Trixell Pixium 4600 Manual

FID / Document identification CTD / Type VS / Release

1000513 108 F

1 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

PIXIUM 4600 : Installation, Service, and Users manual

This manual describes the installation procedures and operation of the PIXIUM 4600 digital X-ray detector.

It also provides information for service and safety operation. It is intended for use by a system integrator.

Please read this manual carefully before performing any installation or use of a PIXIUM 4600 detector.

Document history

Index Date Author Nature of the modification

A 06 / 04 / 00 J. DUTIN Initial document

B 05 / 09 / 03 J. DUTIN Laser diode classification (DM 12 074)

Product evolution (DM 14 425)

C 30 / 10 / 03 P. SALQUE Accompanying documents evolution (DM 17029)

D 25 / 04 / 05 C. BOUCHET Acclimatization time regularization (DM 21908)

E 22 / 07 / 05 J. DUTIN Recycling label (DM 23669)

F 22 / 09 / 05 J. DUTIN Removal of CD-ROM (DM 22958)

G

FID / Document identification CTD / Type VS / Release

1000513 108 F

2 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

Table of contents

1PIXIUM 4600 PRESENTATION .......................................................................................................................... 4

1.1 GENERAL DESCRIPTION............................................................................................................................ 4

1.2 DELIVERY ..................................................................................................................................................... 4

1.3 DETECTOR .................................................................................................................................................... 4

1.4 IDENTIFICATION ......................................................................................................................................... 4

1.5 APPLICABLE STANDARDS :...................................................................................................................... 5

1.5.1 International Standards :............................................................................................................................ 5

1.5.2 European Directive : .................................................................................................................................. 5

1.5.3 National standards : ................................................................................................................................... 6

1.6 CERTIFICATIONS............................................................................................................................................... 6

1.7 GUIDANCE FOR MANUFACTURER'S DECLARATION .......................................................................................... 6

2PIXIUM 4600 TECHNICAL FEATURES ........................................................................................................... 7

2.1 MECHANICAL FEATURES ......................................................................................................................... 7

2.1.1 Dimensions and fixations............................................................................................................................ 7

2.1.2 Weight......................................................................................................................................................... 7

2.1.3 Input window .............................................................................................................................................. 7

2.2 ELECTRICAL FEATURES............................................................................................................................ 7

2.2.1 Power supply and mains synchronization input connector......................................................................... 7

2.2.2 Remote control and X-ray enable output connector ................................................................................... 8

2.2.3 Data transfer connector.............................................................................................................................. 9

2.2.4 Protective earth........................................................................................................................................... 9

2.3 SOFTWARE FEATURES............................................................................................................................. 10

2.4 OPERATION MODE - SYNCHRONIZATION........................................................................................... 10

2.5 ENVIRONMENTAL CONDITIONS ........................................................................................................... 10

2.6 ACCESSORIES ............................................................................................................................................ 11

3PIXIUM 4600 INSTALLATION ......................................................................................................................... 12

3.1 UNPACKING................................................................................................................................................ 12

3.2 COOLING ..................................................................................................................................................... 12

3.3 INSTALLATION .......................................................................................................................................... 12

3.4 CONNECTION ............................................................................................................................................. 13

4PIXIUM 4600 FIRST OPERATION................................................................................................................... 15

4.1 ADJUSTMENT............................................................................................................................................. 15

4.2 SWITCHING POWER ON ........................................................................................................................... 15

4.3 INITIALIZATION ........................................................................................................................................ 15

4.4 IMAGE ACQUISITION ............................................................................................................................... 15

5PIXIUM 4600 REGULAR OPERATION........................................................................................................... 16

5.1 RECOMMENDATIONS............................................................................................................................... 16

5.1.1 Temperature.............................................................................................................................................. 16

5.1.2 Cooling ..................................................................................................................................................... 16

5.1.3 EMC compliance....................................................................................................................................... 16

5.1.4 Warm-up time from a cold start................................................................................................................ 17

5.2 INTEGRATION ............................................................................................................................................ 17

5.2.1 Front protective label ............................................................................................................................... 17

5.2.2 Mechanical fixations : .............................................................................................................................. 17

