Trion Comfort-D75 User manual

Table of Contents

Introduction����������������������������������������������������������������������������������������������� 2

Contents ��������������������������������������������������������������������������������������������������� 2

Unit Dimensions ��������������������������������������������������������������������������������������� 3

Specications ������������������������������������������������������������������������������������������� 4

Unit Location��������������������������������������������������������������������������������������������� 5

Install Location���������������������������������������������������������������������������������������6-7

Ducting ����������������������������������������������������������������������������������������������������� 8

Wiring �������������������������������������������������������������������������������������������������� 9-11

Electrical Requirements�������������������������������������������������������������������������� 12

Condensate Removal����������������������������������������������������������������������������� 12

Operation�������������������������������������������������������������������������������������������13-14

Maintenance������������������������������������������������������������������������������������������� 14

Parts Diagram����������������������������������������������������������������������������������������� 15

Warranty ������������������������������������������������������������������������������������������������� 16

Whole House Central Dehumidier

Comfort-DTM

Models: D75 and D95

266314-301 05/12

Please complete the following on the day of the installation�

Homeowner to retain for their future informational purposes�

Unit Model Number ___________________________

Serial Number _______________________________

Installation Date______________________________

Installing Contractor Name _____________________

Installing Contractor Phone _____________________

2

The benets of a properly humidied environment are many. They include personal

comfort as well as the preservation of furniture, draperies, carpets, wooden oors

and cabinets, paintings, pianos, etc� Higher humidity levels can also increase the

growth-rate of mold, bacteria, viruses, and even dust mites in the home� Your

home can be more comfortable at a warmer temperature with drier air than without

controlling humidity during the humid summer months� Since every degree of

temperature change represents about 3% to 5% of the total cooling costs, each

degree warmer you can set the thermostat can represent a signicant annual

savings�

During the cooling season, warm, moist air inltrates the home and must be cooled.

When cooled, this air can still be humid as air conditioners are designed to cool the

air, not dehumidify the air. A small amount of dehumidication may be a benet of

air conditioners, but they actually work harder and longer to cool the air when the

air is moist. Only by using a whole house dehumidier to reduce the humidity in the

entire home's air, can a balance between humidity levels, temperature, comfort,

and energy costs be optimized�

Introduction

Contents

The following items should be included with your Trion Comfort-D Dehumidier.

▪ Comfort-D75 or Comfort-D95 Dehumidier

▪ Installation/Operation Manual

▪ Condensate Drain Trap

▪ (4) Adjustable Support Legs

If any items are not found, please contact Trion Customer Service at 800-884-0002

to acquire replacements�

The following are a list of items that may be required for a complete installation:

▪ 8 inch (D75) or 10 inch (D95) exible duct to isolate vibrations from return duct.

▪ Ducting (Length and size based on type of installation and unit size.

See pages 6-7 of manual for installation types.)

▪ Remote Humidistat

▪ Condensate Pump

▪ 8 inch (D75) or 10 inch (D95) “take offs” for connection to HVAC duct work

▪ ¾” PVC pipe and ttings for completion of drain to pump, outside space,

or code approved service drain

▪ Level (unit must be level or slightly tilted toward drain outlet to drain properly)

▪ 18-20 gauge thermostat wire

Caution: Read the entire manual carefully and completely

before installing this product. Installation and maintenance

should be completed by qualied personnel. Installation

contrary to these guidelines may void warranty.

