Troll systems VLSG-01 User manual

Troll Systems Corporation

Ground-Based Products

VanLink System

Installation Guide

Troll Systems Corporation Technical Publications

Document VLSG-01 Revision – 0

10/17/2008

www.trollsystems.com

NOTICE

The information in this document incorporates proprietary rights of

Troll Systems Corporation

24950 Anza Avenue

Valencia, CA 91355, U.S.A.

Any party accepting this document acknowledges that it contains

proprietary confidential information and agrees that it shall not be

duplicated in whole or in part, nor disclosed to others without the

written consent of Troll Systems Corporation.

© 2008 Troll Systems Corporation

VANLINK SYSTEM GUIDE

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

Document VLSG-01 - 10/21/08 -1

Summary ...................................................................................................................................1

VanLink Equipment Components .............................................................................................1

Required Hardware ............................................................................................................... P-1

Software Requirements ......................................................................................................... P-1

Abbreviations, Acronyms, Terms ......................................................................................... P-2

Packaging .............................................................................................................................. P-4

Warranty ............................................................................................................................... P-4

Conventions Used in this Document ..................................................................................... P-5

VanLink Component Set-up and Operation ......................................................................... P-5

Warnings, Cautions, Notes, and Hints .................................................................................. P-5

Warnings ............................................................................................................................... P-5

Cautions ............................................................................................................................... P-6

Notes ..................................................................................................................................... P-6

Hints ..................................................................................................................................... P-6

Contact Information ............................................................................................................P-7

Hazard Advisory Placards/Signs ........................................................................................... S-1

Know and Comply with Local, State, and Federal Safety Requirements ............................. S-1

Do Not Service or Adjust Alone ........................................................................................... S-1

Electrical Power/Shock Hazards ........................................................................................... S-2

Be Familiar With Resuscitation Techniques ......................................................................... S-3

Coincidental Damage to Equipment in Cabinets .................................................................. S-3

Lifting/Handling Hazards ..................................................................................................... S-3

Electrostatic Discharge Sensitive (ESDS) Components ....................................................... S-4

System Overview .................................................................................................................. 1-1

VanLink System Features ............................................................................................... 1-2

Remote Control from the Studio or Control Center ....................................................... 1-3

SPECIFICATIONS ......................................................................................................... 1-4

Required System Components ........................................................................................ 1-4

Hardware Requirements ................................................................................................. 1-4

Table of Contents

C100 User Interface VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

-2 Document VLSG-01 - 1/11/2007

Master Controller Software Requirements ..................................................................... 1-4

Introduction ..................................................................................................................... 2-1

Safety Recommendations ............................................................................................... 2-1

Installation Requirements ............................................................................................... 2-2

Power Requirements ....................................................................................................... 2-2

Rack Installation ............................................................................................................. 2-2

Rack Space Requirements .............................................................................................. 2-2

Cable Requirements........................................................................................................ 2-2

Running Cables .............................................................................................................. 2-3

V750 Cable and Connector Requirements ...................................................................... 2-3

Pan and Tilt Cabling and Connector Requirements ........................................................ 2-4

GPS/IMU Connectivity ................................................................................................... 2-5

EVDO/3G Router Connectivity ...................................................................................... 2-5

IP Connectivity ............................................................................................................... 2-5

Master Controller(s) and TNS Accessibility .................................................................. 2-5

Typical Network Configuration for VanLink ................................................................. 2-7

GPS/IMU Mounting Considerations .............................................................................. 2-7

GPS/IMU Assembly ....................................................................................................... 2-7

GPS/IMU Mounting Considerations .............................................................................. 2-7

VanLink GPS .................................................................................................................. 2-8

Calibration ...................................................................................................................... 2-9

Magnetometer Calibration .............................................................................................. 2-9

Antenna Calibration ........................................................................................................ 2-9

Remote and Local Control .............................................................................................. 2-9

Operating Requirements ............................................................................................... 2-10

Transmitter Control / Available Options ...................................................................... 2-10

Introduction ..................................................................................................................... 3-1

VANLINK SYSTEM GUIDE

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation Introduction

Document VLSG-01 - 10/21/08 P-1

INTRODUCTION

This Installation Guide is intended for use with the VanLink System featuring

TouchStar™ Technology designed and fabricated by Troll Systems Corporation. The

sections and appendices that make up this manual are as follows:

Safety Considerations

Section 1 - Vanlink System Overview

Section 2 - VanLink System Requirements

Section 3 - Engineering Drawings

This guide or manual is based on the latest information available at the time of

publication.

