Trina Solar DUOMAX Series User manual

INSTALLATION MANUAL

IEC Version

THE MODULE

Screw

TSM-DEG6HC.27(II)

TSM-DEG15HC.27(II)

TSM-DEG6HC.20(II)

TSM-DEG15HC.20(II)

TSM-DEG6MC.27(II)

TSM-DEG15MC.27(II)

TSM-DEG6MC.20(II)

TSM-DEG15MC.20(II)

TSM-NEG6MC.20(II)

TSM-NEG6MC.27(II)

TSM-NEG15MC.20(II)

TSM-NEG15MC.27(II)

Clamp

TSM-DEG6HC.07(II)

TSM-DEG15HC.07(II)

TSM-DEG6HC(II)

TSM-DEG15HC(II)

TSM-DEG6MC.07(II)

TSM-DEG15MC.07(II)

TSM-DEG6MC(II)

TSM-DEG15MC(II)

TSM-NEG6MC(II)

TSM-NEG6MC(II)

TSM-NEG15MC(II)

TSM-NEG15MC.07(II)

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 2 - of

21

CONTENT

1. DISCLAIMER OF LIABILITY............................................................................................................................- 3 -

2. SAFETY PRECAUTIONS.....................................................................................................................................- 3 -

3. UNPACKING AND STORAGE............................................................................................................................- 3 -

4. PRODUCT IDENTIFICATION ...........................................................................................................................- 4 -

5. ENVIRONMENTAL CONDITIONS AND SITE SELECTION........................................................................- 4 -

5.1 CLIMATE CONDITION ..........................................................................................................................- 4 -

5.2 SITE SELECTION ....................................................................................................................................- 4 -

6. MOUNTING INSTRUCTIONS..............................................................................................................................- 4 -

6.1 COMPONENT OVERVIEW........................................................................................................................-4-

6.1.1 CLAMP....................................................................................................................................................- 4 -

6.1.2 SCREW……………………………………………………………………………………………… … .-4-

6.2 MOUNTING METHODS……………………………………………………………………………………...-6-

6.2.1 CLAMP...................................................................................................................................................-6-

6.2.2 SCREW ASSEMBLY...........................................................................................................................-11-

6.3GROUNDING ..............................................................................................................................................- 19 -

6.4INSTALL EFFECT CHART......................................................................................................................- 19 -

7. MODULE WIRING............................................................................................................................................- 19 -

8. MODULE TILT ANGLE...................................................................................................................................- 19 -

9. MAINTENANCE AND CARE..............................................................................................................................- 20 -

10. SPECIFICATIONS ..............................................................................................................................................- 20 -

11. CONTACTS..........................................................................................................................................................- 20 -

12. HISTORY…………………………………………………………………………………………………………..-18

Date: 2018.8.13 Doc No: PS-M-0691 Ver. A Page - 3 - of 14

1. DISCLAIMER OF LIABILITY

The installation, handling and use of Trina Solar DUOMAX crystalline series modules are beyond company control.

Accordingly, Trina Solar does not assume responsibility for loss, damage, injury or expense resulting from improper

installation, handling, use or maintenance.

Trina Solar assumes no responsibility for any infringement of patents or other rights of third parties that may result from

use of the module. No license is granted by implication or under any patent or patent rights.

Specifications included in this manual are subject to change without prior notice.

2. SAFETY PRECAUTIONS

1. When designing the PV system, please always take into consideration the variation of the voltage under different

temperatures (please check the respective temperature coefficient specifications of the modules, the Voc of the modules

will rise when the temperature drops);

2. Trina Solar requires that every DUOMAX series PV module string should be fused prior to be connected with other

strings. For the maximum fuse rate, please refer to the detailed SPEC in the last page.

3. Solar photovoltaic (PV) modules generate electricity when exposed to light. An array of many such modules can cause

lethal shocks and/or burn hazards. Only authorized and trained personnel should have access to the modules.

4. Use properly insulated tools and appropriate protective equipment to reduce risk of electric shock.

5. Do not stand or step on the module.

6. Do not damage or scratch the front or backside surfaces of the module.

7. Never use a module with broken glass or top substrate. Broken modules should not be repaired and contact with any

module surface can lead to electrical shock.

8. Do not disassemble the modules or remove any part of the module.

9. Protect plug contacts against soiling and do not make any plug connections using soiled plug contacts.

10. Do not install or handle modules when they are wet or during periods of high wind.

11. Do not connect cable from the positive terminal to the positive terminal of one single PV module.

12. Make sure connectors have no gap between insulators. A gap can cause fire hazard and/or danger of an electrical

shock.

13. Make sure that the polarity of each module or a string is not reversed relative to the other the modules or strings

14. Artificially concentrated sunlight should not be used on the PV module.

15. In markets conforming to IEC standard, maximum system voltage must not exceed 1500V DC. In markets conforming

to UL standard, maximum system voltage must not exceed 1000V DC. For roof use, the maximum system voltage

must not exceed 600V according to National Electrical Code.

16. Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current and/or

voltage than reported at standard test conditions. The requirements of the National Electrical Code (NEC) in Article

690 shall be followed to address these increased outputs. In installations not under the requirements of the NEC, the

values of ISC and VOC marked on this module should be multiplied by a factor of 1.25 when determining component

voltage ratings, conductor ampacities, over-current device ratings, and size of controls connected to the PV output.

17. Our module application class is class A, modules rated for use in this application class may be used in systems

operating at greater than 50V DC or 320W, where general contact access is anticipated..

18. Installation shall be in accordance with CSA C22.1, Safety Standard for Electrical Installations, Canadian Electrical

Code, Part 1.

19. A module with exposed conductive parts is considered to be in compliance with UL 1703 only when it is electrically

grounded in accordance with the instructions presented below and the requirements of the National Electrical Code.

20. The DUOMAX modules have achieved fire rating Type 13 according UL1703 updated on 20th May 2014. The fire

rating of this module is valid only when mounted as specified in the mechanical mounting instructions in this

document.

21. The actual system fire rating should always be evaluated along with the roof cover and mounting.

22. Any module without a frame (laminate) shall not be considered to comply with the requirements of UL 1703 unless the

module is mounted with hardware that has been tested and evaluated with the module under this standard or by a field

Inspection certifying that the installed module complies with the requirements of UL 1703.

3. UNPACKING AND STORAGE

1. Before installation, keep all modules and electrical contacts clean and dry.

2. If it is necessary to store modules temporarily, a dry, ventilated room should be used.

3. When unpacking, carry modules with both hands. Do not place modules on top of each other.

4. The double glass module should be handled carefully, so non-slip gloves are required for handling and installation.

5. Please use the appropriate removal tools when dismantling the plywood cases.

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 4 - of

21

4. PRODUCT IDENTIFICATION

We recommend that you take note of the unique serial number on each module.

5. ENVIRONMENTAL CONDITIONS AND SITE SELECTION

5.1 CLIMATE CONDITION

Install Trina Solar Crystalline series modules in the following conditions:

•Operating temperature: -40°C to +85°C

•Storage temperature: -20°C to +50°C

•Humidity: below 85RH%

•Altitude: ≤2000m

•Mechanical Load Pressure: 2400Pa (245 Kg/m²) Max from the front side 2400Pa from the rear.

* Mechanical load bearing specifications of the module is based on Trina Solar mounting methods. A professional system

installer must be responsible for the mechanical load calculations based on the specific system design.

