B - 1 Operating manual – DA 4 / DA 4 M Flow Rate Control Unit EN

TABLE OF CONTENTS

01. General description ................B - 01

02. Read before commissioning .........B - 02

03. Commissioning ....................B - 03

04. Operation ........................B - 03

05. Decommissioning ..................B - 05

06. Care and maintenance ..............B - 05

07. Faults and error rectification .........B - 06

08. Internal view of the DA 4 ............B - 06

09. Technical data .....................B - 06

This publication replaces all previous publications. No part of this publication

may be reproduced in any form nor processed, copied or distributed by means

of electronic systems without our prior written approval. We reserve the right

to technical modifications. All rights reserved. Product names are used without

guaranteeing the free usability and are generally in accordance with the presen-

tation of the manufacturers. The product names used are registered trade names

and should be regarded as such. Changes in construction in the interest of an

ongoing product improvement as well as modifications in form and colour are

reserved. The scope of delivery may deviate from the product images. This docu-

ment was created with due diligence. We do not assume any liability for errors

or omissions. © TROTEC®

01. GENERAL DESCRIPTION

The DA 4 / DA 4 M MultiQube flow rate control unit

is a device for commercial use in order to rectify wa-

ter damage in interspace and insulation layers. It is

a mobile, noise-reduced and electronically operated

device for controlling suction air flows.

In practice, new water damage is characterised by

The flow rate control unit has been designed for

vacuum drying and, by means of the active control of

three drying zones, makes it possible to optimize and

shorten the drying phase.

The flow rate control unit has two sensors - one air

sensor for measuring the room air humidity and tem-

perature and one humidity sensor for recording the

humidity values of the insulation layers affected.

The automatic controls of the DA 4 record in se-

quence the humidity values of three different ducts by

means of the humidity sensor and then concentrate

the entire compressor performance to the duct with

the highest humidity value. After a 10-minute drying

phase, the humidity values of the individual ducts are

measured again and the most humid duct is selected

again.

In this way, the total drying time can be significantly

accelerated - between 30 and 70%, depending on the

construction concept.