SUMMARY

VanLink is a system composed of several Troll Systems components that are

coordinated work in a synchronous manner using proprietary software. This complex

and innovative system configuration enables complete studio control of a broadcast

news van while it is in the field.

VANLINK EQUIPMENT COMPONENTS

Required Hardware

The VanLink system is comprised of the following hardware components:

• V750 - Troll Systems Remote VanLink controller

• GPS/IMU – Troll Systems GPS & Magnetometer assembly

• Quickset Pan/Tilt – Pan/Tilt pedestal w/ Azimuth and Elevation feedback

• Pan/Tilt controller – Pan/tilt controller with remote interface capability

• EVDO or 3G Router

Software Requirements

• TouchStar 2008 – Windows application providing the control interface for VanLink.

• TouchStar 02 Mapping Software – Displays and provides control for all receive sites

including each vehicle equipped with VanLink.

INTRODUCTION

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

P-2 Document VLSG-01 - 10/17/2008

ABBREVIATIONS, ACRONYMS, TERMS

Listing of general abbreviations, acronyms, and terms that may be used throughout this

document are defined in the following list.

Term Definition

AC Alternating Current

ALT Altitude

ANT Antenna

AUX Auxiliary

Az Azimuth

BAS Broadcast Auxiliary Service

CAL Calibrate

CAM Camera

Ch Channel

COMM Communication

COTS Commercial-Off-The-Shelf

CPU Central Processing Unit

dB Decibel

DC Direct Current

DMM Digital Multimeter

e.g. Latin: exempli gratia, meaning “for example”

EMI Electro-Magnetic Interference

ENG Electronic News Gathering

ESD Electro-Static Discharge

et al Latin: et alia, meaning “and others”

FM Frequency Modulation

GPS Global Positioning System

GUI Graphic User Interface

HD High Definition

Hz Hertz

H/W Hardware

I/O Input/Output

i.e. Latin: id est, meaning “that is”

ABBREVIATIONS, ACRONYMS, TERMS

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation Introduction

Document VLSG-01 - 10/17/2008 P-3

LAT Latitude

LCD Liquid Crystal Display

LED Light Emitting Diode

LNA Low-Noise Amplifier

LNG Longitude

MICOWV Microwave

NEMA National Electrical Manufacturing Association

NIC Network Interface Card

nm (NM) Nautical Mile (note: 1 nautical mile equals 1.150782 miles)

NTSC National Television System Committee

NAV NavTrack

NV Non-Volatile

PC Personal Computer

PED Pedestal

POL Polarization

PRSETS Presets

RAM Random Access Memory

RF Radio Frequency

RFI Radio Frequency Interference

ROM Read Only Memory

RPC Remote Procedure Call

RX Receiver/Receive

S/W Software

SDI Serial Digital Interface

SV System Variable

TX Transmitter/Transmit

V Volt

VAC Volts Alternating Current

VDC Volts Direct Current

WWatt

Term Definition

INTRODUCTION

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

P-4 Document VLSG-01 - 10/17/2008

PACKAGING

Use the original packaging material used for your TNS3000 network Server if available

and in good condition.

If you must return your product to Troll Systems Corporation for repair (and you no

longer have your original box and packing materials), Troll will send you a packing box

specifically designed to ship the product without damage.

WARRANTY

Troll warrants, to the original Customer only, that the product is free from defects in

material and workmanship and conforms to the specification, if any. If no specification

is listed, the items are warranted to conform to our currently published specification for

the product. The warranty period is for a period of one year from the date of shipment.

