Tritech SuperZip User manual

SuperZip

SuperZip

Product Manual

0711-SOM-00003, Issue: 05

SuperZip

0711-SOM-00003, Issue: 05 2 © Tritech International Ltd.

© Tritech International Ltd

The copyright in this document is the property of Tritech International Ltd. The document is supplied by Tritech International Ltd on

the understanding that it may not be copied, used, or disclosed to others except as authorised in writing by Tritech International Ltd.

Tritech International Ltd reserves the right to change, modify and update designs and specifications as part of their ongoing

product development programme.

All product names are trademarks of their respective companies.

SuperZip

0711-SOM-00003, Issue: 05 3 © Tritech International Ltd.

Table of Contents

Help & Support ............................................................................................ 4

Warning Symbols ........................................................................................ 5

1. Introduction .............................................................................................. 6

2. Specification ............................................................................................ 7

3. Installation ............................................................................................... 8

3.1. Mounting ....................................................................................... 8

3.2. Water Hoses ................................................................................. 9

3.3. Hydraulics ................................................................................... 10

3.4. Seal Compensator ...................................................................... 12

4. Operating Principles .............................................................................. 13

4.1. Suction ........................................................................................ 13

4.2. Jetting .......................................................................................... 14

4.3. Testing in Air .............................................................................. 14

5. Maintenance .......................................................................................... 15

5.1. General Guidelines ..................................................................... 15

5.2. Basic Procedures ........................................................................ 15

5.3. Dismantling ................................................................................. 17

5.4. Re-assembly ............................................................................... 18

6. Troubleshooting ..................................................................................... 23

A. Motor Protector Assembly Procedure .................................................. 24

B. Parts List and Exploded Diagram ........................................................ 26

SuperZip

0711-SOM-00003, Issue: 05 4 © Tritech International Ltd.

Help & Support

First please read this manual thoroughly (particularly the Troubleshooting

section, if present). If a warranty is applicable, further details can be found in

a Warranty Statement at the end of the manual.

Tritech International Ltd can be contacted as follows:

Mail

Telephone

Email

Website

Tritech International Ltd

Peregrine Road

Westhill Business Park

Westhill, Aberdeenshire

AB32 6JL, UK

+44 (0)1224 744111

www.tritech.co.uk

Prior to contacting Tritech International Ltd please ensure that the following

is available:

1. The Serial Numbers of the product and any Tritech International Ltd equipment connected

directly or indirectly to it.

2. Software or firmware revision numbers.

3. A clear fault description.

4. Details of any remedial action implemented.

Contamination

If the product has been used in a contaminated or hazardous

environment you must de-contaminate the product and report

any hazards prior to returning the unit for repair. Under no

circumstances should a product be returned that is contaminated

with radioactive material.

The name of the organisation which purchased the system is held on record

at Tritech International Ltd and details of new software or hardware packages

will be announced at regular intervals. This manual may not detail every

aspect of operation and for the latest revision of the manual please refer to

www.tritech.co.uk

Tritech International Ltd can only undertake to provide software support of

systems loaded with the software in accordance with the instructions given in

this manual. It is the customer's responsibility to ensure the compatibility of

any other package they choose to use.

SuperZip

0711-SOM-00003, Issue: 05 5 © Tritech International Ltd.

Warning Symbols

Throughout this manual the following symbols may be used where applicable

to denote any particular hazards or areas which should be given special

attention:

Note

This symbol highlights anything which would be of particular

interest to the reader or provides extra information outside of the

current topic.

Important

When this is shown there is potential to cause harm to the

device due to static discharge. The components should not be

handled without appropriate protection to prevent such a discharge

occurring.

Caution

This highlights areas where extra care is needed to ensure that

certain delicate components are not damaged.

Warning

DANGER OF INJURY TO SELF OR OTHERS

Where this symbol is present there is a serious risk of injury or

loss of life. Care should be taken to follow the instructions correctly

and also conduct a separate Risk Assessment prior to commencing

work.

SuperZip

0711-SOM-00003, Issue: 05 6 © Tritech International Ltd.

