INSTRUCTIONS CM453

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 3 of 4

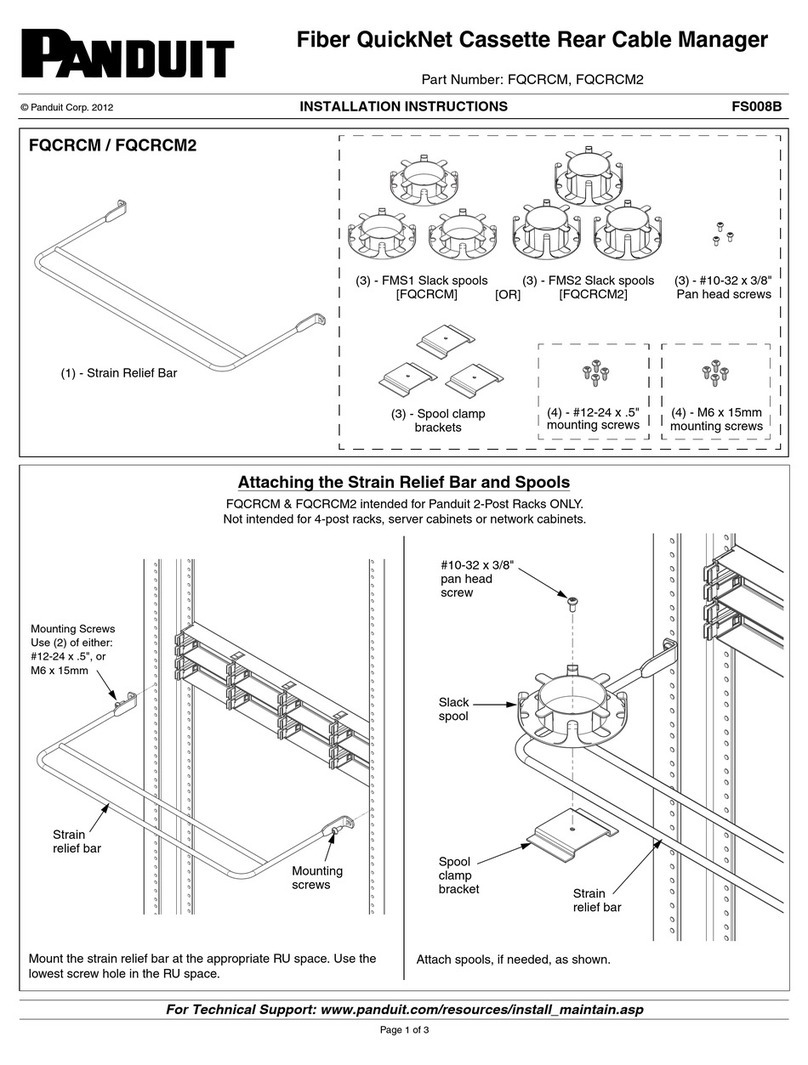

Extend Telescoping Duct Assembly

Extend upper tier of duct assembly to desired height and install (4) #10-32 Phillips screws and lockwashers to support upper tier. Tighten all

#10-32 Phillips screws to 26 in-lbs. 2” spacing of threaded holes in upper tier of exhaust duct allows for variable height adjustment of

exhaust duct. 2” long slot in lower tier allows for additional fine adjustment of upper tier height.

TOP COLLAR NOT SHOWN IN VIEW FOR CLARITY

Install Screws

(4) #10-32 Phillips Screws

and Lockwashers

(4) #10-32 Phillips Screws

and Lockwashers

NOTE: Top collar is not shown

in view to add clarity.

2” Threaded Hole Spacing

(Upper Tier)

allows for variable adjustment

of exhaust duct height

2” Long Slot (Lower Tier)

allows for fine adjustment of

upper tier height

Extend Top Collar

Position top collar to desired height and install (4) #10-32 Phillips screws and lockwashers to support top collar as shown. Loosen #10-32

Phillips screws to make fine adjustments of top collar and tighten screws to secure top collar in postion. Tighten all #10-32 Phillips screws

to 26 in-lbs. Screws and lockwashers must be removed and re-installed to a different set of threaded holes to allow for an adjustment

greater than 2”.

Tighten ALL #10-32 Phillips

Screws to 26 in-lbs