Trogear Bowsprit User manual

Trogear Bowsprit Install Manual | www.trogear.com | info@trogear.com 1

Trogear SAS

www.trogear.com

info@trogear.com

+33 (0)9 70 44 58 11

Skype: trogear1

Trogear Bowsprit Through Hull Installaon Manual

Congratulaons on your purchase of the Trogear Bowsprit which can be installed on most sailboats. The through

hull installaon is not a complicated process, but it does require careful measurements. Please read the instrucons

thoroughly rst, and if in doubt contact us or your boat rigger with any quesons.

Keep in mind that these instrucons present the basic process. As each boat is designed dierently, your boat may

require specic installaon modicaons. Again, please consult your rigger if in any doubt, and you may decide that it is

best to have your rigger install the Bowsprit for you.

NOTE: If you are not able to install our bowsprit using this method, our side mounts or deck mounng soluon might be

right for your yacht. Custom opons are also possible and we can work with you to devise a suitable method for your

yacht. See our website or contact us for details.

Materials and Tools Required

Parts for the Adjustable Bobstay Aachment (not included )

●5/16 Dyneema (The bobstay purchase is 2:1. Measurements are specic to each boat)

●U Bolt for Bob stay aachment (consult your rigger or sailmaker to determine the working loads for your boat)

●Low fricon rings, Stainless steel rings or blocks

●Bungee cord (Recommended from Davis - MiniShockleTM)

●Preventer Dyneema (Safety feature)

