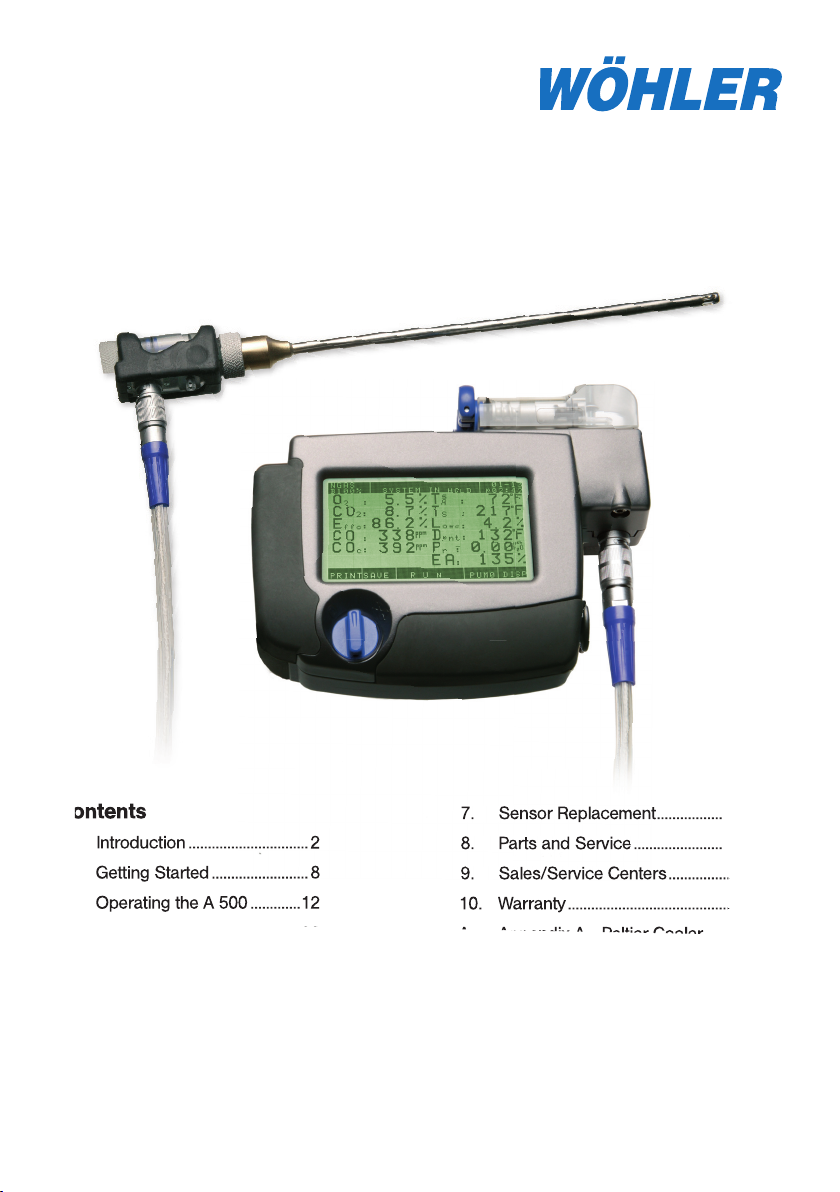

• Measures and displays: O

and CO content in the flue-gas, combustion-air tempe-

rature, stack temperature, and pressure / draft.

• Calculates and displays: CO

content in the flue gas, combustion efficiency, excess

• Measures and displays: NO, NO

• Displays emission measurements for NO, NO

• Emission conversions can be displayed in parts per million (ppm), milligrams of

pollutant per cubic meter of gas (mg/m

), pounds of pollutant per giga BTU (#/

GBTU), or grams of pollutant per gigajoule (g/GJ).

• All combustion calculations and measurements are displayed on one screen with

emission measurements and calculations on a second.

• Real-time, on-screen, graphical display of any measured or calculated test values.

