AuCom EMX4i User manual

EMX4i Soft Starter

USER MANUAL

CONTENTS

710-14888-00C EMX4i User Manual 1

Contents

1. About This Manual.....................................3

1.1 Disclaimer ......................................................3

2. Caution Statements ..................................4

2.1 Electrical shock risk......................................4

2.2 Unexpected Operation ..................................5

2.3 Avertissements à l'attention des clients

canadiens........................................................6

3. System Design ...........................................8

3.1 Feature List ....................................................8

3.2 Model Code.....................................................9

3.3 Model Selection .............................................9

3.4 Current Ratings .......................................... 10

3.5 Dimensions and Weights .......................... 13

3.6 Physical Installation................................... 14

3.7 Accessories ................................................. 14

3.8 Main Contactor ........................................... 15

3.9 Circuit Breaker ........................................... 15

3.10 Power Factor Correction........................... 16

3.11 Short Circuit Protection Devices (SCPD) 16

3.12 IEC Coordination with Short Circuit

Protection Devices ..................................... 17

3.13 UL Coordination with Short Circuit

Protection Devices ..................................... 18

3.14 Fuse Selection for Type 2 Coordination .. 21

3.15 Specifications.............................................. 22

3.16 Disposal Instructions................................. 23

4. Installation ...............................................24

4.1 Command Source ...................................... 24

4.2 Setup Procedure Overview ....................... 24

4.3 Inputs............................................................ 25

4.4 Outputs......................................................... 27

4.5 Control Voltage ........................................... 28

4.6 Power Terminations .................................. 28

4.7 Typical Installation ..................................... 31

4.8 Quick Setup ................................................. 33

5. Setup Tools ..............................................34

5.1 Set Date and Time...................................... 34

5.2 Command Source ...................................... 34

5.3 Commissioning........................................... 34

5.4 Run simulation............................................ 35

5.5 Load/Save Settings .................................... 36

5.6 USB Save & Load........................................ 36

5.7 Auto-Start/Stop........................................... 38

5.8 Network Address........................................ 38

5.9 Digital I/O State ........................................... 39

5.10 Analog I/O State .......................................... 39

5.11 Serial Number & Rating............................ 39

5.12 Software Versions....................................... 40

5.13 Thermistor Reset........................................ 40

5.14 Reset Thermal Model.................................40

6. Logs.......................................................... 41

6.1 Event Log ..................................................... 41

6.2 Counters....................................................... 41

6.3 QR Code........................................................ 41

7. Keypad and Feedback ............................. 42

7.1 The Keypad .................................................. 42

7.2 Remote Keypad........................................... 43

7.3 Lighten/Darken the Display ...................... 43

7.4 Starter status LEDs.................................... 44

7.5 Displays........................................................ 44

8. Operation ................................................. 46

8.1 Start, Stop and Reset Commands............ 46

8.2 Command Override.................................... 46

8.3 Auto-Start/Stop........................................... 46

8.4 PowerThrough ............................................ 47

8.5 Emergency Mode........................................ 48

8.6 Auxiliary Trip................................................ 48

8.7 Typical Control Methods............................ 49

8.8 Soft Start Methods...................................... 50

8.9 Stop Methods .............................................. 53

8.10 Pump Clean................................................. 57

8.11 Reverse Direction Operation..................... 57

8.12 Jog Operation.............................................. 58

8.13 Inside Delta Operation ............................... 59

8.14 Secondary Motor Set.................................. 60

9. Programmable Parameters .................. 61

9.1 Main Menu ................................................... 61

9.2 Altering Parameter Values ....................... 61

9.3 Adjustment Lock......................................... 61

9.4 Parameter List............................................ 62

9.5 1 Motor Details............................................ 70

9.6 2 Motor Start/Stop...................................... 71

CONTENTS

2EMX4i User Manual 710-14888-00C

9.7 3 Motor Start/Stop-2.................................. 74

9.8 4 Auto-Start/Stop ....................................... 77

9.9 5 Protection Levels..................................... 80