*The modules have been evaluated by TUV according to IEC61215 for a maximum positive design loading of below

1600Pa, and negative design loading 1600Pa, with 1.5 times safety factor

5.2 SITE SELECTION

1. In most applications, Trina Solar PV modules should be installed in a location where they will receive maximum

sunlight throughout the year.

2. Modules should not be shaded by buildings, trees, chimney, etc. at any time of the day.

3. Do not install in corrosive environments, such as beaches or landfill that can be easily flooded.

4. Do not install PV modules in a location where modules could be immersed in water or continually exposed to water

from a sprinkler or fountain.

5. Do not install PV modules over naked flames or flammable materials.

6. Interspaces, the clearance between the module edge and surface of the wall or roof, of at least 115mm is required to

prevent wiring damage and to allow air to circulate behind the module.

6. MOUNTING INSTRUCTIONS

The module is considered to be in compliance with IEC only when the module is mounted in the manner specified

by the mounting instructions below. This mounting is using Trina Clamps or Screws, alternate mountings are

available.

6.1 COMPONENTS OVERVIEW

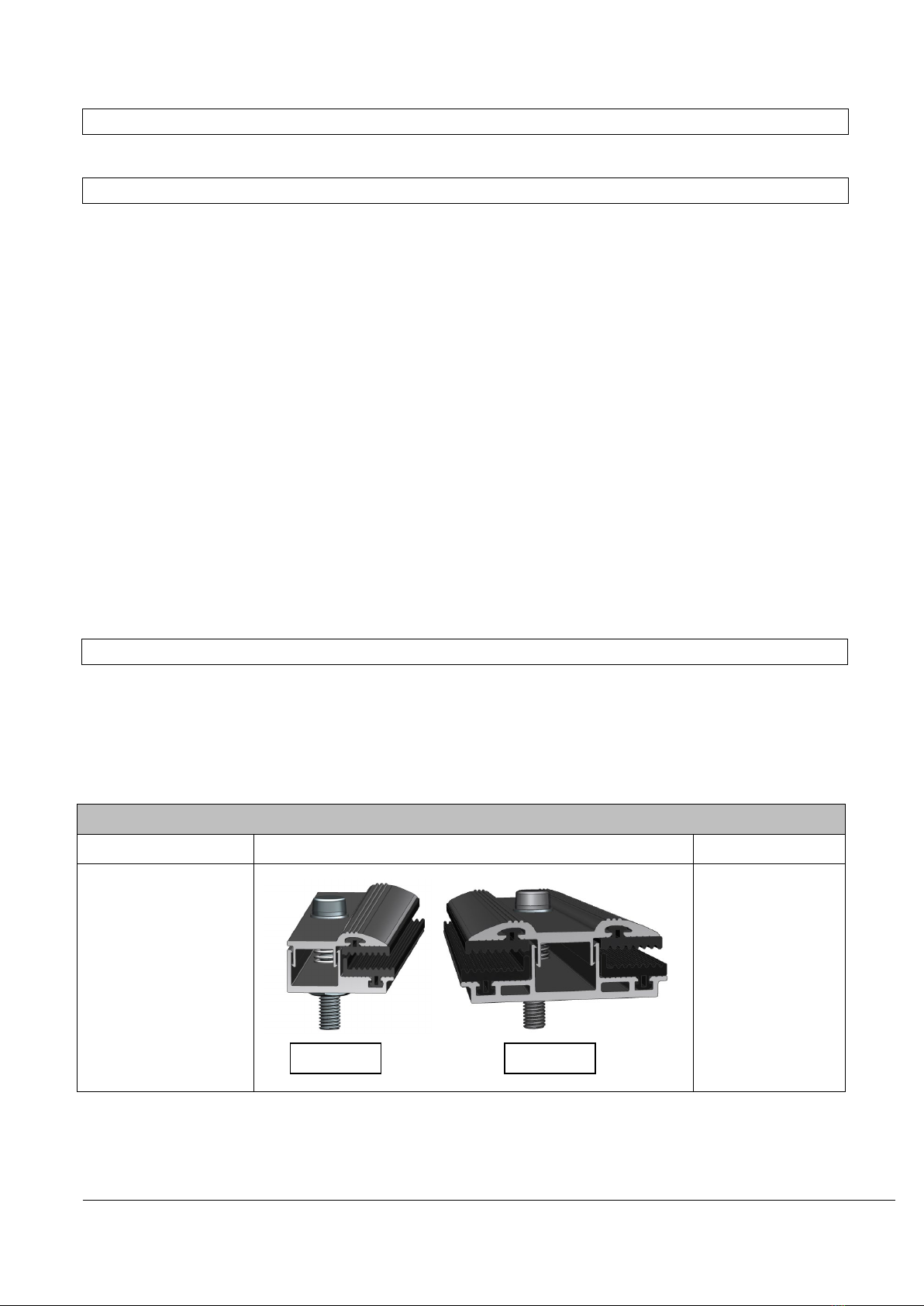

6.1.1 CLAMP

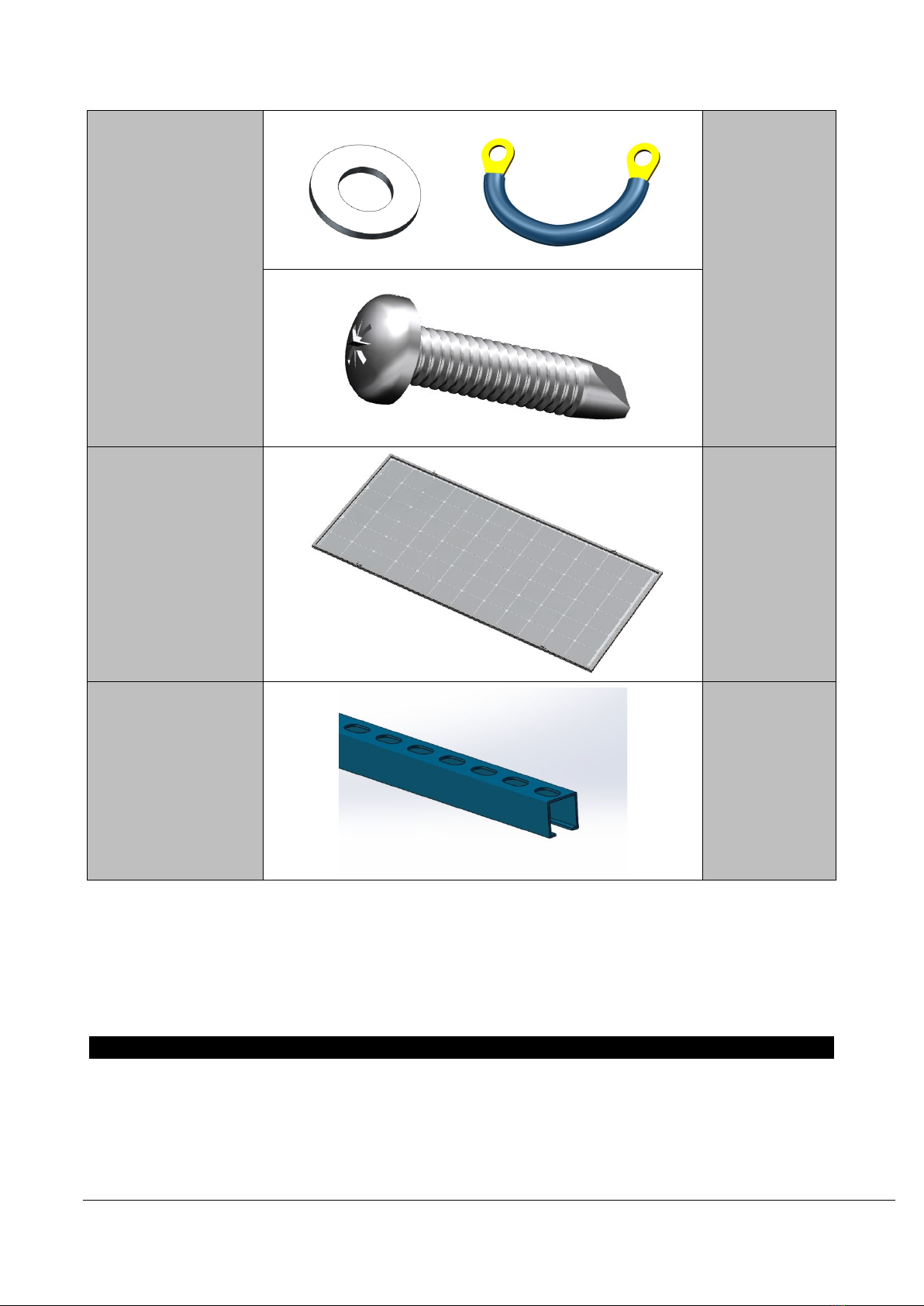

These components are only for use in the installation example in this section

Components Name

Overview

Description

Clamp

Material:

Aluminum alloy

6063

EPDM(ethylene-p

ropylene-diene-te

rpolymer rubber),

spring, bolt, nut,

washer, spring

washer

Used to connect

modules together

MATERIAL BOM OF CLAMP:

Clamp 1

Clamp 2

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 5 - of

21

These components are only for use in the installation example in this section

Item Name Picture Size

(

mm

)

Material

1 Clamp 1

