9Operating manual – Material moisture measuring device T610 EN

• In order to minimize measurement errors caused by varying

material thicknesses or inhomogeneities, it is recommended

to perform a preferably close-meshed grid measurement

covering the entire area to be examined.

• The sensor's microwave field exhibits a distinct lateral ex-

pansion. A minimum distance to the side limits of the meas-

ured material must be observed, for otherwise the measured

value might be falsified. In simplified terms the measuring

volume can be seen as a cylinder with a radius of 10 to 15

cm. Therefore, the minimum distance for delimiting the ma-

terial is stated as 10 cm.

• A moisture measurement with less distance to the side edge

of the material can result in a distortion of the measured val-

ue.

• For a significant and exact measurement with the microwave

sensor it must be ensured that the observed measuring vol-

ume is sufficiently dimensioned.

• The measured values are to be interpreted as relative values,

for the microwave method only enables a differentiation be-

tween dry and wet building materials.

• The main area of use consists in comparative measurements

at the same construction material or similar components. De-

pending on the display value, humid zones can be deter-

mined and narrowed down.

• Measuring according to the microwave method is further

suited for the examination of water damage and for leak de-

tection.

• If the test material contains metal (e.g. pipes, lines, reinforce-

ments, plaster base), the measured value skyrockets. Thanks

to the depth effect (penetration), the device is also suitable for

localizing metal objects and detecting reinforcements.

• Owing to the correlation between the material's bulk density

and the dielectric constant of building materials described

above, there can be different display values with different

material densities and multi-layered wall or floor construc-

tions. Cluster measurements are recommended to avoid the

misinterpretation of the measured values. For this, at least

five individual depth measurements are carried out within a

radius of 20 cm and from these individual results an average

value is to be calculated. This value then constitutes the ref-

erence value for other cluster measuring spots.

• For a more precise analysis of homogenous materials (brick-

work thicker than 30 cm) a cluster measurement is advisa-

ble. Generally, three measurements within a radius of 15 cm

are a sufficient basis for evaluation.