9.10 6 Protection Action..................................... 82

9.11 7 Inputs......................................................... 86

9.12 8 Relay Outputs........................................... 89

9.13 9 Analog Output .......................................... 91

9.14 10 Display..................................................... 92

9.15 11 Pump Clean............................................ 95

9.16 12 Communications Card ......................... 96

9.17 20 Advanced ................................................ 99

9.18 30 Pump Input Configuration ................. 100

9.19 31 Flow Protection ................................... 102

9.20 32 Pressure Protection ........................... 103

9.21 33 Pressure Control................................. 104

9.22 34 Depth Protection ................................. 105

9.23 35 Thermal Protection............................. 105

9.24 36 Pump Trip Action................................. 106

10. Application Examples............................108

10.1 Smart Card - Pump Control and

Protection .................................................. 108

10.2 Smart Card - Level Controlled Pump

Activation ................................................... 110

11. Troubleshooting ....................................112

11.1 Protection Responses.............................. 112

11.2 Trip Messages........................................... 112

11.3 General Faults .......................................... 121

ABOUT THIS MANUAL

710-14888-00C EMX4i User Manual 3

1. About This Manual

WARNING

Indicates a hazard that may cause personal injury or death.

CAUTION

Indicates a hazard that may damage the equipment or installation.

NOTE

Provides helpful information.

1.1 Disclaimer

The examples and diagrams in this manual are included solely for illustrative

purposes.

The information contained in this manual is subject to change at any time and

without prior notice. In no event will responsibility or liability be accepted for direct,

indirect or consequential damages resulting from the use or application of this

equipment.

© 2018 AuCom Electronics Ltd. All Rights Reserved.

As AuCom is continuously im

proving its products it reserves the right to modify or change the specification

of its products at any time without notice

. The

text, diagrams, images and any other literary or artistic works

appearing in this document are protected by copyright. Users may copy some of the material for their

personal reference but may not copy or use material for any other purpose without the prior consent of

AuCom Electronics Ltd. AuCom endeavours to ensure that the information contained in this document

including images is correct but does not accept any liability for error, omission or differences with the

finished product.

CAUTION STATEMENTS

4EMX4i User Manual 710-14888-00C

2. Caution Statements

Caution Statements cannot cover every potential cause of equipment damage but

can highlight common causes of damage. It is the installer's responsibility to read

and understand all instructions in this manual prior to installing, operating or

maintaining the equipment, to follow good electrical practice including applying

appropriate personal protective equipment and to seek advice before operating this

equipment in a manner other than as described in this manual.

NOTE

The EMX4i is not user serviceable. The unit should only be serviced by

authorised service personnel. Unauthorised tampering with the unit will

void the product warranty.

FOR YOUR SAFETY

•The STOP function of the soft starter does not isolate dangerous voltages

from the output of the starter. The soft starter must be disconnected by

an approved electrical isolation device before accessing electrical

connections.

•Soft starter protection features apply to motor protection only. It is the

user’s responsibility to ensure safety of personnel operating machinery.

•The soft starter is a component designed for integration within an

electrical system; it is therefore the responsibility of the system

designer/user to ensure the system is safe and designed to comply with

relevant local safety standards.

2.1 Electrical shock risk

WARNING – ELECTRICAL SHOCK RISK

The voltages present in the following locations can cause severe electric

shock and may be lethal:

•AC supply cables and connections

•Output cables and connections

•Many internal parts of the starter

SHORT CIRCUIT

The EMX4i is not short circuit proof. After severe overload or short circuit,

the operation of the EMX4i should be fully tested by an authorised service

agent.

CAUTION STATEMENTS

710-14888-00C EMX4i User Manual 5

GROUNDING AND BRANCH CIRCUIT PROTECTION

It is the responsibility of the user or person installing the EMX4i to provide

proper grounding and branch circuit protection according to local electrical

safety codes.

2.2 Unexpected Operation

WARNING – ACCIDENTAL STARTS

In some installations, accidental starts may pose an increased risk to safety

of personnel or damage to the machines being driven. In such cases, it is

recommended that the power supply to the soft starter is fitted with an

isolating switch and a circuit-breaking device (eg power contactor)

controllable through an external safety system (eg emergency stop, fault

detector).

WARNING – STARTER MAY START OR STOP UNEXPECTEDLY

The EMX4i will respond to control commands from various sources, and

could start or stop unexpectedly. Always disconnect the soft starter from

mains voltage before accessing the starter or load.