3

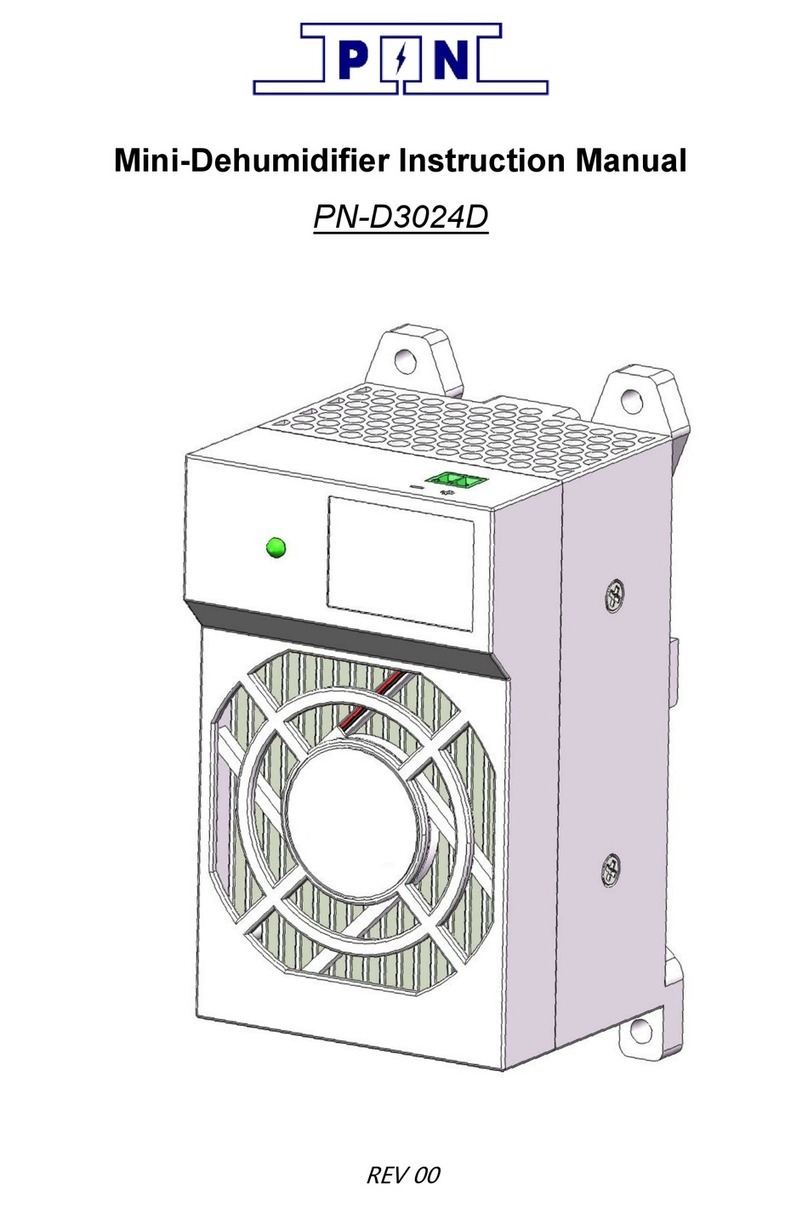

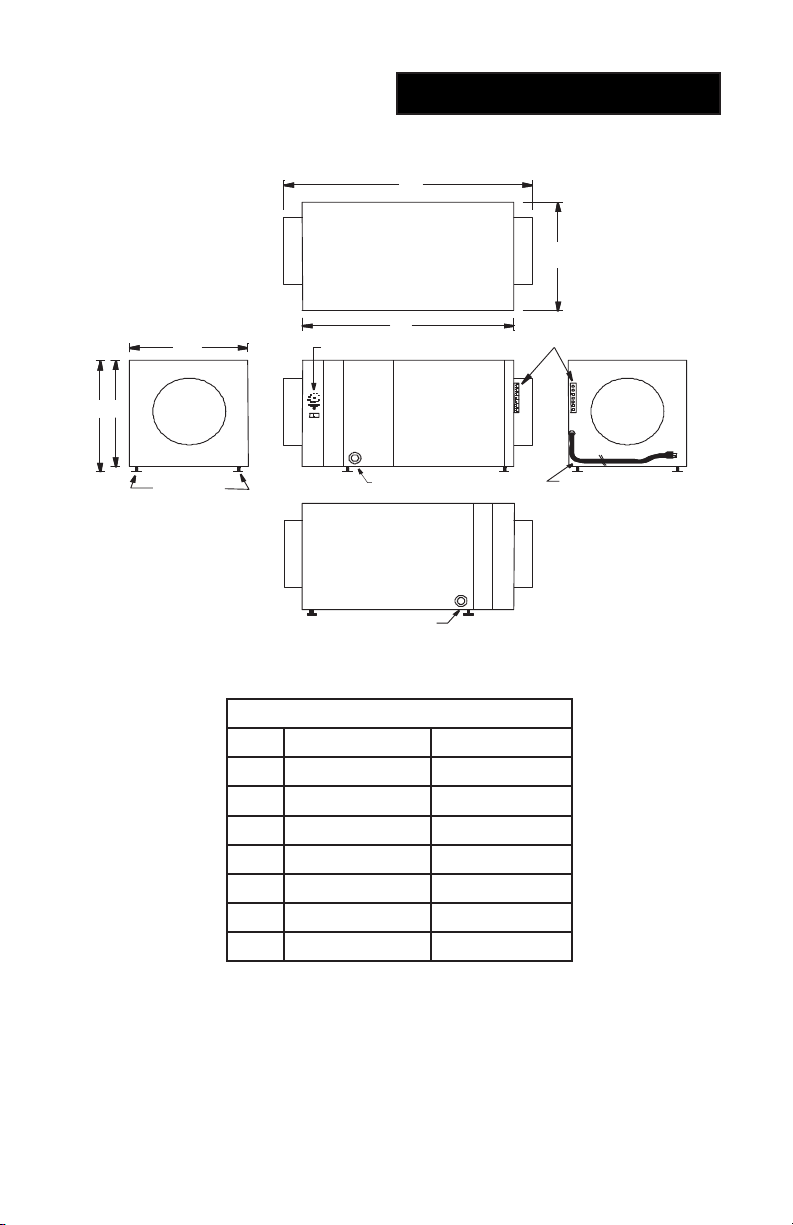

Unit Dimensions

A

C

B

B

Return Supply

FG

sseccAretliF

Filter Access

3/4" NPT Drain

3/4" NPT Drain Option

Factory Installed Plug

120 V Power Cord

Grounded - 90"

Service Access

Adjustable

Legs 1/4"- 1"

