be used for this task.

Procut S3 237 and 290 only:

Once torqued, remove the Spacers.

Stripe across the Grub Screws with a

Yellow Paint Marker

9

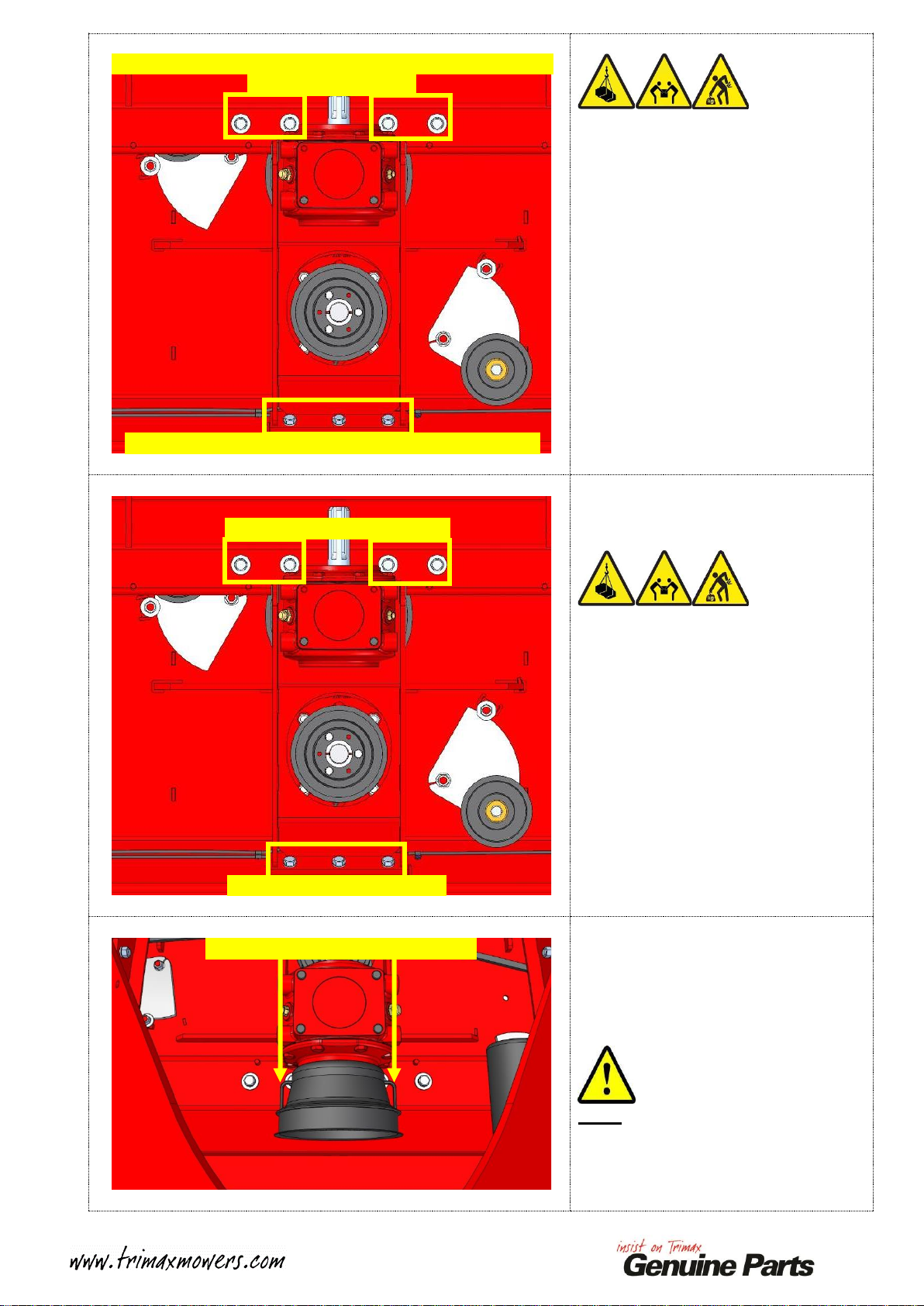

Re-fit the Gearbox Assembly into its

original position.

Apply MEDIUM STRENGTH

THREAD LOCKING

COMPOUND to ALL Gearbox

Mounting Bolts

Secure the REAR of the Gearbox

Assembly using the M12 x 30 Bolts

and M12 Spring Washers.

Secure the FRONT of the Gearbox

Assembly using the M12 x 35 Bolts,

M12 Spring Washers and M12 Heavy

Flat Washers.

Hand tight only at this stage.

Support the weight of the Gearbox

Assembly so it is contacting the Body

at BOTH ends simultaneously.

While supported, fully tighten the

Rear Gearbox Mount Bolts FIRST.

Then, fully tighten the Front Gearbox

Mount Bolts LAST.

Remove ALL Lifting Equipment.

Refit the P.T.O Cone using the

M8 x 16 Bolts and M8 Flat Washers

that were removed earlier.

Tighten to secure.

Note:

Ensure that the P.T.O Cone Safety

Chain Lugs are HORIZONTAL as

shown.

Tighten FRONT Bolts LAST

Tighten REAR Bolts FIRST

M12 x 35 Bolts, M12 Spring Washers and M12 Heavy Flat

Washers used this side

M12 x 30 Bolts and M12 Spring Washers used this side

Safety Chain Lugs HORIZONTAL

10

Refit and tension the Drive Belts.

Refit the Covers.

Installation is the reverse of removal.

For further detail, please refer to your

Operators Manual.

This process is now complete.

Other manuals for Genuine Parts Stealth S3

1

Popular Tractor Accessories manuals by other brands

Land Pride

Land Pride STH1590 Operator's manual

McConnel

McConnel EZI-EDGER Operator's & parts manual

MTD

MTD 19A30045OEM Operator's manual

New Holland

New Holland 717173046 Operator's manual

Grouser Products

Grouser Products 450 Owner's manual & parts book

Tiger

Tiger JD5075E T4F Mounting and operating instructions