1

TROX GmbH

Heinrich-Trox-Platz

D-47504 Neukirchen-Vluyn

Telephone +49/28 45 /2 02-0

Telefax +49/ 28 45/ 2 02-2 65

e-mail trox@trox.de

www.troxtechnik.com

Product Information

Volume Flow Controller Type EN

Installation, Operation, Maintenance

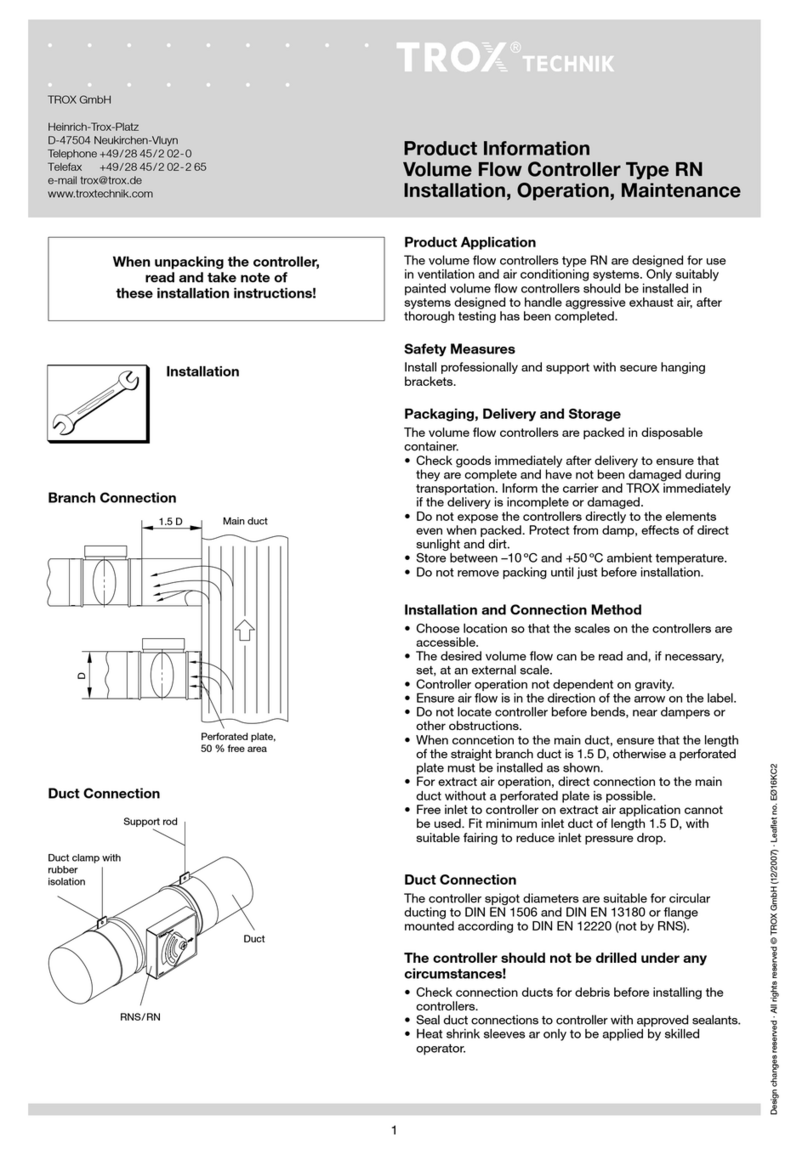

Installation

When unpacking the controller,

read and take note of

these installation instructions

Design changes reserved · All rights reserved © TROX GmbH (12/2007) · Leaflet no. EØ16KC4

min. 1.5 x B

Product Application

The volume flow controllers type EN are designed for use in

ventilation and air conditioning systems. Only suitably

painted volume flow controllers should be installed in

systems designed to handle aggressive exhaust air, after

thorough testing has been completed.

Safety Measures

Install professionally and support with secure hanging

brackets.

Packaging, Delivery and Storage

The volume flow controllers are packed in disposable

container.

• Check goods immediately after delivery to ensure that

they are complete and have not been damaged during

transportation. Inform the carrier and Trox immediately

if the delivery is incomplete or damaged.

• Do not exposed the controllers directly to the elements

even when packed. Protect from damp, effects of direct

sunlight and dirt.

• Store between –10 ºC bis + 50 ºC.

• Do not remove packing until just before installation.

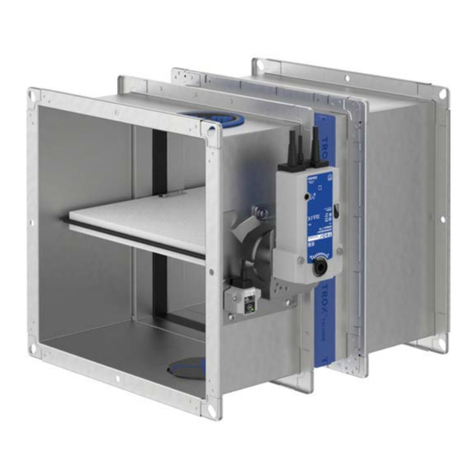

Installation and Connection Method

• Choose location so that the scales on the controllers

are accessible.

• The desired volume flow can be read and, if necessary,

set, at an external scale.

• Controller operation not dependent on gravity.

• Ensure air flow is in the direction of the arrow on the

label.

• Do not locate controller before bends, near dampers or

other obstructions.

• When connection to the main duct, ensure that the

length of the straight branch duct is 1.5 B. The length of

the straight branch must generally be 0.5 B.

• For extract air operation, direct connection to the main

duct without a perforated plate is possible.

• Free inlet to controller on extract air application cannot

be used. Fit minimum inlet duct of lenght 1.5 B, with

suitable fairing to reduce inlet pressure drop.

Duct Connection

• Check connection ducts for debris before installing the

controllers.

The controller should not be drilled under any

circumstances.

Branch Connection

Duct Connection

B

Main duct

Duct

Support rod

EN