Low Voltage Terminal Strip

Humidistat Blower Control

TOP VIEW

FRONT VIEW

RIGHT SIDE

LEFT SIDE

BACK VIEW

D

E

Dimension Table

Comfort-D75 Comfort-D95

A 27�25 inch 29�25 inch

B 13�00 inch 14�25 inch

C 23�25 inch 25�25 inch

D 12�75 inch 14�25 inch

E 13�75 inch 15�25 inch

F 8�00 inch dia� 10�00 inch dia�

G 8�00 inch dia� 10�00 inch dia�

4

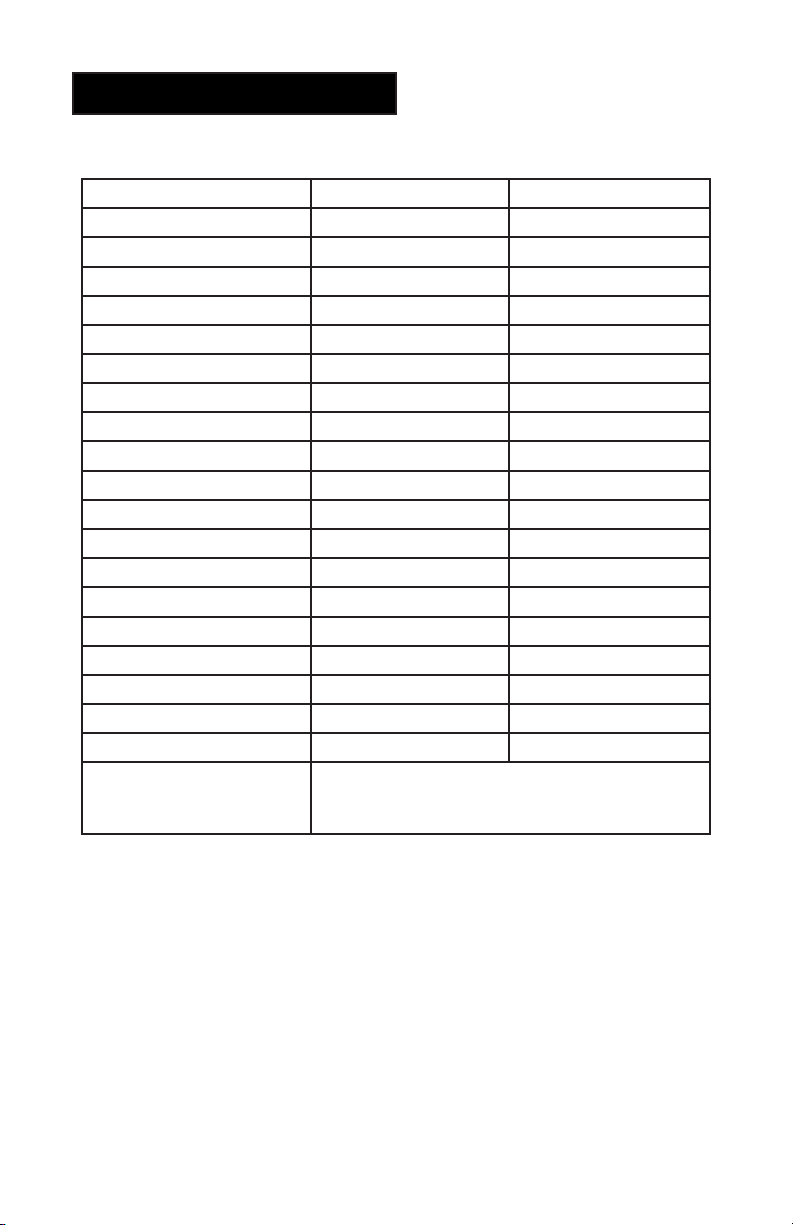

Model D75 D95

Capacity(@80°F,60% RH) 74 Pints/Day 95 Pints/Day

Temperature Range 50-95°F 50-95°F

Volts/Hertz 120V, 60Hz 120V, 60Hz

FLA (@80°F, 60% RH) 6�7 Amps 10�8 Amps

LRA (@80°F, 60% RH) 46�5 Amps 59�0 Amps

Inlet Diameter 8 inch round 10 inch round

Outlet Diameter 8 inch round 10 inch round

Unit Dims. (LxWxH) 27.25"x13.00"x12.75" 29.25"x14.25"x14.25"

Filter Dims (LxWxH) 11.75"x11.75"x2.00" 13.75"x13.75"x2.00"

Filter Efciency MERV 11 MERV 11

Compressor Size 5/8 HP 3/4 HP

Fan Motor Size 90 W 115 W

Refrigerant R-410A R-410A

Refrigerant Amount 17�5 oz 16�0 oz

Weight (Shipping Weight) 65 lbs (80 lbs) 90 lbs (105 lbs)

Energy Star Rated Yes No

ETL (USA & Canada) ANSI/UL STD 474,

Applicable Sections of ANSI/UL STD 1995,

CAN/CSA STD� C22�2 No�-92-197

Specications

5

The Comfort-D can be installed in a variety of locations to meet the owner's

needs as listed below� In all cases keep the following cautions in mind:

1� The unit is designed to be installed indoors in a space that is protected from

rain, ooding and/or other forms of excess water. Unit is not designed to be

exposed to chlorinated pool conditions or spaces where unit will be exposed

to corrosive chemicals or conditions�

2� Install the unit with space to access the front panel for maintenance and service�

Also allow easy access to the lter cover panel. DO NOT INSTALL UNIT

WITH THE FRONT PANEL OR FILTER COVER PANEL INACCESSIBLE.