Length and width

150*35.8 Aluminum alloy 6063

2 Clamp Block

1

Length and width

150*35.8 Aluminum alloy 6063

3 Clamp 2

Length and width

150*50.9 Aluminum alloy 6063

4 Clamp Block

2

Length and width

150*50.9 Aluminum alloy 6063

5 EPDM1

Length width and

thickness

150*14.5*3.5

Rubber (suggest to use:

MH45643, type name

PMP-P-2100, made by

PIONEER MATERIAL

PRECISION TECH )

6 EPDM2

Length width and

thickness

150*15.5*3.5

Rubber (suggest to use:

MH45643, type name

PMP-P-2100, made by

PIONEER MATERIAL

PRECISION TECH )

7 Connector

parts

M8 Bolt + washer +

spring washer + Nut SUS304

6.1.2 SCREW

These components are only for use in the installation example in this section

Components Name

Overview

Description

4 Set M8 Hexagon

bolts, Nut, Spring

Washer, Washer.

Material: SUS 304

Used to connect

modules and rails

together

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 6 - of

21

Grounding screw

GB845-85-ST4.2*13-F-

H+ , #5 star washer,

5#flat washer, 5#

ground wire

Grounding

Components

Frame

Material:

Aluminum 6063

Frame can

protect the DG

modules and

easily for

installation.

Racking

Material: Q235B

(Supply By EPC or

Racking suppliers,

suggested specification:

overall dimensions is

41*62mm, thickness is

2.6mm)

Rails, support the

PV modules.

6.2 MOUNTING METHODS

Please read this chapter in its entirety to familiarize with the process before beginning the installation. Also, be sure that

the site has been completely prepared before beginning the installation.

6.2.1 CLAMP

Installation Example A - For C structure steels type 2 rails- For TSM-xxx system

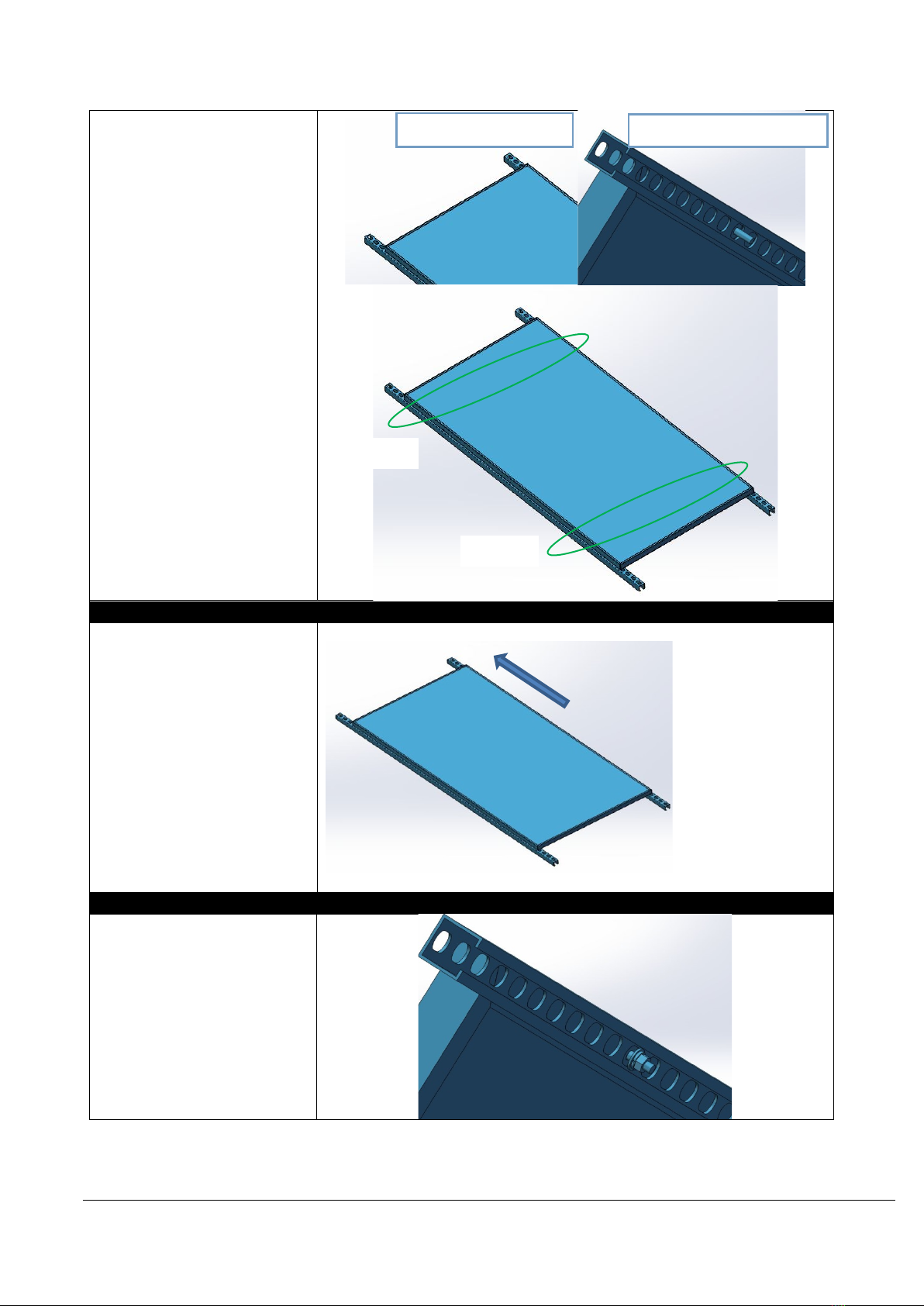

STEP 1: Remove the connector parts

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 7 - of

21

Remove the bottom connector

parts. Connector parts: M8 Nut,

spring washer and washer.

