Page | 3

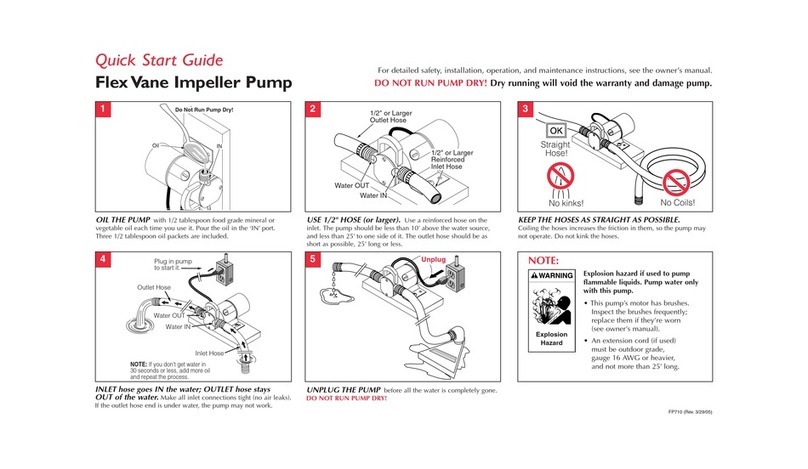

connected to plastic or rigid pipe. This hose should be anchored where it meets the hard plumbing to reduce plumbing vibration.

OPERATION:

This pump is designed for intermittent duty only. The pump operates normally up to about 40-psi, where a spring-loaded by-pass

valve opens, allowing flow back from the output side to the input side, providing smooth, steady flow with virtually no cycling, all

the way down to a trickle. As a faucet is opened back up, the pressure will drop, the by-pass will close and full flow is again

obtained. This allows good flow, even with today’s restrictive showers and pullout sprayer faucets. Performance will vary, of

course, depending on the voltage to the pump; lower voltage = lower flow, higher voltage = higher flow. Remember your

electrical safety: It is always best to shut power to the pump OFF when leaving the RV unattended.

About the By-Pass NOTE: By-pass adjustment should only be performed by a qualify technician with proper

gauges and equipment. The by-pass is a spring loaded diaphragm that opens up allowing water from the discharge side back

to the inlet side. The by-pass is set to begin opening at about 40 psi and creating full by-pass at about 62 psi. The pressure

switch on the pump is set to shut off at 55 psi. If the switch or by-pass are adjusted too much, the by-pass and switch shut-off

can overlap and THE PUMP WILL NOT SHUT OFF. Screwing the switch screw in clockwise will raise the shut-off pressure.

Unscrewing the switch screw counterclockwise will lower the pump shut-off pressure. Screwing the by-pass screw in will raise

the pressure at which the by-pass starts and raise the full by-pass pressure. Unscrewing the by-pass screw counterclockwise

will lower the pressure at which by-pass starts and lower the full by-pass pressure. WARNING: If full by-pass is reached

before the shut-off setting, the pump will not shut off. Full by-pass pressure setting should be at least 10 psi higher than

pump shut off pressure.

Sanitizing

Potable water systems require periodic maintenance to keep components working properly and deliver a consistent flow of fresh

water. Sanitizing is recommended: prior to storing, after a period of storage, or any time the system is opened or contaminated,

as follows: NOTE: Check your Vehicle Owner’s Manual for specific instructions. By-pass anyfilters or remove filter

cartridges.

1. Determine the amount of common household bleach needed to sanitize the tank.

A)2 ounces of bleachper 15 gallons tank size: 60gallon tank [15 x 4] = 4 x 2 ounces =8 ounces of bleach.

B) I ml bleach per 1 liter tank size: 300 liter tank = 300 milliliters of bleach.

2. Mix the bleach with water in a container such as a gallon jug. If tank is filled through a pressurized fitting, pour the bleach into

the hose before attaching the hose to the city water entry.

3. Pour thebleachsolution into the tank and fill the tank with potable water. Rock the RV back and forth tocoat top and sides of

potablewatertank.

4. Open all faucets (Hot &

Cold) allowing the water to run until the odor of chlorine is detected. Allow four (4) hours of

contact time to disinfect completely. Doubling the solution concentration allows for a contact time of one (1) hour.

5. Drain the tank. Refill the tank and flush the system once or twice until the odor has decreased. The residual chlorine

odor and taste is not harmful.

Winterizing Refer to the vehicle owner’s manual for specific winterizing instructions.

If water is allowed to freeze in the system, serious damage to the plumbing and pump may occur. Failures of this type will void the

warranty. The best guarantee against damage is to completely drain the pump and perform the following:

1. Drain the water tank. If the tank doesn't have a drain valve, open all faucets allowing the pump to operate until the tank is

empty.

2. Open all the faucets (including the lowest valve or drain in the plumbing), allow the pump to purge the water from the

plumbing, and then turn the pump OFF.

3. Using a pan to catch the remaining water, remove the plumbing at the pump's inlet/outlet ports. Turn the pump ON,

allowing it to operate until the water is expelled. Turn OFF power to the pump once the plumbing is emptied. Do not

reconnect the pump plumbing. Make a note at tank filler as a reminder: "Plumbing is disconnected".

4. All faucets must be left open to guard against any damage.

5. Potable anti-freeze maybe poured down drains and toilets to protect p-traps and toilet seals. Sanitize the plumbing system

before putting the plumbing system back in service.

Troubleshooting:

Vibration induced by driving can loosen plumbing, strainers and pump hardware. Check for system components that are loose. Also,

refer to the chart below for trouble-shooting tips.

PUMP WILL NOT START / BLOWS CIRCUIT: PUMP WILL NOT SHUT-OFF / RUNS WHEN FAUCET IS CLOSED:

Electrical connections, fuse or breaker, main switch, and ground connection.

Output side (pressure) plumbing for leaks, and inspect for leaky valves or toilet.

Is the motor hot? Thermal breaker may have triggered; it will reset when cool.

For air trapped in outlet side (water heater) or pump head.

Is voltage present at the switch? Bypass pressure sw. Does the pump operate?

For correct voltage to pump (±10%).

Charging System for correct voltage (±10%) and good ground.

For loose drive assembly or pump head screws.

For an open or grounded circuit, or motor; or improperly sized wire.

Are the valves held open by debris or is the rubber swollen?

For seized or locked diaphragm assembly (water frozen?).

Pressure switch operation. By-pass set higher than shut-off.