3� Avoid discharging the air directly at people, over the water in pool areas, or

other areas or objects where dehydration or evaporation of moisture is not

desired�

4� If used near wet areas, be certain there is NO chance the unit could fall

into the water or be splashed and that it is wired into a GROUND FAULT

INTERRUPTER protected circuit�

5� A secondary drain pan MUST be placed under the unit if installed above a

living area or above an area where water leakage could cause damage (see

local codes for other requirements)

6. DO NOT position the Comfort-D directly on structural members where noise or

vibration may be objectionable. The unit is equipped with adjustable support

feet to raise and level the unit from the mounting surface, these adjustable

feet should be utilized to provide improved drainage from the drain pan and

should be adjusted to tilt slightly toward the drain utilized.

7� The Comfort-D should be located near the existing air handling system to

minimize the required ductwork for connecting of the Comfort-D to the existing

air handling system� When the remote control option is used, the control

(humidistat) unit must be located in the space that is to be conditioned. The

control (humidistat) may be low voltage (24 volt) and should be connected to

the Comfort-D with code approved, low voltage thermostat cable�

8� When locating the Comfort-D in areas of extreme heat or high humidity,

>120-degrees/90% humidity, additional external insulation may be required to

prevent undesired condensation on the exterior of the unit.

Unit Location

6

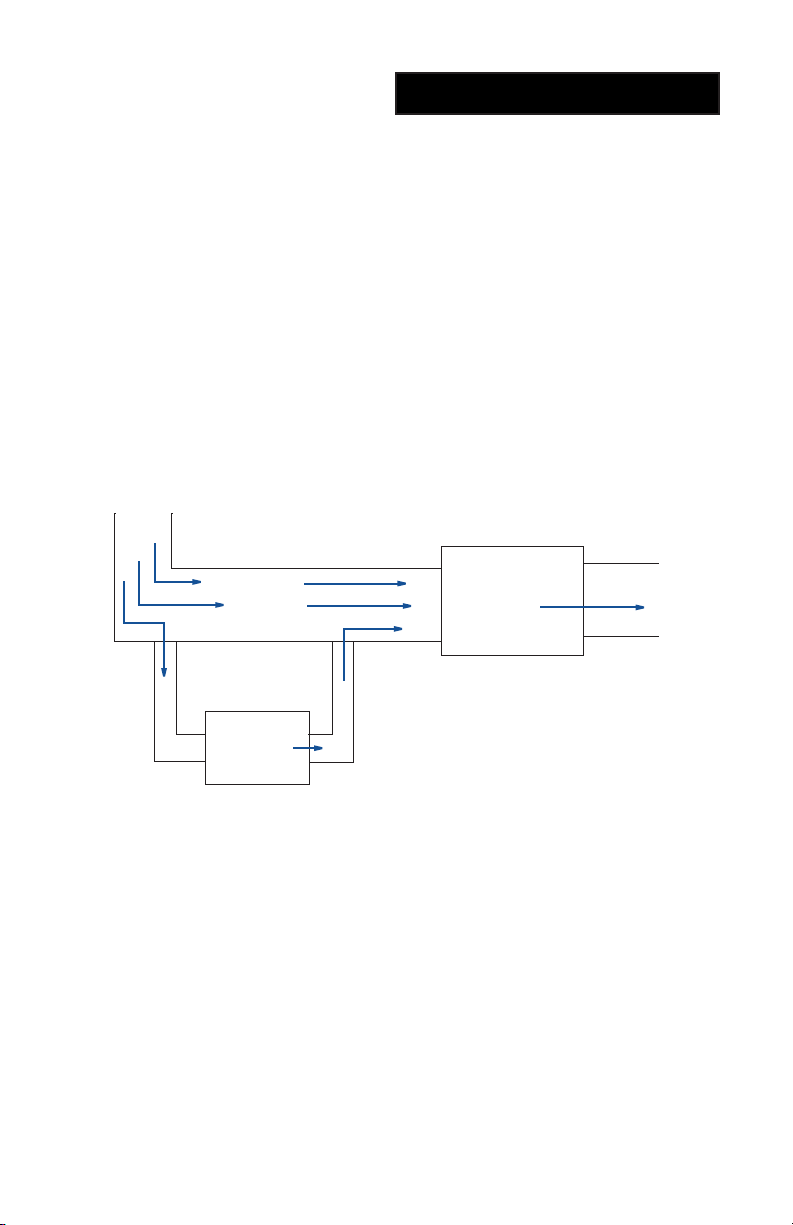

Comfort-D Dehumidiers are designed for installing as a Whole House Dehumidi-

er, but in some instances, Spot Dehumidication may be necessary. See below

for the type of installation that best ts the situation:

Whole Home Dehumidier Installations:

In a Basement or Crawl Space with an Existing Forced Air HVAC System

If the structure in which the Comfort-D System is to be installed has an existing

forced air HVAC system, utilize the HVAC system to make the Comfort-D System

installation easier and provide better system performance�

Basement or Crawl Space Installation: Install a separate 8" (D75) or 10” (D95)

return for the Comfort-D in a central area of the structure or if the return ducting is

adequate tap into the existing return duct system near the return air grill. Duct the

supply of the Comfort-D System to the return ducting of the existing HVAC system.

