苏 州 特 鲁 利 电 子 材 料 有 限 公 司

Suzhou Trojan Industry Material Co.,Ltd

Building A,No.53#, Xinze Road,Singapore Industry Park,Suzhou,Jiangsu Province,

China.

Tel: 0512-67580617 Fax: 0512-67508229

Basic Infomation

Introduction

Suzhou Trojan Industry Material Co., Ltd is a professional supplier and service provider of

metallographic equipment and consumables and developed and manufactured a series of

metallographic cutting machines. Beta-300 series cutting machine applied a new cutting

technology, with a variety of cutting modes. Beta-300 series cutting machine applied the

newest cutting technology. Various cutting modes can satisfy different cutting requirements

from the customers.

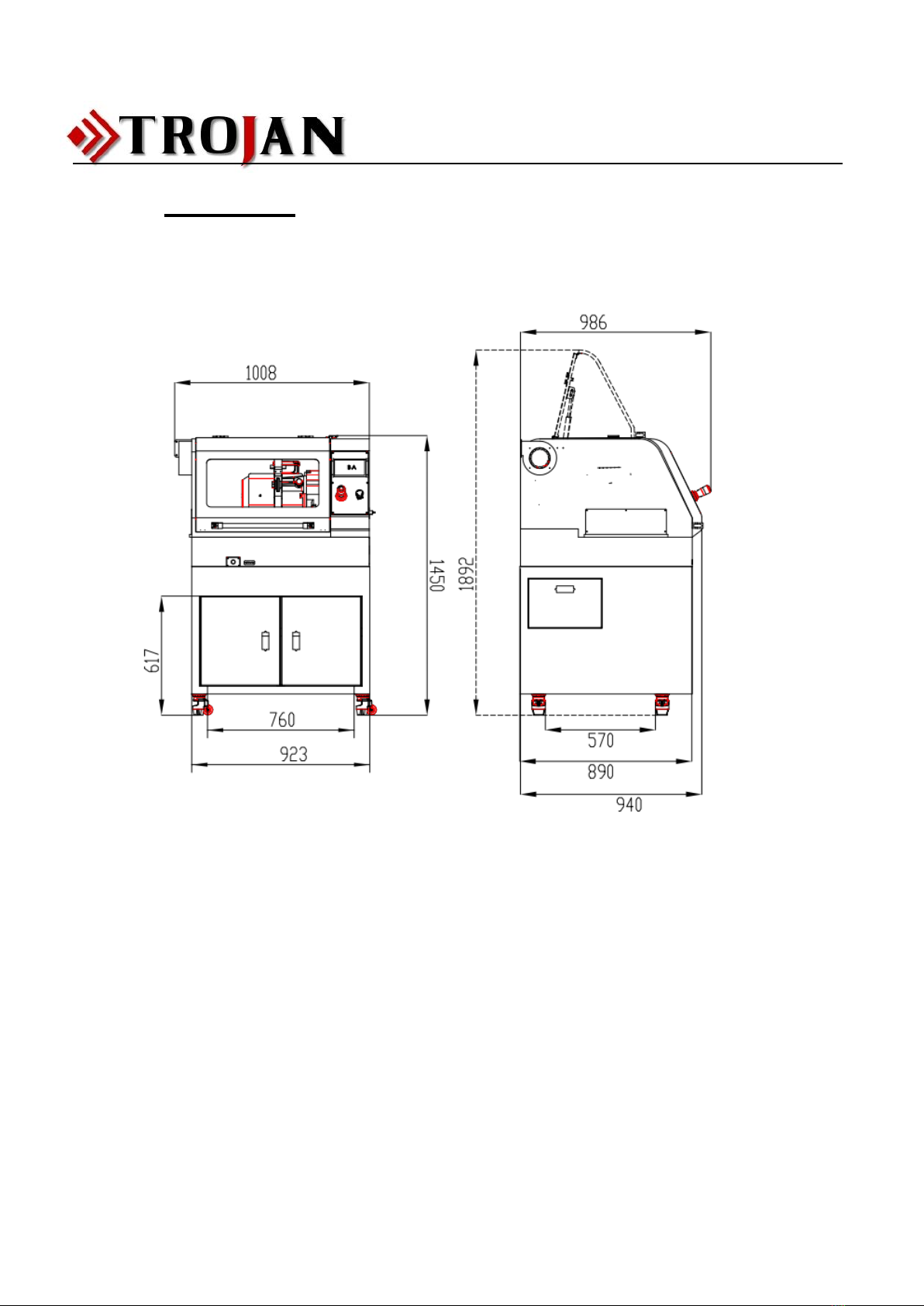

Beta-300 can be loaded with the cutting discs maximum diameter 300mm and equipped

with XYZ three-axis rocker and 7-inch touch screen. It can achieve table-feed cutting (Y

axis), chop cutting (Z axis), and segment cutting (YZ axis). The flexible cutting method

avoids the damage of the sample in cutting process.