STEP 2: Install the clamp

Put the clamp bolts into the

installation holes, and then

tighten the nuts.

Repeat, put all clamp on the rail,

keep the distance between two

clamps can install the PV

modules. (about 1m between

each clamp)

The 60pcs module can be

installed with 4 clamps, and the

72pcs module can be installed

with 6 clamps

STEP 3: Install the PV modules

Insert the PV module into the

clamp, and make sure the module

edge touch to the EPDM

closely and then tighten the nut

with uniform torque values using

a qualified torque wrench to

ensure the double glass module is

firmly secured. Trina suggests

using M8 bolts to affix the double

glass modules onto the clamp.

The torque for the M8 nuts is

16N∙m~20N∙m

60

72

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 8 - of

21

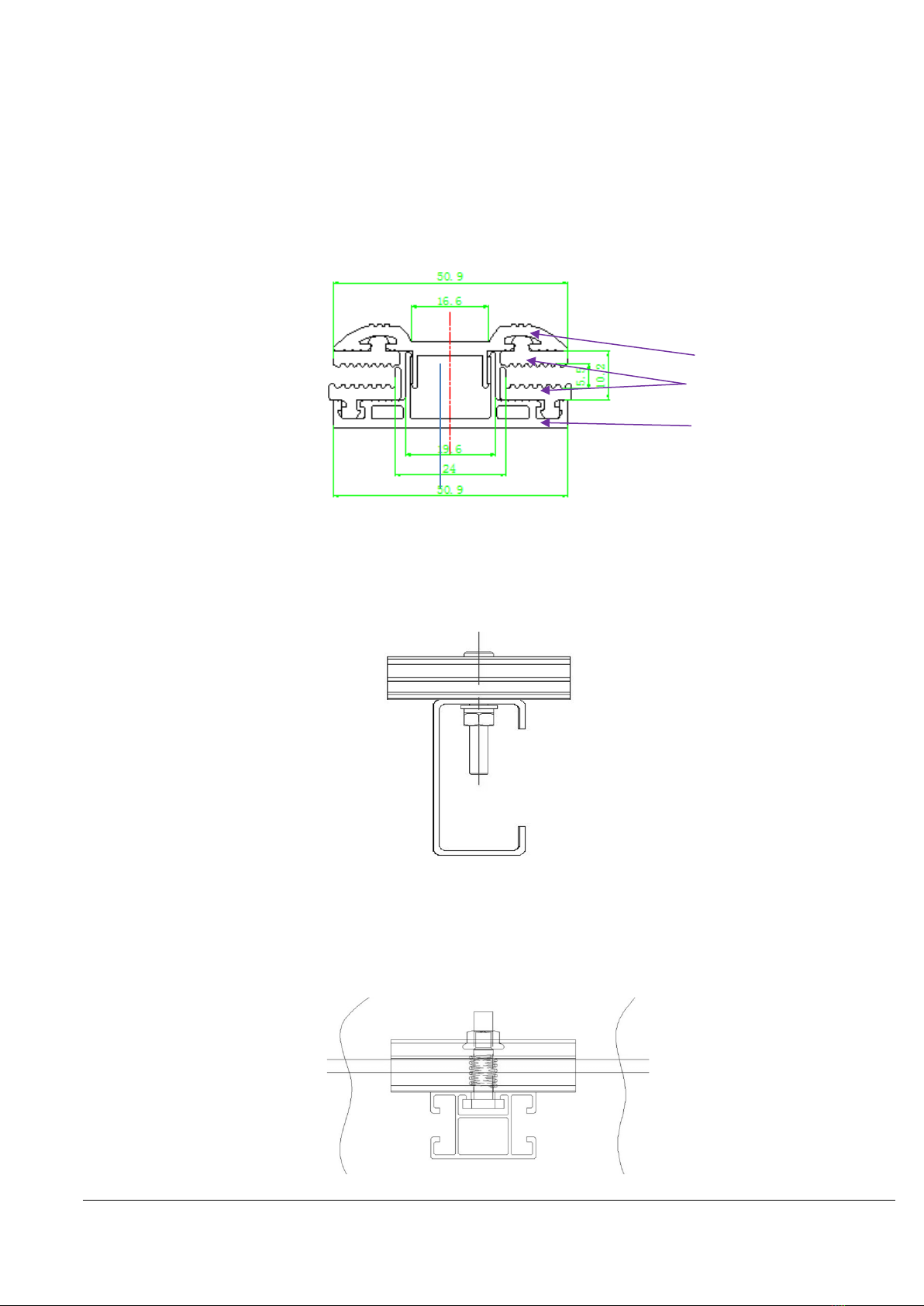

6.2.1.1 TRINA CLAMP COMPATIBILITY WITH VARIOUS RACKING SYSTEMS

The following examples illustrate how to evaluate Trina Clamp compatibility with various racking systems.

Please find the dimension below to evaluate the racking system, contact Trina Solar if you want to change the size of the

screw. Please note that all dimensions below are in mm units.

Section view of the installation

Example A: C structure steel type 2 racking installation

Trina suggests using M8 bolts to fix the clamp. The torque for M8 screw is 16-20 N*M.

When choosing the bolts and nuts for the clamp, please note your racing’s dimensions first.

Example B: Aluminum racking installation

Trina suggests using M8 bolts to fix the clamp. The torque for M8 screw is 16-20 N*M.

When choosing the bolts and nuts for the clamp, please note your racing’s dimensions first.

Aluminum frames limit the screws fastening. As shown below, the screw cannot fasten downwards. In this case, the

T type of cap is recommended.

1. Clamp

2. EPDM

3. Clamp Block

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 9 - of

21

Example C: C structure steel type 1 racking installation

Trina suggests using M8 bolts to fix the clamp. The torque for M8 screw is 16-20 N*M.

When choosing the bolts and T-shape nuts for the clamp, please note your racing’s dimensions first.

For C structure steel type 1 racking, due to the amount of space inside the racking section, many choices are

available including T-shape nuts.

*NOTE: Please consult with a Trina Solar engineer before installing with the frameless clamps

PV modules can be mounted to the substructure using either corrosion-proof M8 bolts placed through the

mounting holes on the rear of the module or specially designed module clamps.

Regardless of the fixing method the final installation of the modules must ensure that:

•A clearance of at least 115mm(4.5in) (recommended) is provided between modules frame and the surface

of the wall or roof. If other mounting means are employed this may affect the UL Listing or the fire class

ratings.

•The minimum distance between two modules is 10mm(0.4in).

•The mounting method does not block the module drainage holes.

•Panels are not subjected to static loads exceeding the maximum permissible loads, and are not subject to

excessive forces due to the thermal expansion of the support structures.

*NOTE: The drain holes cannot be blocked in any situation during installation or use.

A. Mounting with Bolts

•The frame of each module has 4-φ9*14mm mounting holes, ideally placed to optimize the load

handling capability, to secure the modules to supporting structure.

•To maximize mounting longevity, Trina Solar strongly recommends the use of corrosion proof

(stainless steel) fixings

•Secure the module in each fixing location with an M8 bolt and a flat washer, spring washer and nut as

shown in Figure 1 and tighten to a torque of 16~20 N.m(140-180lbf.in.).

•All parts in contact with the frame should use flat stainless steel washers of minimum 1.8mm thickness

with an outer diameter of 20-24mm(0.79-0.94in).