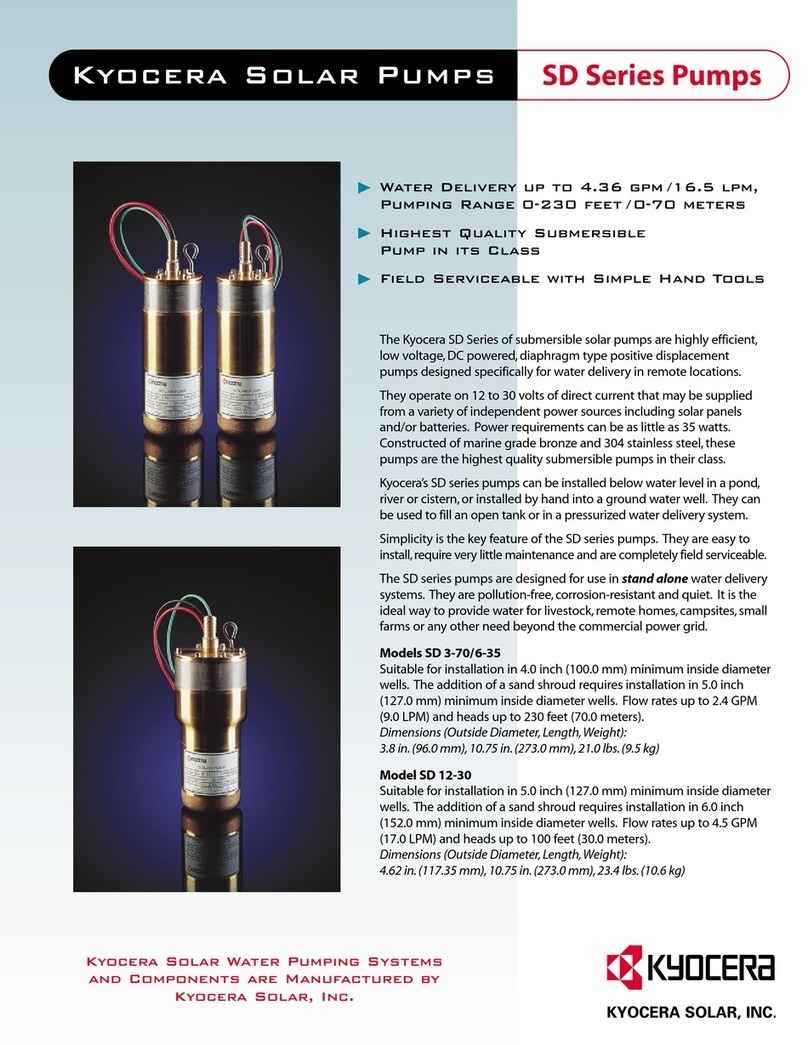

1. Introduction

The SuperZip is a development from the Tritech International Ltd Zip Pump

and ZipJet range of products.

The integrated eductor based excavation system is designed to pump mud,

sand, gravel, drill cuttings and shale without the risk of blockage. A heavy

duty cylinder reverses the flow at the nozzle to eject any object which may

be causing and obstruction. A second cylinder operates a diverter valve to

provide a powerful direct jet to break up heavy and cohesive seabed mud and

sand prior to excavation.

Key features include:

• Separately compensated seal void to minimise ROV hydraulic oil

contamination

• Easy seal change and maintenance

• Lift handle and stabiliser foot

• Suction and jetting nozzles aligned

• Optional feed water filter

• Optional integrated suction and jetting nozzles

• Modular pump core to simplify maintenance

SuperZip

0711-SOM-00003, Issue: 05 7 © Tritech International Ltd.