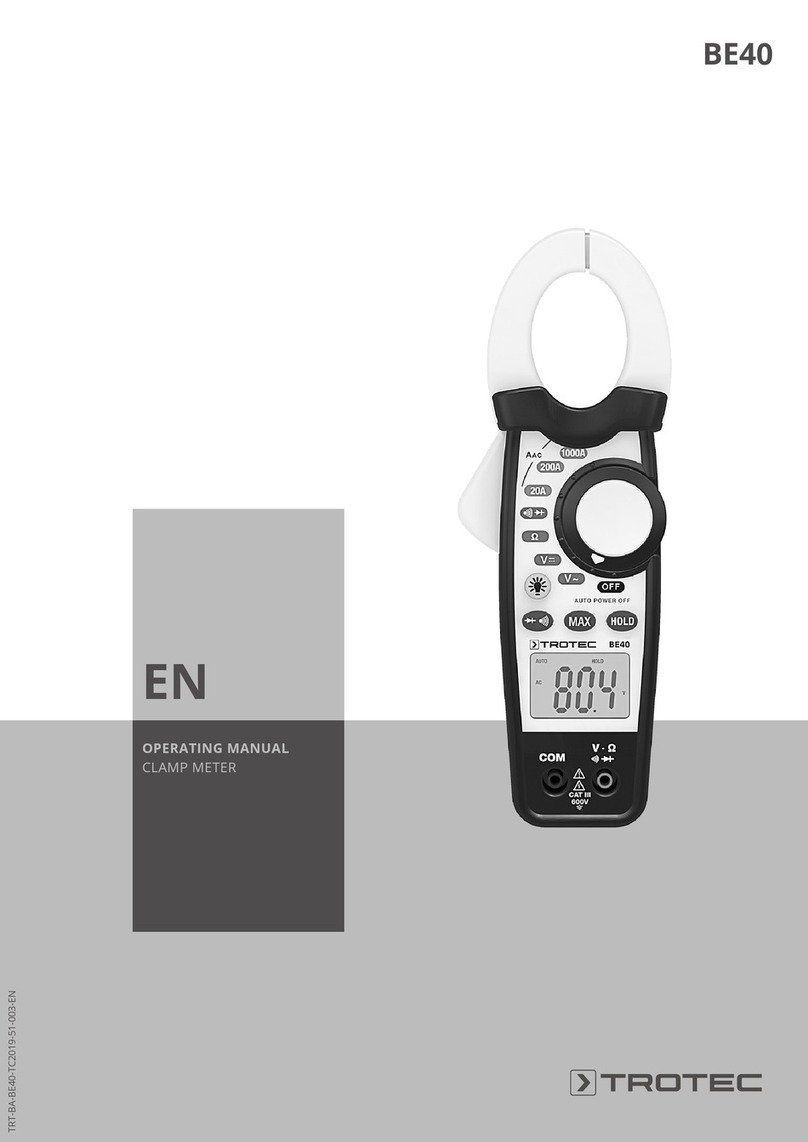

Use the MultiMeasure Studio Standard PC software (free standard

version) or MultiMeasure Studio Professional (paid professional

version, dongle required) to carry out a detailed analysis and vis-

ualisation of your measured results. You can only use all config-

uration, visualisation and functional options of the device when

using this PC software and a TROTEC® USB dongle (professional).

Installation requirements

Ensure that the following minimum requirements for installing the

MultiMeasure Studio Standard or MultiMeasure Studio Profes-

sional PC software are fulfilled:

• Supported operating systems (32 or 64 bit version):

– Windows XP from service pack 3

– Windows Vista

– Windows 7

– Windows 8

• Software requirements:

– Microsoft Excel (to display stored Excel files)

– Microsoft .NET Framework 3.5 SP1 (is otherwise automat-

ically installed during the software installation)

• Hardware requirements:

– Processor speed: min. 1.0 GHz

– USB connection

– Internet connection

– 512 MB RAM, minimum

– 1 GB hard disk space, minimum

– Optional: TROTEC® USB dongle (Professional) for using the

professional version of the PC software

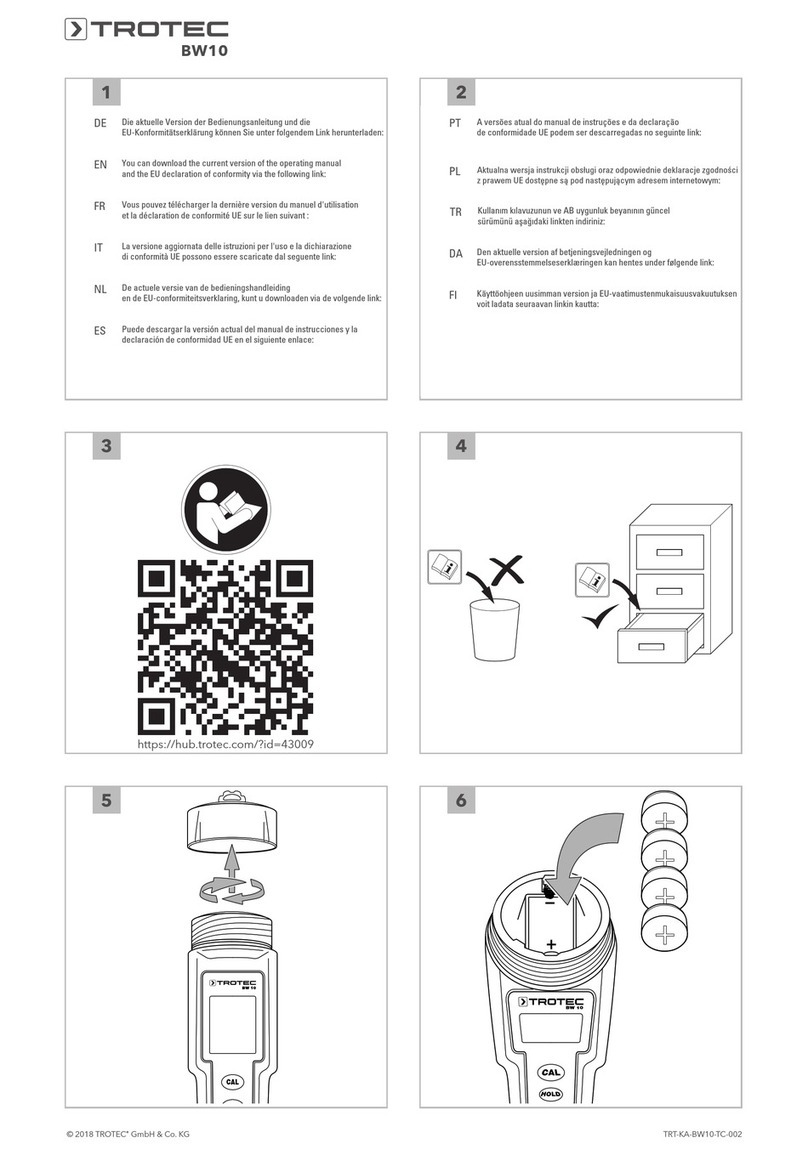

radius:

10 to 15 cm

PC software