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 10 - of

21

Figure 1. PV module installed with Bolt fitting method

1) Aluminum Frame 2) M8 Stainless Bolt

3)Flat Stainless Washer 4)Spring Stainless Washer

5) HEX Stainless Nut

B. Mounting with Clamps

•Trina Solar has tested its modules with a number of clamps from different manufacturers and

recommends the use of clamps which have an EPDM or similar insulating washer, fixing bolt of at

least M8. The length of clamp ≥40mm(1.57in).

•The clamp must overlap the module frame by at least 7mm (0.28in) but no more than 10mm (0.39in).

•Use at minimum 4 clamps to fix modules on the mounting rails.

•Modules clamps should not come into contact with the front glass and must not deform the frame.

•Be sure to avoid shadowing effects from the module clamps.

•The module frame is not to be modified under any circumstances.

•When choosing this type of clamp-mounting method, use at least four clamps on each module, two

clamps should be attached on each long sides of the module (for portrait orientation) or each short

sides of the module (for landscape orientation). Depending on local wind and snow loads, additional

clamps may be required to ensure that modules can bear the load.

•Applied torque should refer to mechanical design standard according to the bolt customer is using, ex:

•M8 ---- 16-20N.m(140-180lbf.in)

End Clamp installation

Middle Clamp installation

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 11 - of

21

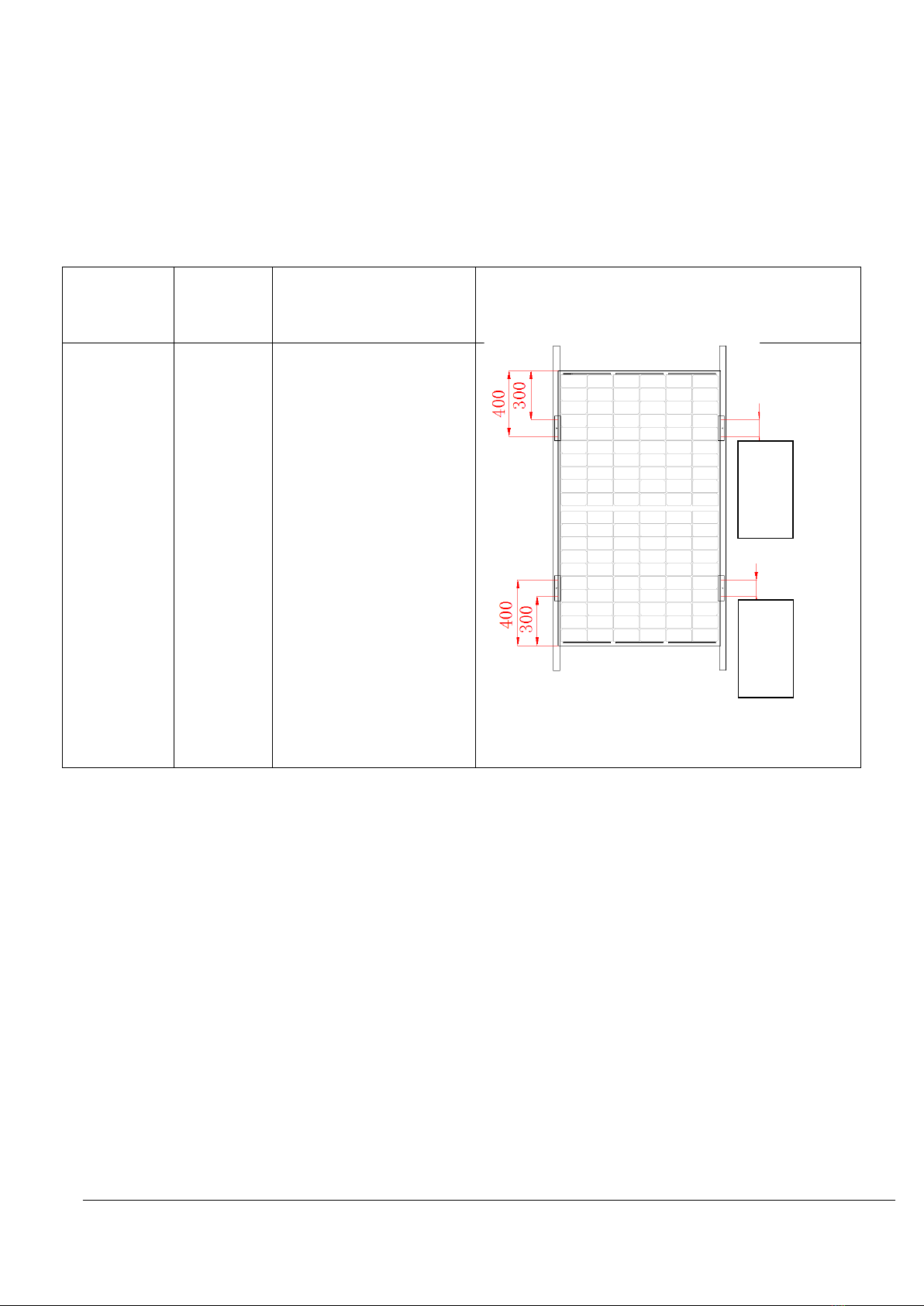

6.2.1.2 CLAMP OPTIONS

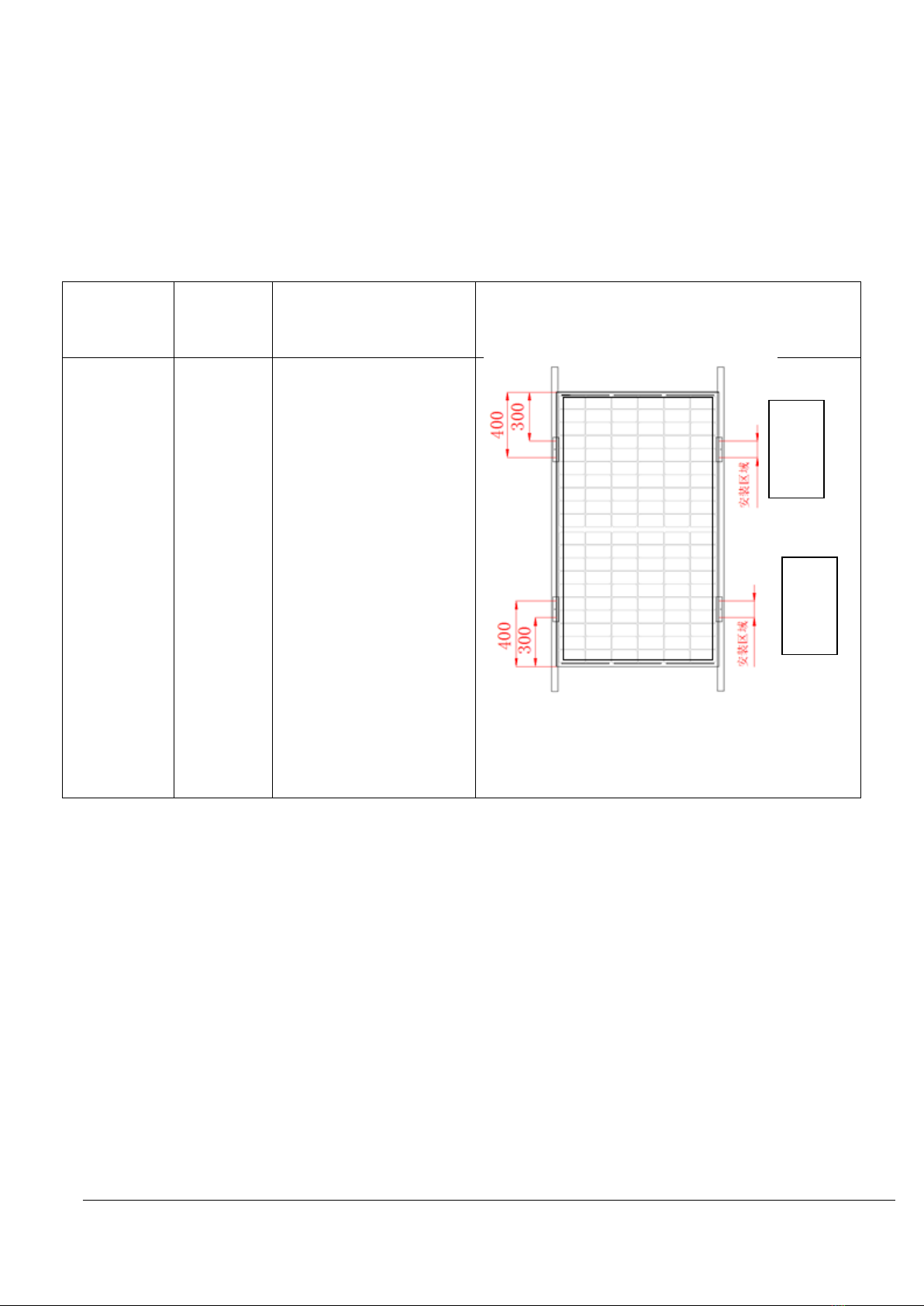

Clamps should be connected to the module between 300 and 400 mm from the edge of the module. This distance is from

the module edge to the middle of the clamp.

*NOTE: Need two support rails below the PV module to make sure the Mechanical load.

60Pcs MODULES (frameless)

Mechanical

Load

Pressure

Safety

Factor

Length Of The Clamp Mounting Direction

+1600 Pa /

-1600 Pa 1.5 150mm

(Half-cut cells Module)

*NOTE: The above-described distance is from

the module edge to the middle of the clamp.

*NOTE: Need two support rails below the PV module

to make sure the Mechanical load.