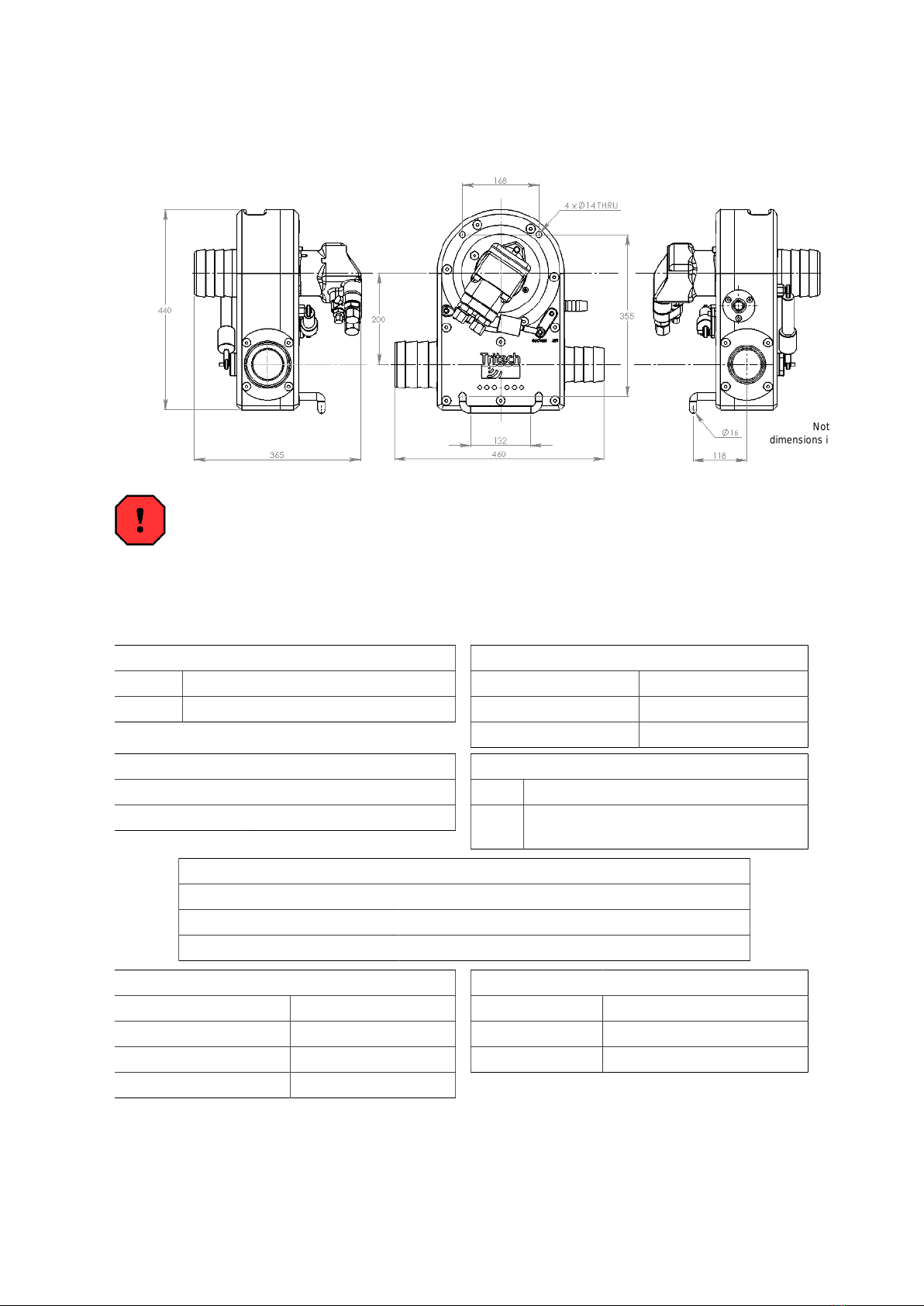

2. Specification

Not to scale,

dimensions in mm.

Warning

Never use the same size fitting for pressure hoses and the case drain. If

this is done there is significant risk of incorrect hook-up which will lead to

pressure being applied to the motor casing and could result in an explosion

and personal injury.

Hydraulic Motor Input

Pressure 150 to 220 Bar (2200 to 3200 psi)

Flow 40 to 60 litres/min (11 to 16 USgpm)

Hydraulic Fittings

Motor A & B No. 12 JIC male

Motor case drain No. 6 JIC male

Actuator Connection No. 4 JIC male

Actuator

Min. pressure 110 Bar (1595 psi)

Max. pressure 240 Bar (3480 psi)

Check Valve

Norm. Tritech Volvo Protector Assembly

Alt. Integrated Hydraulics FPR-1/22-0.5

(cracking pressure 0.5 bar)

Output

Jetting performance 1000 litre/min @ 2 Bar (270 USgpm)

Suction flow 500 - 1000 litres/min (135 to 270 USgpm)

Solids removal rate 5 - 10 tonnes/hour (184 - 368 lb/min)

Nozzle Dimensions

Jetting 25.4mm (1")

Discharge 104mm (4")

Suction 77.3mm (3")

Clean Water Inlet 104mm (4")

Weight and Materials

Weight in air 25kg (55lb)

Weight in water 11kg (24lb)

Materials Nylacast, UHMWPE

SuperZip

0711-SOM-00003, Issue: 05 8 © Tritech International Ltd.

