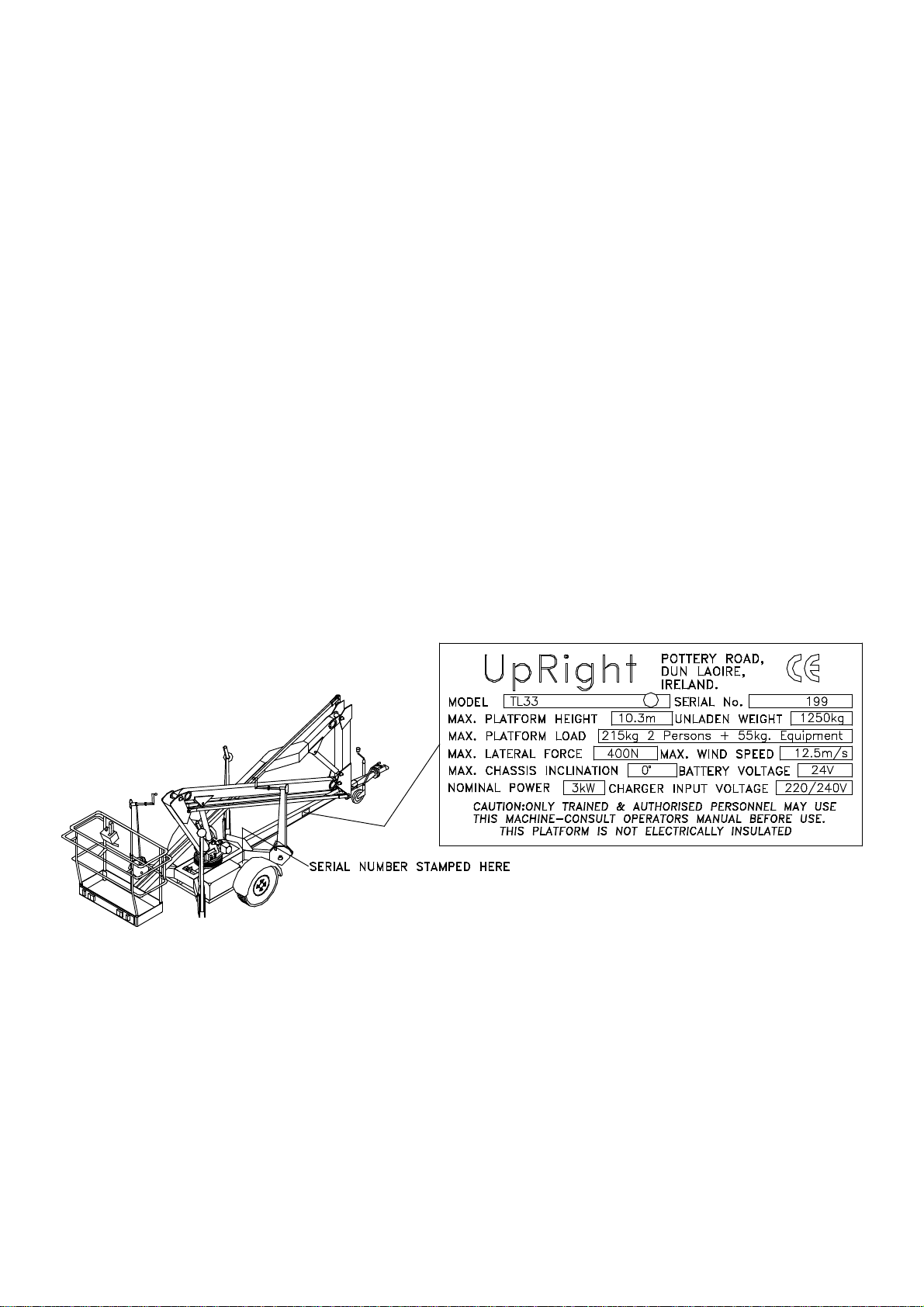

TL33 Work Platform I

Section

Section Page

No. No.