Mounting

area

Mounting

area

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 12 - of

21

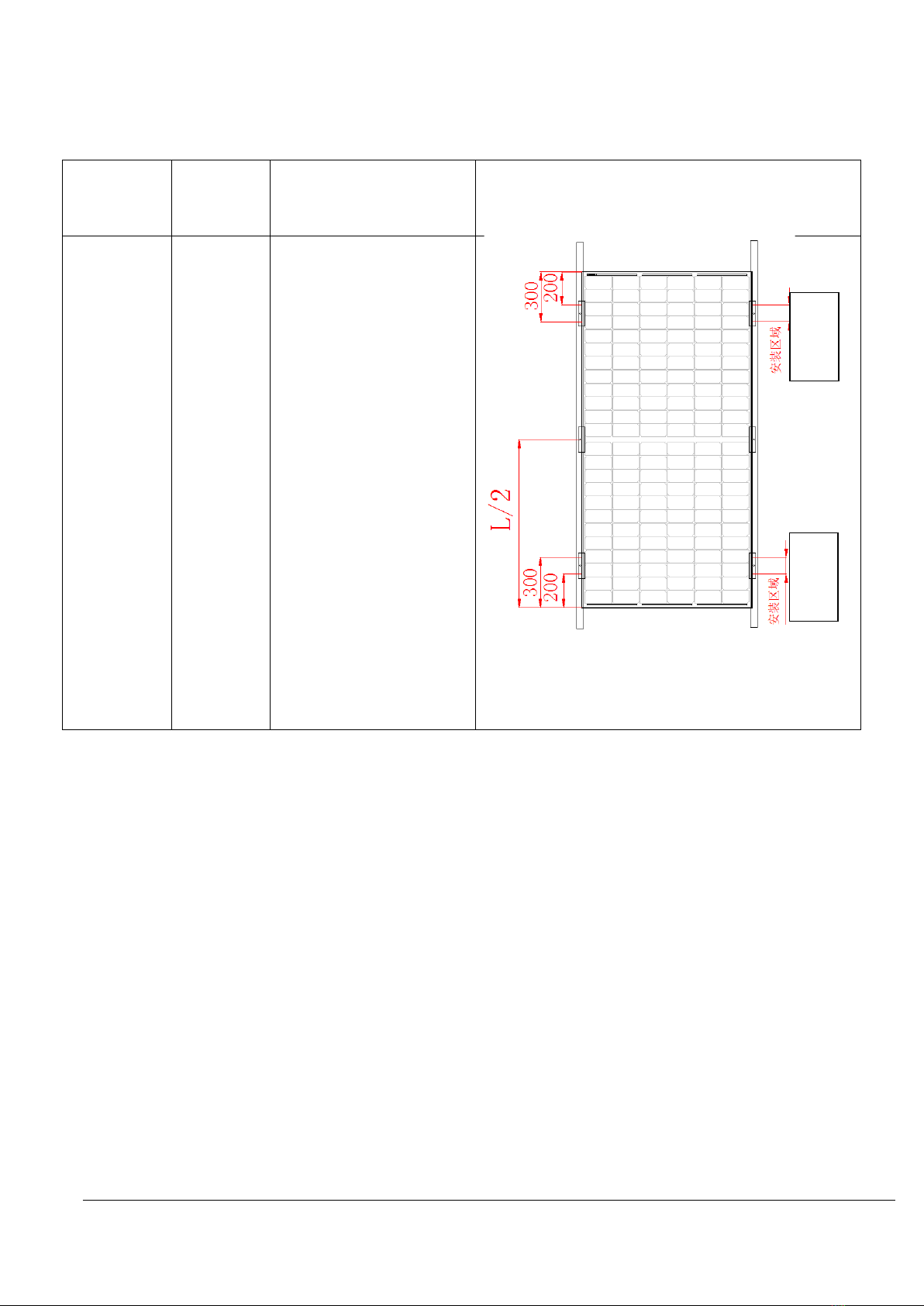

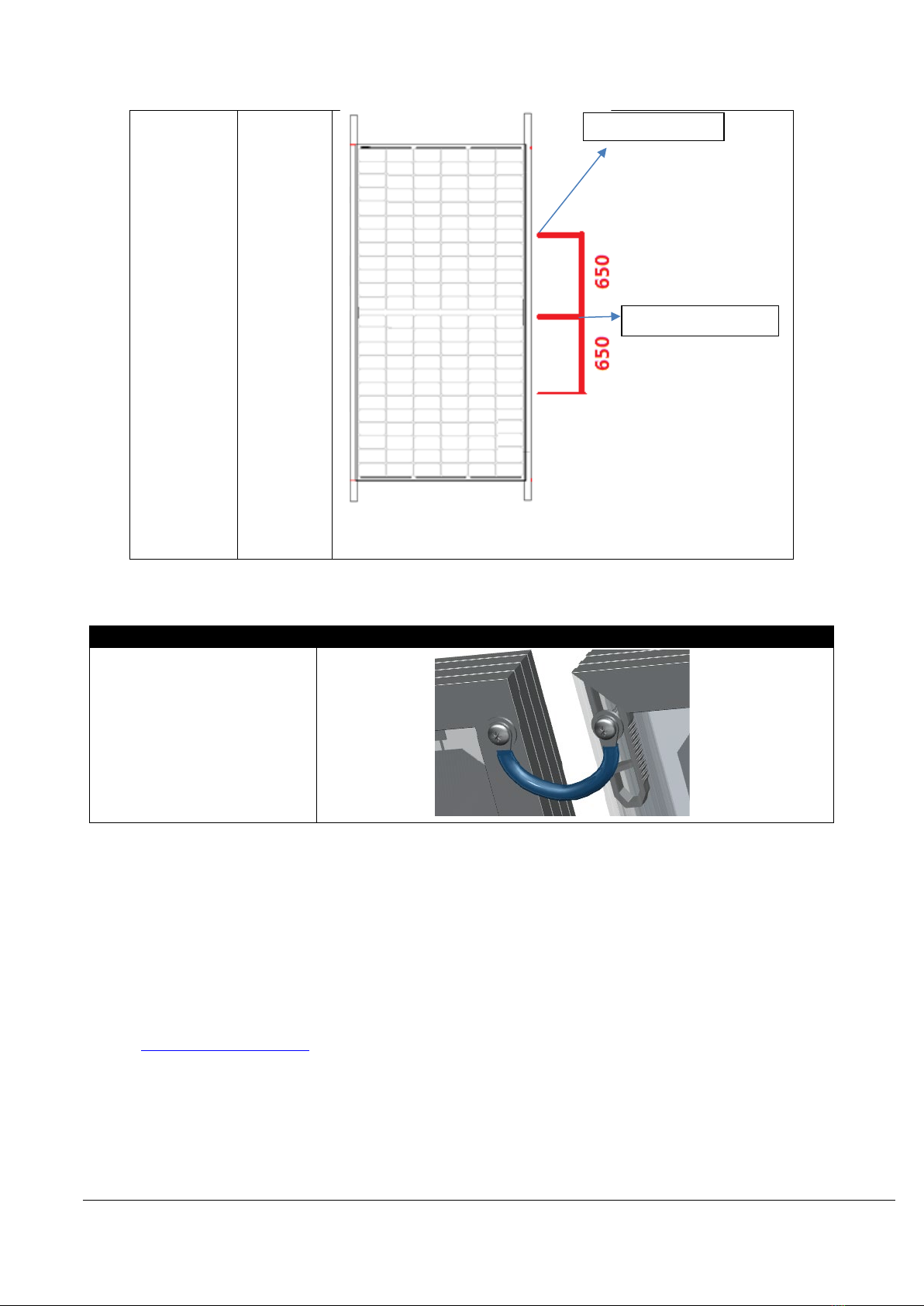

72Pcs MODULES (frameless)

Mechanical

Load

Pressure

Safety

Factor

Length Of The Clamp Mounting Direction

+1600 Pa

/-1600 Pa 1.5 150mm

(Half-cut Module)

*NOTE: The above-described distance is from the

module edge to the middle of the clamp.

*NOTE: Need two support rails below the PV

module to make sure the mechanical load.

6.2.2.1 Installation steps

Step 1: insert bolts

Setting the specified bolts into

the 4 holds of frame.

Step 2: Insert the bolt into the holes

Mounting

area

Mounting

area

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 13 - of

21

1. Lift up the module; ensure the

bolt over the racking.

2. Aim the bolt to racking.

3. Insert the bolt into the holes;

Step 3: Push the modules to the right position

Push the PV modules to the right

position, so that the bottom two

screws are in the middle of the

border screw slot.

Step 4: Fixed the bolts (Torque requirement of M8 bolts: 16~20Nm; )

flat washer, spring washer and

the Nuts are placed in turn, and

then tighten the nut. Repeat this

step and finish the 4 holes.

(16N·m~20N·m)

*Note: Don't place the screws in the slot

1. Lift up the modules

2. Insert the bolt into the holes

UP

DOWN