●Masking Tape

●Marker or pencil

●Tape measure

●Drill motor

●Pilot drill bit and 1 inch drill bit

●Round or rotary le

●Structural Epoxy –West System Six10 or similar

●Isopropyl alcohol or acetone

●Vinyl gloves

●Paper towels

●Sandpaper grid 60

●Blue Locte

●Safety Goggles

Trogear Bowsprit Install Manual | www.trogear.com | info@trogear.com 2

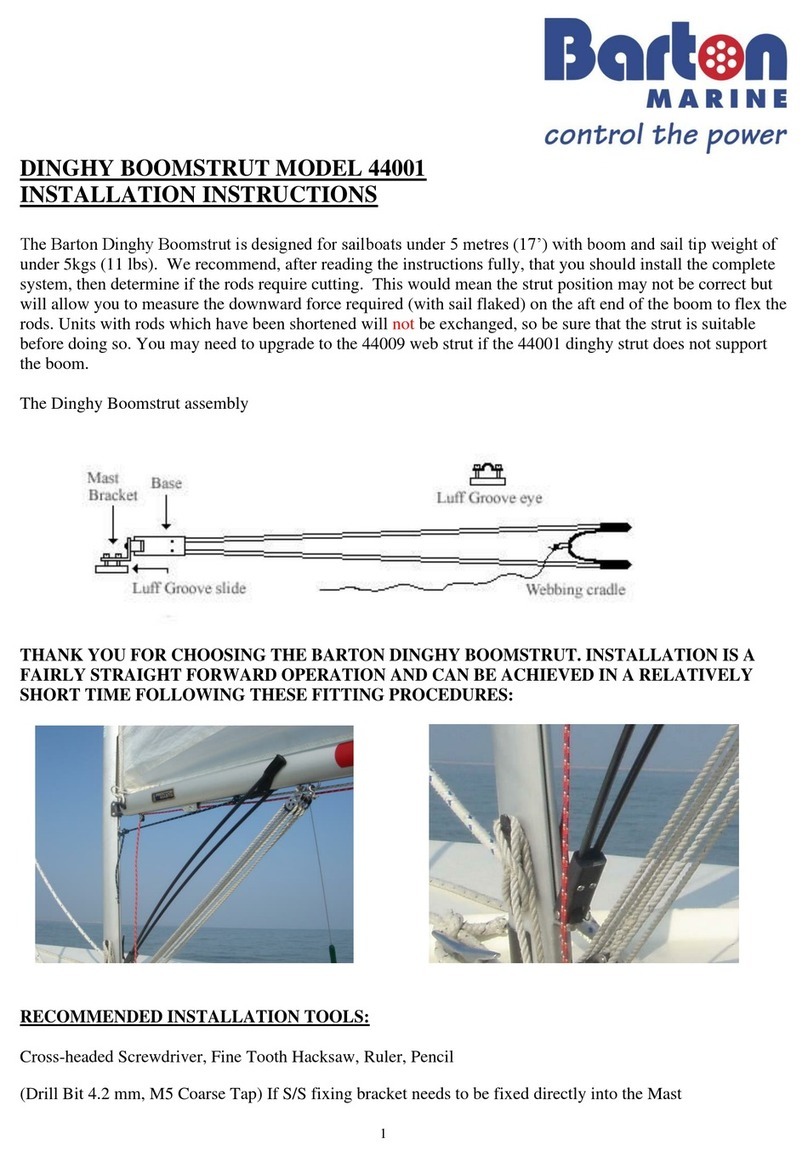

OVERVIEW

The bowsprit is aached to the boat via a removable sha connecng the bowsprit ends. The sha rotates

inside a transversely mounted Fiberglass tube

(Hinge tube).

The Hinge tube is permanently bonded to

the hull with structural epoxy such as West

System Six10 or equivalent. The installaon is

similar to other through hull installaons such

as depth sensors, through valves, etc.

In some cases, depending of the construcon

(cored hulls) or thickness of the hull, the

area surrounding the Hinge tube should be

reinforced by adding layers of Fiber Glass or

Marine Grade Plywood from inside. (Consult

your rigger or contact us if in doubt)

Due to the high compression forces that

the bowsprit can generate, each Hinge tube

end should not protrude past the hull more

than ¾”. If the hull is narrow, such as on a

trimaran, the Trogear Side Mounts or external structural spacers are a viable soluon. Please contact us with

any quesons.

Important: Before installing, do a dry t of the bowsprit. Be sure that the bowsprit can move up freely and

not hit the sides of the boat, bow roller or a rub rail if relevant. Addionally, be sure there are no obstrucons

below deck in the area.

(Fig. 1 & Fig 2)

Fig. 1: Inside the hull is clear Fig. 2: Inside the hull showing the Hinge Tube installed

Trogear Bowsprit Install Manual | www.trogear.com | info@trogear.com 3

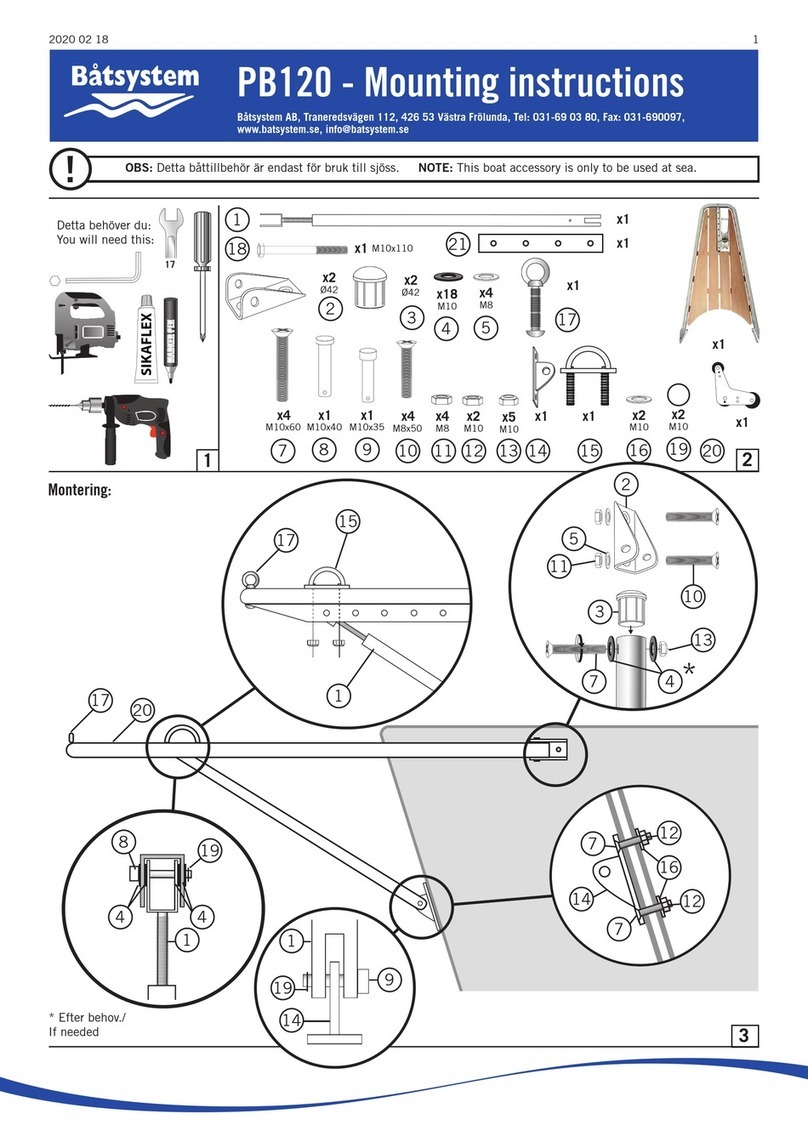

INSTALLATION PROCEDURE

A) Determine the Locaon of the Through Hull Holes for the Hinge Tube:

Note: Keep in mind that for the strongest aachment, the

posion of the tube should be as close to the deck hull

joint as possible. Make sure the Hinge tube is low enough

to not interfere with the deck.

1. First, determine the vercal distance from the deck

for the center of the Hinge tube hole. Place masking

tape below the deck on each side of the bow in the

area where the tube will be installed. This protects

the hull nish and is for temporary markings. (Fig. 3)

2. Horizontal locaon of the Hinge tube: Align the

Bowsprit symmetrically with the Bow and have

the ends touching the hull. Insert a marker in the

Bowsprit Sha aachment holes and mark the Hinge

tube locaons. (Fig. 4)

(This is best accomplished with a helper)

3. The locaon of the Port and Starboard hole should

be symmetrical. Check by comparing the distances

using a piece of non-stretching line aached to the

headstay or other method as appropriate. (Adjust

the hole center locaons if necessary) (Fig. 5)

Fig 3: Tape below the deck.

Fig 4: Use the Bowsprit to determine placement.

Fig 5: Using non-stretching line aached to the headstay, or other method as appropriate, check that the distances you marked are the same on

each side of the boat.

Trogear Bowsprit Install Manual | www.trogear.com | info@trogear.com 4

B) Drilling Holes for the Hinge Tube:

NOTE: You may cover upholstery or other parts inside

against debris

1. First, drill a pilot hole through the hull on

each side. The hole should be horizontal and

perpendicular to the boat’s longitudinal axis.

(Fig. 6)

2. Next, using a 1” step drill, drill the holes for the

tube. (Fig. 7)

3. Fine-tune the holes with a rotary or round le

unl the Hinge Tube can be pushed through.

For the best results, the gap between the Hinge

tube and opening should be approximately

0.01”. (Fig. 8)

C) Bonding Hinge Tube to the Hull:

1. Mask area around the holes leaving about ¼ “ exposed

for epoxy llet. (Fig. 9)

2. Mask the Hinge tube ends to prevent the epoxy from

entering the tube. Clean area surrounding the drilled

holes and Hinge Tube ends with alcohol or acetone and

lightly sand with 60-grid sandpaper. Blow out the dust

and don’t touch.

3. For Yachts with cored hulls: reinforce the area by

removing at least ½” of core surrounding the hole and

lling it with West System 404 High Density Adhesive

Epoxy Filler or similar. Aer the epoxy cures, make sure

the tube will t and has a proper gap of approx. 0.01”.

Fine tune the hole as needed. (see B 3 above).

Fig 6: Drill a pilot hole rst.

Fig 7: Drill holes using a 1” step drill. Fig 8: ne tune holes with a rotary or round le.

Fig 9: Leave about ¼ “ exposed for epoxy llet.

Trogear Bowsprit Install Manual | www.trogear.com | info@trogear.com 5

4. If for some reason the Gap between the Hinge tube and

Hull opening is too large (more than 0.05”): Mix epoxy and

completely coat the drilled holes, working the epoxy into the

surface. Aer the epoxy cures, trim any excess epoxy from the

holes with a round or rotary le. For the best results the gap

between the Hinge Tube and opening should be 0.01”

5. Applying Thickened Structural Epoxy onto the holes and

bonding the tube: Mix Epoxy and completely coat the drilled

holes, working the epoxy into the surface. Coat about 2” of

the Hinge Tube end and insert it into the previously coated

hole and slide it in about a half of its length. Next, also coat

about 2” of the protruding tube end and push and rotate the

tube at the same me unl it protrudes from the opposite

opening. Move and rotate the tube back and forth, and if

necessary add addional Epoxy, to make sure that there is a

proper bond without voids or gaps. (Fig. 10 ) Then, center the tube so that both ends protrude an equal distance

from the hull; you can form a llet around the tube/hull locaons at this me. (Fillets around the tube could be

added later once Epoxy cures). Remove the tape before the epoxy dries.

NOTE: There must be no voids or gaps between Hinge Tube and Hull.

D) Install a Bobstay U Bolt:

The Bobstay is aached on one end to the p of the

Bowsprit and is routed to a U Bolt aached to the bow.

To further decrease bobstay fricon during adjustment,

a low fricon ring can be inserted inside the U Bolt, as

shown here. (Fig. 11)

Select the U Bolt based on hull thickness and choose a Marine

grade Stainless Steel with minimum working load based on your

sails and intended bowsprit use. (Most boats should be ne with

5/16” U Bolts). The angle of the Bobstay is important. For a best

load distribuon, it should at least 45 deg. when the Bowsprit is in

a horizontal posion.

(IMPORTANT: Code 0 type sail generates forces on bobstay twice

as high as an Asymmetrical Spinnaker) – if in doubt, consult your

rigger or sail maker.

Install the U Bolt following the manufacturer’s instrucons.

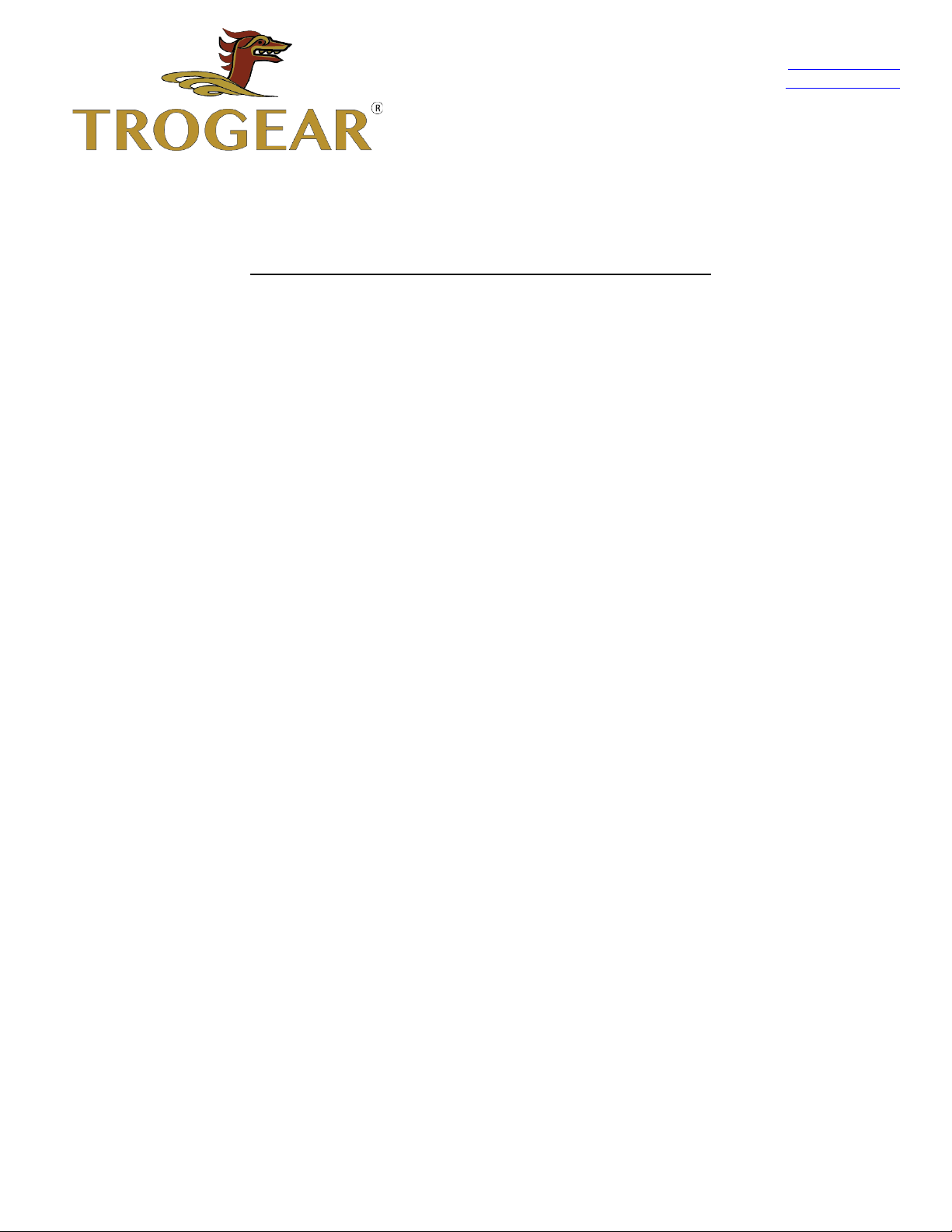

E) Aaching the Bowsprit:

Note: This is best done with a helper but with a lile skill it

can be done alone too.

1. Align the Bowsprit tube end hole with the Hinge tube

hole and slide the Hinge sha into the tube. Use 5/16

bolts, threads coated with a blue Threadlocker or

equivalent and washers to secure it in place.

(Torque 130 in-lbs)

2. If the Bobstay rigging and Stop strap and Bungee are

not in place yet, temporarily secure the bowsprit in

place with a line. (Fig. 12)

Fig 10: Make sure that there is a proper bond without voids

or gaps.

Fig 11: U Bolt aached to the bow.

Fig 12: Temporarily secure the Bowsprit with a line

Trogear Bowsprit Install Manual | www.trogear.com | info@trogear.com 6

F) Rigging the Bowsprit:

There are many ways to rig the Trogear Bowsprit. (For more rigging details, see our rigging example secon online).

1. Permanently Fixed Bowsprit:

The simplest rigging is when the Trogear Bowsprit is used in a permanently extended posion without the need for

adjustment. Use a xed length Bobstay with one end aached to the U Bolt and the other aached to the p of the

Bowsprit.

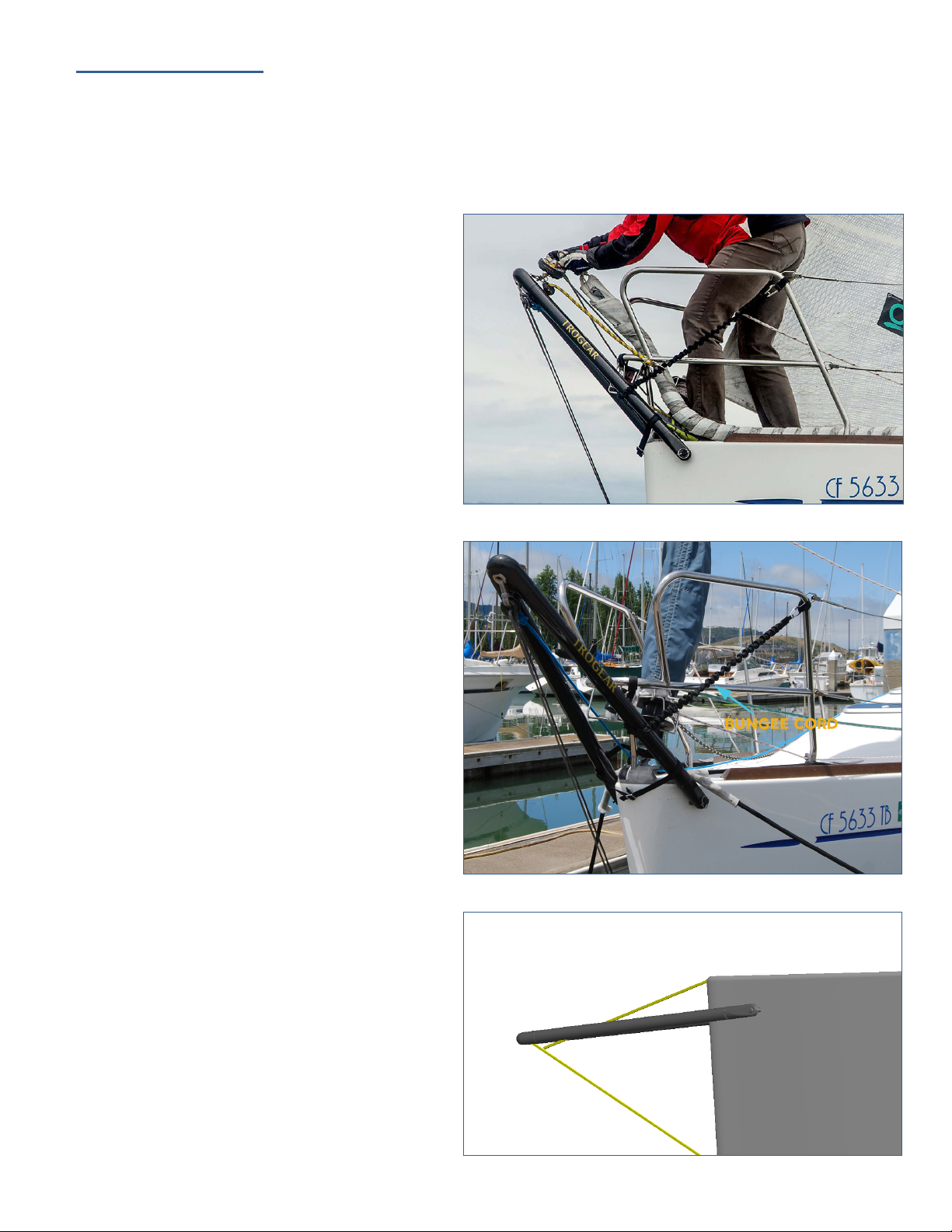

2. Adjustable Bowsprit – hinged aachment:

The Trogear bowsprit’s main design feature is the

hinged aachment, which allows it to rotate up and

down. We recommend a 2:1 Bobstay purchase with

the control line leading to a clutch and winch in the

cockpit. This allows you to take full advantage of

our unique design and adjust the sail lu tension

or bring the Bowsprit to an upright posion (for

stowing or changing sails only) (Fig. 13).

IMPORTANT NOTE: The Trogear Bowsprit should

be close to a horizontal posion when ying the

sails. See our use instrucons enclosed with your

purchase or online for more details.

A Bungee cord can be used to hold the Bowsprit in

an upright posion or pop it up when the bobstay is

released (similar in funcon to a Pole Topping li).

We recommend the MiniShockleTM from Davis but

others can be suitable as well. (Fig. 14)

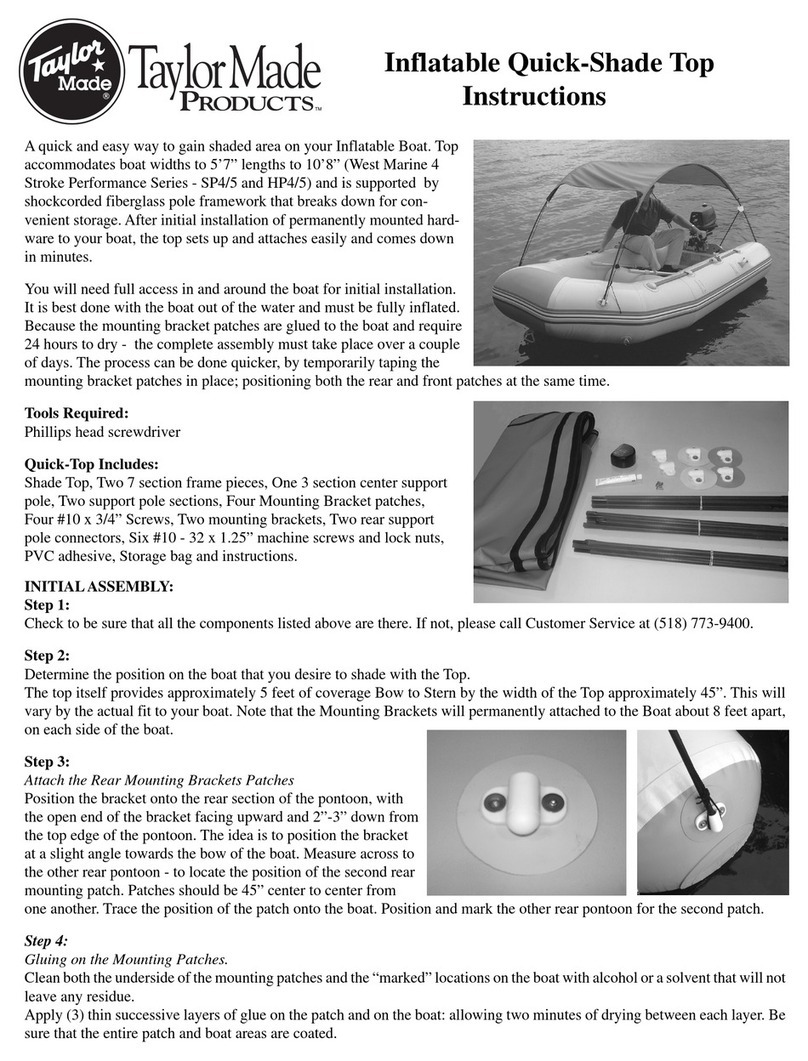

Safety Measure: A method of prevenng the

bowsprit from pivong down past a predened

angle is needed in the event the sail drops to the

water.

Preventer Dyneema: The preventer should

be made from Dyneema and aached to the

headstay toggle and the lower fricon ring at the

p of the Bowpsprit. The length of the Dyneema

should be such that the sprit does not drop past

~20deg of horizontal when under tension. Think

of it as an inverted bobstay or a topping li on a

spinnaker pole. (Fig. 15)

See next page for more rigging details.

Fig 13: Bowsprit in upright posion to aach a furler.

Fig 14: Showing Bungee Cord and Stop Strap.

Fig 15: Preventer from Dyneema

Trogear Bowsprit Install Manual | www.trogear.com | info@trogear.com 7

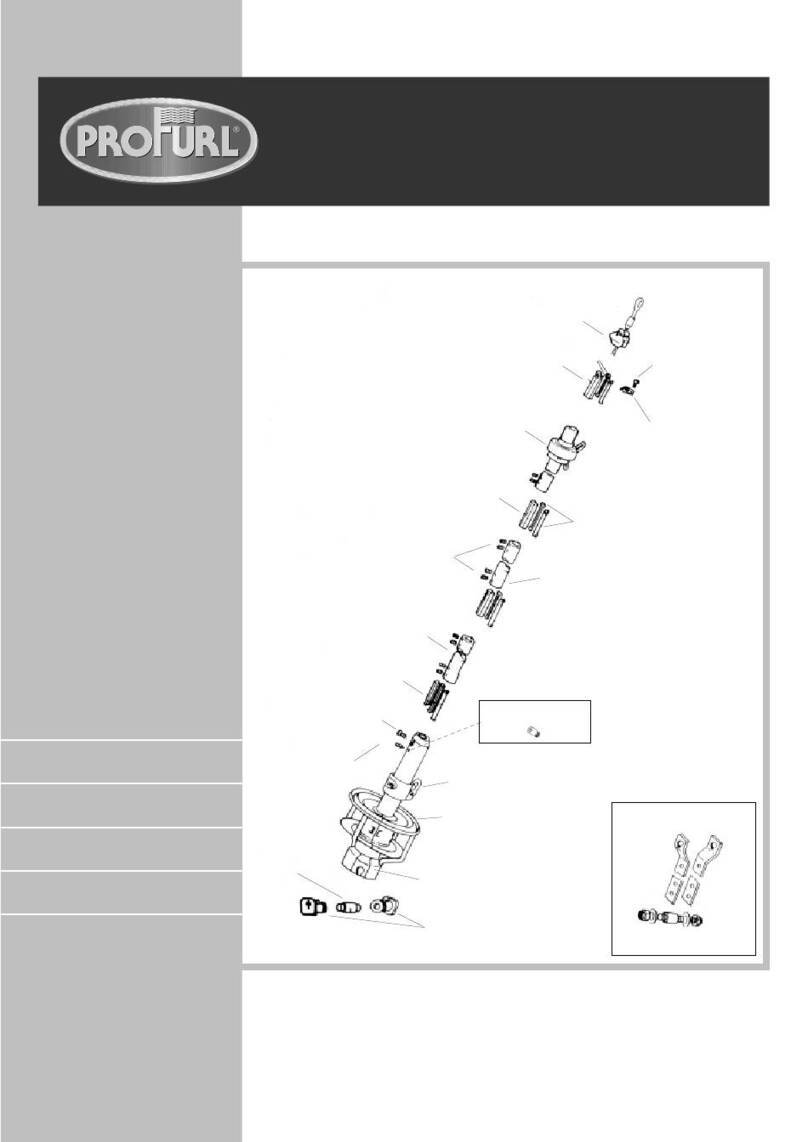

1. U Bolt (shown here with low fricon ring)

2. Bobstay Dyneema - 2:1 purchase

3. Low fricon ring

4. Stainless steel ring for furler aachment or with block for tack line

5. Dyneema loop lead through the bowsprit bushing connects stainless steel ring (#4) and low fricon ring (#3)

6. Bobstay control line led through a clutch to a winch in the cockpit.

7. Bungee cord

1. Furler aached to stainless steel ring.

2. Block for tack line

3. Bobstay Dyneema

Rigging Example: (each yacht owner can congure the rigging that is most suitable for their needs.)

Table of contents

Popular Boating Equipment manuals by other brands

Bearon Aquatics

Bearon Aquatics Ice Eater P250 owner's manual

Taylor Made

Taylor Made Inflatable Quick-Shade Top instructions

Power-Pole

Power-Pole micro anchor Installation and owner's guide

Glendinning

Glendinning HoseMaster user manual

Bootzeil

Bootzeil ShapeX Motor Cruiser Installation instruction

EZZY SAILS

EZZY SAILS Infinity 2010 Rigging guide