5.3 X-RAY GENERATOR CONNECTION....................................................................................................... 17

5.4 CONFIGURATION AND UPGRADE......................................................................................................... 18

FID / Document identification CTD / Type VS / Release

1000513 108 F

3 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

5.5 CALIBRATION ................................................................................................................................................. 18

5.6 DETECTOR MODE SELECTION............................................................................................................... 19

6PIXIUM 4600 TROUBLESHOOTING............................................................................................................... 21

6.1 POWER SUPPLY RANGE ................................................................................................................................... 21

6.2 X-RAY ENABLE OUTPUT ................................................................................................................................. 21

6.3 INTERNAL TEMPERATURE ............................................................................................................................... 21

6.4 OTHER FAILURE.............................................................................................................................................. 21

7PIXIUM 4600 SERVICE...................................................................................................................................... 21

8PIXIUM 4600 CLEANING, STERILIZATION AND DISINFECTION INSTRUCTIONS.......................... 22

8.1 CLEANING ...................................................................................................................................................... 22

8.2 STERILIZATION AND DESINFECTION................................................................................................................ 22

9PIXIUM 4600 MANUFACTURER ..................................................................................................................... 22

10 APPENDIX B : IDENTIFICATION LABELS .................................................................................................. 23

Reference documents

Ref [1] PIXIUM 4600 General cautions and standards prescriptions

applying to system integration (document reference 61416485 – 108)

Ref [2] PIXIUM 4600 Storage, handling and packing instructions

(document reference 1001500 – 108)

Ref [3] PIXIUM 4600 Mechanical Interface Specification

(document reference 1000202 – 580)

Ref [4] PIXIUM 4600 Outline drawing

(document reference 1000015 – 041)

Ref [5] PIXIUM 4600 Software Interface Specification

(document reference 1000169 – 580)

Ref [6] PIXIUM 4600 Electrical Interface Specification

(document reference 1000201 – 580)

Warning

This manual is intended to help integrators in the installation of a PIXIUM 4600 detector and its

first operation. The figures and data given in this manual cannot be considered to be a contractual

specification. Consult TRIXELL for additional information.

FID / Document identification CTD / Type VS / Release

1000513 108 F

4 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

1 PIXIUM 4600 PRESENTATION

1.1 GENERAL DESCRIPTION

The PIXIUM 4600 is a flat panel X-ray detector used for radiological applications, and is part of a

digital image acquisition of an overall Radiography System.

1.2 DELIVERY

The standard PIXIUM 4600 delivery includes :

• a detector,

• a CE compliance certificate,

• a print of the final test report,

• miscellaneous labels and cards according to customer specification,

1.3 DETECTOR

A E D B F

C

The detector consists of a metal housing with a carbon fiber composite window for X-ray input on

the upper side, and internal lead shielding against X-radiation.

It includes on one side (right side of the active sensitive array) :

• an input connector for the external power supply [A]

• a bi-directional RS-232 serial link connector for remote control [B]

• an output connector (optical link) for data transfer [C]

• two bolts : one to ground the detector [D] and the other to fasten the serial link cable in

order to provide cable strain relief [E]

• five LED indicators to display the state of the detector [F]

• identification and warning labels (refer to appendix B)

1.4 IDENTIFICATION

The identification labels on the right side of the detector housing provide information for :

• the type (PIXIUM 4600)

• the part number (P/N)

• the revision code (REV.)

FID / Document identification CTD / Type VS / Release

1000513 108 F

5 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

• the serial number (S/N)

• information for power supply connection

See appendix B for label models.

1.5 APPLICABLE STANDARDS :

1.5.1 International Standards :

Basic Safety Standard :

• IEC 601.1 2nd edition (1988), including amendment no 1 (1991) and amendment no 2

(1995) “Medical electrical equipment. Part 1: General requirements for safety” :

§ 5.1 : Pixium 4600 is a Class I equipment

§ 5.1 : Pixium 4600 has no applied part

§ 5.3 : Pixium 4600 has no specific protection against ingress of water

§ 5.4 : Pixium 4600 can be sterilized and disinfected (see the special corresponding section

in this document)

§ 5.5 : Pixium 4600 is not suitable for use in the presence of flammable mixtures