WARNING – DISCONNECT MAINS BEFORE ACCESSING STARTER OR

LOAD

The soft starter has built-in protections which can trip the starter in the

event of faults and thus stop the motor. Voltage fluctuations, power cuts and

motor jams may also cause the motor to trip.

The motor could restart after the causes of shutdown are rectified, which

may be dangerous for personnel. Always disconnect the soft starter from

mains voltage before accessing the starter or load.

CAUTION – MECHANICAL DAMAGE FROM UNEXPECTED RESTART

The motor could restart after the causes of shutdown are rectified, which

may be dangerous for certain machines or installations. In such cases, it is

essential that appropriate arrangements are made against restarting after

unscheduled stops of the motor.

CAUTION STATEMENTS

6EMX4i User Manual 710-14888-00C

2.3 Avertissements à l'attention des clients canadiens

AVERTISSEMENT

L'icône AVERTISSEMENT ci-contre signale les informations concernant des

risques pouvant entraîner des blessures graves, voire mortelles. Pour votre

sécurité, veuillez consulter les avertissements sur cette page ou demander

une copie du présent manuel en français auprès de votre distributeur local.

AVERTISSEMENT – RISQUE DE CHOC ÉLECTRIQUE

Les zones suivantes sont soumises à des tensions pouvant provoquer des

risques de chocs électriques graves, voire mortels :

•Raccordement et câbles d'alimentation AC

•Câbles et raccordements de sortie

•De nombreuses pièces internes du démarreur

PAR SÉCURITÉ

•La fonction STOP du démarreur progressif n'isole pas des tensions

dangereuses de la sortie du démarreur. Le démarreur progressif doit

être déconnecté par un dispositif d'isolement électrique approprié avant

d'accéder aux connexions électriques.

•Les fonctions de protection du démarreur progressif ne concernent que

la protection du moteur. Il relève de la responsabilité de l'utilisateur

d'assurer la sécurité des personnes travaillant sur les machines.

•Le démarreur progressif est un appareil conçu pour s'intégrer dans un

système électrique ; il relève donc de la responsabilité du concepteur ou

de l'utilisateur de veiller à ce que ce système soit sûr et conçu selon les

normes de sécurité locales en vigueur.

AVERTISSEMENT – DÉMARRAGES ACCIDENTELS

Dans certaines installations, des démarrages accidentels peuvent

provoquer un risque supplémentaire pour la sécurité des personnes ou

endommager les machines contrôlées. Dans de tels cas, il est

recommandé de doter l'alimentation du démarreur progressif d'un

interrupteur d'isolement et d'un coupe-circuit (par exemple, un disjoncteur)

contrôlable à partir d'un système de sécurité externe (par exemple, un arrêt

d'urgence, un détecteur de défaut).

CAUTION STATEMENTS

710-14888-00C EMX4i User Manual 7

AVERTISSEMENT – LE DÉMARREUR PEUT DÉMARRER OU S'ARRÊTER À

TOUT MOMENT

L’EMX4i répond aux commandes de contrôle de différentes origines et peut

par conséquent démarrer ou s'arrêter à tout moment. Toujours

déconnecter le démarreur de la tension secteur avant d'accéder au

démarreur ou à la charge.

AVERTISSEMENT – DÉCONNECTER L'ALIMENTATION PRINCIPALE

AVANT D'ACCÉDER AU DÉMARREUR OU À LA CHARGE

Le démarreur progressif comporte des protections intégrées qui peuvent

déclencher des mises en sécurité dans l'éventualité de défauts et ainsi

arrêter le moteur. Des fluctuations de tension, des coupures d'alimentation

et des blocages du moteur peuvent produire des mises en sécurité de

celui-ci.

Le moteur pourrait redémarrer une fois que les causes de l'arrêt ont été

résolues, ce qui pourrait mettre en danger le personnel. Toujours

déconnecter le démarreur de la tension secteur avant d'accéder au

démarreur ou à la charge.

AVERTISSEMENT

Ne pas appliquer la tension du secteur au démarreur tant que tout le

câblage n'est pas terminé.

AVERTISSEMENT

Toujours appliquer la tension de commande avant (ou en même temps que)

la tension secteur.

AVERTISSEMENT

Lors du raccordement de l’EMX4i en connexion 6 fils, toujours installer un

contacteur principal ou un disjoncteur magnéto-thermique à bobine de

déclenchement.

