If the valve is a ... Then ...

Pure-Flo diaphragm

valve

Install with the raised hash marks (castings) or small machined dots (forgings)

on the valve body at the 12 o’clock position to achieve the optimum drain angle.

3. Prior to pressurization (with the valve slightly open), tighten the bonnet fasteners.

For more information, see Tighten the bonnet fasteners in this manual.

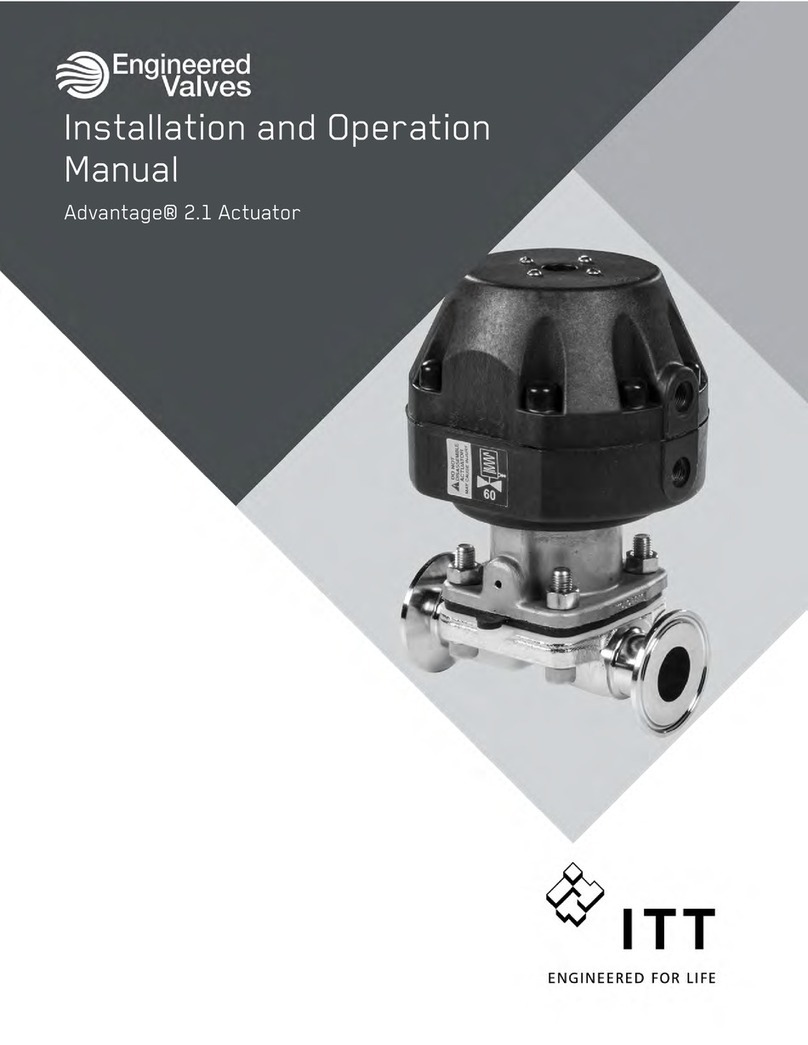

4. Connect the air line.

Connection size is 1/8" NPT.

NOTICE:

Air line connections should be made with care so as not to damage the actuator covers.

5. Cycle the valve two to three times to verify smooth operation.

Disassemble the valve

1. Remove all line pressure.

2. Do you have a switch package?

• If yes: Proceed to step 3.

• If no: Proceed to step 5.

3. Do you have a fail open or double acting actuator?

• If yes: Proceed to step 4.

• If no: Proceed to step 5.

4. Do you have a series 33 actuator or adjustable opening stop?

• If yes: Remove the switch package.

• If no: Proceed to step 5.

5. If the actuator mode of operation is fail open or fail close, then load the actuator with air.

If the actuator mode of

operation is ...

Then ...

Fail open Load the air port in the upper cover of the actuator with sufficient air

to partially close the valve.

Fail close Load the air port in the bottom cover of the actuator with sufficient air

to partially open the valve.

6. Remove the bonnet fasteners.

7. Lift the topworks assembly from the valve body.

8. If the actuator mode of operation is fail open, then remove pressure load from the actuator.

9. Do you have a fail open or double acting actuator?

• If yes: Proceed to step 10.

• If no: Procedure is complete.

10. Do you have a series 33 actuator or adjustable opening stop?

• If yes: When the actuator is not on the valve body, do not allow the flats on the indicating spindle

to move below the upper cover spindle o-ring.

• If no: Procedure is complete.

Installation

Advantage® Actuator 2.0 Installation and Operation Manual 9