§ 5.6 : Pixium 4600 is designed to run in continuous operation

Collateral Safety Standards :

• IEC 601.1.2 2nd edition (2001-09), “Medical electrical equipment – General requirements

for safety – 2 – Collateral standard : Electromagnetic Compatibility – Requirements and

tests”

• IEC 601.1.3 1st edition (1994), “ Medical electrical equipment – General requirements for

safety – 3 – Collateral standard : Radiation Protection in Diagnostic X-Ray equipment”

• IEC 601.1.4 Edition 1.1(2000-04), “Medical electrical equipment – 4 – Collateral standard

: Programmable Electrical Medical Systems”

1.5.2 European Directive :

• Medical Device Directive MDD 93/42/EEC, of June 14, 1993, revision 398L0079 (Dec. 7,

1998) and 300L0070 (Dec. 13, 2000). Applies to all medical equipment except for active

implantable devices.

FID / Document identification CTD / Type VS / Release

1000513 108 F

6 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

1.5.3 National standards :

United States :

• UL 2601-1 “Medical electrical equipment. Part 1: General requirements for safety”; 2nd

edition, October 1997

• DHHS “Radiation protection (Code of Federal Regulations, title 21, Subchapter J, section

1020)"; revised version of April 1, 2002

Canada :

• CAN/CSA-C22.2 No. 601.1-M90 “Medical electrical equipment. Part 1: General

requirements for safety”; November 1990 + A1:1991 + A2:1995

E205430 / class PIDF2 and PIDF8

1.6 CERTIFICATIONS

The PIXIUM 4600 is certified and labeled as follow :

• UL : Combined UL/CSA certification (C-UL) label with following UL file reference :

E205430 / class PIDF2 and PIDF8

• CSA : Combined UL/CSA certification (C-UL) label (see above)

• CE : CE label

1.7 GUIDANCE FOR MANUFACTURER'S DECLARATION

Refer to accompanying document :

“General cautions and standards prescriptions applying to system integration”.

(document reference 61416485 – 108)

FID / Document identification CTD / Type VS / Release

1000513 108 F

7 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

2 PIXIUM 4600 TECHNICAL FEATURES

2.1 MECHANICAL FEATURES

2.1.1 Dimensions and fixations

Refer to outline drawing in Mechanical Interface Specification.

2.1.2 Weight

20 kg maximum (detector alone)

2.1.3 Input window

The X-ray input window (upper side of the detector) is made of a carbon fiber composite substrate,

to protect the sensitive layer and active array of the detector. This input window can withstand a

maximum pressure of 60 N/cm² over 2 cm² on the window center.

! ! ! CAUTION ! ! !

FRAGILE : Do not push on the upper face of the detector

! ! ! ATTENTION ! ! !

FRAGILE : Ne pas appuyer sur la face avant du détecteur

2.2 ELECTRICAL FEATURES

2.2.1 Power supply and mains synchronization input connector

Power supply Detector input voltage (nominal value) Input current (peak value)

+ 24V Vin low : + 23.7V / Vin high : + 25.3V 2A

+5V Vin low : + 5.0V / Vin high : + 5.2V 2A

-5V Vin low : - 5.2V / Vin high : - 5.0V 2A

Mains synchronization input : 50 or 60 Hz mains frequency internal synchronization for the detector

timing (trigger on the falling edge of a TTL compatible input signal). This link should be externally

opto-isolated to prevent ground loops in the detector connections. The detector input is an open-

collector schematics.

Connector type (detector side) : D-Sub / 9 contacts / male

Cable length : as short as possible.

FID / Document identification CTD / Type VS / Release

1000513 108 F

8 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

Connector pinout (see label on detector for pin locations):

PIN NUMBER

(9-pin connector)

FUNCTION

(3 power supplies with mains synchronization)

1 - 5 V Return (GND)

2 + 5 V Return (GND)

3 + 24 V Return (GND)

4 Mains synchronization signal

5 Mains synchronization signal return and shield (GND)

6 - 5 V

7 + 5 V

8 + 24 V

9 + 24 V

Housing Shield (GND)

2.2.2 Remote control and X-ray enable output connector

• Bi-directional RS-232C serial link for remote control of the detector with no hardware

handshake and transfer rate set to 9600 bds / even parity / 1 bit stop. This link should be

externally opto-isolated to prevent ground loops in the detector connections.