3. Installation

Warning

Do not power the pump or hydraulic valve actuators until all hoses

are properly connected to the pump.

There is a serious risk of injury to fingers if inserted into either the

power water intake or the pump delivery port.

If undertaking any testing operations suitable guards and other

safety measures must be in place.

3.1. Mounting

The pump may be mounted in any orientation on the vehicle. There are

four mounting holes each with 12mm diameter clearance. Two of these are

occupied by the stabiliser foot, which may either be removed or used itself as

a mounting. If desired a second stabiliser bar may be fitted in the alternative

hole set

The pump should not be mounted using the motor or hose nozzles as

attachment points.

Figure 3.1. Mounting Holes

Installation SuperZip

0711-SOM-00003, Issue: 05 9 © Tritech International Ltd.

3.2. Water Hoses

Hose Types

Note

The recommended hose type is the Kanaline AW/Hydrasun

Arizona

Kanaline AW hoses have plastic reinforcement and a semi-transparent wall

which assists in visual inspection for damage or blockages. Alternative makes

of suction and discharge hose may be used provided that they have a smooth

internal bore.

Any crush resistant PVC coil strengthened hose may be used if the

recommended hoses are not available.

Lay-flat style hoses are not recommended for discharge.

Fittings

Use standard Kanaline fittings or heavy-duty worm drive clips. Use of heavy-

duty two bolt clamps will result in damage to the hose connections on the

pump unit.

Clean Suction Intake Screen

It is recommended that a Tritech International Ltd supplied suction strainer

is used with the pump. If using another strainer it must meet the following

specifications:

• Maximum hole size: square mesh of 40mm aperture or circular perforations

of 60mm diameter.

• Minimum total free flow area: 0.016m²

The pump should not be operated in any circumstances without a suction

screen.

Dredge Suction Nozzle

Suction nozzles should be designed with a nozzle cross-section area of

approximately 40cm²

Smaller nozzles may be used but material removal rates will be reduced.

Larger nozzles are of no benefit and will reduce performance.

Installation SuperZip

0711-SOM-00003, Issue: 05 10 © Tritech International Ltd.

A nozzle guard should be fitted that will pass a maximum of a 40mm diameter

sphere or 35mm sided cube. The pump can pass single objects of a larger

size, but if it takes in a stream of objects then blockages can occur.

Jet Nozzle

The recommended sizes are 14 to 19mm diameter or an equivalent area.

The optimum size will need to be determined by trial because the water

output from the power pump will vary depending on the oil pressure and flow

available from the ROV hydraulic system.

3.3. Hydraulics

Oil

The pump should be operated using a premium grade mineral based

hydraulic oil of ISO VG 22 to 32

Filtration

The hydraulic system filtration must be to a minimum of 10μm absolute

standard. A 10μm nominal standard is regarded as inadequate.

The recommended filtration is UN elements produced by Pall Industrial

Hydraulics Ltd. or equivalent products.

