Table of contents

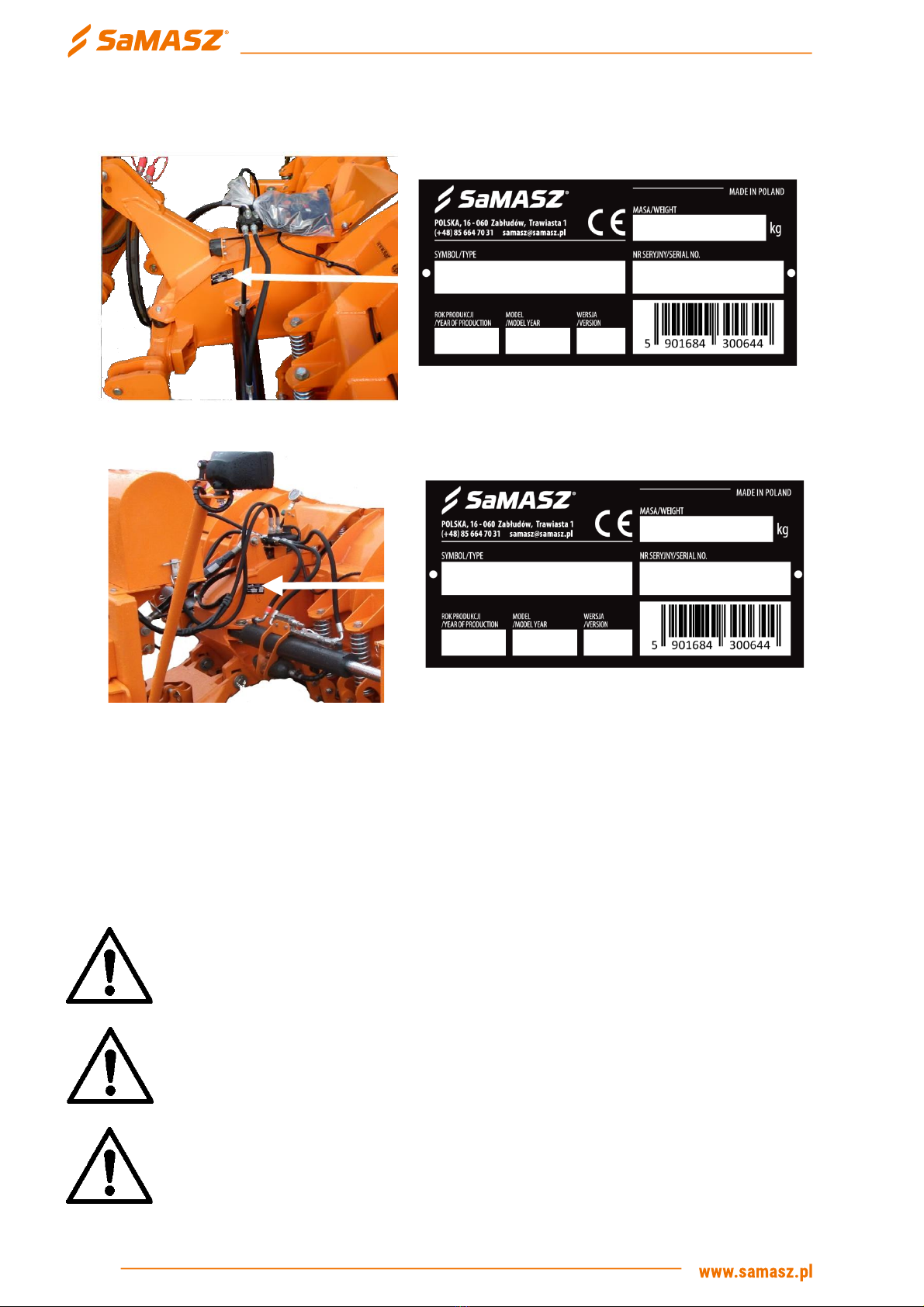

1. IDENTYFICATION......................................................................................................................4

2. SAFETY CONDITIONS................................................................................................................5

2.1. Safety rules........................................................................................................................5

2.2. Qualifications of operator...................................................................................................6