• Current loop (20mA) interface which can be used to enable the X-ray generator through an

optocoupler device.

• Connector type (detector side) : 6-pin mini-DIN female

• Connector pinout (receptacle) :

pin #1: TX Output pin #2 : XRAY-ENABLE +

pin #3 : GND pin #4 : +5V Output

pin #5 : RX Input pin #6 : XRAY-ENABLE -

Connector metal housing : shield (GND)

The pin #4 (labeled +5V) is a power supply output, available for external uses. The maximum

current available on this +5V pin is 100mA (@ 4.75V).

FID / Document identification CTD / Type VS / Release

1000513 108 F

9 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

2.2.3 Data transfer connector

Optical link transmission is used for image data output using 160 Mbits per second serial

asynchronous transmission (AMD Taxi protocol) on a fiber optic.

Fiber optic characteristic : multimode link with 62.5 / 125 µm fiber.

Connector type : ST II style

2.2.4 Protective earth

! ! ! CAUTION ! ! !

Connector and cable shields must not be used as Protective Earth connection.

! ! ! ATTENTION ! ! !

Le blindage des connecteurs et des câbles ne doit pas être utilisé pour mettre le détecteur à

la terre de protection.

Chassis grounding is carried out using an specific bolt on the side of the detector (see section 1.3

[D]). Used for Protective Earth connection of the detector.

! ! ! CAUTION ! ! !

The specific bolt must not be used for any other purpose than Protective Earth

connection. Removing this connection must need a service tool.

! ! ! ATTENTION ! ! !

Le goujon spécifique de mise à la masse ne doit pas être utilisé à d’autres fins que la

connexion de la terre de protection. La déconnexion nécessite un outil de maintenance.

For EMC reasons, there is no protective insulation between the electronics inside the detector and

the metal housing.

FID / Document identification CTD / Type VS / Release

1000513 108 F

10 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

2.3 SOFTWARE FEATURES

The detector is interfaced with the Radiographic System through programmation and control via a

serial link and a message protocol.

The detector can send to the System, upon request, messages containing the hardware and software

revision numbers, and the detector's serial number and date code.

The detector has built-in self-test features to provide the System with information for malfunction

diagnostic and preventive maintenance (see mode table).

The detector can generate, if enabled, error or warning messages in case of communication or

internal electronics malfunctions (such as internal voltages drifts or breakdowns). It is the System's

responsibility to decide what to do in case of such an error or warning.

The detector has built-in low-level routines that can be used by the System to perform image quality

tests.

The detector has a built-in set of test patterns that can be used to check the operation of the

detector's electronics (analog test patterns) and of the image data transmission (digital test patterns)

: see mode table and software interface specification.

If the detector has to reboot due to an internal error, it is able to come up to a normal operating

mode by itself.

2.4 OPERATION MODE - SYNCHRONIZATION

The internal detector timing is synchronized with an external signal connected to the Mains

synchronization input (see Power supply and mains synchronization input connector in section

2.2.1)

External synchronization period is 20 ms when operating on 50Hz mains frequency and 16.7 ms

when operating on 60 Hz mains frequency. The operation timing sequences remain the same

whatever the mains frame rate is.

2.5 ENVIRONMENTAL CONDITIONS

The transport and storage environmental conditions are (detector inside its original packing) :

- temperature range : - 25 °C to + 55 °C

- relative humidity : 10 % to 95 % R.H.

- pressure : 70 to 106 kPa

- shocks : 25 g , 6 ms , 150 shocks in X,Y,Z axis

- vibrations : 5-9 Hz , 3.5 mm / 9-500 Hz , 1 g / X,Y,Z axis

FID / Document identification CTD / Type VS / Release

1000513 108 F

11 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

The operation environmental conditions are :

- detector ambient temperature range:

+ 18°C to + 30 °C for specified performance

+ 10°C to + 40°C for functionality only (no performance level is

guaranteed)

- relative humidity : 20 % to 75 % R.H.