Hook-up

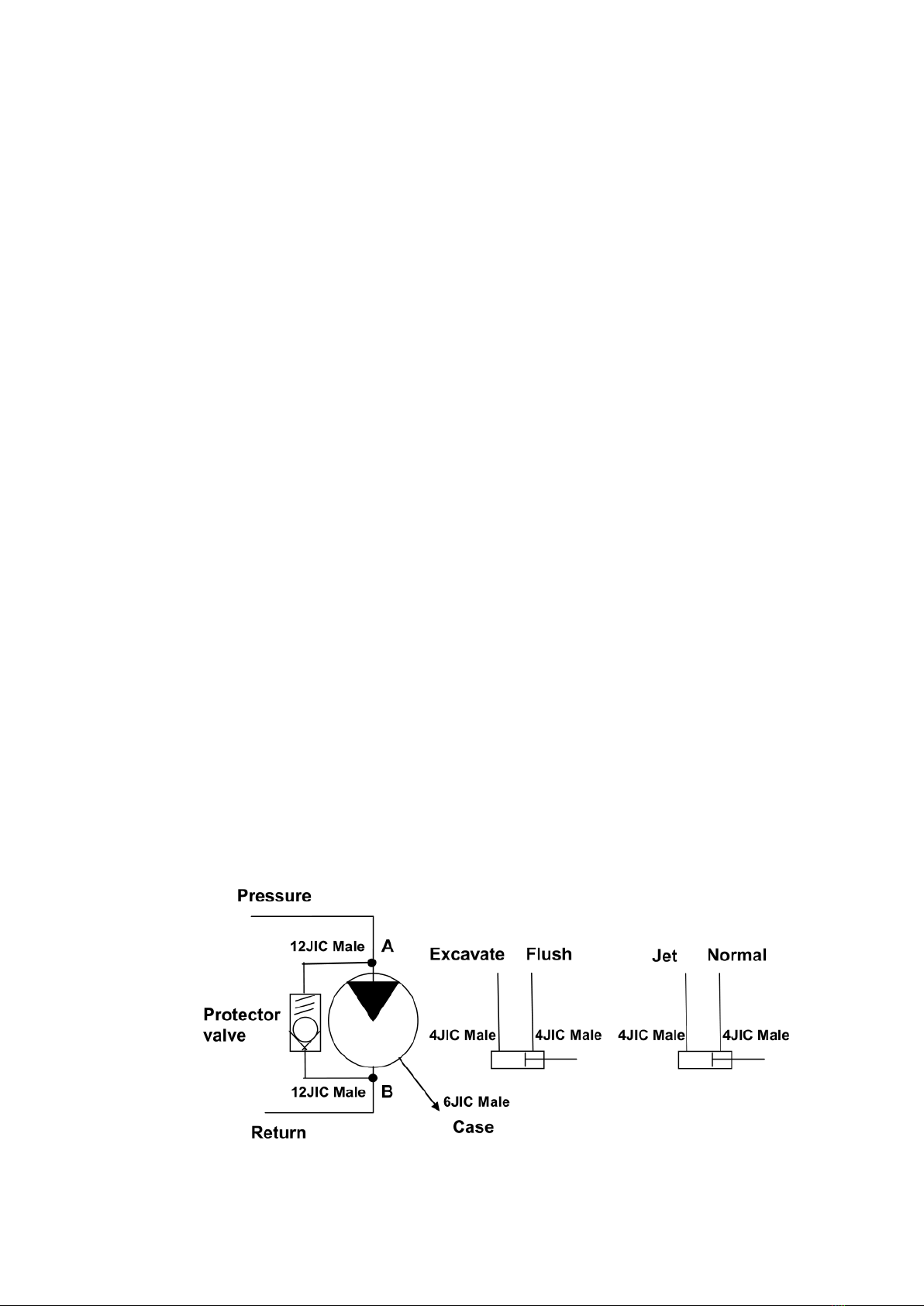

Figure 3.2. Hydraulic Hook-up Orientation

Installation SuperZip

0711-SOM-00003, Issue: 05 11 © Tritech International Ltd.

The pump is configured for correct rotation when the hydraulic supply is

connected to the "A" port of the Volvo motor and the return line to the "B" port.

Figure 3.3. Motor viewed when fitted to SuperZip with hydraulic fittings

downwards

The drain connection from the motor back to the tank is required to be a

minimum of ⅜ inch bore. The drain line should return straight to the tank

without restriction. It is possible to connect the drain line back to a larger

bore drain manifold, which has been correctly sized to accomodate all drains

attached to it.

The drain line should not be connected to any return flow lines.

Warning

Self-sealing quick disconnect connectors should not be used on

the drain line. Such connectors, if incorrectly fitted, may result

in pressurisation of the motor casing which could fail explosively

under pressure resulting in significant risk of personal injury.