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 14 - of

21

6.2.2.2 TRINA FRAME COMPATIBILITY WITH VARIOUS RACKING SYSTEMS.

The following examples illustrate how to evaluate Trina Frame compatibility with various racking systems.

Please pay attention to the size from component battery to the edge of the frame, and the bracket or pad

shall not obscured the battery

Please note that the connection location should be reserved for bracket under the grounding hole.

Example A: zigzag racking installation

When selecting zigzag steel, please confirm the structural strength of profiles.

When selecting zigzag steel, please confirm the size and the hole position of it so that the gaskets,

washers and screws can be installed.

Please press the waist type wind hole at the bottom of zigzag steel.

Example C: C structure steel type 1 racking installation

When selecting C structure steel, please confirm the structural strength of pads.

When selecting C structure steel, please confirm the size and hole position of pads so that the gaskets, washers and

screws can be installed.

For C structure steel type 1 racking, due to the amount of space inside the racking section, many choices are

available including T-shape nuts.

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 15 - of

21

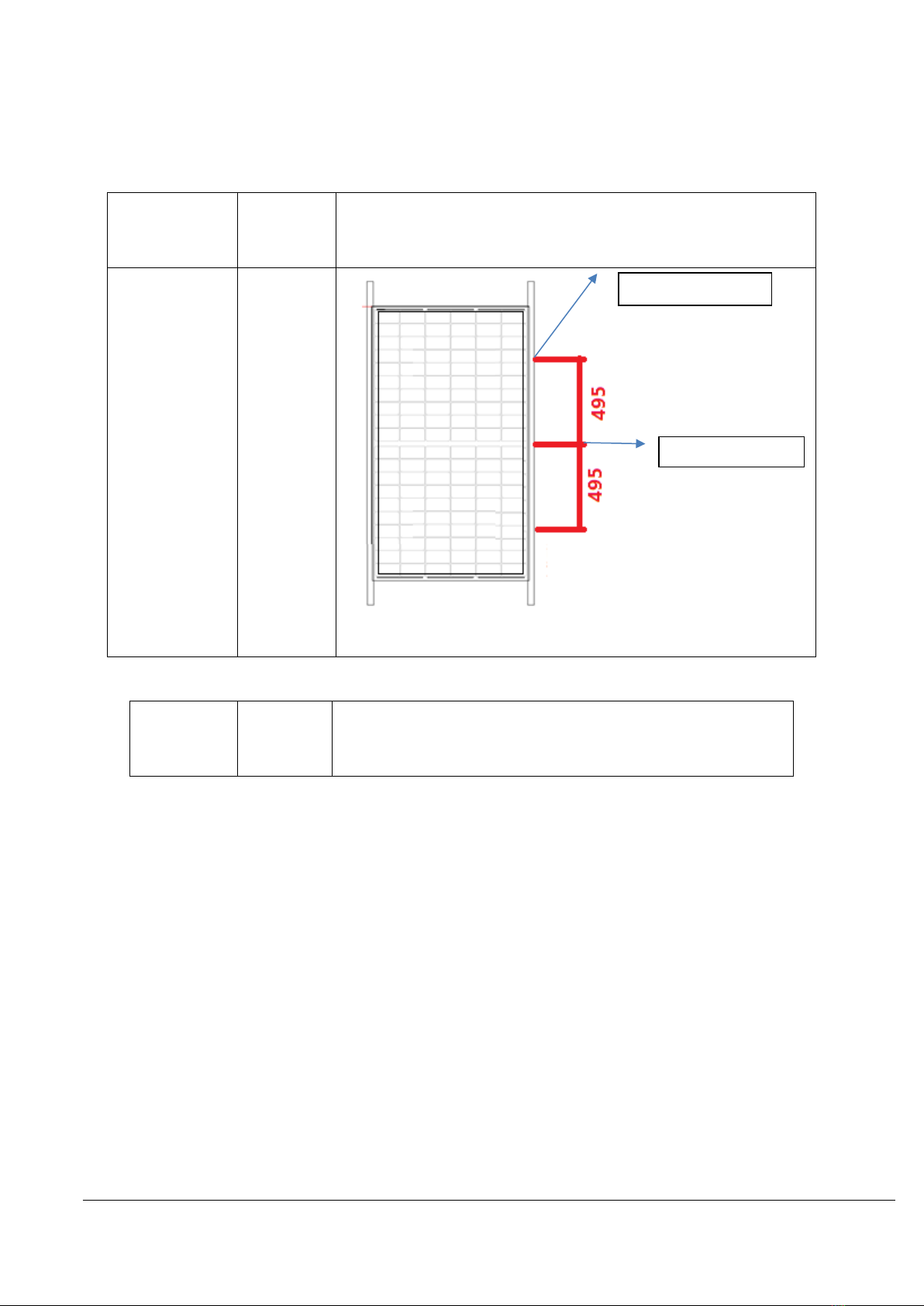

6.2.2.3 SCREW OPTIONS

CLAMP OPTIONS

60Pcs MODULES (frame)