AVERTISSEMENT

Si l'entrée de démarrage est fermée lorsque la tension de commande est

appliquée, le démarreur tentera d'effectuer un démarrage.

Vérifier que l'entrée de démarrage/arrêt est ouverte avant d'appliquer la

tension de commande.

SYSTEM DESIGN

8EMX4i User Manual 710-14888-00C

3. System Design

3.1 Feature List

Streamlined setup process

•Configuration profiles for common

applications

•Built-in metering and inputs/outputs

Easy to understand interface

•Multi-language menus and displays

•Descriptive option names and feedback

messages

•Real-time performance graphs

Supports energy efficiency

•IE3 compatible

•99% energy efficient when running

•Internal bypass

•Soft start technology avoids harmonic

distortion

Extensive range of models

•24 A~580 A (nominal)

•200~525 VAC

•380~690 VAC

•Inside delta installation

Extensive input and output options

•Remote control inputs

(2 x fixed, 2 x programmable)

•Relay outputs

(1 x fixed, 2 x programmable)

•Analog output

Versatile starting and stopping

options

•Scheduled start/stop

•Adaptive Control

•Constant Current

•Current Ramp

•Kickstart

•Pump Clean

•Timed voltage ramp start/stop

•Coast To Stop

•DC Brake

•Soft Brake

•Reverse Direction

Customisable protection

•Motor overload

•Excess Start Time

•Undercurrent/Overcurrent

•Underpower/Overpower

•Undervoltage/Overvoltage

•Current imbalance

•Input Trip

•Motor thermistor

Optional features for advanced

applications

•Smart cards

•Communication options:

DeviceNet, Ethernet/IP, Modbus

RTU, Modbus TCP, Profibus,

Profinet

SYSTEM DESIGN

710-14888-00C EMX4i User Manual 9

3.2 Model Code

EMX4i- 0 0 6 9

–

–

Control voltage

C1 = 110~120 VAC or 220~240 VAC

C2 = 24 VAC/VDC

Mains voltage

V5 = 200~525 VAC

V7 = 380~690 VAC

Bypass

B = internally bypassed

Nominal current rating

3.3 Model Selection

Starter sizing

The soft starter must be the correct size for the motor and the application.

Select a soft starter that has a current rating at least equal to the motor's full load

current (nameplate) rating, at the start duty.

The soft starter's current rating determines the maximum motor size it can be used

with. The soft starter's rating depends on the number of starts per hour, the length

and current level of the start, and the amount of time the soft starter will be off (not

passing current) between starts.

The soft starter's current rating is only valid when used in the conditions specified in

the AC53b code - the soft starter may have a higher or lower current rating in

different operating conditions.

SYSTEM DESIGN

10 EMX4i User Manual 710-14888-00C

3.4 Current Ratings

For operating conditions not covered by these ratings charts, download AuCom's

free WinStart selection application, or contact your local supplier.

IEC ratings

•AC53b format

80 A

:

AC-53b

3.5

-

15

:

345

Off time (seconds)

Start time (seconds)

Start current

(multiple of motor full load current)

Starter current rating (amperes)

•Ratings

All ratings are calculated at altitude of 1000 metres and ambient temperature of 40 ºC.