Installation SuperZip

0711-SOM-00003, Issue: 05 12 © Tritech International Ltd.

Required Hydraulic Flow

For the Volvo F11-10 motor the vehicle hydraulic system should be capable

of supplying a flow rates and pressure detailed in Chapter 2, Specification.

Achieving the required flow in an unloaded condition is no guarantee that the

supply can actually be met in working conditions.

It is recommended that the installation be checked using a hydraulic flow

meter equipped with a loading valve which can simulate the motor running

under load.

In order to avoid pressure losses a minimum of ½ inch bore pipes or hoses

are used on the flow and return lines ¾ inch or larger is recommended).

3.4. Seal Compensator

The SuperZip has a separately compensated seal void which is grease filled

and has its own miniature compensator.

On installation the compensator level should be checked. The stem has an

indicator groove showing when it is full. If necessary gently apply grease

via the grease nipple provided until the groove just shows or the grease is

expelled from the overflow.

Caution

Pump the grease very slowly to avoid building up excessive

pressure in front of the motor face.

SuperZip

0711-SOM-00003, Issue: 05 13 © Tritech International Ltd.

4. Operating Principles

4.1. Suction

The SuperZip pump is based on the principles of the annular eductor pump. It

has a monoblock configuration and common body within which the educator

pump and power pump are contained.

The power for the eductor section of the pump is provided by a stream of

clean water driven by the centrifugal impeller.

Clean water is drawn into the inlet, passes through the impeller of the power

pump and is then injected into the main suction stream via the annular eductor

nozzle.

Figure 4.1. SuperZip Flow Diagram

The main suction stream can contain a heavy concentration of sand, mud,

gravel and drilling debris. The pump has a retro flush valve just behind the

eductor and when this is closed (operating cylinder extended) the power fluid

Operating Principles SuperZip

0711-SOM-00003, Issue: 05 14 © Tritech International Ltd.

is then directed to the suction nozzle. This feature can be used to clear a

blocked suction nozzle or to complete a deburial operation by blowing away

the last sand and mud from around an object.

The optimum performance will be obtained with the nozzle pushed deep into

the debris and agitated gently. Where a large amount of debris is encountered

it will be necessary to keep withdrawing the nozzle.

4.2. Jetting

The body of the pump contains a diverter vane. The purpose of the vane is to

switch the flow of the power pump water between the suction educator and

the jetting outlet.

The diverter should be operated fully in one direction or the other. Attempting

to share the flow between the eductor and the jet nozzle by using a

mid position will result in poor performance from both. The diverter is set

for suction when the cylinder is retracted and for jetting with the cylinder

extended.

4.3. Testing in Air

Warning

Under no circumstances must the flow be allowed to exceed 70

litres per minute when testing in air.

There is no back pressure on the impeller to control its speed and many

vehicle hydraulic systems are capable of higher deliveries when there are no

thrusters running. Motor over-speed can cause a catastrophic failure

To avoid excessive wear and the possibility of damaging the impeller and

body, the unit should not be run for extended periods out of the water (no

more than about 30 seconds). This is especially true when the unit is new.

Absence of water around the plastic removes the natural cooling mechanism

and may result in the moving parts becoming misshapen due to the heat.

SuperZip

0711-SOM-00003, Issue: 05 15 © Tritech International Ltd.

5. Maintenance

5.1. General Guidelines

Warning

Do not power the pump or hydraulic valve actuators until all hoses

are properly connected to the pump.

There is a serious risk of injury to fingers if inserted into either the

power water intake or the pump delivery port.

If undertaking any testing operations suitable guards and other

safety measures must be in place.

The pump is designed for low maintenance operation. The main materials are

stainless steel and wear resistant polymer plastics.

The only internal moving parts that may need maintenance are:

• The power pump impeller

• The hydraulic motor and shaft seal

• The retro-flush valve spool

• The diverter valve vane

• Impeller water seal

The eductor set may need replacement after prolonged use with extremely

abrasive materials or if aggressive chemicals have been encountered.

5.2. Basic Procedures

Hydraulic Motor Shaft Seals

The pumps are fitted with either an 'H' (red) or 'V' (brown) type seal. The type

V is the standard seal and is high pressure, high temperature.

