3(22)

1. Foreword

Avant Tecno Oy would like to thank you for your purchase of this AVANT attachment. It has been designed

and manufactured on the basis of years of experience and product development. By familiarising yourself

with this manual and following the instructions, you ascertain your safety and ensure the reliable operation

and long service life of the equipment. Read the instructions carefully before starting to use the equipment or

performing maintenance.

With these instructions, even an inexperienced user can use the attachment and loader safely. The manual

includes important instructions for experienced AVANT operators as well. Ensure that all persons using the

loader have received proper guidance and familiarised themselves with the manual of the loader and

attachment and all safety instructions before using the equipment. Using the equipment for other purposes or

use in any other way than described in this manual is prohibited. Keep this manual at hand throughout the

service life of the equipment. If the manual is lost or damaged, you can request a new one from the retailer

or manufacturer. If you sell or transfer the equipment, be sure to hand over this manual to the new owner.

2. Designed purpose of use

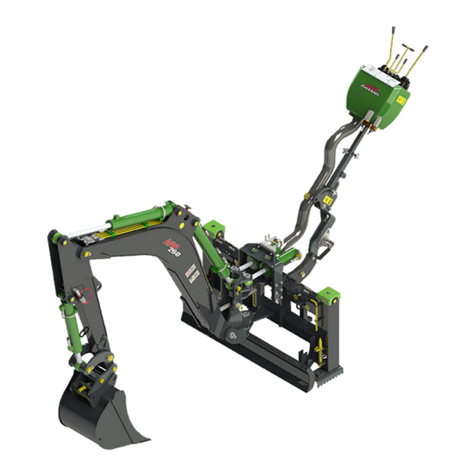

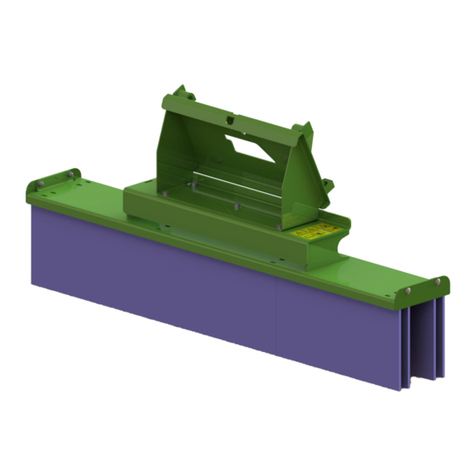

The AVANT Digger 150 is an attachment designed and manufactured to be suitable for use with AVANT

multi purpose loaders shown in Table 1. The digger is intended for occasional use as a quick and simple to

use digging attachment, that is also easy to transport. The digger can be attached quickly and is very

effective for its size. The robust digger can be used with several available bucket options in general

excavation, and moving and loading of soil. The digger makes use of the movements of the loader boom and

there is a hydraulic cylinder for moving the bucket.

The digger is controlled from the operator’s seat of the loader by using the controls of the boom and auxiliary

hydraulics. Excavated soil is dumped to sides by taking use of the articulation and driving of the loader, and

can also be transported further away, or loaded high thanks to its high reach. The control patterns differ from

conventional excavators, but also unexperienced operator’s, as well as operators who are used with other

typer of excavators, can easily assimilate with safe and efficient use of the controls. In addition, the operator

must get familiarised with hazards related to excavation and trenching work. Recommended options for the

most efficient use are telescopic boom on the loader and electric auxiliary hydraulics control buttons. When

using with bucket tilt adapter, also the optional attachment control switch pack is recommended. Using the

digger for other than occasional excavations with original buckets, tools or options is prohibited. The digger

must not be used for lifting of objects.

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. Shown in this manual are also fitting instructions of the bucket tilting adapter, for

persons with at least basic knowledge and experience about performing work on hydraulic assemblies and

the related hazards. All fitting and maintenance tasks can’t be performed by the operator, and demanding

repair and maintenance operations should be left for professional maintenance. All maintenance work must

be done using proper safety equipment and original spare parts. Familiarise yourself with the instructions

regarding service and maintenance shown in this manual. Please contact your AVANT retailer, if you have

any additional questions about the operation or maintenance of the equipment, or if you require spare parts

or maintenance services.

Table 1 – Digger 150 A35317 compatibility with Avant loaders 745, 750

630, R35, 635, 640

520, 525LPG, R28, 528

419, 420

•

••

•

320 -

For compatibility information with a model not shown in

table, contact your Avant retailer.