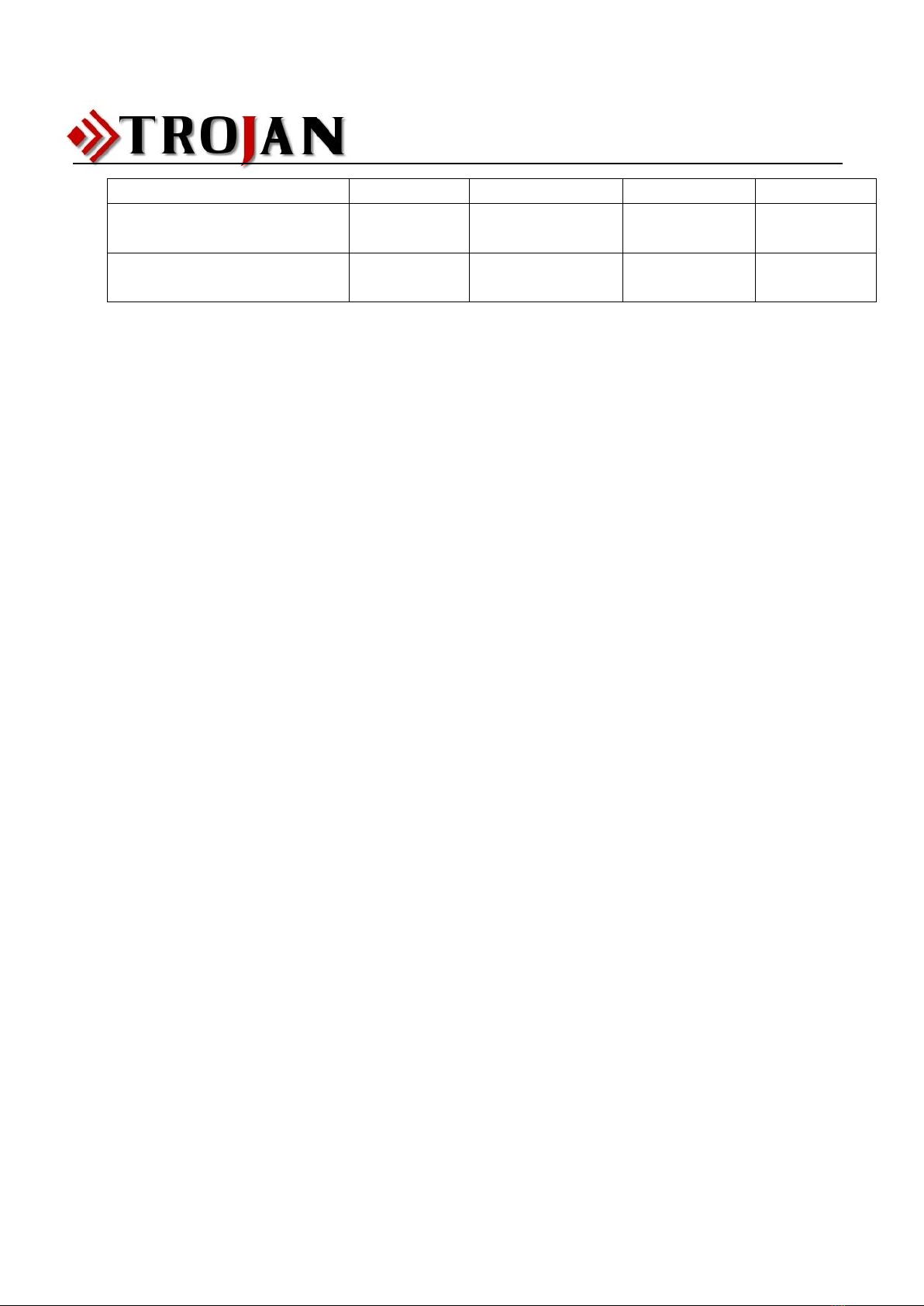

Beta-300 offers the following 3 optional models:

Beta-300 Pro Automatic Cutting Machine: LCD Touch Screen, Three-Axis Rocker Control,

X-Axis, Y-Axis, Z-Axis automatic cutting system. Adjustable speed of cutting disc: 1000-

3500rpm, the maximum cutting diameter 110 mm. The maximum cutting section:

80x200mm. Laser Positioning. Various cutting modes can realize automatic adjustment of

cutting speed in Y and Z directions, pulse cutting and step cutting.

Beta-300 MY manual/automatic integrated semi-automatic cutting machine: LCD Touch

Screen. Single-axis Y-Axis rocker, only Y Axis can realize automatic feed and pulse cutting.

Z-Axis manual hand-wheel control can realize Z-Axis manual cutting. Cutting disc speed

is not adjustable: 2800rpm.

Beta-300M manual cutting machine: No LCD touch screen, operate by control panel and

button. Y-axis movement controlled by hand-wheel, it can realize Y-Axis manual feed

cutting. Z-axis cutting disc is also controlled by manual. Cutting disc speed is not adjustable:

2800rpm.

Beta-300 is equipped with a caster-movable circulating cooling water tank. Capacity 80L.

There are 2 optional filtering type:

⚫100µm filter basket (standard)

⚫Magnetic filter (optional);