Mechanical

Load

Pressure

Safety

Factor

Length Of The Clamp Mounting Direction

+1600 Pa /

-1600 Pa 1.5 150mm

(Half-cut Module)

*NOTE: The above-described distance is from

the module edge to the middle of the clamp.

*NOTE: Need two support rails below the PV module

to make sure the Mechanical load.

Mounting

area

Mounting

area

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 16 - of

21

72Pcs MODULES (frame)

Mechanical

Load

Pressure

Safety

Factor

Length Of The Clamp Mounting Direction

+1600 Pa

/-1600 Pa 1.5 150mm

(Half-cut Module)

*NOTE: The above-described distance is from the

module edge to the middle of the clamp.

*NOTE: Need two support rails below the PV

module to make sure the mechanical load.

Mounting

area

Mounting

area

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 17 - of

21

CLAMP OPTIONS

60Pcs MODULES (frame)

Mechanical

Load Pressure

Safety

Factor

Mounting Direction

+1600 Pa /

-1600 Pa 1.5

(Cut-half Module)

72Pcs MODULES (frame)

Mechanical

Load

Pressure

Safety

Factor

Mounting Direction

Fixed by bolt

1/2 module length

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 18 - of

21

+1600 Pa

/-1600 Pa 1.5

(

Cut-half Module

)

6.3 GROUNDING

Grounding of the modules (Grounding bolts: GB845-85-ST4.2*13-F-H: )

Star washer, flat washer,

grounding wire are placed in

turn, then screwed into the

grounding hole to bond the

adjacent modules

•All module frames and mounting racks must be properly grounded in accordance with appropriate respective

National Electrical Code.

•Proper grounding is achieved by bonding the module frame(s) and all metallic structural members together

continuously using a suitable grounding conductor. The grounding conductor or strap may be copper, copper

alloy, or any other material acceptable for use as an electrical conductor per respective National Electrical

Codes. The grounding conductor must then make a connection to earth using a suitable earth ground electrode.

•Trina Solar modules can be installed with the use of third party listed grounding devices for grounding the

metallic frames of PV modules. The devices have to be installed in accordance with the grounding device

manufacturer’s specified instructions.

•Please refer to the “Product Catalogue” link for detailed grounding hole locations and size at

http://www.trinasolar.com/

•Grounding hardware comes in a package that includes the grounding screw, flat washer、star washer and wire

•Electrical contact is made by penetrating the anodized coating of the aluminum frame, and tightening the

mounting screw (come with the star washer) to the proper torque of 25lbf.in.

•Grounding wire size (6 to 12 AWG solid bare copper) should be selected and installed underneath the wire

binding bolt.

Fixed by bolt

1/2 module length

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 19 - of

21

6.4 INSTALL EFFECT CHART

The install effect chart is as follows. Please consult with Trina Solar engineers to confirm whether the rails match Trina

clamp/frame or not. And confirm there are no shelter on the back of the modules.

7. MODULE WIRING

Each module has two 4mm2 diameter type standard 90°C sunlight resistant output cables each terminated with plug & play

connectors. This cable is suitable for applications where wiring is exposed to the direct rays of the sun. We recommend that

all wiring and electrical connections comply with the appropriate national electrical code(s).

For field connections, use the minimum 4mm2diameter copper wires insulated for a minimum of 90°C and sunlight

resistant as well.

The minimum and maximum outer diameters of the cable are 5mm to 7mm. Refer to Datasheet Specifications for the

maximum electrical rating of series fuse.

8. MODULE TILT ANGLE

Trina Solar PV modules connected in series should be installed at the same orientation and angle. Different orientation or

angle may cause loss of output power because each module may be exposed to different amounts of solar irradiation.

Trina Solar PV modules produce the most power when they are perpendicular to incoming sunlight. For installations where

the PV modules are attached to a permanent structure, the PV modules should be tilted for optimum winter performance.

The module tilt angle is measured between the solar modules and the ground. Optimal tilting of PV module is almost the

same as the latitude of installation location.

SPV module Tilt angle

Date: 2019.5.6 Doc No: PS-M-0691 Ver. A Page - 20 - of

21

9. MAINTENANCE AND CARE

•Under most weather conditions, normal rainfall is sufficient to keep the PV module glass surface clean. If dust or dirt

build-up becomes excessive, clean the glass only with a soft cloth using mild detergent and water.

•Do not clean the modules with cold water during the warmer hours of the day in order to avoid creating any thermal

shock that may damage the module.

•At least once a year, it is recommended to check the torque of terminal screws and the general condition of wiring.

Also, check that mounting hardware is properly torqued. Loose connections will result in damage of the array.

•Modules that are replaced must be the same type. Do not touch live parts of cables and connectors. Use appropriate

safety equipment (insulated tools, insulating gloves, etc.) when handling modules.

•Cover the front surface of modules by an opaque material when repairing. Modules when exposed to sunlight generate

high voltage and are dangerous.

•Trina Solar PV modules are equipped with bypass diodes in the junction box. This minimizes module heating and

current losses.

Do not try to open the junction box to change the diodes even if they malfunction.

In a system using a battery, blocking diodes are typically placed between the battery and the PV module output

to prevent battery discharge at night.

Trina Solar is a member of the European PV Cycle Association. Through the pre-financed PV Cycle program, Trina Solar

PV modules will be taken back and treated in an environmentally sustainable manner.*Applicable only to participating

countries within the Europe Union.

WARNING: For any electrical maintenance, the PV system must first be shut down. Improper maintenance can

cause lethal electric shock and/or burns.

10. SPECIFICATIONS

For module specifications, please see the Datasheet included in the shipment carton and visit Trina Solar website

www.trinasolar.com to get the datasheet of each product or the comprehensive product catalogue.

11. CONTACTS

These solar modules do not contain any user serviceable parts.

If you suspect that your installation is not working properly, then contact your installer immediately.

1. Contact your installer

2. Contact Trina Solar after-sales service team at: http://customerservice.trinasolar.com

3. Submit the Customer Feedback form at: www.trinasolar.com; one of our technical service representatives

will contact you as quickly as possible. A username and password is required to send feedback from the

customer service link

WARNING: For any electrical maintenance, the PV system must first be shut down. Improper maintenance

can cause lethal electric shock and/or burns.

12. HISTORY

Edition Revision Date Revised Item Revised Content

New Edition 2019.03.06 158 series half-cut modules

Other manuals for DUOMAX Series

3

Table of contents

Other Trina Solar Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual