10 EN

moisture measuring device T510

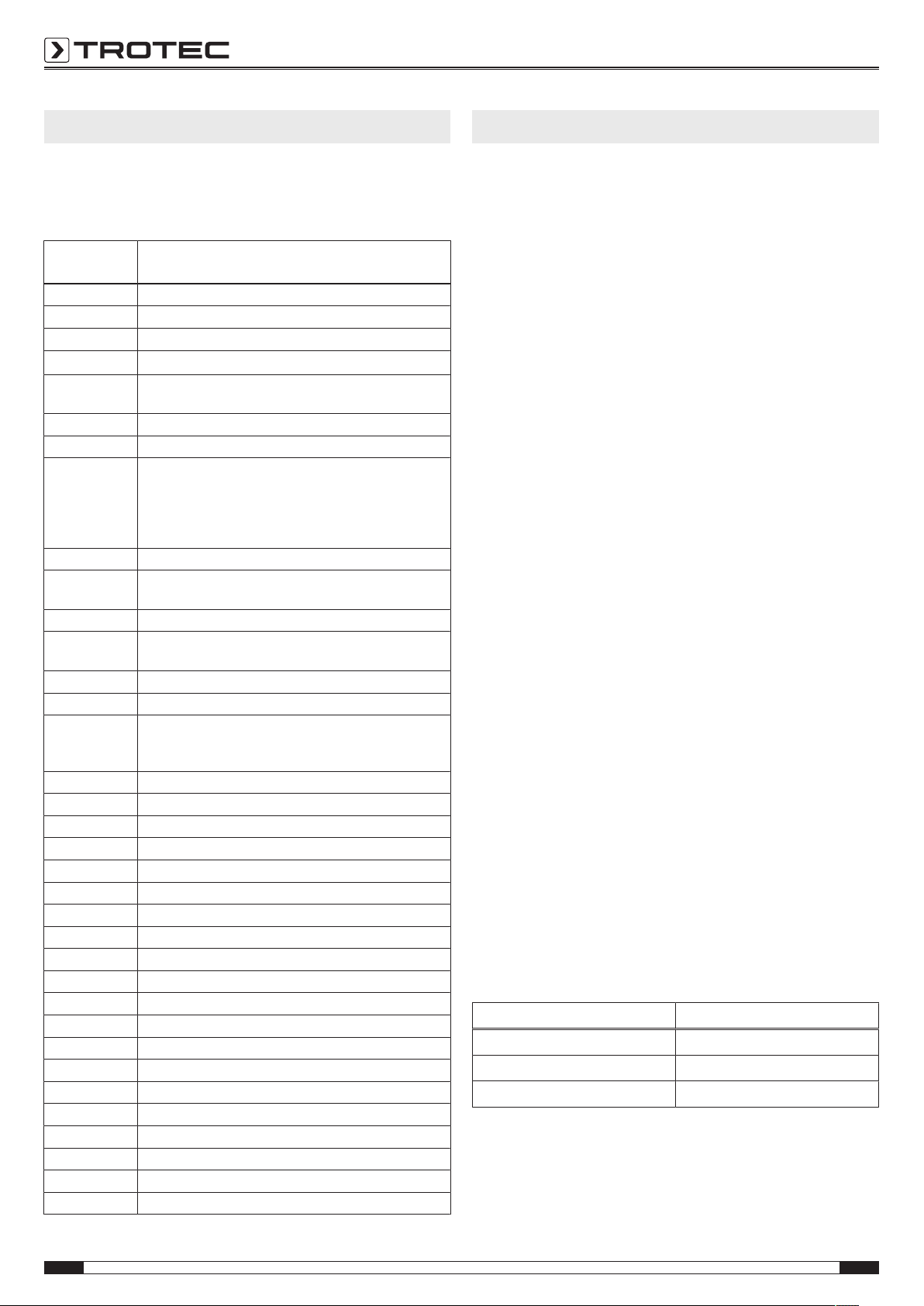

Table of wood types

The tables of wood types included in the scope of delivery contains

approx.200types of wood with their corresponding material codes.

The following tables contains all the material codes stored within the

device incl. typical examples of wood types:

Material code

H-

Wood type

examples

1 pine; pitch pine, control code

2 Cembra pine

3 Meranti, dark red

4poplar, silver, white poplar

5 birch, yellow, silver, sweet/black; wood fibre insulating

boards; cherry

6 spruce, Norway

7 chipboard urea; wenge

8 maple (sycamore), Scottish maple, acer, sugar maple;

acacia; yew; alder; ash; spruce Central Europe; chestnut,

sweet, buckeye; mahogany sapele, Philippines; Meranti,

light red; walnut; plum; pine, red; robinia, locust; elm;

Kauramin chipboard; cypress

9 larch; limba

10 Gaboon; mahogany, genuine, big-leaf, Okoumé; walnut,

American black; Padauk; plane

11 woodfibre hardboard; lime, basswood

12 Douglas fir; oak, red oak, northern red, English oak,

durmast oak; Oregon pine

13 rosewood, shisham

14 beech, common

15 pear; beech, common hornbeam, European; oak, white

oak, Arizona; buckeye, American chestnut; mecrussé

(Lebombo ironwood); olive; chipboard isocyanate; teak

16 mahogany Gaboon

17 Nargusta

18 bamboo light

19 red ironwood

20 oak, holm oak

21 ash, American ash

22 cocus wood (granadillo)

23 bamboo dark, melamine-faced chipboard

24 doussie (Afzelia)

25 iroko (African teak); kambala

26 ebony, African, black

27 cork; chipboard phenolic resin

28 (see table of wood types printed version)

29 (see table of wood types printed version)

30 (see table of wood types printed version)

31 (see table of wood types printed version)

32 (see table of wood types printed version)

33 (see table of wood types printed version)

34 (see table of wood types printed version)

35 (see table of wood types printed version)

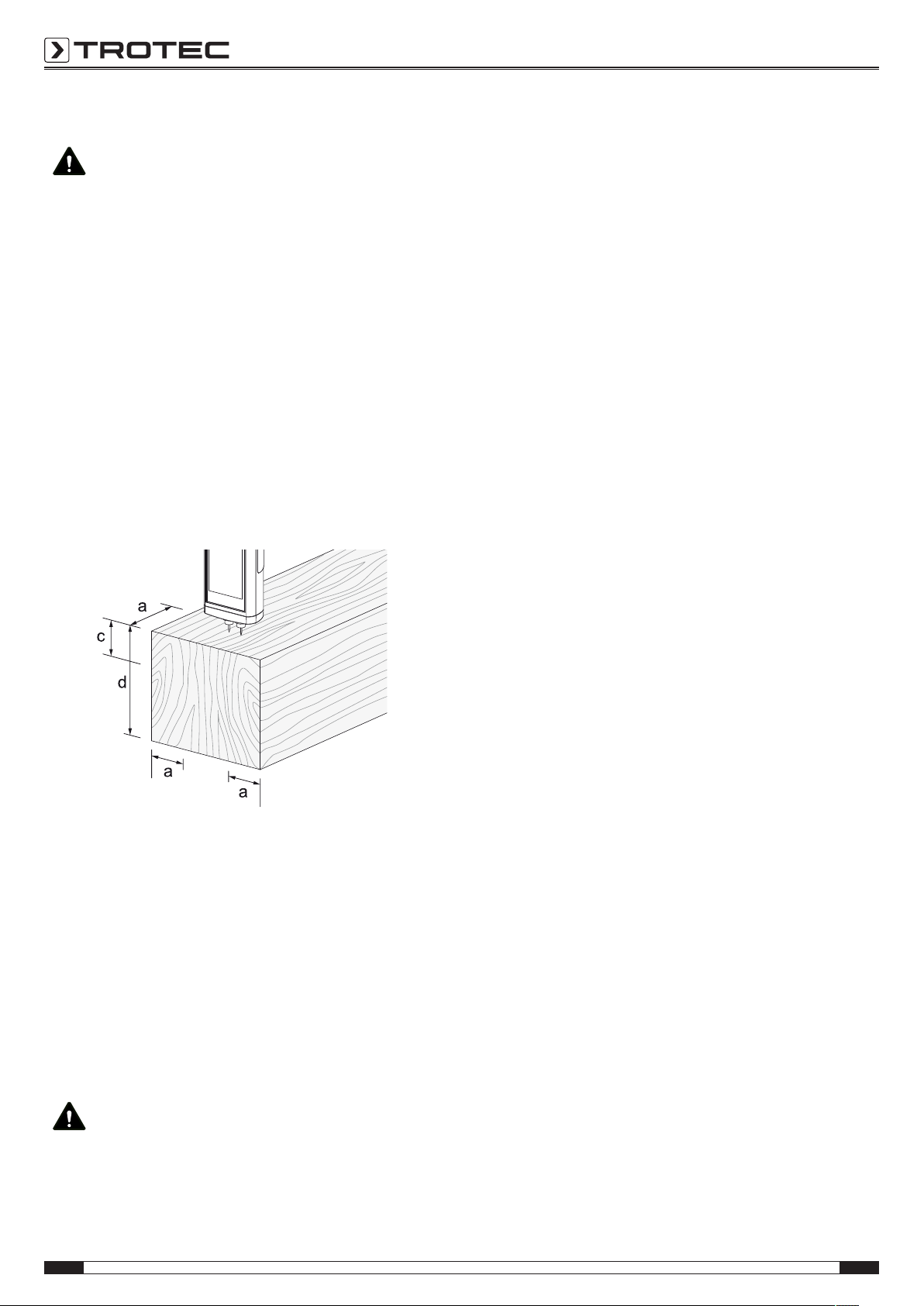

Measuring principle

During moisture measurement according to the resistance

principle an electric measuring current is generated within the

measuring device, which is conducted through the material to

be measured by means of electrodes.

With an increasing water content of the measured material to be

examined the resistance drops and conductivity builds up.

If the material to be measured has a high resistance, the

moisture content is low.

If the material to be measured has a low resistance, the

moisture content is high.

Thus, moisture measurement according to the resistance

principle is an indirect measurement method, since the humidity

is deduced from the conductivity of the measured material.

Wood moisture measurement

Every type of wood has a distinct conductivity. In order to take

this fact into consideration for the measurement, every wood

type comes with a material code that can be set.

The wood's conductivity is further influenced by the wood

temperature. In order to take this fact into consideration for the

measurement, the wood temperature can also be determined.

The wood temperature is to be determined before moisture

measurement and set accordingly.

The measuring device comes equipped with an internal

temperature compensation. The resistance curves of the

selected wood type are automatically adapted depending on the

set wood temperature.

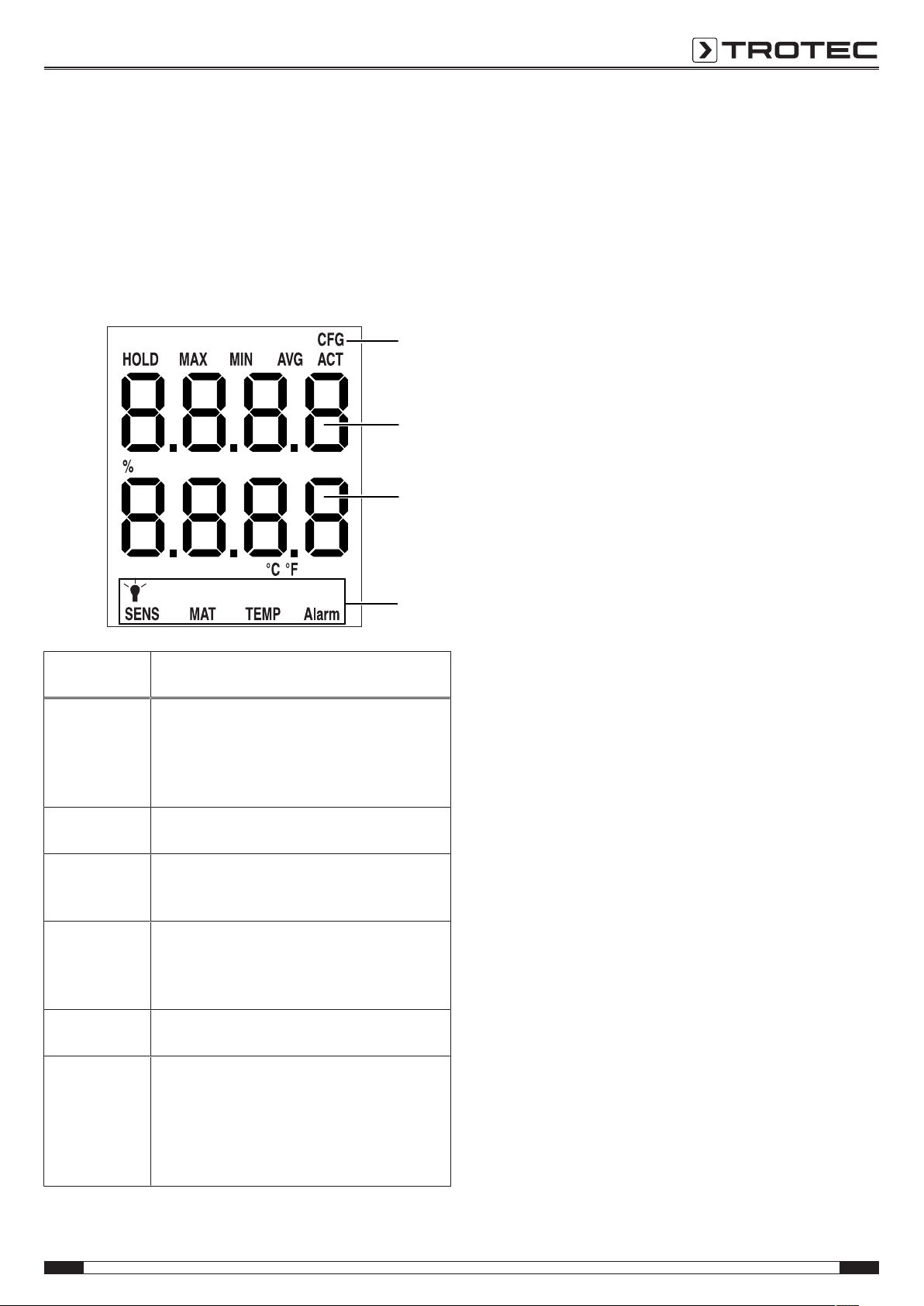

Error sources

During resistance measurement the accuracy of the

measurement method needs to be examined. Two fundamental

types of error sources become apparent within the measuring

range from 0 to 100M%.

• There is one error stemming from the measuring principle

of the resistance measurement. This is particularly

noticeable in case of high resistance values (low

conductivity at less than 5M%). Due to the low measuring

currents the measurement value display is i.a. increasingly

falsified by molecular attraction. Listed below are the

principle-related measurement errors:

Measured value Error

0 - 5 M% 0.8 M%

6 - 30 M% 0.2 M%

31 - 100 M% 0.1 M%