- pressure : 70 to 106 kPa

- shocks : 15g, 6 ms, 100 shocks in X,Y,Z axis.

- vibrations : 10-60 Hz , 0.035 mm / 60-500 Hz , 0.5g / X,Y,Z axis

2.6 ACCESSORIES

For proper operation of the detector within a Radiographic System, an anti-scattering grid and an

automatic exposure control device must be used. These devices are not part of the detector, they

must be supplied and installed by the System integrator. The detector has no direct mechanical

interface for such devices.

FID / Document identification CTD / Type VS / Release

1000513 108 F

12 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

3 PIXIUM 4600 INSTALLATION

3.1 UNPACKING

! ! ! CAUTION ! ! !

Do not open the inner plastic bag before a sufficient acclimatization time. The

acclimatization time is typically 24 hours. It is recommended to remove the detector

from the two cardboard boxes during this time - however do not under any condition

open the sealed protective bag during this time. Take care to not apply undo shocks to

the shipping containers even if empty.

! ! ! ATTENTION ! ! !

N’ouvrir le sac plastique interne qu’après un temps d’acclimatation suffisant. Le temps

d’acclimatation est de 24 heures. Il est recommandé de sortir le détecteur des deux cartons

pendant cette période - toutefois n'ouvrir sous aucun prétexte le sachet de protection

étanche pendant cette période. Ne pas appliquer de chocs excessifs même sur l’emballage

vide.

Refer to the Storage and handling instructions (document referenced 1001500) for complete

information : a copy is attached to the side of the large outer cardboard box containing the PIXIUM

4600.

! ! ! CAUTION ! ! !

The detector is sensible to moisture. While not used, it must be stored with protection

against humidity

! ! ! ATTENTION ! ! !

Le détecteur est sensible à l’humidité. Lorsqu'il n'est pas utilisé, il doit être tenu à l'abri de

l'humidité.

3.2 COOLING

There is no particular requirement for cooling of the detector while operating the detector in

ambient temperature range, as long as there is natural airflow cooling (free convection around the

detector housing).

In regular operation, a warning message can be programmed to be sent by the detector to the

System if internal temperature exceeds a pre-determined threshold. It is the System's responsibility

to decide what to do in case of a detector temperature warning message.

3.3 INSTALLATION

Use ESD protection and precautions while unpacking the PIXUM 4600 from its protective bag and

installing it in its operational place.

FID / Document identification CTD / Type VS / Release

1000513 108 F

13 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

Components needed for installation and operation of the PIXIUM 4600, but not supplied with the

detector :

• three DC power supplies (+24V / +5V / -5V)

• power supply cable

• fiber optic cable for data link

• serial cable for communication link

• protective earth cable for ground connection

• mains synchronization generator

• system computer (for instance a PC with Windows NT 4.0 operating system and with

acquisition boards and software installed)

All installation work is possible with standard mechanical service tools.

During installation, ensure that no sharp corners or edges can damage the cabling.

Check and adjust the alignment between X-Ray generator and detector.

3.4 CONNECTION

Connect the Protective Earth terminal (specific bolt marked with PE symbol : see section 1.3 [D])

to your local protective earth with a large section cable and using the supplied clamping means.

! ! ! CAUTION ! ! !

Connectors and cable shields must not be used as PE connection.

The specific bolt must not be used for any other purpose than PE connection.

Removing this connection must need a service tool.

! ! ! ATTENTION ! ! !

Les connecteurs et les blindages de câble ne doivent pas être utilisé pour la mise à la terre.

Le goujon spécifique doit être utilisé exclusivement pour la mise à la terre.

Le démontage de cette connexion doit nécessiter un outillage.

Connect the optical fiber from the detector (ST connector : see section 1.3 [C]) to the image

acquisition board of the computer.

! ! ! CAUTION ! ! !

Switch off detector main supply before moving optical fiber.

! ! ! ATTENTION ! ! !

Couper l’alimentation du détecteur avant de manipuler la fibre optique.

Connect the serial link cable between the detector (mini-DIN connector : see section 1.3 [B]) and

the computer, and fasten the cable with the specified M4 bolt (see section 1.3 [E]) on the detector

housing for strain relief.