(See diagram on next page.) The fan interlock provision must be utilized for proper

system performance�

In an Attic with an Existing Forced Air HVAC System

ALWAYS install a secondary drain pan with a drain or oat interrupt for condensa-

tion under the Comfort-D in an attic to prevent condensate overow that may drip

down, damaging the ceiling or living space below�

Install a separate 8" (D-75) or 10” (D-95) return for the Comfort-D in a central area

of the structure or if the return ducting is adequate, tap into the existing return duct

system near the return air grill� Duct the supply of the Comfort-D System to the

return ducting of the existing HVAC system. The fan interlock provision must be

utilized for proper system performance�

Installation in a Structure with Two Forced Air HVAC Systems

Attach the Comfort-D return to an independent return from the upper level� At-

tach the Comfort-D supply to the return of the basement HVAC system. This will

promote circulation of air through the whole structure from the upper level to the

lower level through the Comfort-D. If the Comfort-D is not connected to both HVAC

systems, it may not control the humidity of the entire structure� The fan interlock

provision should be connected to the lower, ducted, HVAC system and must be

utilized for proper system performance�

Installation in a Structure with No Existing Forced Air HVAC System

When installing the Comfort-D in a structure that does not have a forced air HVAC

system, a single return for the Comfort-D should be installed in central open area

of the structure� DO NOT locate the return in a bathroom or a kitchen� The supply

of the Comfort-D should be located in the remote areas of the structure (such as

bedrooms, den, etc...). By ducting this way, the air inside the structure will circu-

late through the Comfort-D to be ltered and dehumidied. 5" (D75) or 6" (D95)

diameter duct is recommended for branches to the bedrooms, 6" (D75) or 8" (D95)

diameter duct is recommended for branches to larger areas�

Install Location

7

Install Location

Spot Dehumidier Installations:

Installation in a Sealed Crawl Space or Sealed Attic

When installing the Comfort-D in a sealed crawlspace or sealed attic, a single re-

turn for the Comfort-D should be installed in the central open area of the structure�

If the area is open without partitions, return ducting is not necessary� Supply duct-

ing is recommended to enhance the performance of the system, a minimum length

of supply duct, 3’ to 6’ will aid in air distribution. If the area(s) being served are

divided by walls or partitions, a supply and return duct system is recommended�

In all cases, sound duct design practices must be followed such as those provided

in ACCA Manual “D”, or ASHRAE’s “Fundamentals of Air System Design”.

Typical Installation Diagram

Comfort-D

RETURN AIR

AIR HANDLER SUPPLY AIR

8

Ducting

Installing Duct

The Comfort-D is equipped with either an 8" (D75) or 10” (D95) round duct collar

inlet, and an 8" (D75) or 10” (D95) round exhaust/supply collar that provides for

connecting to the supply distribution system� In all cases sound duct design prac-

tices must be followed such as those provided in ACCA manual “D”, or ASHRAE’s

“Fundamentals of Air System design”.

Ducting for Dehumidication

For the ideal installation, draw air from the central part of the home and return it to

the isolated areas of the home like the bedrooms, den, utility room, or family room�

The ductwork of the existing HVAC system can be used to supply air to the home.

If the existing supply duct adequately serves all areas of the home, discharge the

supply air of the Comfort-D into the return of the existing HVAC system where it

can distributed throughout the space. The existing return duct, if adequate, may

be used as return for the Comfort-D� DO NOT draw air directly from the kitchen,

laundry, or isolated basement� You may draw air from a basement that is open to

the home. All exible ducting connected to the Comfort-D should be approved by

local codes and in most cases insulated�

Return air ducts should be designed to allow unimpeded air ow to the return side

of the system. For returns less than 10 feet in length, an 8" (D75) or 10” (D95)

round or equal may be utilized� Multiple returns are acceptable�

The supply air outlet and the return air inlet are located on each end of the Com-

fort-D. A length of acoustical ex ducting on the outlet of the Comfort-D will reduce

air noise from the fan. A length of exible ducting on all Comfort-D duct connec-

tions is recommended to reduce noise and vibration transmitted to rigid ductwork

in the structure�

Ducting the Comfort-D as mentioned in the “Ducting” sections requires consider-

ation of the following points:

Duct Sizing: For total duct lengths up to 10', use a minimum 8" (D75) or 10” (D95)

diameter round or equivalent rectangular� For longer lengths, up to 25’, use a mini-

mum 10" (D75) or 12" (D95) diameter or equivalent duct size. Grills or diffusers

utilized must not excessively restrict airow.

Isolated Areas: Effective dehumidication may require that ducting be branched

to isolated, stagnant areas. Use 8" (D75) or 10” (D95) or larger diameter branch

ducting to each of two or three areas, use 6" or larger to each of four or more areas�

Connecting to Existing HVAC Systems: For proper operation, connecting to

existing air handler and duct systems requires the fans of each system to be in-

terlocked utilizing the low voltage interlock method provided in the Comfort-D low

voltage connection diagram� Refer to low voltage connection diagram in this docu-

ment and on the unit�

9

Wiring

Freeze

Stat

Blower Motor

Compressor

S

R

C

Fan Relay

Compressor

Run Capacitor

120 Volt 60Hz 15 Amp

1 Phase Power Supply

Compressor Relay

GT GF RF

D GCR

Humidistat / Ventilation Control

Blower InterLock Connections (Low Voltage)

Fan C oil / Air H and ler

C ontrol Ther mos tat ( Ty p)

G

R

W

Y

G

R

W

Y

Existing Field Supplied

Control Wiring (Typ)

Field Supplied Control Wiring

D is c onn ec t Ex is ting C ontrol Wir ing

From Fan (G) C ontrol Ter minal.