Troll will repair or replace (at its option) any such device which is returned to the Troll

factory office, with transportation charges prepaid and within the warranty period. The

liability of Troll shall be limited to the repair or replacement of the device and shall not

include installation, or any other charge or expense incurred. This warranty shall not

apply to any unit or part thereof which, in the opinion of Troll, has been installed or used

improperly; damaged by accident, corrosion, misused, or negligence; or altered or

repaired in such a manner as to impair performance. Troll must receive written notice of

the defect within the warranty period. Customer must pay packing, crating and

transportation costs to and from the factory. At the Customer’s request, Troll will make

reasonable efforts to provide warranty service at the Customer’s premises, provided that

Customer pays Troll’s then current rates for field service and the associated travel and

living expenses. If a fault has been caused by improper installation, maintenance or use,

or by abnormal conditions of operation, those repairs will be billed at normal rates. Troll

shall have the right of final determination as to the existence and cause of any such

defect.

CONVENTIONS USED IN THIS DOCUMENT

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation Introduction

Document VLSG-01 - 10/17/2008 P-5

CONVENTIONS USED IN THIS DOCUMENT

VanLink Component Set-up and Operation

The Troll Systems V750 Remote Site Controller and its innovative capabilities is the

heart of the VanLink system. For comprehensive information for this complex and

dynamic component, consult the Troll Systems manual for the S750 Remote Site

Controller manual which is identical to the V750 in almost all respects and functions.

Text appearing on the bottom line of the front panel display (just above the function

keys) of the V750 Remote site controller (i.e., commands associated with function keys

A, B, C, D, and E) appear in the font, Arial Rounded MT Bold

Text and terms that are emphasized to draw the reader’s attention (due to their

significance within the text) appear in italics. See the example below.

WARNINGS, CAUTIONS, NOTES, AND HINTS

Warnings

Warnings are included to alert the user that possible hazards are associated with the

processes/procedures described. These may cause death or injury in any form, if the

instructions in the operational or procedural task are not followed precisely. Warnings

describe the potential hazards and possible impact that could occur if the warnings are

not observed.

WARNING: This format is used for general warnings.

WARNING: This format is used for electrical warnings.

WARNING: This format is used for mechanical warnings.

INTRODUCTION

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

P-6 Document VLSG-01 - 10/17/2008

Cautions

Cautions are included to alert the user that damage to the equipment is possible if the

instructions in the operational or procedural task are not followed precisely. Cautions

describe the hazards and possible impact that could occur if the cautions are not

observed.

Notes

Notes are included to provide the user with supplemental information, which is helpful

but does not necessarily belong in the core text. Many operational and procedural tasks

are easier with the addition of notes.

Hints

Hints are generally included to inform the user of special features and/or methods of

performing various tasks. These are usually unique features/methods that provide

streamlined use of the equipment and/or user interface.

Hint: This format is used for all hints.

WARNING: This format is used for warnings which include the risk

of fire.

CAUTION: This format is used for all cautions.

NOTE: This format is used for all notes.

CONTACT INFORMATION

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation Introduction

Document VLSG-01 - 10/17/2008 P-7

CONTACT INFORMATION

Troll Systems Corporation is committed to providing its customers with quick and

friendly service. If you have questions regarding your Troll product, or if you

experiencing a technical problem, please contact us at:

Troll Systems

24950 Anza Drive

Valencia, CA 91355

Phone: (661) 702-8900

Fax: (661) 702-8901

Alternatively, you can contact us via e-mail at:

Sales

Service

Troll Systems Corporation is continually updating and enhancing its existing products

while also developing new products for the Electronic News Gathering (ENG) and

Airborne Law Enforcement (ALE) industries. Visit us on the world wide web at:

www.trollsystems.com

INTRODUCTION

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

P-8 Document VLSG-01 - 10/17/2008

NOTES

VANLINK SYSTEM GUIDE

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation Safety Considerations

Document VLSG-01 - 10/17/2008 S-1

SAFETY CONSIDERATIONS

GENERAL SAFETY PRECAUTIONS

The following general safety precautions are not related to any specific procedures and

therefore do not appear elsewhere in this publication. They are, however, precautions

that personnel need to understand and apply when operating or repairing equipment.

Installation, operation, and maintenance should be performed only by qualified

personnel.