In-line installation

3.0-10:350

3.5-15:345

4.0-10:350

4.0-20:340

5.0-5:355

EMX4i-0024B 24 20 19 16 17

EMX4i-0042B 42 34 34 27 32

EMX4i-0052B 52 42 39 35 34

3.0-10:590

3.5-15:585

4.0-10:590

4.0-20:580

5.0-5:595

EMX4i-0064B

64

63

60

51

54

EMX4i-0069B 69 69 69 62 65

EMX4i-0105B 105 86 84 69 77

EMX4i-0115B 115 108 105 86 95

EMX4i-0135B 135 129 126 103 115

EMX4i-0184B 184 144 139 116 127

EMX4i-0200B

200

171

165

138

150

EMX4i-0229B

229

194

187

157

170

EMX4i-0250B 250 244 230 200 202

EMX4i-0352B 352 287 277 234 258

EMX4i-0397B 397 323 311 263 289

EMX4i-0410B 410 410 410 380 400

EMX4i-0550B 550 527 506 427 464

EMX4i-0580B

580

579

555

470

508

SYSTEM DESIGN

710-14888-00C EMX4i User Manual 11

Inside delta installation

3.0-10:350

3.5-15:345

4.0-10:350

4.0-20:340

5.0-5:355

EMX4i-0024B 36 30 28 24 25

EMX4i-0042B 63 51 51 40 48

EMX4i-0052B 78 63 58 52 51

3.0-10:590

3.5-15:585

4.0-10:590

4.0-20:580

5.0-5:595

EMX4i-0064B

96

94

90

76

81

EMX4i-0069B

103

103

103

93

97

EMX4i-0105B 157 129 126 103 115

EMX4i-0115B 172 162 157 129 142

EMX4i-0135B 202 193 189 154 172

EMX4i-0184B 276 216 208 174 190

EMX4i-0200B

300

256

247

207

225

EMX4i-0229B

343

291

280

235

255

EMX4i-0250B 375 366 345 300 303

EMX4i-0352B 528 430 415 351 387

EMX4i-0397B 595 484 466 394 433

EMX4i-0410B 615 615 615 570 600

EMX4i-0550B 825 790 759 640 696

EMX4i-0580B

870

868

832

705

762

SYSTEM DESIGN

12 EMX4i User Manual 710-14888-00C

NEMA motor ratings

All ratings are calculated at altitude of 1000 metres and ambient temperature of 50 ºC.