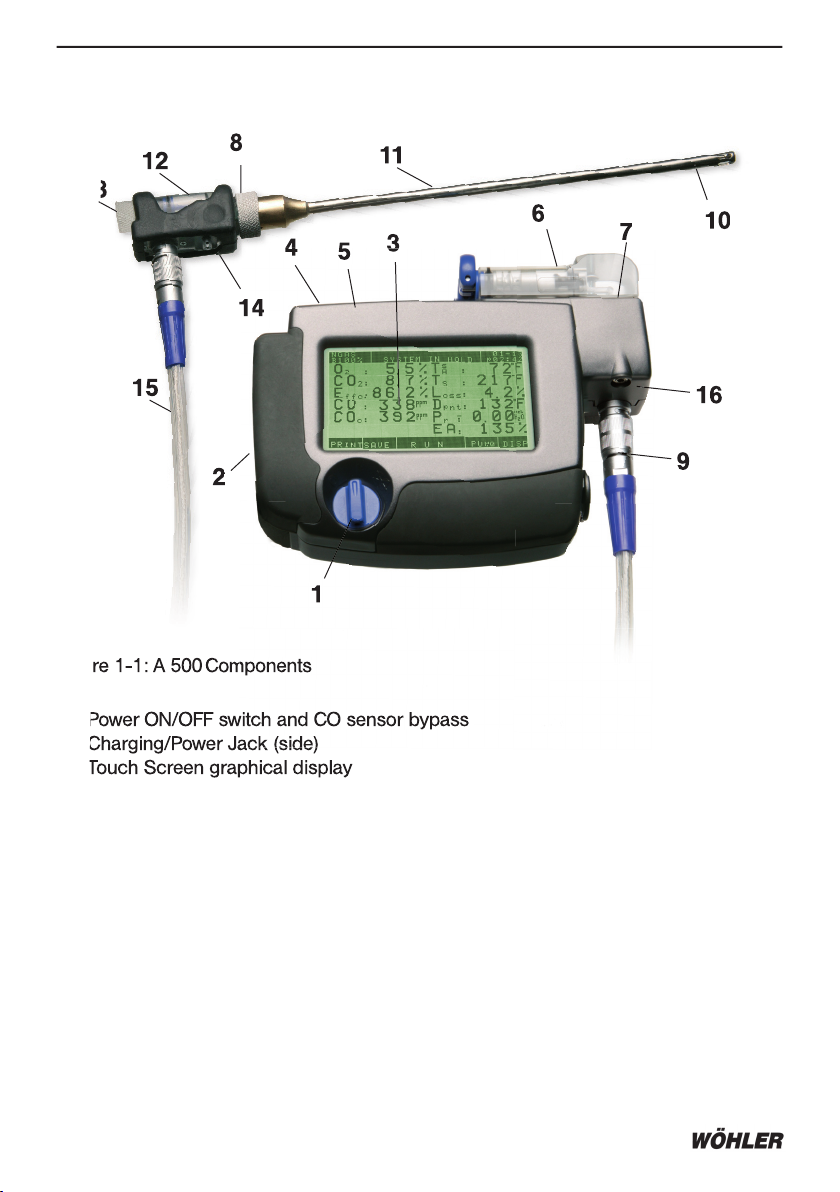

• CO sensor has a warning indicator manual bypass to protect the sensor from high

concentrations of carbon monoxide.

• Displays temperature in either °C or °F and pressure in either inches of water co-

• When unit is turned on it automatically zeros and purges all sensing channels with

ambient air for 60 seconds .

• The water trap and filters are conveniently located at the top of the analyzer for

easy viewing, draining or changing.

can operate from either an AC adapter, internal rechargeable batteries,

or standard AA alcaline batteries.

• Battery utilization display.

• Built-in memory for 850 individual combustion test records.

• Records can be recalled for printing or for transmission to a PC.

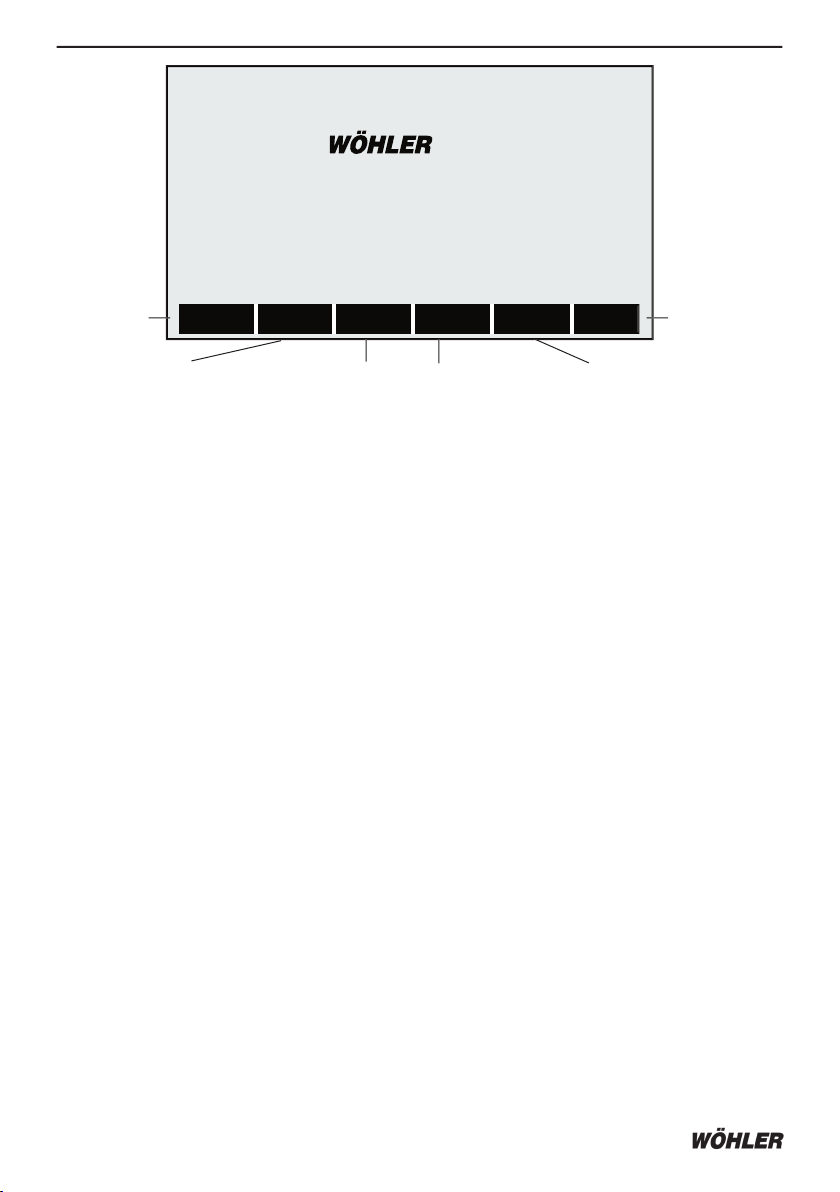

• All operator and data management functions are via the Touch-screen interface.

• Customer records can include the customer name, ID, device number, and com-

ments. Information is entered using the touch screen alphanumeric display.

• Customer data appears on the printout.