Hazard Advisory Placards/Signs

Read and heed all hazard advisory placards or signs affixed to the equipment or

surrounding enclosures. They warn of potential hazards to personal safety and possible

damage to equipment if correct maintenance practices are not followed. Ignoring hazard

advisory placards (WARNINGS/CAUTIONS) places personnel at risk for serious injury or

death.

Know and Comply with Local, State, and Federal Safety Requirements

You should be familiar with all local, state, and federal safety requirements applicable to

the equipment, processes, and materials you use during maintenance. Before using any

substances or materials marked toxic or hazardous, always refer to the Material Safety

Data Sheets (MSDS) for that substance/material for any special protective equipment,

handling, and/or disposal requirements.

Do Not Service or Adjust Alone

Do not start a maintenance or adjustment procedure if that procedure requires more

than one technician to be safely performed. It is particularly important that such work

not be performed in a remote area, away from other qualified personnel who may be

needed to render assistance. When a maintenance task requires two or more personnel

to be safely accomplished, delay the task until qualified personnel are available to assist

you.

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

S-2 Document VLSG-01 - 10/17/2008

VanLink Safety Considerations

For safety reasons Troll Systems does not offer control of masts. There are, however,

methods for implementing safety measures to prevent any damage to the antenna or

surrounding equipment by monitoring the mast’s position and locking out control when

the mast is down. Due to the number of unique vehicle configurations and mast controls

available this shall be considered an option that will require additional preparation and

information from the customer/installer prior to implementation. Currently it is the

operator’s responsibility to ensure that the antenna is clear from any obstructions before

enabling remote control for the studio.

Electrical Power/Shock Hazards

Always verify that electrical power is disconnected and that applicable safety procedures

have been followed before doing maintenance on any electrical/electronic equipment.

High voltage electrical energy is stored in some electrical equipment (electrolytic

capacitors, UPS batteries, etc.) even after the source of primary external power has been

disconnected. Always remove external power, deactivate equipment, or discharge the

potential to ground (when applicable) before working on the equipment.

If a high-potential insulation test is required, follow the procedures and precautions

outlined in the appropriate National Electrical Manufacturing Association (NEMA)

standards. Check with the area supervisor if unfamiliar with these standards, specific

equipment, or procedures.

When electrical troubleshooting of a system must be accomplished with power applied,

first verify that all personnel in the hazard area are advised, that the equipment is

tagged, and/or that an assistant is posted at the point of power control.

WARNING: Potentially lethal voltage/current is present throughout

many electrical installations. Maintenance personnel

shall employ positive power lockout devices and post all

required warning tags/signs when applicable to ensure

that no unauthorized application of power can occur

during maintenance. Failure to heed this warning could

result in serious injury or death by electrocution.

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation Safety Considerations

Document VLSG-01 - 10/17/2008 S-3

Be Familiar With Resuscitation Techniques

Personnel working with or near high voltages should be familiar with modern methods

of resuscitation. It is beneficial to ensure that personnel are capable of performing

Cardio-pulmonary resuscitation (CPR) should the need arise.

Coincidental Damage to Equipment in Cabinets

When removing equipment from cabinets/consoles, exercise care so that surrounding

wiring installations and equipment are not physically damaged in the process.

Disconnect and secure any surrounding wiring or hardware which could cause damage

to or be damaged by the equipment being removed.

When installing equipment into cabinets/consoles, exercise care to protect surrounding

wiring installations and equipment from being physically damaged in the process.

Neatly stow excess cable/wiring and replace all tie wraps, clamps, and other retaining

devices which were removed. Neat installations reduce the chances of coincidental

damage to adjacent equipment and promote more efficient air circulation and equipment

cooling.

Lifting/Handling Hazards

The removal and installation of large, heavy, or awkward component assemblies,

especially equipment attached to the external areas of the aircraft, will require a

minimum of two (2) personnel to safely handle. Alternatively, the use of appropriately

rated material handling equipment can be used when determined to be safe. Where

limited access prevents the use of material handling equipment, ensure that an adequate

number of personnel are present to safely handle the anticipated loads.