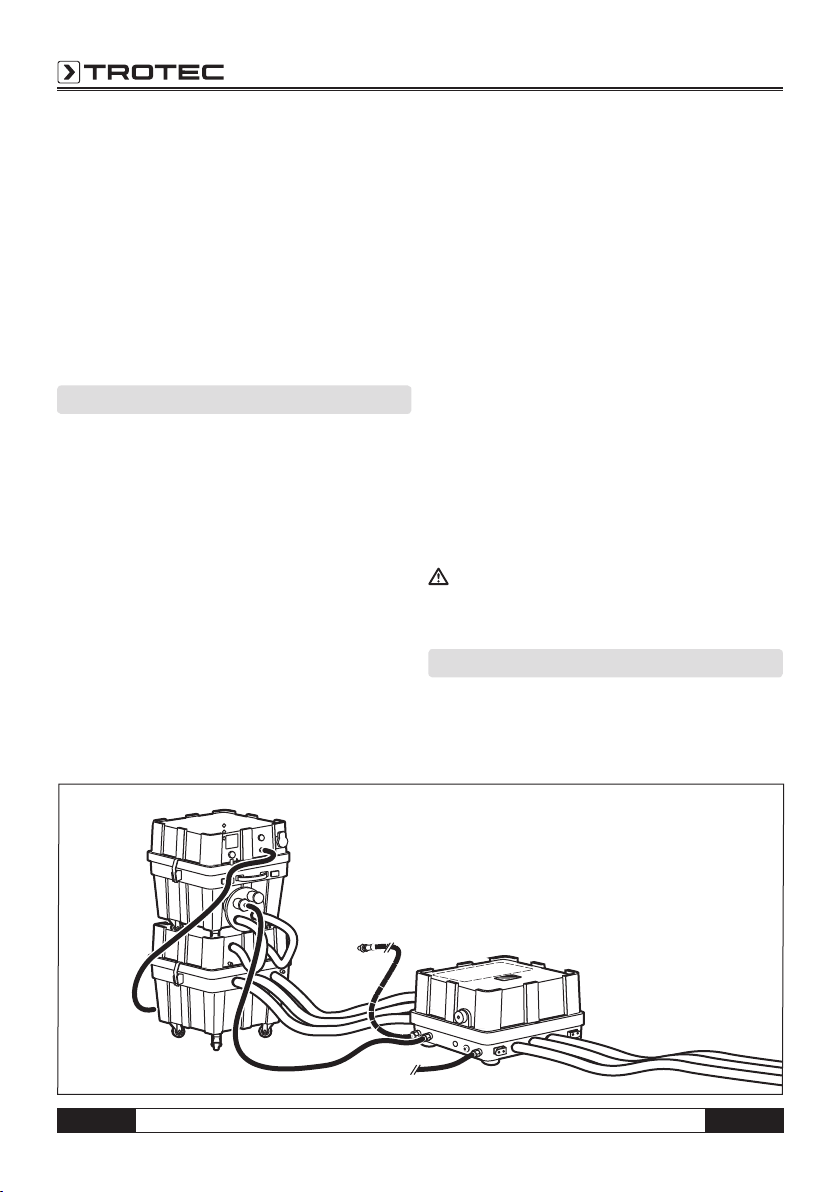

The flow rate control unit is installed between the wa-

ter extractor and the drying zones.

The air sensor of the flow rate control unit records the

room humidity and temperature. If the room humidity

exceeds values which no longer enable a drying proc-

ess, warning signals are emitted.

