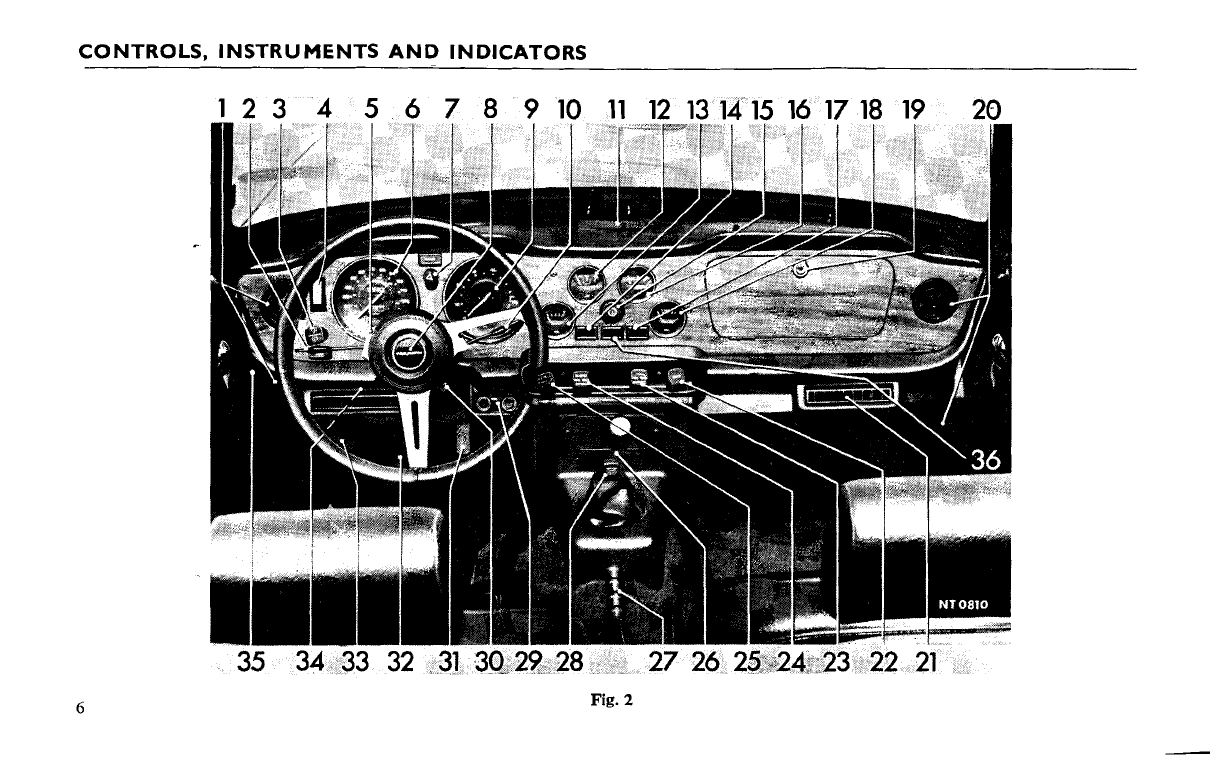

CONTROLS, INSTRUMENTS AND INDICATORS

Hazard Warning Switch and Indicator (7)

i

If thevehicle is immobilised and constitutes a hazard to other

vehicles, warning may be given by using the "hazard warning

system". To operate, pull the switch (7) when all turn-signal

lights will flash intermittently.

When the hazard switch is operated, a bulb in the switch will

flash in unison with the exterior warning lamps.

Horn Push (8)

Press to operate the horns.

Tachometer

(9)

The tachometer indicates the engine speed in revolutions per

minute andcombines two warning indicators(39,40. See Fig. 5).

The speed range within the colored segments is subject to the

"Recommended Speed Limits" mentioned on page 38.

Headlight Dipper Switch (10)

When the headlights are illuminated (see 'Lighting Switch' on

page

S),

thehighbeams may be loweredby moving thelever down.

Toreturn to the high beam position, move the lever up.

The high beam position is indicated by a blue warning light

(37) near the bottom of the speedometer dial.

Lifting the lever towards the steering wheel flashes the head-

light high beams.

Ashtray

(1

1)

An ashtray is provided

in

the center of the facia top. To

empty, lift the assembly from the surround.

Oil Pressure Gauge (12)

Oil pressure at 2,000 r.p.m. under normal operating condi-

tions, should

be

45-65 Ibs./sq. in. Severe operating conditions,

such

as

competition work, may cause the oil pressure to drop

below 25 lb./sq. in., indicating that the oil temperature is

excessive. Under these circumstances fitment of anoil cooler may

be

necessary.

Temperature Gauge

(1

3)

When the ignition switch is turned 'ON' the pointer moves

slowly across the dial taking up to one minute to reach a true

reading.

Normal operating temperature is reached when the pointer

registers in the central sector of the dial. Shouldthepointer reach

the highest mark, stop the engine immediately and check the

level of coolant

in

the radiator. Refer to page

49.

Brake-line Failure/Handbrake Warning Indicator (14)

When the ignition switch is turned on the "brake line failure"

and "low oil pressure" indicator lights glow faintly and are

extinguished when the engine is running. Should failure of the

front or rear brake lines occur, the indicator (14) will glow

brightly.

A

broken bulb filament is indicated by the warning light

failing to glow when the ignition is turned on, before starting the

engine.

The warning light will also glow brightly, as a reminder to

the driver, when the handbrake is applied, provided that the

ignition switch is "ON".

9