Light

300%, 10 s,

6 starts per hour

Normal

350%, 30 s,

4 starts per hour

Heavy

450%, 30 s,

4 starts per hour

A

HP

@230

VAC

HP

@460

VAC

HP

@575

VAC

A

HP

@230

VAC

HP

@460

VAC

HP

@575

VAC

A

HP

@230

VAC

HP

@460

VAC

HP

@575

VAC

EMX4i-0024B 24 7.5 15 20 17 5 10 15 14 3 10 10

EMX4i-0042B 42 15 30 40 28 10 20 25 22 7.5 15 20

EMX4i-0052B 52 15 30 50 35 10 25 30 28 10 20 25

EMX4i-0064B

64

20

50

60

52

15

30

40

40

10

25

30

EMX4i-0069B

69

25

50

60

59

20

40

50

46

15

30

40

EMX4i-0105B 100 30 75 100 77 25 50 60 52 15 40 50

EMX4i-0115B 115 40 75 100 81 30 60 75 65 20 50 60

EMX4i-0135B 135 50 100 125 99 30 75 100 77 25 60 75

EMX4i-0184B 164 60 125 150 124 40 75 100 96 30 60 75

EMX4i-0200B 200 75 150 200 131 50 100 125 104 40 75 100

EMX4i-0229B

229

75

150

200

156

60

125

150

124

40

100

100

EMX4i-0250B

250

100

200

250

195

75

150

200

156

60

125

150

EMX4i-0352B 341 125 250 350 240 75 150 200 180 60 150 150

EMX4i-0397B 389 150 300 400 261 100 200 250 203 75 150 200

EMX4i-0410B 410 150 300 450 377 150 300 350 302 100 250 300

EMX4i-0550B 550 200 450 500 414 150 350 450 321 125 250 300

EMX4i-0580B 580 200 500 500 477 200 400 500 361 150 300 350

SYSTEM DESIGN

710-14888-00C EMX4i User Manual 13

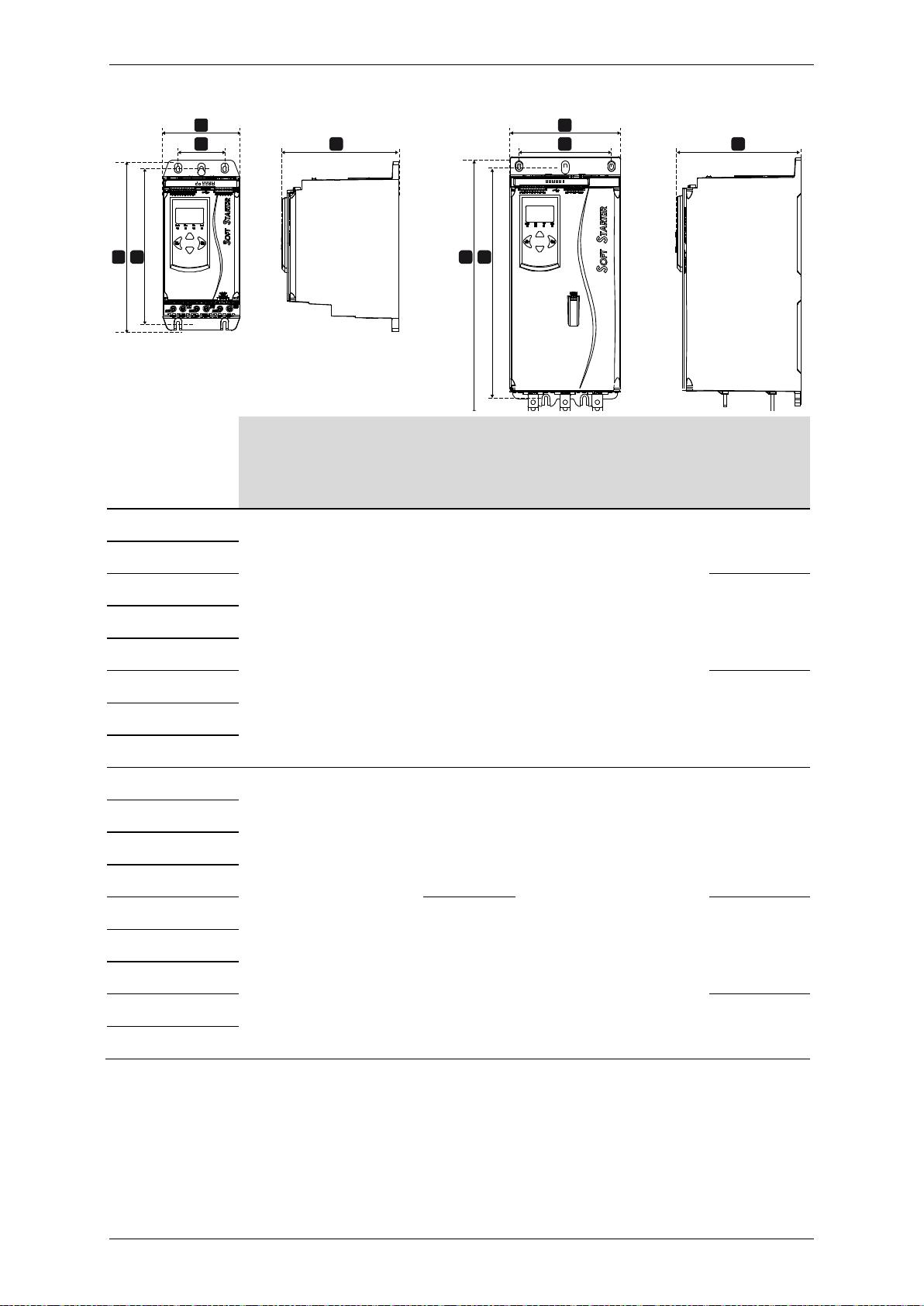

3.5 Dimensions and Weights

A

B

CD

E

A

B

CD

E

17043.B

Width

mm (inch)

Height

mm (inch)

Depth

mm (inch)

Weight

kg (lb)

A

B

C

D

E

EMX4i-0024B

4.8

EMX4i-0042B

(10.7)

EMX4i-0052B

4.9

EMX4i-0064B 152 92 336 307 231 (10.9)

EMX4i-0069B

(6.0)

(3.6)

(13.2)

(12.1)

(9.1)

EMX4i-0105B

5.5

EMX4i-0115B

(12.1)

EMX4i-0135B

EMX4i-0184B

EMX4i-0200B

495

12.7

EMX4i-0229B 216 180 (19.5) 450 243 (28.0)

EMX4i-0250B

(8.5)

(7.1)

(17.7)

(9.6)

EMX4i-0352B

15.5

EMX4i-0397B

523

(34.2)

EMX4i-0410B

(20.6)

EMX4i-0550B

19.0

EMX4i-0580B

(41.9)

SYSTEM DESIGN

14 EMX4i User Manual 710-14888-00C

3.6 Physical Installation

DD

17044.B

C

C

B

A

Between starters

Solid surfaces

A

B

C

D

> 100 mm (3.9 inch) > 10 mm (0.4 inch) > 100 mm (3.9 inch) > 10 mm (0.4 inch)

3.7 Accessories

Expansion Cards

The EMX4i offers expansion cards for users requiring additional inputs and outputs

or advanced functionality. Each EMX4i can support a maximum of one expansion

card.