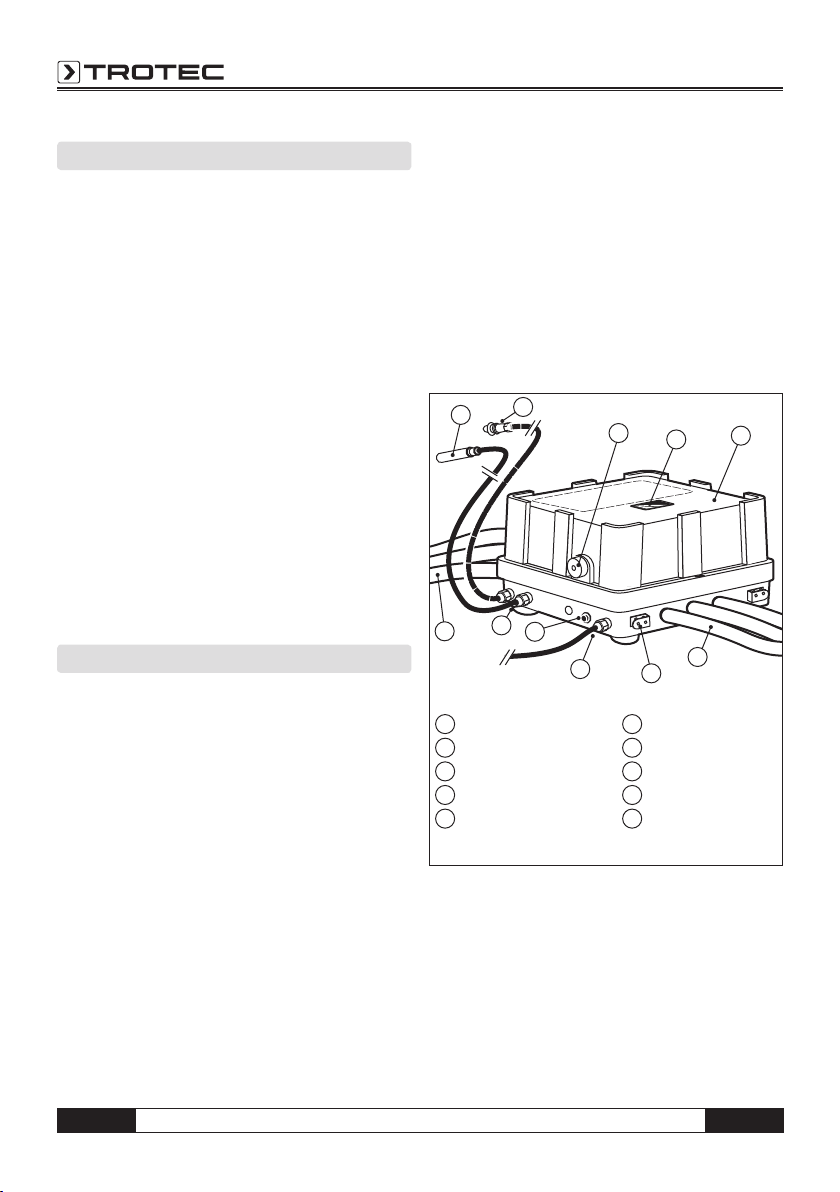

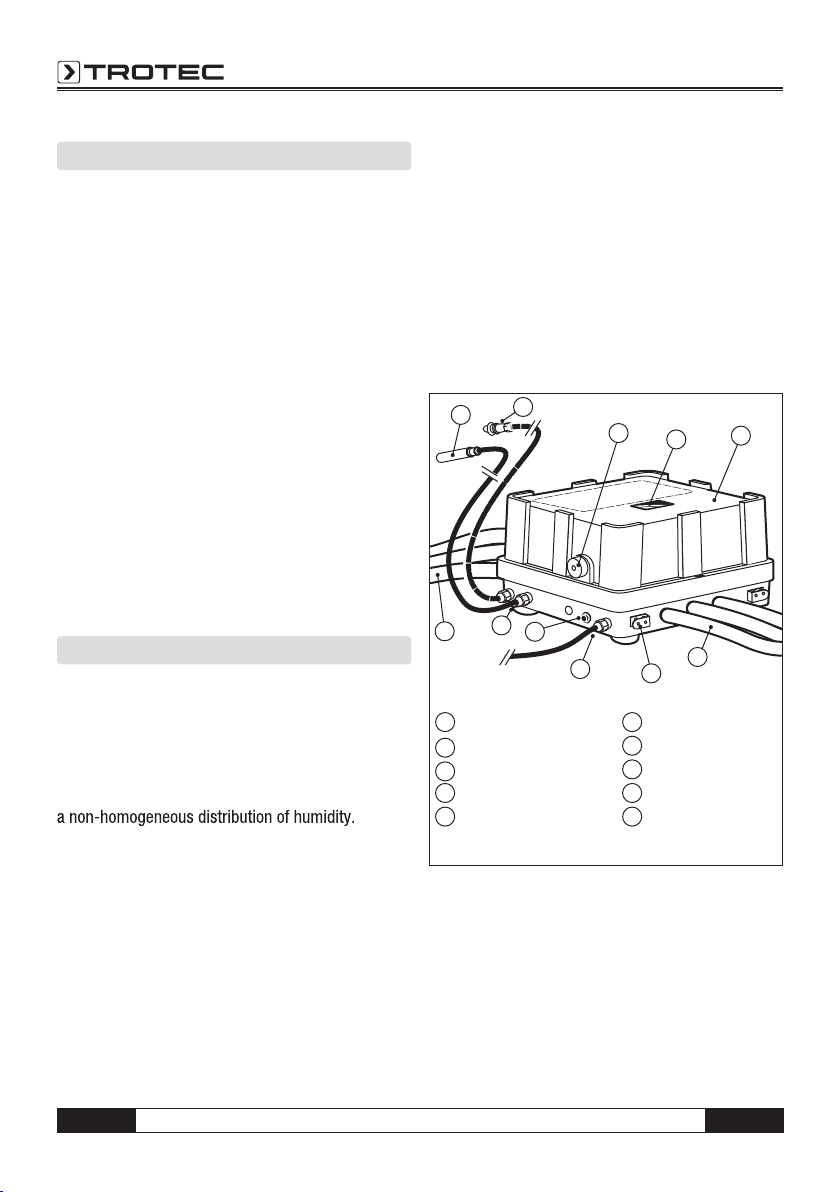

The DA 4 and DA 4 M flow rate control unit saves

230 V

9

8

3

6

6

45

7

10

2

1

1 Humidity sensor

2 Room sensor

3 Adapter for sensor

4 Display

5 Casing

6 Inputs/outputs

7 Cable winding

8 Network cable 230

9 Key

10 Sensor connections

(Fig.1: product overview)