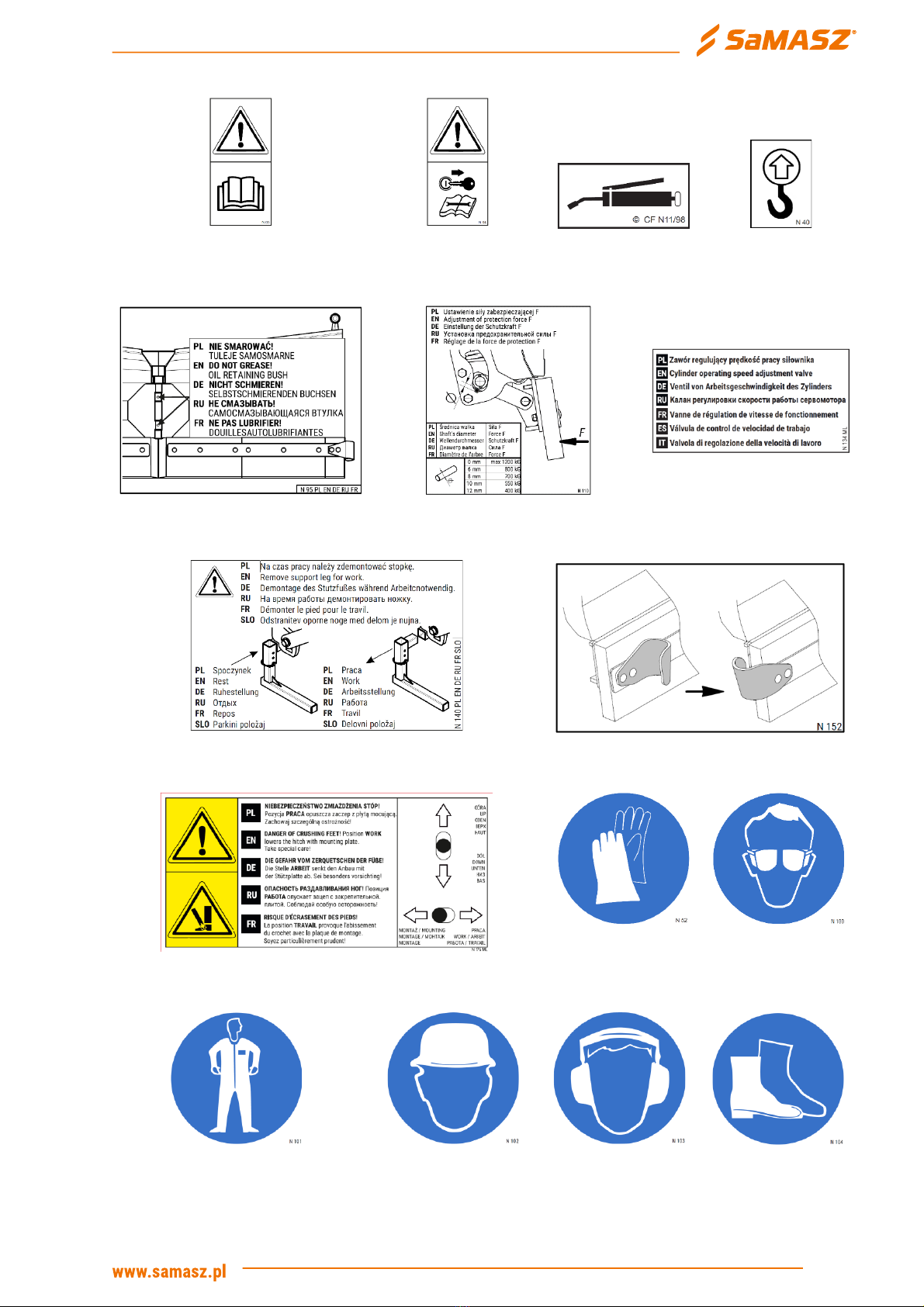

2.3. Warning signs ....................................................................................................................6

2.4. Warnings and prohibitions ..................................................................................................8

2.5. Transport and delivery ........................................................................................................9

3.1. Technical charakteristics..................................................................................................11

3.2. AlpS and Olimp plows.......................................................................................................12

3.3. AlpS Up (H) and Olimp Up (H) snow plows.........................................................................14

4. EQUIPMENT AND SPARE PARTS .............................................................................................15

4.1. Standard equipment .........................................................................................................15

4.2. Optional equipment ..........................................................................................................15

4.3. Spare parts ......................................................................................................................15

5. PLOW OPERATION..................................................................................................................16

5.1. Connecting the plow.........................................................................................................16

5.1.1. Connecting the plow to the tractor .............................................................................16

5.1.2. Montage plow AlpS Up, Olimp Up on truck/ tractor .....................................................18

5.1.3. Mounting AlpS Up H, Olimp Up H plow on a truck........................................................19

5.2. Plow control.....................................................................................................................20

5.2.1. AlpS and Olimp plow standard control........................................................................21

5.2.2. Optional control with AlpS and Olimp plows – Multi Plus ............................................21

5.2.3. AlpS and Olimp plow optional control - multifunctional ...............................................22

5.2.4. AlpS Up, Olimp Up plow control..................................................................................22

5.2.5. Controlling plow AlpS Up H, Olimp Up H .....................................................................23

5.3. Plow transport and parking positions ................................................................................24

5.3.1. Transport and parking positions of the AlpS and Olimp plow.......................................24

5.3.2. Preparing the plow for operation AlpS Up (H), Olimp Up (H) plow ................................25

5.4. Preparing the plow for operation.......................................................................................26

5.5. Operating the plows .........................................................................................................28

6. OPERATIONAL MAINTENANCE................................................................................................36

7. MAINTENANCE AND STORAGE ...............................................................................................37

8. DISASSEMBLY AND DISPOSAL................................................................................................37

8.1. Disassembly.....................................................................................................................37

8.2. Dismantling and disposal .................................................................................................37

8.3. The environment ..............................................................................................................38

9. WARRANTY ............................................................................................................................38

9.1. Warranty card...................................................................................................................38

9.2. Warranty conditions .........................................................................................................39

9.3. Record of warranty repairs................................................................................................41