04-6152-0120

Utility Crane

09/2017 | Rev. 02

TABLE OF CONTENTS PAGE

1.0 PRODUCT INFORMATION ..............................................................................................................................................1

1.1 DESCRIPTION....................................................................................................................................................1

1.2 MODEL & SERIAL NUMBER..............................................................................................................................1

1.3 MANUFACTURER..............................................................................................................................................1

2.0 SAFETY INFORMATION..................................................................................................................................................1

2.1 USAGE AND SAFETY INFORMATION..............................................................................................................1

3.0 TRAINING.........................................................................................................................................................................1

3.1 TRAINING REQUIREMENTS.............................................................................................................................1

3.2 TRAINING PROGRAM .......................................................................................................................................1

3.3 OPERATOR TRAINING......................................................................................................................................1

4.0 SPECIFICATIONS ............................................................................................................................................................2

5.0 FEATURES.......................................................................................................................................................................3

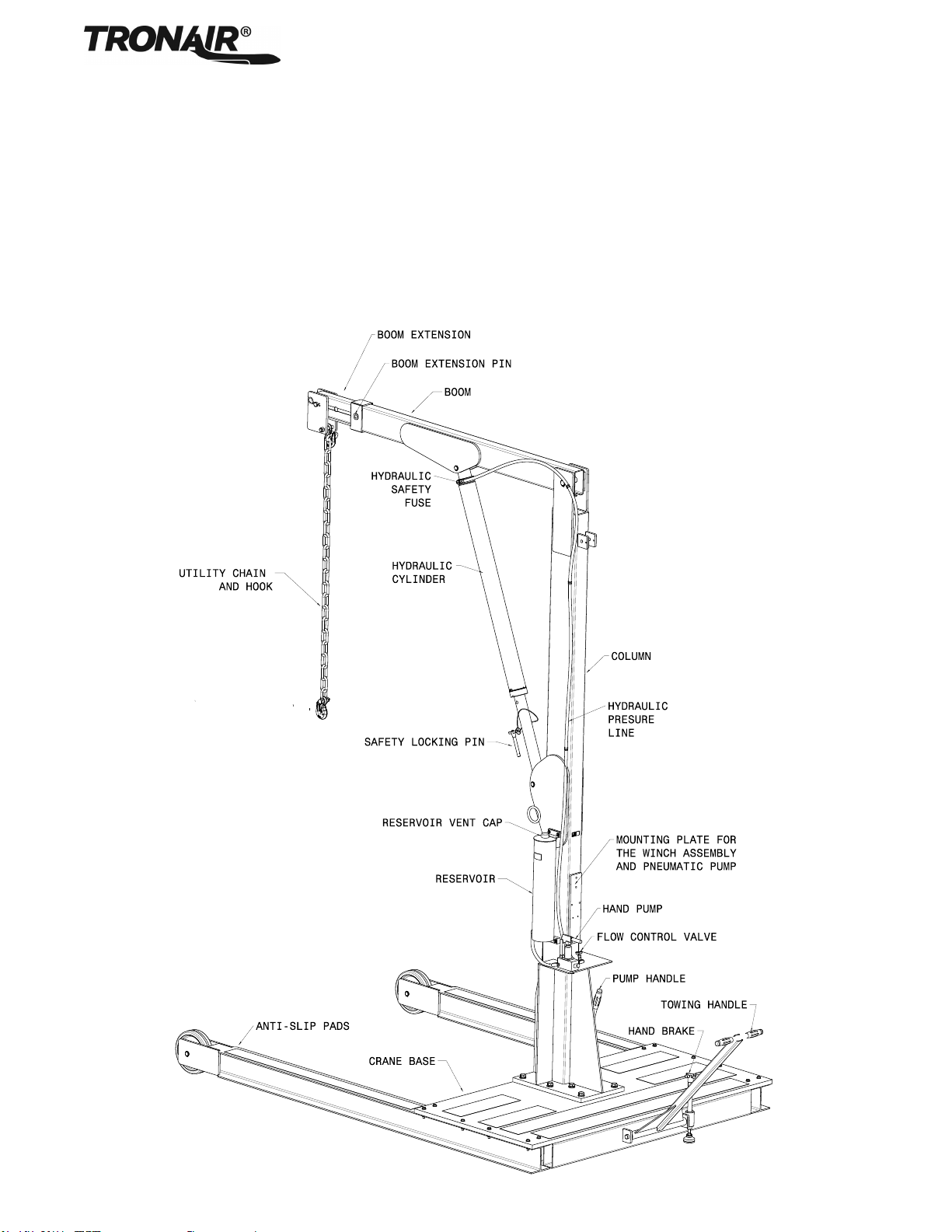

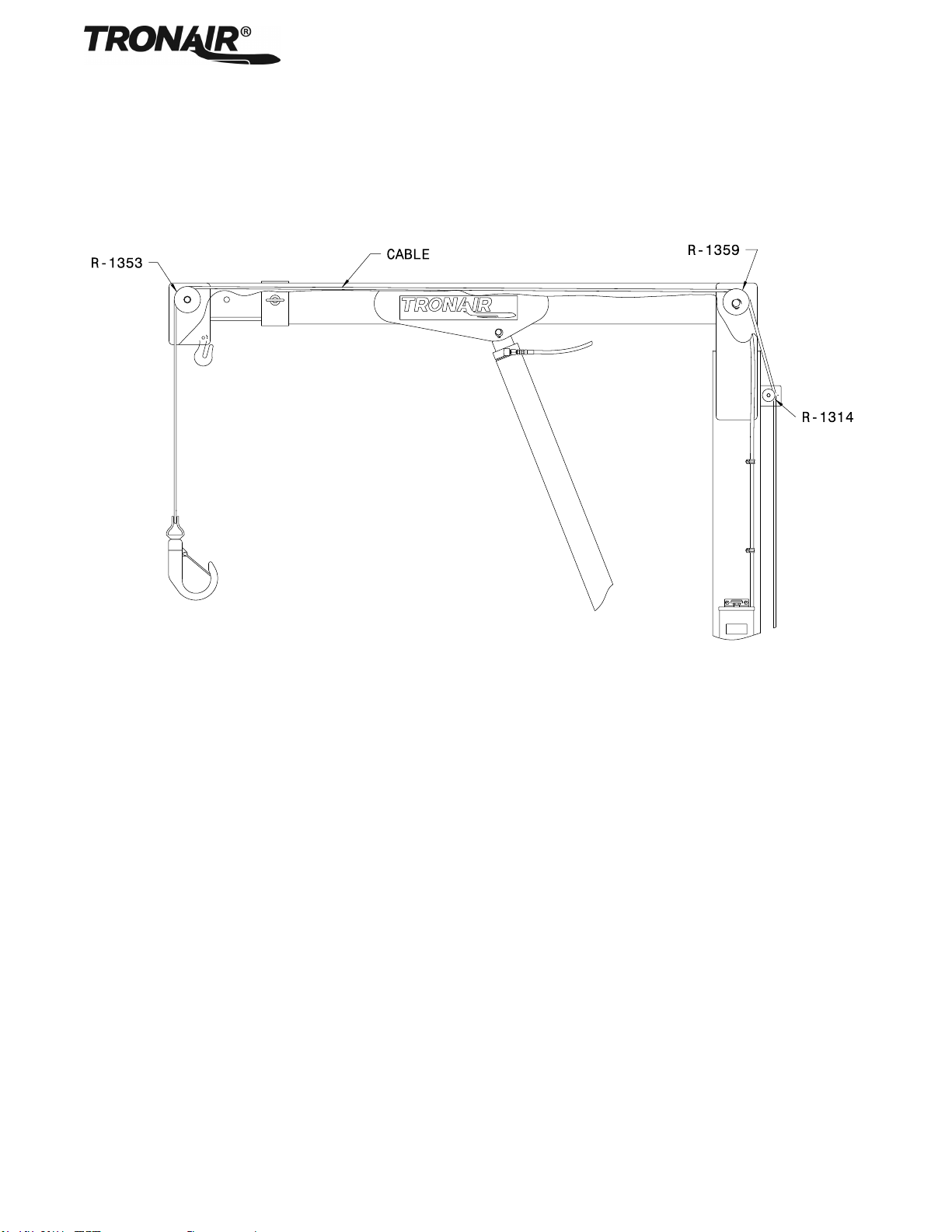

5.1 OPERATOR CONTROLS AND PARTS..............................................................................................................3

5.2 OPTIONAL FIELD INSTALLED KITS .................................................................................................................4

6.0 PREPARATION FOR USE ...............................................................................................................................................4

6.1 CRANE ASSEMBLY...........................................................................................................................................4