•Smart Card

The smart card has been designed to support integration with pumping applications

and provides the following additional inputs and outputs:

•3 x digital inputs

•3 x 4-20 mA transducer inputs

•1 x RTD input

•1 x USB-B port

•Remote keypad connector

•Communication Expansion Cards

The EMX4i supports network communication via easy-to-install communications

expansion cards. Each communications card includes a remote keypad connector

port.

Available protocols:

DeviceNet, Ethernet/IP, Modbus RTU, Modbus TCP, Profibus, Profinet.

SYSTEM DESIGN

710-14888-00C EMX4i User Manual 15

Remote Keypad

EMX4 starters can be used with a remote keypad, mounted up to 3 metres away

from the starter. Each expansion card includes a keypad connection port, or a

dedicated keypad connector card is available.

Finger Guard Kit

Finger guards may be specified for personnel safety. Finger guards fit over the soft

starter terminals to prevent accidental contact with live terminals. Finger guards

provide IP20 protection when used with cable of diameter 22 mm or greater.

Finger guards are compatible with models EMX4i-0184B ~ EMX4i-0580B.

Soft Starter Management Software

PC software can provide real-time or offline management of soft starters.

•For real-time management in a network of up to 254 starters, the

software must connect to the soft starter via a Modbus TCP or Modbus

RTU card. The software can monitor, control and program the starter

across the network.

•The software can be used to program the starter via the USB port on the

pumping smart card.

•For offline management, a configuration file generated in the software

can be loaded into the starter via the USB port.

3.8 Main Contactor

A main contactor is recommended to protect the soft starter from voltage

disturbances on the network, while stopped. Select a contactor with an AC3 rating

greater than or equal to the full load current rating of the connected motor.

Use the main contactor output (33, 34) to control the contactor.

WARNING

When connecting the EMX4i in inside delta configuration, always install a

main contactor or shunt trip circuit breaker.

3.9 Circuit Breaker

A shunt trip circuit breaker may be used instead of a main contactor to isolate the

motor circuit in the event of a soft starter trip. The shunt trip mechanism must be

powered from the supply side of the circuit breaker or from a separate control

supply.

SYSTEM DESIGN

16 EMX4i User Manual 710-14888-00C

3.10 Power Factor Correction

If power factor correction is used, a dedicated contactor should be used to switch in

the capacitors.

To use the EMX4i to control power factor correction, connect the PFC contactor to a

programmable relay set to Run. When the motor reaches full speed, the relay will

close and power factor correction will be switched in. Do not use the soft starter

relay output to directly switch in power factor correction.

K1 K1

1

2

4

3

20234.A

1

Soft starter

2 Programmable output (set = Run)

3 Power factor correction contactor

4 Power factor correction

CAUTION

Power factor correction capacitors must be connected to the input side of

the soft starter. Connecting power factor correction capacitors to the output

side will damage the soft starter.

3.11 Short Circuit Protection Devices (SCPD)

Fuses may be installed to protect the soft starter or the installation.

Type 1 Coordination

Type 1 coordination requires that, in the event of a short circuit on the output side of

a soft starter, the fault must be cleared without risk of injury to personnel. There is

no requirement that the soft starter must remain operational after the fault.

HRC fuses (such as Ferraz/Mersen AJT fuses) can be used for Type 1 coordination

according to IEC 60947-4-2 standard.

Type 2 Coordination

Type 2 coordination requires that in the event of a short circuit on the output side of

a soft starter, the fault must be cleared without risk of injury to personnel or

damage to the soft starter.

Semiconductor fuses for Type 2 circuit protection are additional to HRC fuses or

MCCBs that form part of the motor branch circuit protection.

SYSTEM DESIGN

710-14888-00C EMX4i User Manual 17

CAUTION

DC Brake: A high brake torque setting can result in peak currents up to

motor DOL being drawn while the motor is stopping. Ensure protection

fuses installed in the motor branch circuit are selected appropriately.

CAUTION

Integral solid state short circuit protection does not provide branch circuit

protection. Branch circuit protection must be provided in accordance with

the National Electrical Code and any additional local codes.