Replacement of seals with anything other than a genuine seal (or Tritech

International Ltd supplied seal) will invalidate the warranty.

Maintenance SuperZip

0711-SOM-00003, Issue: 05 16 © Tritech International Ltd.

Pre-dive

Before use check the following:

• The level of the seal compensator (re-charge if necessary)

• All hoses are secure

• All mountings are secure

• Clean water suction strainer is in place and clear

Note

If the vehicle is inactive for more than 48 hours run fresh water into

the clean water suction strainer for a few minutes and then spin the

hydraulic motor for about 15 seconds (taking care not to allow it to

over-speed).

Storage

If the pump is removed from the vehicle, then the hydraulic ports should be

blanked off with metal caps and the unit washed out with fresh water.

Leave the actuator valves in their retracted position.

Visually inspect the leading edges of the power pump impeller for damage

and erosion.

Up to four blades may have leading edge damage of 5mm width and 4mm

depth before replacement becomes essential.

Note

If the majority of leading edges are eroded more than 3.5mm back

from the bore of the inlet nozzle then consideration should be given

to replacing the impeller.

Maintenance SuperZip

0711-SOM-00003, Issue: 05 17 © Tritech International Ltd.

5.3. Dismantling

In order to dismantle the pump the following tools will be required:

• 13 and 19mm socket

• 4,5,6 and 8mm Allen key

• Torque wrench

• 3 jaw puller

• Grease gun

• Anti-seize compound

• Silicon grease

• Loctite "Studlock" medium strength

Removal of hydraulic motor, power pump impeller and impeller

seal replacement

1. Disconnect all hydraulic hoses from the motor and fit caps to the ports.

2. Remove the 6 bolts holding the motor mounting plate to the pump (this will

include removing the jetting actuator retaining bolt for access).

3. Remove the mounting plate/motor/impeller assembly. This also provides

access to the impeller seal.

4. Remove the four countersunk setscrews securing the impeller to the boss

(these will be tight since they are retained by Loctite). Remove the impeller.

5. Remove the retaining setscrew and end-cap from the end of the motor

shaft.

6. Using a suitable 3 jaw puller remove the impeller boss from the motor shaft.

Removal of the retro-flush valve

Note

This requires splitting the pump casing.

1. Disconnect all hoses and remove the pump from the vehicle.

2. Remove the motor assembly as above.

Maintenance SuperZip

0711-SOM-00003, Issue: 05 18 © Tritech International Ltd.

3. Remove the valve core arm by releasing the two securing bolts.

4. Remove the 6 remaining case bolts and the 11 bolts on the hose nozzles

and separate the casing.

5. The valve core is now free for removal.

Removal of the diverter valve vane

Note

This requires splitting the pump casing.