CAUTION: Pushing or forcing equipment into/out of equipment

cabinets and enclosures can easily damage surrounding

equipment, cables/wiring, or fiber optic cable installations.

Be alert to avoid coincidental damage to equipment when

accessing crowded installations. Coincidental damage is

often difficult to detect and even more difficult to

troubleshoot.

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

S-4 Document VLSG-01 - 10/17/2008

Electrostatic Discharge Sensitive (ESDS) Components

Computers, microprocessors, and other solid state components (circuit cards,

I/O boards, etc.) which are not clearly marked with the ESDS symbol will be handled as

ESD sensitive components until determined otherwise. Retain protective ESDS packing

and shipping bags, containers, non-conductive foam pads, etc. (see Figure S–1) for use

in the return of repairable components.

CAUTION: Beware of electrostatic buildup. Delicate solid-state

Integrated Circuits (ICs) can be damaged by improper

handling procedures. Use proper electrostatic safeguards

when installing/removing circuit cards and handling ESD

sensitive assemblies. As required, wear a grounded wrist

strap, use antistatic floor and table mats, and minimize the

handling of sensitive solid-state devices. Keep all ESD

sensitive components in their original containers until

ready for use. Always discharge personal static before

handling ESD sensitive components and do not slide solid

state devices over any surface. Handle plug-in card

assemblies only by their non-conductive edges.

Minimize Handling. Keep parts in original containers

until ready for use.

Discharge personal static

before handling devices.

Handle devices by the body. Use anti-static containers for

handling and transport.

Do not slide devices over any

surface.

Avoid plastic, vinyl and

styrofoam in work area.

When removing plug-in

assemblies, handle only by

non-conductive edges and

never touch open edge

connector except at static-free

work station. Placing shorting

strips on edge connector

usually provides complete

protection to installed devices.

Handle devices only at a static-

free work station.

Only anti-static type solder

suckers should be used.

Only grounded tip soldering

irons should be used.

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation Safety Considerations

Document VLSG-01 - 10/17/2008 S-5

Figure S–1. Procedures for Handling Electrostatic Sensitive Components

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

S-6 Document VLSG-01 - 10/17/2008

NOTES

VANLINK SYSTEM GUIDE

VanLink System featuring TouchStar™ Technology - Troll Systems Corporation VanLink System Overview

Document VLSG-01 - 10/21/08 1-1

SECTION 1

VANLINK SYSTEM OVERVIEW

1.1 SYSTEM OVERVIEW

The Troll Systems VanLink remote broadcast van control interface is a comprehensive

and dynamic system designed to be integrated into vehicles utilized in Electronic News

Gathering functions in the field. Refer to Figure 1–1 through Figure 1–3.

TOUCHST A R

S750

QPT - 90/115 with

Local and Remote Controller

Transmitter

to V750 serial input

EVDO to V750 Ethernet

with Static IP or Dynamic DNS WAN

Field Vehicle with Tx,GPS

and Magnetometer

controlled remotely by

studio operator

Van Tx Antenna

with Pan and Tilt

Rooftop or Antenna

Mounted IMU

Troll Systems V750

Remote Site Controller

12 wire Nycoil

from V750 to

Tx Antenna

CONTROL

FEEDBACK

Van External

Control Panel

with QPT set

to Remote

Van External

Control Panel

with QPT set

to Remote

CONTROL

CONTROL

COMM

COMM

CONTROL

Figure 1–1. VanLink System ENG Vehicle Configuration

SYSTEM OVERVIEW

User Manual VanLink System featuring TouchStar™ Technology - Troll Systems Corporation

1-2 Document VLSG-01 - 10/21/08

1.1.1 VanLink System Features

This system enables several operations of the ENG vehicle to be controlled remotely

from the broadcast studio including such key functions as:

TOUCHST AR

S750

Troll Systems V750 Remote Site Controller

communicating with van IMU GPS and Magnetometer while

coordinating with preprogrammed site latitude and

longitudinal data for accurate signal tracking in real time

GPS

Magnetometer

IMU

• Remote tracking of vehicle heading and location including locations of all vehicles

that are mutually equipped with VanLink

• Troll MC17 Master Controller with Graphic User Interface featuring the control page

and GPS enabled screen MAP

• Transmitter antenna control including pan and tilt for azimuth and elevation feedback