3.12 IEC Coordination with Short Circuit Protection Devices

These fuses were selected based on start current of 300% FLC for 10 seconds.

Nominal Rating

(A)

SCR I2t (A2s)

Type 1

coordination

480 VAC, 65 kA

Bussmann NH

fuse links

Type 2

coordination

690 VAC, 65 kA

Bussmann

DIN 43 653

EMX4i-0024B 24 1150 40NHG000B 170M3010

EMX4i-0042B

42

7200

63NHG000B

170M3013

EMX4i-0052B

52

80NHG000B

EMX4i-0064B 64 15000 100NHG000B 170M3014

EMX4i-0069B 69

EMX4i-0105B 105 80000

170M3015

EMX4i-0115B 115

160NHG00B

EMX4i-0135B 135 125000

170M3016

EMX4i-0184B

184

250NHG2B

EMX4i-0200B

200

320000

170M3020

EMX4i-0229B 229

315NHG2B

EMX4i-0250B 250

170M3021

EMX4i-0352B 352 202000 355NHG2B 170M6009

EMX4i-0397B 397

400NHG2B

EMX4i-0410B 410 320000 425NHG2B 170M6010

EMX4i-0550B

550

781000

630NHG3B

170M6012

EMX4i-0580B

580

SYSTEM DESIGN

18 EMX4i User Manual 710-14888-00C

3.13 UL Coordination with Short Circuit Protection Devices

Standard Fault Short Circuit Current Ratings

Suitable for use on a circuit capable of delivering not more than the stated level of

amperes (symmetrical rms, refer ##1 in table), 600 VAC maximum.

•Maximum fuse rating (A) – Standard fault short circuit current

Model

Nominal Rating (A)

3 cycle short cct rating

@600 VAC ##1 †

EMX4i-0024B 24 5 kA

EMX4i-0042B 42

EMX4i-0052B 52

EMX4i-0064B 64

EMX4i-0069B

69

10 kA

EMX4i-0105B

105

EMX4i-0115B 120

EMX4i-0135B 135

EMX4i-0184B 184

EMX4i-0200B 225

EMX4i-0229B 229 18 kA

EMX4i-0250B

250

EMX4i-0352B

352

EMX4i-0397B 397

EMX4i-0410B 410

EMX4i-0550B 550 30 kA

EMX4i-0580B 580

† Suitable for use in a circuit with the prospective current noted, when protected by

any Listed fuses or Listed circuit breakers sized according to the NEC.

SYSTEM DESIGN

710-14888-00C EMX4i User Manual 19

High Fault Short Circuit Current Ratings

•Maximum fuse rating (A) – High fault short circuit current

Suitable for use on a circuit capable of delivering not more than 65,000 rms

symmetrical amperes, 480 VAC maximum, when protected by fuses of the stated

class and rating (refer ##2 and ##3 in table).

Model

Nominal

Rating (A)

Short Circuit

Rating @ 480 VAC

max.

Listed fuse rating

(A)

##3

Fuse class

##2

EMX4i-0024B 24 30

Any

(J, T, K-1, RK1,

RK5)

EMX4i-0042B

42

50

EMX4i-0052B

52

60

EMX4i-0064B 64 80

EMX4i-0069B 69 80

EMX4i-0105B 105 125

EMX4i-0115B 120 65 kA 125 J, T, K-1, RK1

EMX4i-0135B

135

150

EMX4i-0184B

184

200

EMX4i-0200B

225

225

J, T

EMX4i-0229B 229 250

EMX4i-0250B 250 300

EMX4i-0352B 352 400

Any

(J, T, K-1, RK1,

RK5)

EMX4i-0397B 397 450

EMX4i-0410B

410

450

EMX4i-0550B

550

600

EMX4i-0580B

580

600

Table of contents

Other AuCom Controllers manuals

AuCom

AuCom MVE series User manual

AuCom

AuCom Modbus RTU Card User manual

AuCom

AuCom MVSxxxx-V03 User manual

AuCom

AuCom CSX-007 User manual

AuCom

AuCom MVS User manual

AuCom

AuCom CSXI-007 User manual

AuCom

AuCom CSX-007 User manual

AuCom

AuCom EMX3 User manual

AuCom

AuCom EMX3-1600C User manual

AuCom

AuCom EMXAe User manual