Rec onnect to Blue Wire From Comfort-D.

Connec t Brow n Wire From Comfort-D

To Fan (G) Terminal.

Org Brn

Blu

Wiring Connections Line and Low Voltage

GT

GF

RF

Red

Wht

Gry

Y el

Or g

B rn

B lu

Blower Motor

Run Capacitor

Low Voltage Terminal

Transformer

Humidistat

OPTIONAL

*

*

*

Remove J umper IfFan Control Is Us ed

Molex 50-84-1040

Comfort-D Wire Diagram

10

Wiring

Trion Humidistat / Fan Control

Furnace/Air Handler Interlock

C R D

"G" Terminal on existing Thermostat

"G" Terminal on Furnace or Air Handler

(24V Hot) "R" Terminal on Furnace or Air Handler

Low Voltage Terminal

R C H D G

Remove Existing Wire Betw een T-stat "G" and AH/Furnace "G"

*

*

*

G GT GF RF

Wire Diagram - With Humidistat

11

Wiring

Trion Humidistat / Fan Control

Furnace/Air Handler Interlock

C R D G GT GF RF

"G" Terminal on existing Thermostat

"G" Terminal on Furnace or Air Handler

(24V Hot) "R" Terminal on Furnace or Air Handler

Low Voltage Terminal

R C H D G

Humidifier

H H

Field supplied

24 volt relay

Remove Existing Wire Betw een T-stat "G" and AH/Furnace "G"

N.O.

*

*

Wire Diagram - With Humidistat and Humidier

Blower InterLock Connections (Low Voltage)

F a n Co il / Air Ha n d le r Co n tr o l

T h e r m o sta t ( Typ )

G

R

W

Y

G

R

W

Y

Existin g Fie ld S u p p lie d

Co n tr o l Wir in g ( T yp )

F ie ld Su p p lie d

Co n tr o l Wir in g

Disco n n e ct E xistin g Control

Wir in g From Fan (G) Control

T e r m in a l. Reconnect to Blue

Wir e F r o m Comfort-D.

Co n n e ct Br o wn Wir e Fr o m

Comfort-D T o F a n ( G )

T e r m in a l

O r g

Br n

GT

GF

RF

R C D

G

Gt Gf Rf

Close on RHRise

Optional Humidistat Control

See Installation Manual For

Other Control Wiring Options

Blu

Wire Diagram - Field Connections

12

Electricals

Electrical Requirements:

The Comfort-D is equipped with an appliance cord and may be plugged directly

into a 120 volt, 15 amp household type convenience outlet� If used in a wet area

such as an indoor pool, spa room, or an area prone to ooding (basement or

crawlspace), a ground fault interrupter protected circuit is required. In all cases

local codes precede over all installation and wiring recommendations�

If a remote wall mounted Humidistat is utilized, install the Humidistat control in a

central area of the structure where it will sense the relative humidity of the struc-

ture accurately� Do not install the control where it may not accurately sense the

relative humidity: near HVAC supply registers, near exterior doors, or near a pool

or spa� Do not install the control in an area not served by the Comfort-D� The in-

staller must supply the wiring between the Comfort-D and the Humidistat control�

Be sure to safely route the control wiring to prevent damage during installation�

Be careful not to cross the wires when connecting the Comfort-D and the control,

or damage to the transformer may result�

When a remote Humidistat is utilized, set the unit mounted humidistat to the

“OFF” position.

Consult the electrical schematic in this manual or on the access panel of the

Comfort-D before making the control connections�

Condensate Removal:

Condensate drains by gravity, via the ¾” PVC drain outlet located at two loca-

tions, front side and back side� Use of both is not required� As shipped the rear

drain is plugged, and may be removed and placed into the front drain outlet if the

rear outlet is used� Also included with the unit is the condensate drain trap� This

trap must be used to allow the unit to drain properly during operation and prevent

air from being drawn from the area where the unit is located� A condensate pump

kit (by others) may be required if a lift is necessary to dispose of the condensate.

If a condensate pump is used, the condensate trap is still necessary and must be

installed between the unit and pump� When the condensate drain is located in,

or passes through, a non-conditioned space, the condensate piping should be in-

sulated to prevent sweating, which may cause damage� Double trapping should

be avoided and will cause drainage problems if encountered�

Condensate

13

Operation

Operation:

The Comfort-D is designed to deliver dehumidied, ltered air to the living space,

and is equipped with an onboard humidistat and fan control and can be equipped

with various accessories to enhance its operation, including a remote humidistat,

and your system may incorporate any or all of the described operational compo-

nents�

It is recommended that the indoor environment maintain a maximum relative hu-

midity level of 50% to 60%� Other factors may dictate a relative humidity level

different than the recommended, such as musical instruments, antiques, books/

papers, or special situations� Winter minimum humidity levels of 30-35% may not

be attainable without supplemental humidication (Humidier), and may not be

desired during times of low outdoor temperatures�

System Variations:

Humidity Control - Standard:

The system may be installed as free standing or incorporate ducting to an area or

existing heating/cooling system. Control is provided by Humidistat with a dial stem

type adjustment built into the unit. Set the desired humidity set point by turning

the dial stem at to the corresponding set point indicated on the face of the unit.