FID / Document identification CTD / Type VS / Release

1000513 108 F

14 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

Connect the power supply cable to the detector (9-pin connector : see section 1.3 [A]).

! ! ! CAUTION ! ! !

The detector power supplies must be used to power the detector only.

! ! ! ATTENTION ! ! !

Les alimentations du détecteur ne doivent pas servir à alimenter autre chose que le

détecteur.

! ! ! CAUTION ! ! !

Power supply inversion or out of range power supply (including a missing power supply)

may harm the detector. Be sure to correctly connect and clamp the power supply cable

and the connector.

! ! ! ATTENTION ! ! !

Une inversion de polarité ou une alimentation hors gamme peut endommager le

détecteur. Vérifiez le raccordement et la fixation des connecteurs.

Power supplies current limitation should be adjusted to less than 5 A.

Connect the mains synchronization generator.

Check the power supplies polarity before switching on. All three power supplies must be switched

on and off simultaneously. There is no hazard resulting from switching on and off the power

supplies.

As soon as it is installed, it is recommended to keep the detector continuously powered, even when

not used (during night for example).

FID / Document identification CTD / Type VS / Release

1000513 108 F

15 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

4 PIXIUM 4600 FIRST OPERATION

4.1 ADJUSTMENT

All adjustments done on the detector at the factory remain unchanged during transportation and

installation. There is no need to download a setup before operation.

4.2 SWITCHING POWER ON

Switch on the three power supplies simultaneously.

Check the five LED indicators on the right side of the detector (see section 1.3 [F]) :

• D1 turns ON : external DC power OK, then

• D2 turns ON : detector OK, then

• D3 turns ON : communication OK, as soon as a command is sent from the System to the

detector (as stated below)

• D4 starts blinking

4.3 INITIALIZATION

As soon as a command is sent from the System to the detector, D3 indicator turns ON. The detector

is ready then to share commands with the System. D3 indicator remains ON.

4.4 IMAGE ACQUISITION

When a Frame Request is received by the detector, D4 indicator turns ON (from a blinking to a fix

status) during Frame Acquisition duration.

Furthermore, in case of a X-ray exposure request, D5 indicator turns ON for the duration of the X-

ray Enable pulse (500 ms in default operation mode), and turns OFF during readout time.

FID / Document identification CTD / Type VS / Release

1000513 108 F

16 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

5 PIXIUM 4600 REGULAR OPERATION

5.1 RECOMMENDATIONS

5.1.1 Temperature

Operation temperature must be kept as stable as possible within the specified range.

The detector can be operated within the operation environmental conditions without any cooling

means, provided natural convection of air within the detector ambient temperature range along the

detector back plate is made possible by System integration. In case natural convection is not

possible or not sufficient, an external cooling device must be installed and attached to the detector

by the means of dedicated threaded holes in the back plate of the detector housing. The external

cooling device should then extract heat from the detector back plate. Refer to the following section

for additional information on heat sink mounting.

The detector is equipped with a temperature monitor used both to send early warning messages to

the System in case of too low or too high detector temperature, and to measure the detector

electronics temperature. The measured temperature can be sent to the System in a message upon

System request. It is the System's responsibility to decide what to do in case of detector temperature

warning.

5.1.2 Cooling

The detector is not sealed against the ingress of a thermal greace. Therefore do not use any thermal

grease or other material when attaching a heat sink or other thermal exchanger to back face of the

detector. Use of such material can harm the detector and will invalidate the warranty of the detector

if they have been found to have entered the detector housing.

5.1.3 EMC compliance

The power supply cable must be shielded with shield continuity at the power supply input

connector. We recommend to place one EMI core KITAGAWA model KFC-130, on the power

supply cable, as close as possible to 9-pin connector.

The communication cable must be shielded with shield continuity at the communication input

connector. Trixell recommend to :

- use a connector JST series MD on the communication cable.

- use the low capacitance computer cable BELDEN model 8103 or equivalent (24AWG, 3

pairs).

- place one EMI core WÜRTH model 7427113 or equivalent, on the communication cable,

as close as possible to communication connector.

In order to reduce magnetic interferences, the detector needs to be synchronized to the mains

frequency of the System installation (refer to Section 2.4 Operation mode - Synchronization)

Portable and mobile RF communication equipment can affect the detector.