1.0 Introduction & Specifications

1.0 Introduction ................................... 1-1

Purpose.................................................. 1-1

Scope..................................................... 1-1

1.1 General Information ............................... 1-1

Description............................................. 1-1

Purpose and Limitations ......................... 1-2

1.2 Specifications ................................... 1-2

2.0 Machine Preparation

2.1 Preparation for use................................. 2-1

2.2 Preparation for shipment ........................ 2-1

2.3 Forklifting of workplatform...................... 2-2

2.4 Lifting Work Platform ............................. 2-2

2.5 Transport ................................... 2-2

2.6 Storage ................................... 2-2

Preservation........................................... 2-2

Batteries................................................. 2-2

3.0 Operation

3.0 Introduction. .................................. 3-1

General Functioning............................... 3-1

Setting up machine for use..................... 3-1

Operating the booms.............................. 3-1

Design Features.................................... .3-1

3.1 Safety Rules and Precautions............. ... 3-2

3.2 Controls and Indicators....................... ... 3-3

Platform Controls................................. .. 3-3

Lower Controls....................................... 3-4

3.3 Pre-Operation Inspection....................... 3-5

3.4 Operation ................................... 3-6

Towing ................................................ . 3-6

Deploying the outriggers......................... 3-6

Elevating platform................................ .. 3-7

Emergency Lowering ............................. 3-7

Emergency Rotation .............................. 3-8

4.0 Maintenance

4.0 Introduction .................................. 4-1

4.1 Preventative Maintenance ...................... 4-1

Preventative Maintenance Table Key ..... 4-2

Preventative Maintenance Report .......... 4-2

4.2 Battery Maintenance............................... 4-3

Battery Inspection and Cleaning.......... ... 4-3

Battery Charging.................................. .. 4-3

Battery Cell Equalization ................. ...... 4-4

4.4 Lubrication .................................. 4-5

Hydraulic Oil Reservoir and Filter........ ... 4-5

Fluid Level............................................ .4-5

Oil and Filter Replacement................... .. 4-5

4.5 Setting Hydraulic pressures.................... 4-6

Main Relief valve.................................. .4-6

Section Page

No. No.

4.6 Maintenance on Elevating Assembly.......4-6

Setting Slew Cut-Out Limit Switch...........4-7

Outrigger Limit Switches...................... ...4-8

4.7 Hydraulic Manifold ..................................4-9

Removal............................................... ..4-9

Disassembly......................................... ..4-9

Cleaning and Inspection..........................4-9

Assembly................................................4-9

Installation............................................ ..4-9

4.8 Hydraulic Pump ..................................4-11

Removal............................................... 4-11

Installation............................................ 4-11

4.9 Wheel Hubs/Bearings ..........................4-11

Maintenance & Adjustment .................. 4-11

Replacing worn bearings /

Hub Oil Seal ........................................ 4-11

4.10 Braking System ................................. 4-13

Principles of Operation..........................4-13

Adjustment of /wheel Brakes ................4-13

4.11 Hydraulic Cylinders.............................. 4-14

Upper Lift Cylinder............................... .4-14

Removal.......................................... .....4-14

Cleaning and Inspection........................4-14

Assembly..............................................4-14

Installation...................................... ......4-14

4.12 Lower Lift Cylinder ...............................4-16

Lower Lift Cylinder............................... .4-16

Removal.......................................... .....4-16

Cleaning and Inspection........................4-16

Assembly..............................................4-16

Installation...................................... ......4-16

4.13 Electric Motor ..................................4-17

Troubleshooting ..................................4-17

Disassembly................................. 4-17

Inspection ................................. 4-17

Reassembly ................................. 4-18

4.14 Adjustment of Overcentre Valves......... 4-20

5.0 Troubleshooting

5.0 Introduction ................................... 5-1

General Procedure..................................5-1

5.1 Trouble shooting charts.......................... 5-2

5.2 General information .............................. 5-4

5.3 D.C. Motor Control ................................ 5-5

5.4 Troubleshooting the MOS90 .................. 5-6

6.0 Schematics

6.0 Introduction ................................... 6-1

6.1 Electrical Schematic ...............................6-3

6.2 Hydraulic Schematic ...............................6-7

Table of Contents