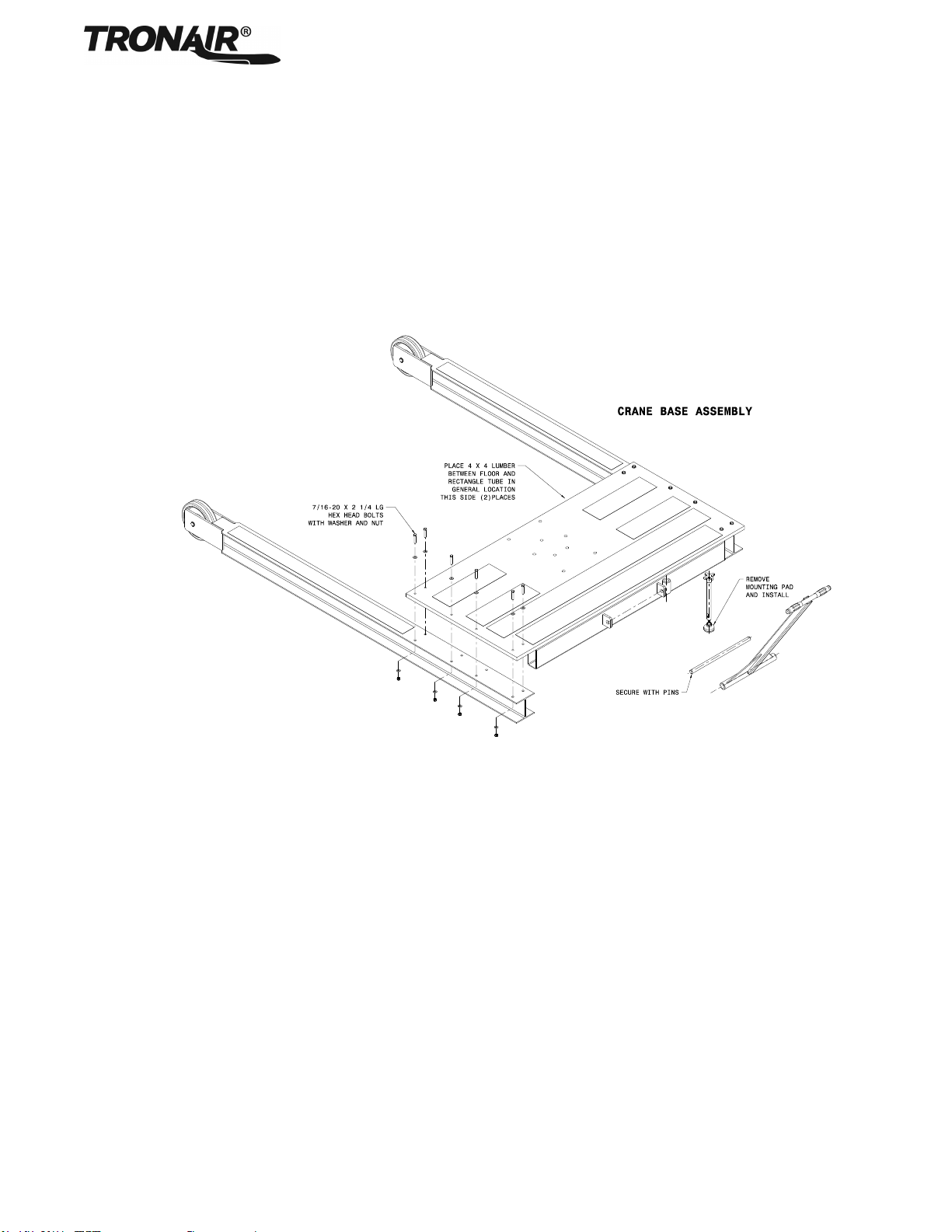

6.1.1 Crane Base Assembly.........................................................................................................................................4

6.1.2 Column and Boom Assembly..............................................................................................................................5

6.2 CRANE OPERATION .........................................................................................................................................5

7.0 WINCH KIT (K-2953 OPTION)..........................................................................................................................................6

7.1 TECHNICAL SPECIFICATIONS.........................................................................................................................6

7.2 INSTALLATION...................................................................................................................................................7

7.3 OPERATION.......................................................................................................................................................7

7.3.1 To Pull the Cable In or Raise the Load ...............................................................................................................7

7.3.2 To Let Cable Out or Lower the Load...................................................................................................................7

8.0 PNEUMATIC PUMP KIT (K-2013 OPTION).....................................................................................................................8

8.1 INSTALLATION...................................................................................................................................................8

8.2 OPERATION.......................................................................................................................................................8

9.0 GOOSENECK KIT (K-2012 OPTION)...............................................................................................................................9

9.1 INSTALLATION...................................................................................................................................................9

10.0 INSPECTION/MAINTENANCE.......................................................................................................................................10

10.1 INITIALINSPECTION .......................................................................................................................................10

10.2 BEFORE EACH USE........................................................................................................................................10

10.3 PERIODIC INSPECTION..................................................................................................................................11

10.4 ANNUAL INSPECTION.....................................................................................................................................11

10.4.1 CRANE INSPECTION & TESTING REQUIREMENTS.....................................................................................11

11.0 PROVISION OF SPARES...............................................................................................................................................12

11.1 SOURCE OF SPARE PARTS...........................................................................................................................12

11.2 RECOMMENDED SPARE PARTS LISTS ........................................................................................................12

12.0 IN SERVICE SUPPORT..................................................................................................................................................12

13.0 GUARANTEES/LIMITATION OF LIABILITY..................................................................................................................12

14.0 APPENDICES.................................................................................................................................................................12