EN Operating manual – DA 4 / DA 4 M Flow Rate Control Unit B - 2

the measurements on an integrated USB flash drive.

Previous drying processes are thus documented. The

DA 4 M flow rate control unit additionally sends the

sensor measurements to a WEB centre and thus of-

fers online remote monitoring of the drying process.

02. READ BEFORE COMMISSIONING

The DA 4 / DA 4 M flow rate control unit is to be

used as a control unit for drying insulation layers in

the suction process of floor screed or flat roofs ex-

clusively. The unit consists of a casing in which the

valves, the control unit and the connection nozzles are

installed, as well as the humidity sensor with adapter,

which is plugged into the respective holding fixture for

transportation purposes. During operation, the sensor

is installed at a four-fold distributor at the compressor

by means of the adapter.

The humidity sensor must not have direct con-

tact with water!

Never place items on the device or step on it.

The flow rate control unit can be used with all con-

ventional compressors in suction processes for the

drying of insulation layers. Furthermore, the device is

specifically aligned to the Trotec Multi-Qube modules

VE 4, WA 4,WA 4i, WA 6 and VE 6.

The task of the flow rate control unit is to efficiently

distribute the suction flow to the existing core drill

holes; it is positioned between the water extractor

and the core drill holes. Water, particulate matter, fine

dust or other small particles are not filtered through

the device. Foreign bodies of this kind do not impair

the function of the device.

Foreign bodies with a diameter of more than

15mm may lead to a clogging of the valves. For

this reason, the core drill hole is to be cleaned

thoroughly before drying. An industrial vacu-

um cleaner is suitable for cleaning.

The flow rate control unit does not have any defined

inputs and outputs. It is irrelevant from which side the

hoses are connected.

All three inputs and all three outputs must be

connected and used.

Ensure a proper connection of the inputs and outputs.

Insufficient connections with the aluminium nozzle of

the flow rate control unit may result in leakages. This

will lead to reduced drying performance. In a worst

case scenario, water leaks from the connection and

causes water damage. Use hoses with smooth and

elastic internal surfaces or spiral hoses with a cor-

responding special clamp. With the flow rate con-

trol unit, you can directly control three core drilling

holes. By means of T/Y pieces or other distributors,

the number of the controllable core drilling holes can

be expanded. Here, ensure that the core drilling holes

which are controlled via one duct are grouped closely

together.

Generally, before using the MultiQube elements, wa-

ter in the core drilling holes must be removed via suc-

tion before starting the drying process. This shortens

the drying time for rectifying the water damage.

All three ducts of the flow rate control unit must be

connected as otherwise correct functioning cannot

be guaranteed and the connected compressor turbine

will be damaged.

The use of a flow rate control unit in explosion-risk

rooms and atmospheres is inadmissible.

The flow rate control unit may only be operated by

specialist staff and experts who have been instructed

regarding the operation of the devices and are trained

in the area of insulation layer drying technologies.

The operating manual must be followed. Instructed

persons are persons who have been informed and,

if required, trained regarding the tasks transferred to

them and the possible hazards occurring in the event

of inappropriate behaviour.

Repair and maintenance work on electrical parts may

only be executed by a specialist electrician. On con-

struction sites, the DA 4 may only be connected via

an electrical 1~230V, 50Hz; 16A energy supply with a

corresponding upstream FI residual current operated

protective device (RCD) 30mA, in accordance with

with DIN VDE 100.