This humidity control unit will operate the compressor and circulation fan when the

dehumidication system is activated, working only when there is a call, or demand

for dehumidication.

Remote Humidity Control (Wall Mounted):

When a remote Humidistat is utilized, set the unit mounted humidistat to the “OFF”

position�

This control provides the same control functions as above but with greater preci-

sion and can be located in the space for easier access, and may included addi-

tional features� Available as an accessory item these controls may have different

features; refer to instructions included with the control�

Typical system operation sequence:

Upon the relative humidity exceeding the humidistat set point, normally by approxi-

mately 3%, the humidistat will energize the dehumidication and air circulation

components of the Comfort-D� If the Comfort-D system is connected and inter-

locked with an existing Heating/Air Conditioning system, this systems circulation

fan will also be energized� The Comfort-D will continue to operate until the humidity

level is reduced to the set point selected on the humidistat and then will cycle off�

During this cycle, the air circulated through the Comfort-D system will be ltered

and dehumidied. If an outside ventilation air duct has been installed, fresh air will

be ltered and dehumidied and introduced to the space during this cycle.

14

Coil Freeze Protection (Auto Defrost):

The dehumidication coil (evaporator) is equipped with a low temperature freeze

thermostat; if the coil temperature is reduced to the point of ice buildup, this ther-

mostat will open the compressor control circuit while allowing the fan to continuing

running� Once the coil has returned to normal conditions the control will close and

allow the compressor to re-start� The prevailing conditions of the return air, tem-

perature and humidity, will determine the length of this cycle�

High Efciency Air Filter:

The Comfort-D is supplied with a 2” pleated high efciency air lter. The 2” lter is

rated MERV 11, and is more efcient than standard air lters and is able to catch

much smaller particles that can aggravate allergies� Operating the unit with a dirty

lter will reduce dehumidier capacity and efciency and may cause the compres-

sor to cycle off and on unnecessarily� Under normal operating conditions, the

lter will last approximately 6 months. However, in high particulate concentrations

more frequent replacements may be required. It is recommended that the lter be

inspected regularly for the rst three to four months to determine the loading and

correct replacement intervals� Your installation contractor should be contacted for

assistance�

To access the air lter, remove the lter access panel from the Front or Back side

of the unit, marked “Filter Access”. The lter should be readily visible and can be

removed by pulling it straight out of the unit�

Replacement lters can be purchased from your installation contractor or ordered

from the factory if a local representative is not available� DO NOT operate the unit

without the lter, or with a less effective lter than originally supplied. The heat

exchange coils inside the unit could become clogged and require disassembly

to clean. FAILURE TO MAINTAIN SERVICE AND CLEAN FILTERS WILL VOID

WARRANTY�

Oiling & Lubrication:

The fan motor is factory lubricated and sealed, and no further oiling is required�

There are no other components requiring the addition of lubricants�

Optional Fresh Air Ventilation (OSA):

If your system includes the optional fresh air system, it will have an outside air

intake� Check and clean the screen on the outdoor fresh air intake seasonally�

The intake screen must remain clear of any debris that could restrict airow into

the system� This intake should never be located where undesirable fumes, gases

or odors make be taken up by the intake� In all cases local codes prevail as to the

location of fresh air intakes�

Operation

Maintenance

15

1

2 & 3 Not Shown

8 Not Shown (Opposite Side)

4

5 Not Shown

6

7

20

9

10

11 & 21

13 & 22 Not Shown 17 18 14 12

13 Not Shown

15

15

16

19

Unit Diagram

Item No. D75 P/N D95 P/N Description

- 266314-001 266314-002 Complete Unit

1 266314-011 266314-012 Drain Pan

2 N/A N/A PVC Drain Trap

3 N/A N/A PVC Drain Adapter 3/4"

4 266314-021 266314-022 MERV 11 Filter

5 266314-031 266314-032 8' Power Cord

6 266314-041 266314-041 Compressor Run Capacitor

7 266314-042 266314-043 Fan Run Capacitor

8 N/A N/A Drain Plug 3/4" MNPT

9 266314-051 266314-051 Curtis Terminal Block

10 266314-061 266314-061 Leveling Mount Foot Base

11 N/A N/A Evaporated Coil

12 N/A N/A Coil, Condenser

13 N/A N/A R-410A Refrigerant

14 266314-071 266314-072 Blower, 115 volt, backward curve

15 N/A N/A 8"/10" Collar

16 266314-081 266314-081 Humidistat

17 266314-091 266314-091 Transformer, 120/24v 20 VA

18 266314-101 266314-101 Relay, Blower, 24V

19 266314-101 266314-102 Relay, Compressor, 24V

20 266314-111 266314-112 Compressor

21 N/A N/A Accumulator, Assembly

22 266314-121 266314-121 Internal Freeze Stat

16

Warranty

Dehumidier Limited Warranty

Applies in U�S�A� and Canada Only

FAILURE TO MAINTAIN YOUR EQUIPMENT WILL VOID THIS WARRANTY. COVERED EQUIPMENT

The following Trion Product equipment is covered by the Limited Warranty:

Whole House Dehumidier Units: Comfort-D75 and Comfort-D95

ONE (1) YEAR COVERAGE—RESIDENTIAL APPLICATIONS

The covered equipment and covered component are warranted by Trion for a period of one (1) year from the date of the original installation,

when installed in residential applications� If, during this period, a covered component fails because of a manufacturing defect, Trion will

provide a free replacement part to the owner through a licensed service contractor� You must pay shipping charges and all other costs of

warranty service, Trion will not pay labor involved in diagnostic calls or in removing, repairing, servicing or replacing parts� Such costs may

be covered by a separate warranty provided by the installer�

EXTENDED COVERAGE - COMPRESSORS

Comfort-D75 and Comfort-D95 —Five (5) Years

Extended warranty coverage on compressors applies to the original equipment purchaser, subject to proof of purchase, and is not transfer-

able. Compressor warranty is ve (5) years in all residential applications.

NOTE: If the date of original installation cannot be veried, the warranty period will be deemed to begin two (2) months after the date of

manufacture�

EXCLUDED COMPONENTS

The following components are not covered by this warranty: cabinets, cabinet pieces, air lters, driers, refrigerant, refrigerant line sets,

belts, wiring, fuses, oil nozzles and unit accessories�

REPAIRS

All repairs of covered components must be made with authorized service parts by a licensed service dealer or contractor� Labor charges

are not covered by this warranty� Such costs may be covered by a separate warranty provided by the installer�

CARE OF EQUIPMENT

Your new unit must be properly installed, operated and maintained in accordance with the unit installation, operation and maintenance

instructions provided with each unit� Failure to provide maintenance according to Trion's instructions will void this warranty� You may be

asked to provide written documentation of annual and other periodic preventive maintenance�

WARRANTY PROCEDURE

When warranty parts are required:

1. Be prepared to furnish the following information: a) Complete model and serial number, b) Proof of required periodic maintenance,

installation date and location, c) An accurate description of the problem.

2� Call your local licensed service dealer or contractor�

3� If the installing dealer is unavailable or unable to provide warranty, consult a licensed service dealer or contractor in your area or contact:

Trion IAQ

101 McNeill Road

Sanford, NC 27330

WARRANTY LIMITATIONS

1� This warranty is void if the covered equipment is removed from the original installation site�

2� This warranty does not cover damage or defect resulting from:

a) Flood, wind, re, lightning, mold, or installation and operation in a corrosive atmosphere, or otherwise in contact with corrosive mater-

ials (chlorine, uorine, salt, recycled waste water, urine, fertilizers, or other damaging substances or chemicals)

b) Accident, or neglect or unreasonable use or operation of the equipment including operation of electrical equipment at voltages other

than the range specied on the unit nameplate (includes damages caused by brownouts)

c) Modication, change or alteration of the equipment, except as directed in writing by Manufacture

d) Operation with system components (indoor unit, outdoor unit and refrigerant control devices) which do not match or meet the specica-

tions recommended by Manufacture

e) Use of contaminated or alternate refrigerant

The installation of replacement parts under the terms of this warranty does not extend the original warranty period.

Trion makes no express warranties other than the warranty specied above. All implied warranties, including the implied warranties of

merchantability and tness for a particular purpose, are excluded to the extent to a period legally permissible. Should such exclusion or

limitation of the warranty be unenforceable, such implied warranties are in any event limited to a period of one (1) year. Liability for incidental

and consequential damages is excluded. Some states do not allow limitation of incidental damages, so the limitations or exclusions may

not apply to you�

Trion will not pay electricity or fuel costs, or increases in electricity or fuel costs, for any reason whatsoever, including additional or unusual

use of supplemental electric heat. This warranty does not cover lodging expenses or labor charges. Trion shall not be liable for any default

or delay in performance under this warranty caused by any contingency beyond its control. This warranty gives you specic legal rights,

and you may also have other rights which vary from state to state� Keep this warranty and your sales slip together for future reference� You

must provide proof of purchase or installation date for in-warranty service�

Write down the following information about your Dehumidier on the front cover to better help you obtain assistance or service if you ever

need it. You will need to know the complete model and serial number. You can nd this information located on the rating plate on the outside

panel for all models�

Trion® | 101 McNeill Road | Sanford, NC 27330

Phone: 800-884-0002 | Fax: 800-458-2379

Web: www.trioniaq.com | Email: [email protected]

This manual suits for next models

1

Table of contents

Other Trion Dehumidifier manuals

Popular Dehumidifier manuals by other brands

Puregas

Puregas Altec AIR P8400W user guide

Domnick Hunter

Domnick Hunter Pneudri Midas Series instruction manual

Mitsubishi Electric

Mitsubishi Electric MJ-E14CG-S1-SWE instruction manual

EdgeStar

EdgeStar DEP501WP owner's manual

Aertesi

Aertesi VESTA 80 FVI Instruction, operating and maintenance manual

El-Björn

El-Björn A 75FT manual