1. Proceed as above as far as separating the case sections.

2. Remove the diverter valve cam by releasing the M6 SKT CAP screw.

3. The diverter arm can now be removed form the case.

5.4. Re-assembly

Hydraulic motor and impeller

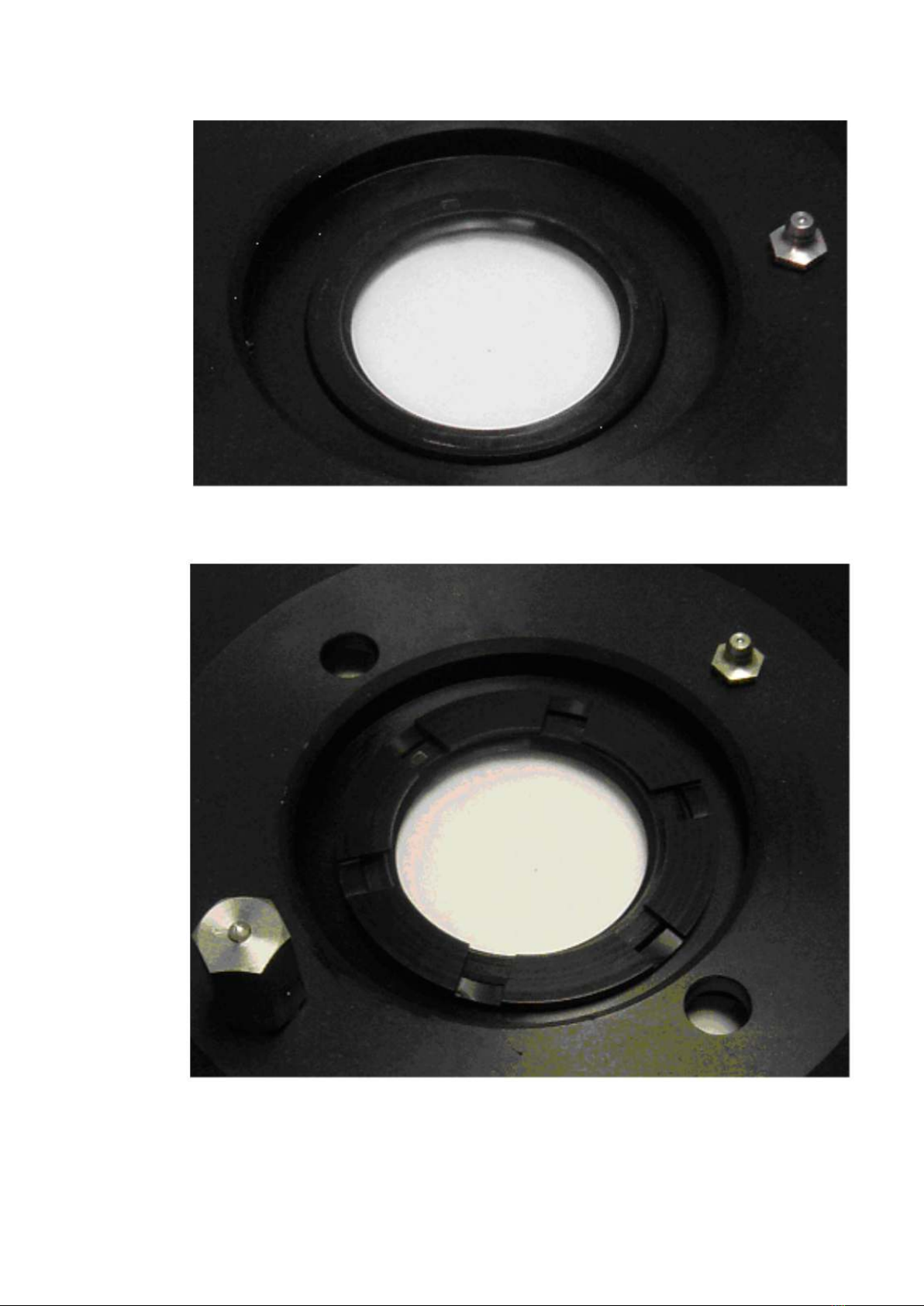

Fit the impeller seal, with the lip facing away from the motor side as shown

in Figure 5.1, “Impeller Seal”, into the centre spigot and press down until

output lip meets the shoulder. Place the seal retaining ring on top ensuring it

is centred correctly (as shown in Figure 5.2, “Seal Retaining Clip”).

Maintenance SuperZip

0711-SOM-00003, Issue: 05 19 © Tritech International Ltd.

Figure 5.1. Impeller Seal

Figure 5.2. Seal Retaining Clip

Maintenance SuperZip

0711-SOM-00003, Issue: 05 20 © Tritech International Ltd.

Place the ID100x2mm o-ring onto the motor and apply some silicon grease

around the surface. Mount the motor on the motor mount disk and secure

(see Figure 5.3, “Motor Mount Disk”).

Figure 5.3. Motor Mount Disk

Apply some anti-seize grease to the motor shaft before fitting the impeller.

Press the impeller boss onto the shaft right up to the shoulder.

Place the ID20x3.5mm o-ring over the top of the motor shaft, assemble the

retainer onto the shaft end and secure the setscrew using a small quantity

of Loctite.

Replace the impeller on the boss and secure the four countersunk screws

with Loctite.

Slowly fill the motor face cavity with grease until the compensator piston

shows the fill mark and grease flows out of the relief port (see Figure 5.4,

“Compensator Piston”).

Table of contents

Other Tritech Water Pump manuals