• Optional roof mount or mast mount of the GPS/IMU to minimize EMI interference

• Automatic tracking of the HD signal with self-optimization of the vehicle transmitter

antenna in real time using the V750’s preprogrammed ability to analyze and

compensate for signal integrity in reference to the studio’s coordinates and the

vehicle’s GPS/IMU location feedback. (see Figure 1–2)

Figure 1–2. VanLink IMU Configuration

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Contemporary Research

Contemporary Research ICC-PRZ product manual

Endress+Hauser

Endress+Hauser ZAD 423 operating instructions

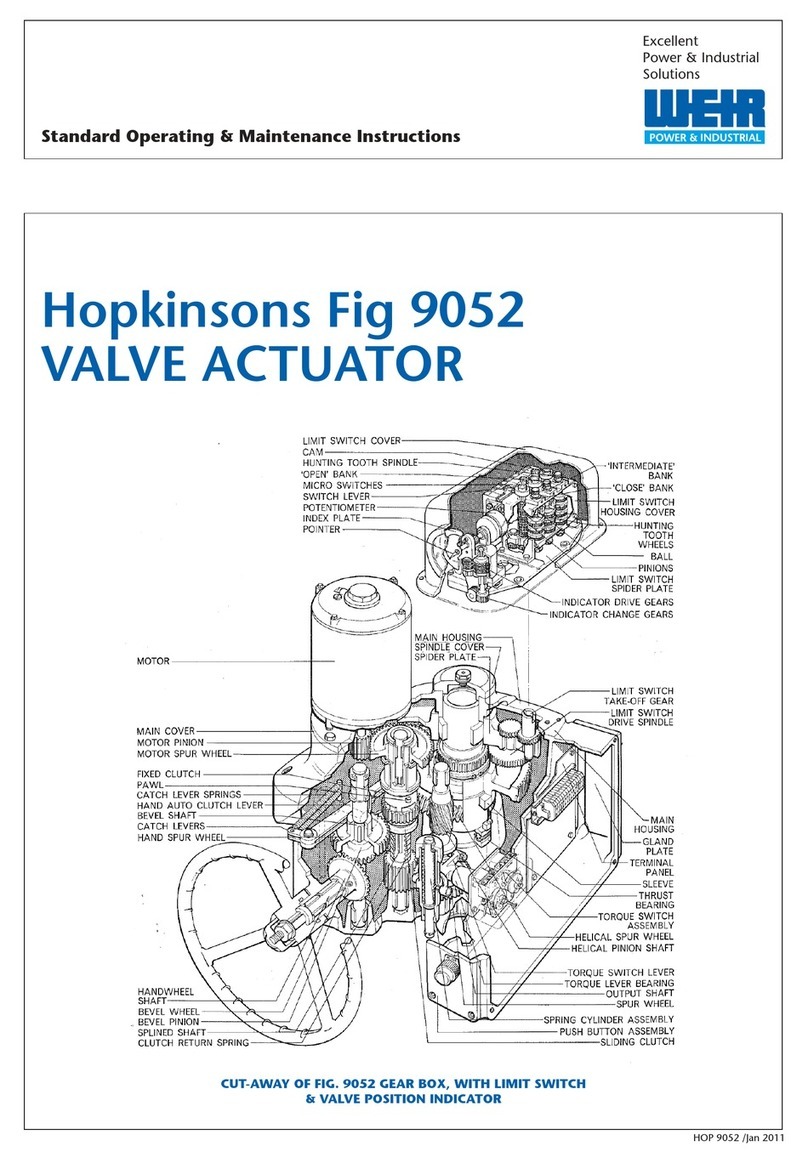

Weir

Weir Hopkinsons Fig 9052 Standard Operating & Maintenance Instructions

CDVI

CDVI ATRIUM A22POE installation manual

Huawei

Huawei SmartACU2000B quick guide

Viconics

Viconics VTR7300 Series installation guide