FID / Document identification CTD / Type VS / Release

1000513 108 F

17 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

5.1.4 Warm-up time from a cold start

The detector will be fully operational within typically 30 minutes after being powered up with

performance levels guaranteed after a maximum of 240 minutes. It is the System responsibility to

check for this delay.

5.2 INTEGRATION

5.2.1 Front protective label

The detector is delivered with a large label attached to the input carbon fiber composite substrate. It

provides marks to align the X-ray beam collimation with the detector sensitive array.

! ! ! CAUTION ! ! !

Remove the protective label before operation (or before detector integration on the

System).

! ! ! ATTENTION ! ! !

Oter l’étiquette de protection avant la mise en service ou l’intégration du détecteur

5.2.2 Mechanical fixations :

In all cases, the detector must be fixed to the System by means of all eight screws M4 (refer to

outline drawing for location), with a threaded length of 4 mm minimum and a total length of 7 mm.

For accessory fixation on the detector back side (such as heat sinks), use up to eight screws M4

(refer to outline drawing for location), with a length of 6 mm maximum.

Refer to appendix C (outline drawing) for the location of these fixations.

The detector can be operated in any position in space (0 to 360° in any X, Y, Z directions).

5.3 X-RAY GENERATOR CONNECTION

The PIXIUM 4600 provides three different possibilities to enable X-Radiation. Depending on the

System receiving the detector, X-ray emission can be enabled using :

• Current-loop signal linked with Com signals on the mini-DIN connector and designed to

drive an optocoupler device

• Microcontroler messages on the RS-232 serial link

• Taxi messages linked with image data on the optic fiber

FID / Document identification CTD / Type VS / Release

1000513 108 F

18 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

! ! ! CAUTION ! ! !

Whatever possibility is used, the X-ray Enable signal only indicates to the System that

the detector is ready to receive X-radiation. It is the System responsibility to control the

actual emission of X-radiation.

! ! ! ATTENTION ! ! !

Quelque soit la solution retenue, le signal “X-ray Enable” ne fait qu’indiquer au système

que le détecteur est prêt à recevoir un rayonnement X. Il est de la responsabilité du système

de contrôler l’émission de rayonnement X.

5.4 CONFIGURATION AND UPGRADE

There is no manual configuration nor adjustment required for the detector (e.g. jumper setting,

etc...). All configuration and adjustment steps are possible via message exchange between the

System and the detector.

The upgrade of the detector's firmware (except the boot software) can be done at the factory via a

setup file download using the communication protocol.

5.5 CALIBRATION

Calibrations needed for image quality are defined by the system program.

FID / Document identification CTD / Type VS / Release

1000513 108 F

19 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

5.6 DETECTOR MODE SELECTION

There are two sets of modes programmed in the detector : Table 0 modes are used for image

acquisition, while Table 1 modes are dedicated to detector tests. Only modes 1 to 5 in Table 0 are

qualified for System use.

The following tables defines the modes :

PIXIUM 4600 / revision lower or equal to Ex

Mode

number

Table 0 : Imaging modes Table 1 : Test modes

1 Single-shot with 0.5 s X-ray Enable

window

Single-shot with 0.5 s X-ray Enable

window

2 Special mode with 3.2 s X-ray Enable

window

Single-shot with reverse array readout

and 0.5 s X-ray Enable window

3 Single-shot with 1 s X-ray Enable

window

Readout IC built-in self test even

4 Single-shot with 2.3 s X-ray Enable

window

Readout IC built-in self test odd

5 Single-shot with 4 s X-ray Enable

window

Vdr voltage readout

6 Internal use only Test mode / 30 µGy equivalent

7 Internal use only Test mode / 5 µGy equivalent

8 Internal use only Single-shot with reverse array readout

and 4 s X-ray Enable window

FID / Document identification CTD / Type VS / Release

1000513 108 F

20 / 24

CONFIDENTIEL TRIXELL

Copyright © 2000-2003-2005 TRIXELL. Tous droits réservés. Ce document et l’information qu’il contient sont la propriété exclusive de

TRIXELL. Ils ne peuvent être reproduits ou divulgués sous quelque forme que ce soit sans l’accord préalable écrit de TRIXELL.

TRIXELL PROPRIETARY INFORMATION

Copyright © 2000-2003-2005 by TRIXELL. All rights reserved. This document and the information contained therein are TRIXELL’s

exclusive property. Any copy and/or disclosure thereof in any form whatsoever are subject to TRIXELL’s prior written consent.

PIXIUM 4600 / revision equal or higher to Fx

Mode

number

Table 0 : Imaging modes Table 1 : Test modes

1 Single-shot with 0.5 s X-ray Enable

window

Single-shot with 0.5 s X-ray Enable

window

2 Special mode with 3.2 s X-ray Enable

window

Single-shot with reverse array readout

and 0.5 s X-ray Enable window

3 Single-shot with 1 s X-ray Enable

window

Readout IC built-in self test even

4 Single-shot mode with 2.3 s X-ray

Enable window

Readout IC built-in self test odd

5 Single-shot with 4 s X-ray Enable

window

Readout IC Vdr voltage readout

6 Internal use only Test mode / 30 µGy equivalent

7 Double exposure mode Test mode / 5 µGy equivalent

8 Not available Single-shot with reverse array readout

and 4 s X-ray Enable window

9 Not available Internal use only

10 Not available Internal use only

11 Not available Internal use only

12 to 16 Not available Not available

Mode description :

• Single-shot : standard image acquisition and readout cycle featuring 0.5 s (default mode)

or 1s or 4s X-ray Enable window duration

• Special : same as above with X-ray enable window duration increased to 3.2 s

• Reverse readout : same acquisition mode with reverse readout of the lines (from center to

top and bottom line)

• Readout IC self test : internal self test of the amplifier readout circuits (outputs a test

image with white odd / even columns)

• Readout IC voltage readout : an internal reference voltage is applied on the inputs of the

amplifier readout circuits (outputs a test image with a constant gray level)

• Test modes : an internal signal source is used to simulate X-ray exposure at 5 or 30 µGy

dose level

• Double exposure : two frames (frame A and frame B) can be acquired within an interval

of max. 2 sec ; the cycle time between two acquisitions in Double exposure mode is min.

6.5 sec.

Table of contents

Popular Security Sensor manuals by other brands

B.E.G.

B.E.G. LUXOMAT PD2N-KNX-ST-UP Mounting instructions

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 390 Additional Installation, Operation and Maintenance Instructions

teko

teko Astra-431 user guide

System Sensor

System Sensor InnovAir DH100ACDCI Installation and maintenance instructions

MG

MG CLSE instruction manual

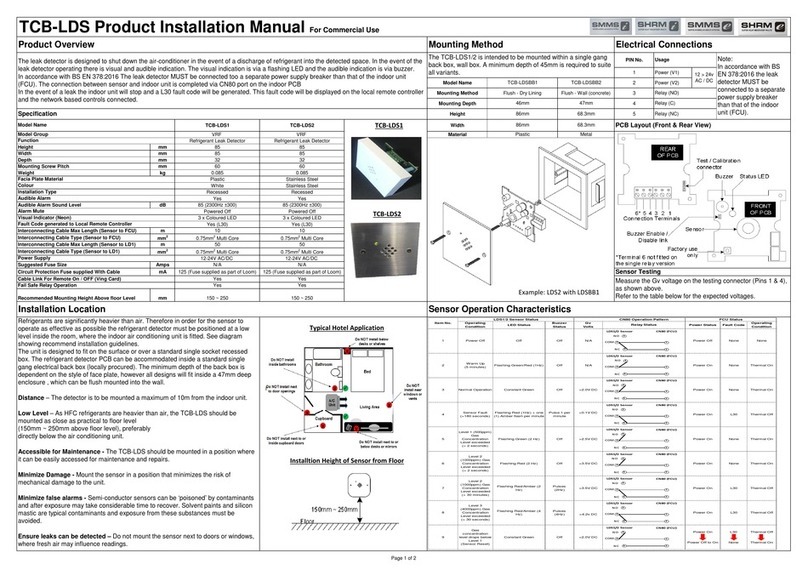

Toshiba

Toshiba TCB-LDS Series installation manual